Patents

Literature

102results about How to "Avoid productive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Screw thread automatic detecting equipment and method

InactiveCN101603804AImprove satisfactionFacilitate the realization of assembly line operationMechanical diameter measurementsFixed frameVia device

The invention relates to screw thread automatic detecting equipment and a method thereof; the main frame of the equipment is a fixing frame, a screw thread detecting pin is driven by a working air cylinder fixed at the center of the outer part of the top side to move downwards to carry out detection, a product detecting fixture is arranged on a base of the fixing frame, and the position of a screw thread hole of the product to be detected is arranged right below the screw thread detecting pin; a sensor is arranged at one side of the screw thread detecting pin, the front end part of the sensor is vertical to the screw thread detecting pin and is arranged at a distance from the screw thread detecting pin, the sensor is triggered to carry out detection by the insertion of a screw thread detecting rod at the front end of the screw thread detecting pin or by different working states generated by preventing from moving downwards. The equipment fully utilizes the difference of pore diameter of an extruding and tapping product before tapping and after tapping to carry out judgment and identification, and full-inspection identification and marking are automatically carried out by the equipment, thereby being beneficial to realizing assembly line work, avoiding changing or lagging the production flow, reducing the risk on producing defective products in the process and having remarkable economic benefit.

Owner:无锡雄伟精工科技有限公司

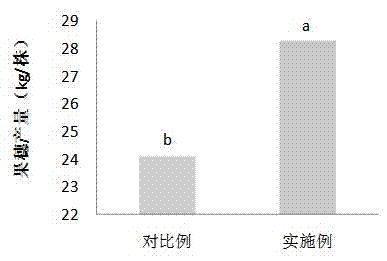

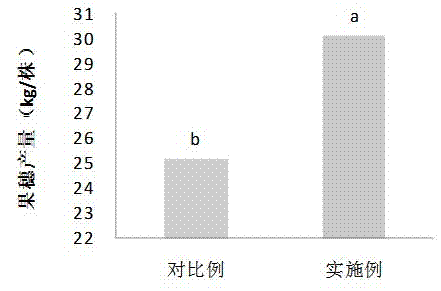

Synchronous nutrition fertilizers, preparation methods thereof and applications thereof

ActiveCN102351602AExpand the connotationExtend the fertilization timeFertilizer mixturesField cropAgricultural science

The invention discloses synchronous nutrition fertilizers, preparation methods thereof and applications thereof. The synchronous nutrition fertilizers comprise four formulas consisting of a high nitrogen formula, a high nitrogen potassium formula, a high potassium formula and an equalization formula, and the synchronous nutrition fertilizers of the four formulas respectively comprise a base fertilizer and a resin coating controlled release component adapted to the base fertilizer. The synchronous nutrition fertilizers of the invention can be applied to the one-time fertilizing of short-growth period field crops or the less-time afterfertilizing of long-growth period or perennial economic crops. The preparation methods of the invention not only allow the nutrient proportion of the fertilizers to satisfy demands of crops, but also allow the speed, the quantity, the proportion of nutrition elements of nutrients in the fertilizers to be controlled to basically fit the demands of nitrogen, phosphor and potassium of the crops with various growth periods. An organic cooperation of the fertilizers of the four base formulas of high nitrogen, high nitrogen potassium, high potassium, and equalization with the resin coating controlled release component is provided in the invention to solve a present limitation that one formula fertilizer only corresponds with the nutrition demands of one or one type crop.

