Wine crock cleaning and filling machine set

A cleaning mechanism and filling technology, which is applied to bottling machines, packaging, bottle filling, etc., can solve the problems of high labor intensity, laborious manual movement, and many labors, so as to reduce labor intensity, improve production efficiency, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

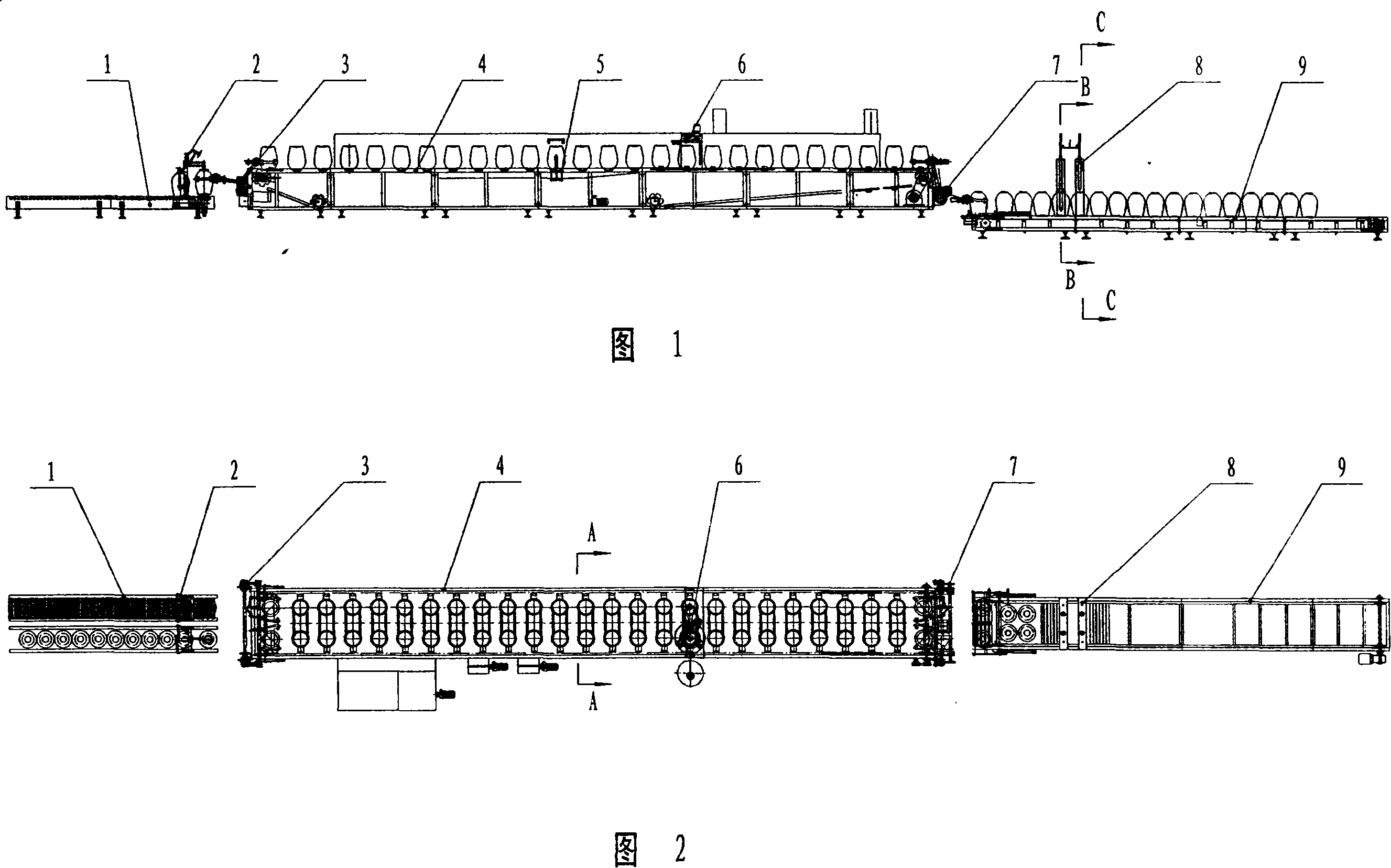

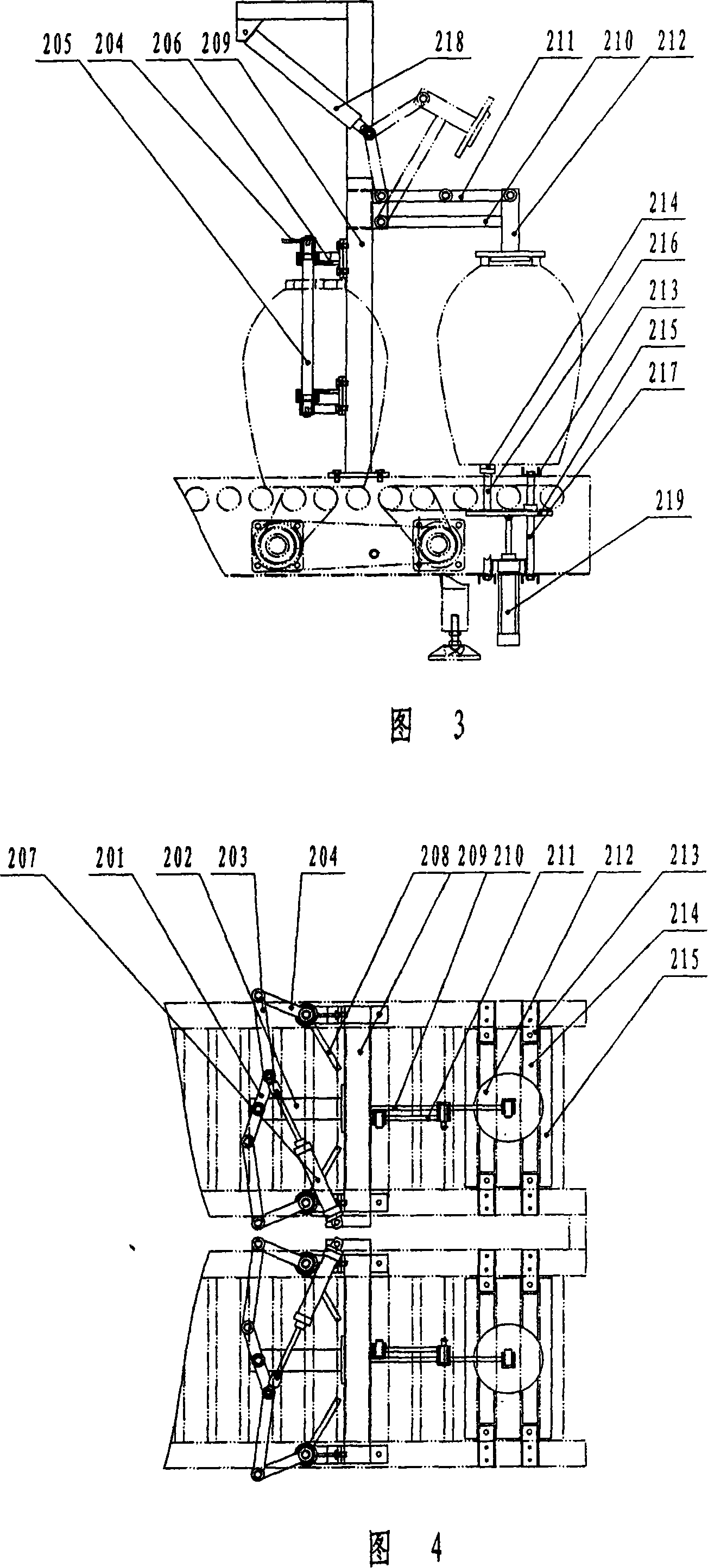

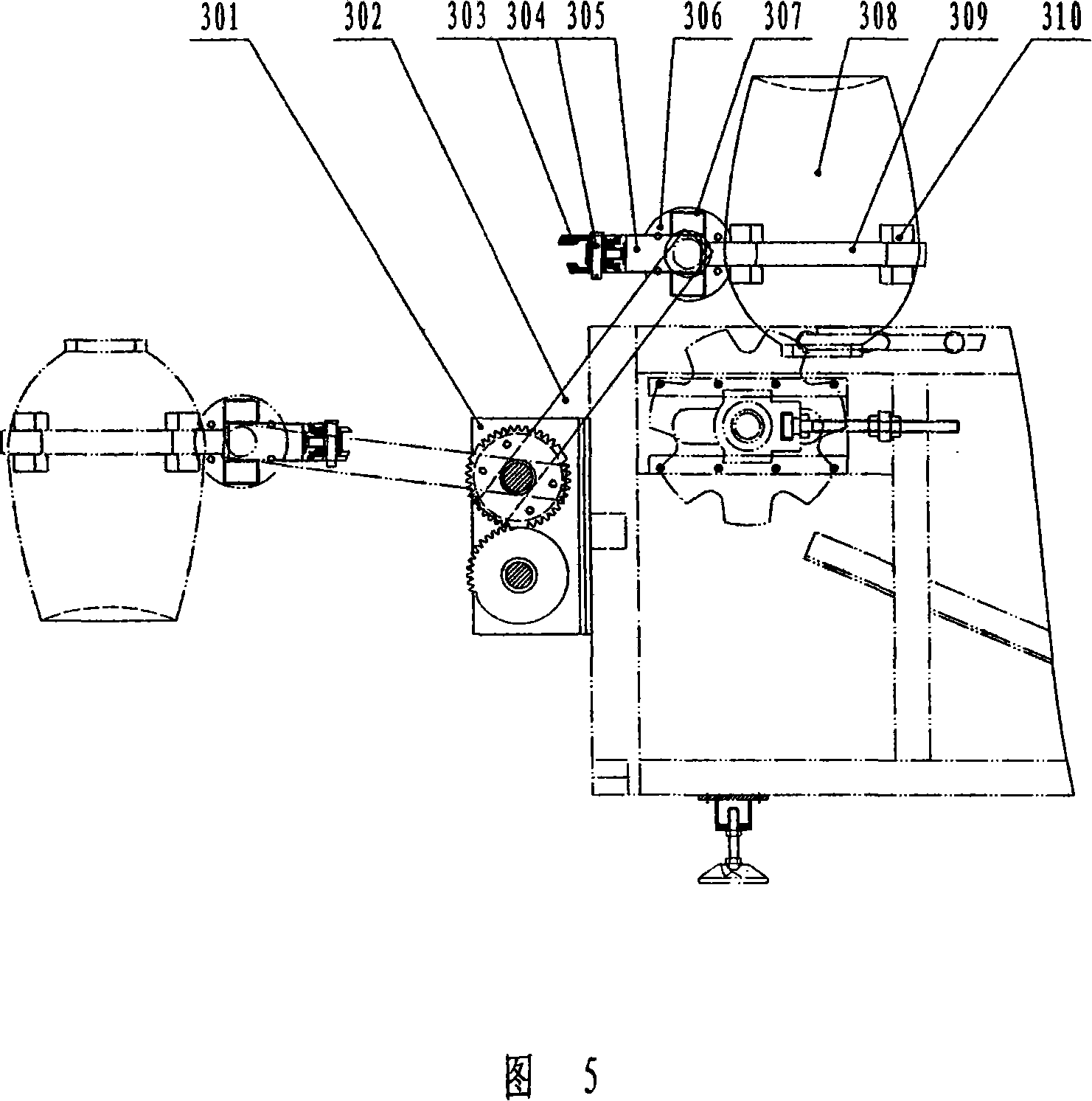

[0029] Shown in Fig. 1-2, a kind of jar cleaning and filling unit of the present invention comprises a jar conveying mechanism, a positioning mechanism 2, a cleaning mechanism 5, a lime water brushing mechanism 6, and a filling mechanism 8; said jar conveying mechanism Including the conveyor belt, frame, motor and transmission device, the jars transported on the conveyor belt have two symmetrical rows, and the operation of the motor is controlled by the electronic automatic control system; the conveying mechanism has a first conveyor connected at an interval from end to end 1, the second conveyor 4, the third conveyor 9; a positioning mechanism 2 is provided on the first conveyor to complete the positioning of the jar; a first manipulator assembly 2 is provided between the first conveyor and the second conveyor, The first manipulator assembly completes the lifting of the jar, inversion, and shelving on the conveyor belt of the second conveyor; a cleaning mechanism 5 and a lime ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com