Method for automatically cleaning glass surface

A glass surface, automatic cleaning technology, applied in the direction of cleaning methods and utensils, cleaning flexible objects, chemical instruments and methods, etc., can solve the problems of being affected by human factors and low cleaning efficiency, so as to achieve assembly line operation and eliminate the problem of cleaning quality Affect and improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

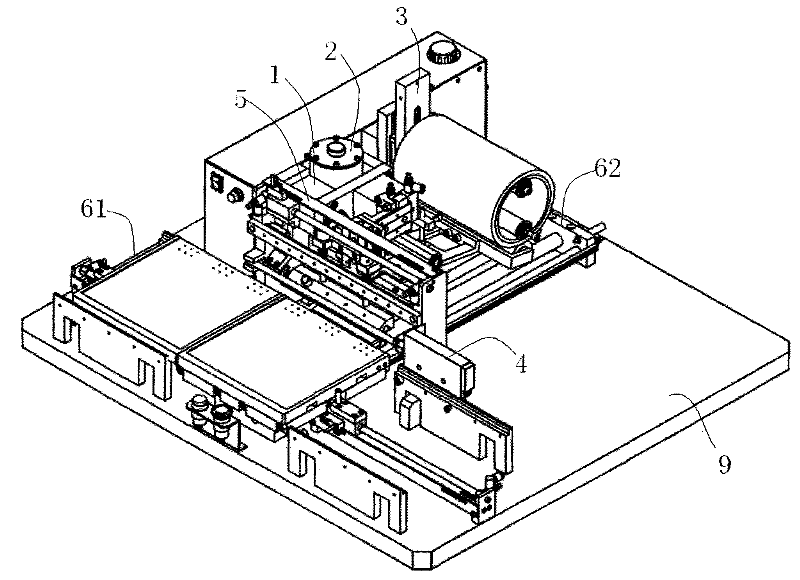

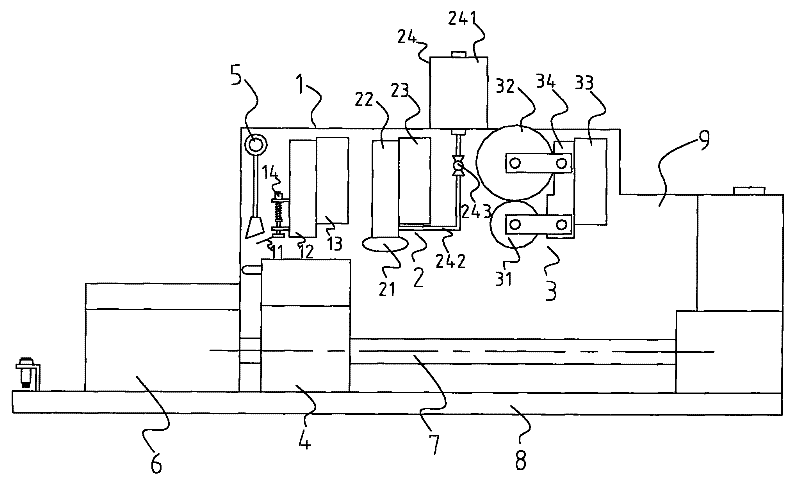

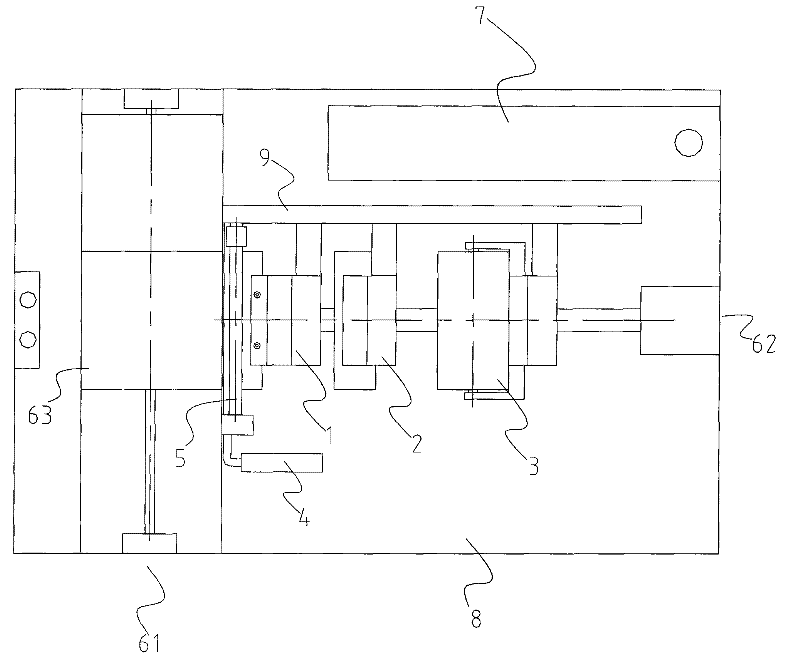

[0022] The method for automatically cleaning the glass surface of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The method for automatic cleaning glass surface of the present invention is, in such as image 3 In the process of the electrical control system 7 driving the feeding part of the feeding mechanism to convey the glass along the feeding direction, the scraping mechanism, the wiping mechanism and the dust-sticking mechanism are each in relative motion to the glass to complete the scraping in sequence. The scraping action of removing foreign matter on the glass surface, the wiping action of wiping the glass surface, and the adhesion action of adhering the dirt remaining on the glass surface; wherein, at least in the process of completing the scraping action, start the static elimination device to eliminate the scraping process Static electricity generated in the glass to prevent dust from accumulating on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com