Owner:SOUTH CHINA AGRI UNIV +2

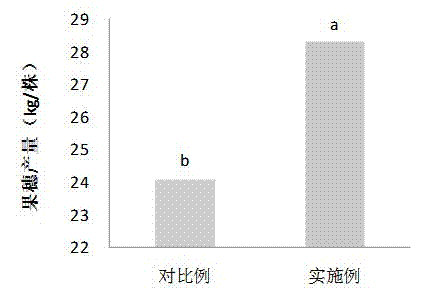

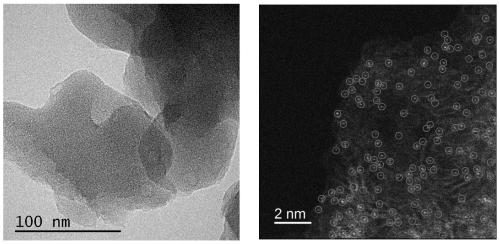

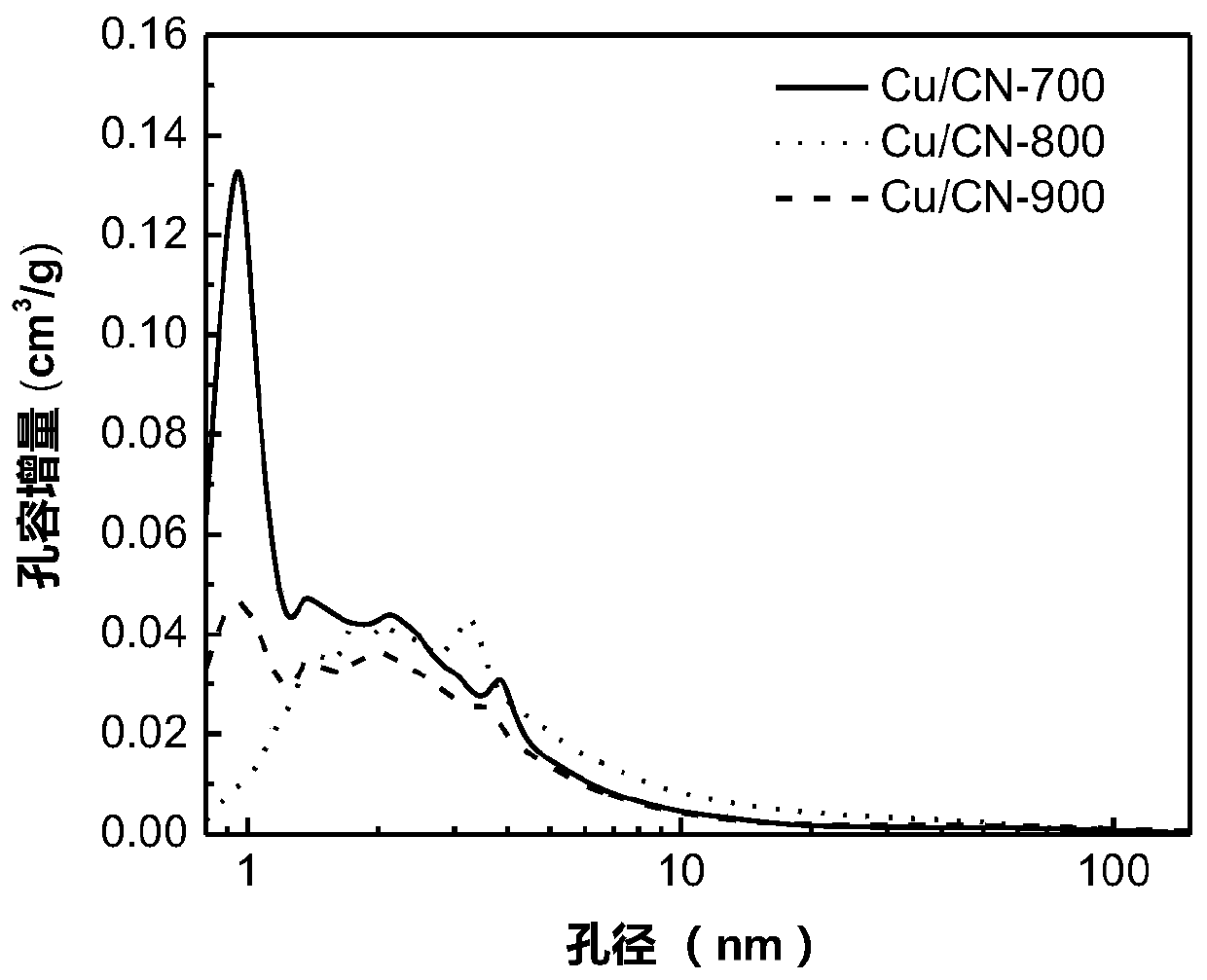

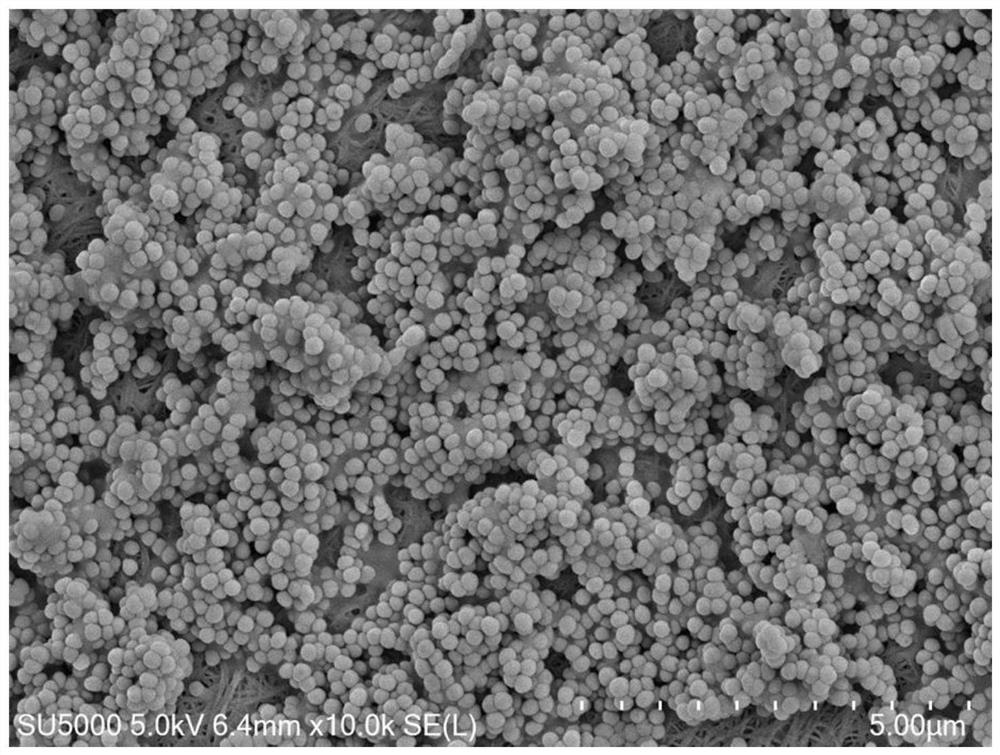

Biomass-based carbon material loaded monatomic copper catalyst as well as preparation method and application thereof

ActiveCN111068682AEasy to prepareAvoid gatheringCarboxylic acid nitrile preparationOrganic compound preparationArylPtru catalyst

The invention discloses a biomass-based carbon material loaded monatomic copper catalyst and a preparation method thereof, and a method for synthesizing a 1, 3-diyne compound by oxidative coupling ofthe catalyst. The catalyst is composed of 0.01 wt%-3 wt% of metal monatomic copper, 70 wt%-90 wt% of a carbon-based carrier and 5 wt%-20 wt% of heteroatoms. The preparation method of the biomass-basedcarrier-loaded monatomic copper catalyst is simple, mild in condition and low in cost, and does not need a common subsequent pickling process. The cheap metal salt and self-doped heteroatom N are used for synergistic coordination, aggregation of metal in the high-temperature pyrolysis process is avoided, and monodispersion of metal atoms is achieved. The metal monatomic content is high, the dispersion is uniform, and the physicochemical structure is stable. The catalyst can take air as an oxidizing agent in oxidative coupling reaction, achieves high conversion rate and excellent substrate universality under alkali-free and ligand-free conditions, and realizes an oxidative cross-coupling reaction among aryl-aryl, aryl-alkyl and alkyl-alkyl differently substituted substrates.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

