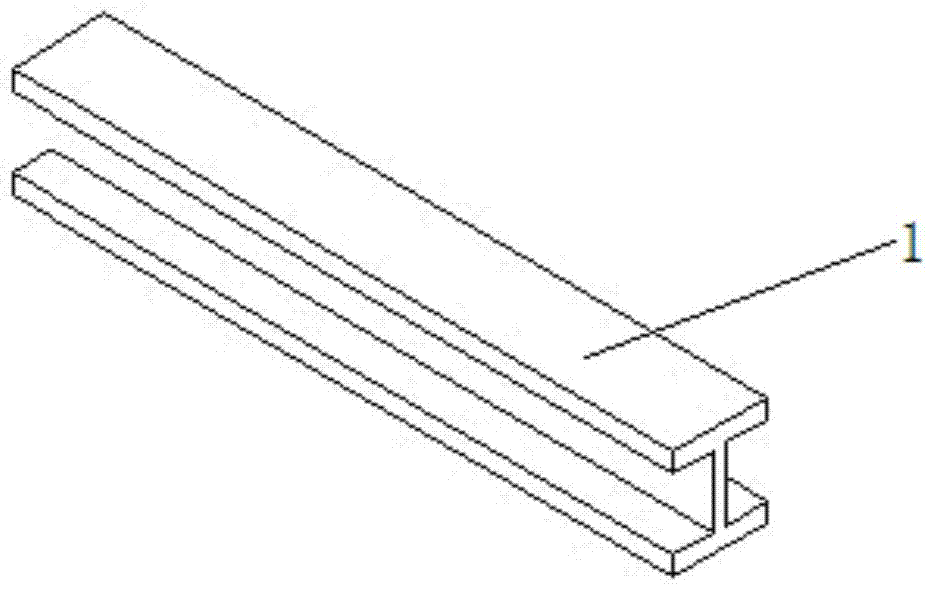

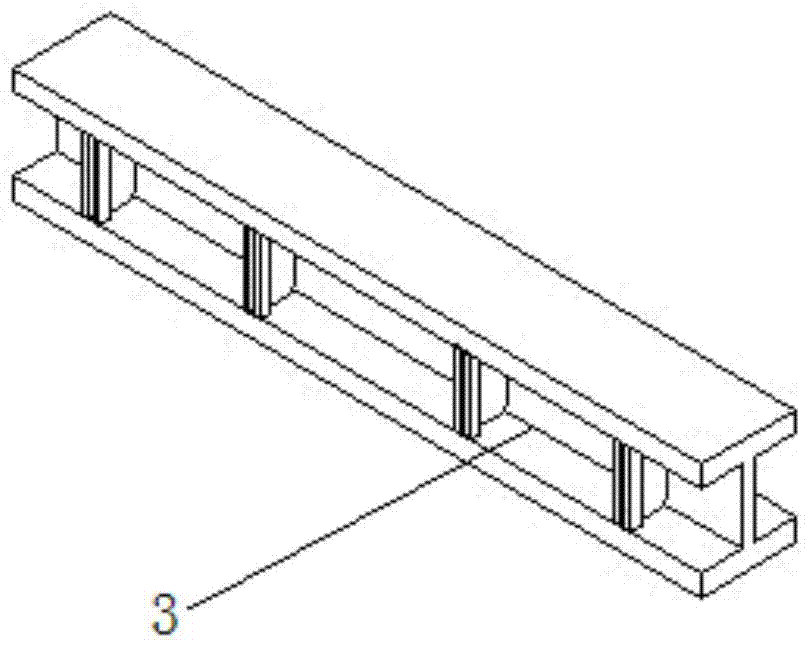

Manufacturing method of inclined electroslag welding component shaped like Chinese character 'ri'

A production method, electroslag welding technology, applied in the direction of welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems that cannot meet the development trend of complex and diversified steel components, and achieve wide coverage, high efficiency, targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

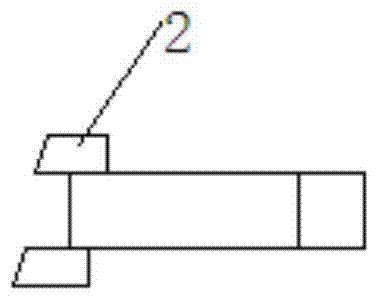

[0036] The manufacturing method of the sun-shaped oblique electroslag welding component will be described in detail below in conjunction with the accompanying drawings.

[0037] Process principle: According to the actual situation of the project and the current level of the steel structure processing enterprise, through a series of cutting and blanking, assembly, welding, calibration, end milling and other procedures to produce small cross-section day-shaped oblique electroslag welding that meets the needs of the project At the same time, the pre-weld preheating and post-weld heat preservation of the thick plate and the stress relief treatment of the weld should be done well during the fabrication process.

[0038] Operational requirements: Stakeout and material numbering. Before material numbering, material numbering personnel should be familiar with the process requirements. Part boards are set out by computer. Each part for blanking processing must be marked with component n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com