Compartment drying production line and conveying system thereof

A conveying system and production line technology, which is applied in the field of vehicle engineering, can solve problems such as extra heat consumption, extra cost, and large volume, and achieve the effects of reducing space occupation, reducing production costs, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

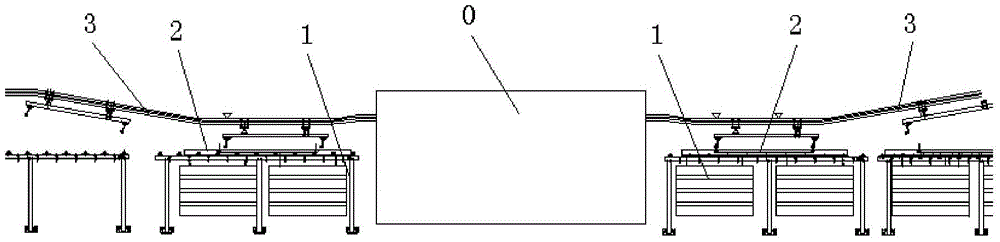

[0020] The core of the present invention is to provide a conveying system for the carriage drying production line, in order to reduce extra heat consumption, prolong the service life of the roller bed, reduce the space occupied by the drying chamber and storage area, and reduce the production cost. Another core of the present invention is to provide a carriage drying production line including the above conveying system.

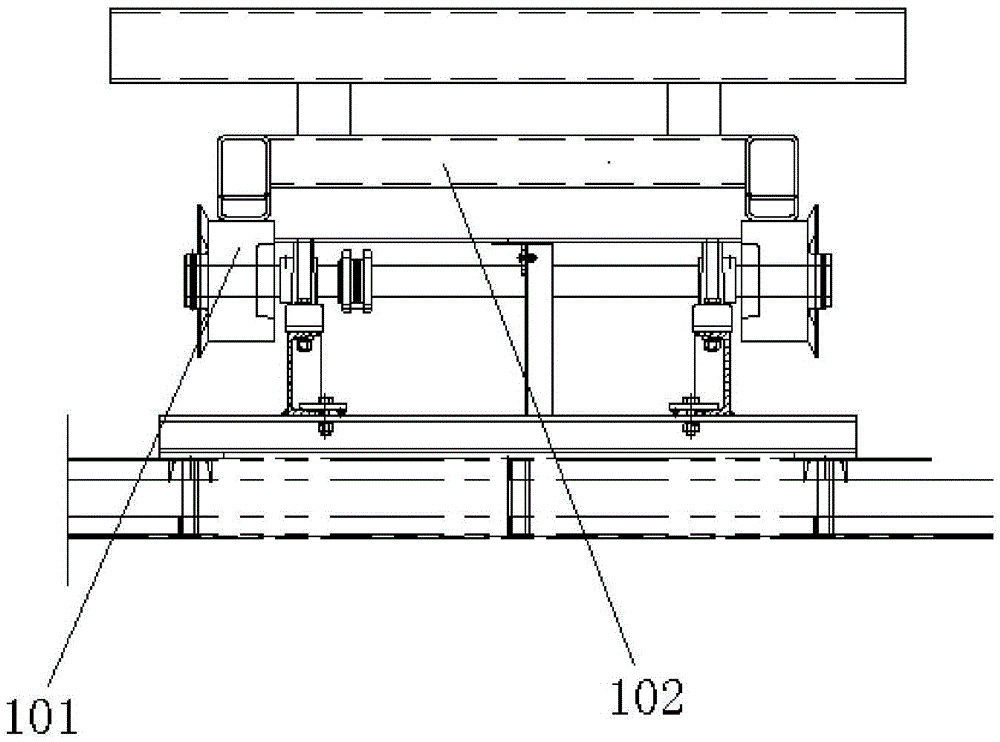

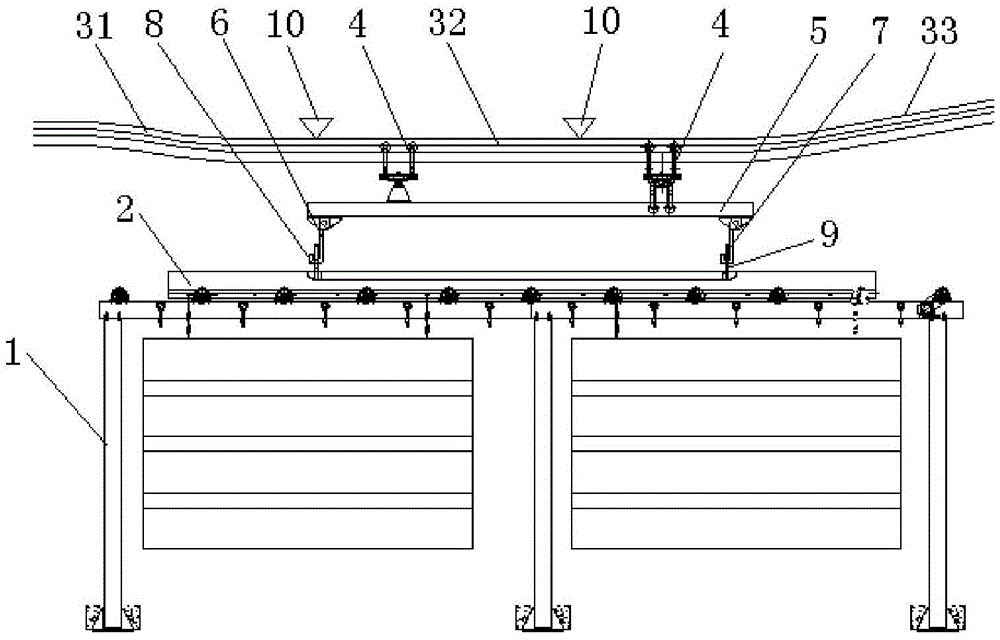

[0021] Please refer to figure 2 and image 3 , figure 2 It is a structural schematic diagram of a specific embodiment of the delivery system provided by the present invention; image 3 for figure 2 An enlarged view of a part of the delivery system shown.

[0022] In a specific embodiment, the conveying system provided by the present invention is used in a carriage drying production line. The conveying system includes a roller bed 1 with a preset height, and a slide 2 is placed on the roller bed 1, and the workpiece to be conveyed is placed On the sled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com