Table board used for automatic stacking of ultrahigh-voltage iron core

An ultra-high voltage, iron core technology, applied in the manufacture of inductors/transformers/magnets, workbenches, electrical components, etc., can solve problems that affect the appearance, size and performance of products, the working position cannot be switched at will, and the position is difficult to determine during operation. Achieve the effect of reducing professional skill requirements, improving operation efficiency and finished product quality, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

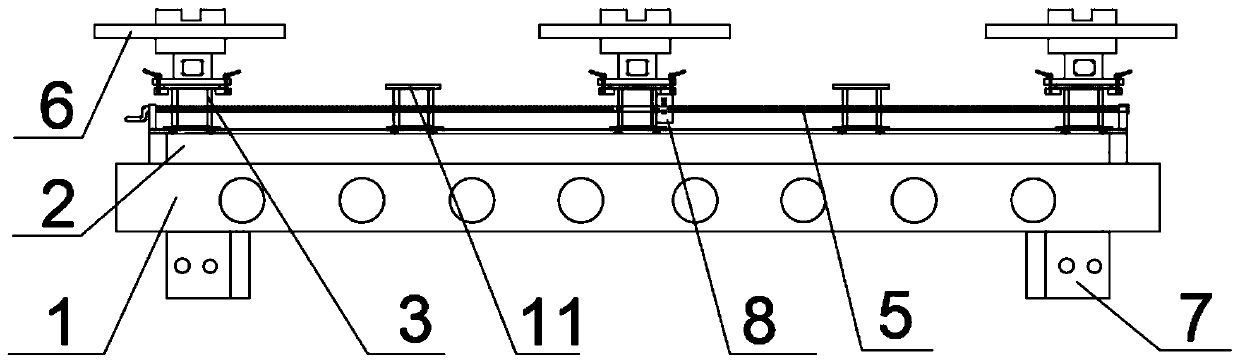

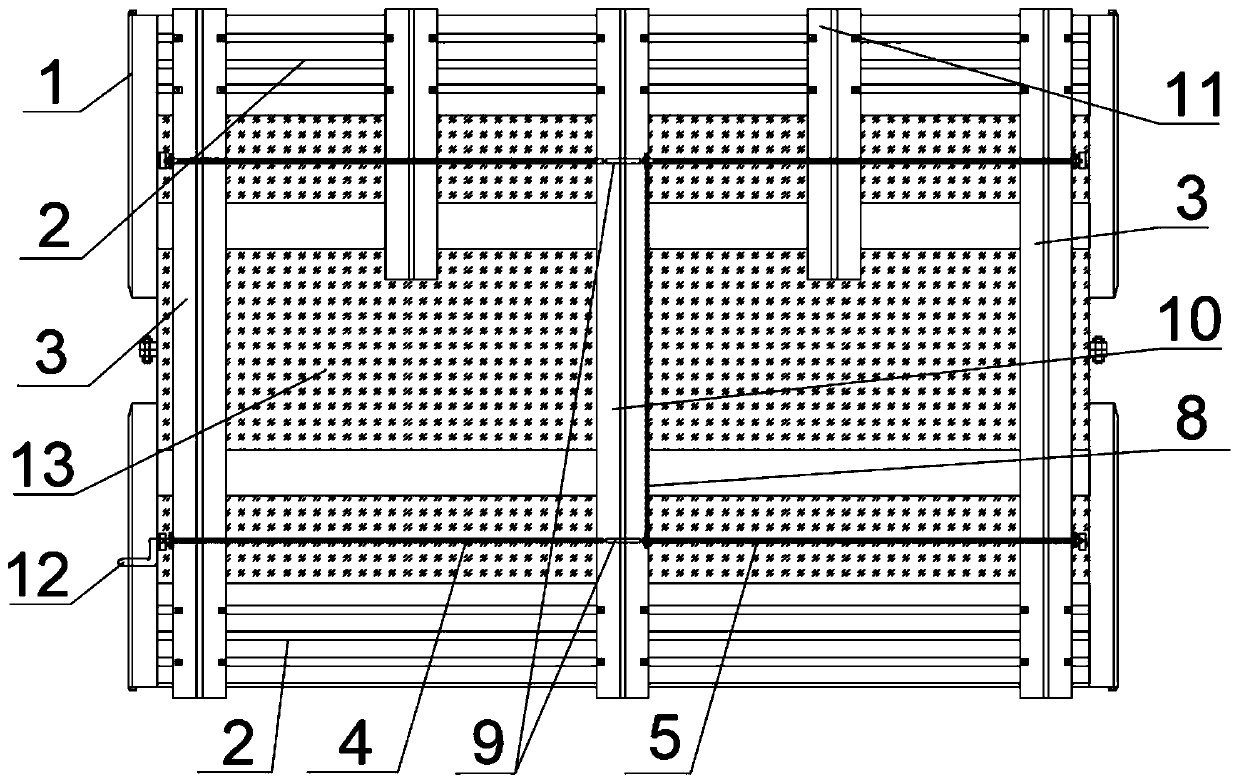

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 and figure 2 As shown, the tabletop for automatic stacking of ultra-high voltage iron cores in this embodiment includes support feet 7 arranged in parallel at intervals, and a crossbeam 1 perpendicular to the stand 7 is installed on each of the two ends of the support feet 7, and a beam 1 is fixedly installed on the two crossbeams 1 respectively. One horizontal slide rail 2, a vertical fixed beam 10 is fixedly installed in the middle of the upper surface of the two horizontal slide rails 2 at the same time, the vertical fixed beam 10 is perpendicular to the horizontal slide rail 2, and there is one on both sides of the upper surface of the two horizontal slide rails 2 One vertical sliding long beam 3, two vertical sliding long beams 3 take the vertical fixed beam 10 as the center line, and slide toward each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com