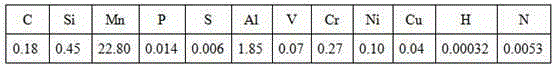

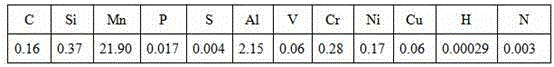

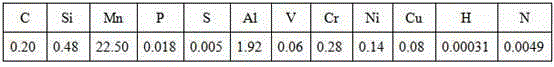

Continuous casting method for high-manganese and high-aluminum type austenite low-magnetic steel

The invention discloses a continuous casting method for high-manganese and high-aluminum type austenite low-magnetic steel. The continuous casting method comprises the steps that 1, the low H content of continuous casting molten steel is controlled; 2, a tundish covering agent with a low SiO2 content is adopted; 3, a big-tapered crystallizer and an upward-tilting water opening are adopted, and the water opening of the crystallizer has a small depth; 4, low and constant pulling speed control is adopted; 5, weak cooling of the crystallizer is adopted; 6, special casting powder with low alkalinity, low Al2O3 content and low melting point is adopted; and 7, continuous casting is carried out in a secondary cooling area in an electromagnetic stirring mode. A large number of slag bars are not generated in slag powder liquid in the crystallizer, the continuous casting process is smooth, no alarm about steel leakage occurs, the surface quality of a casting blank is good, and the requirement of subsequent steel rolling can be met.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

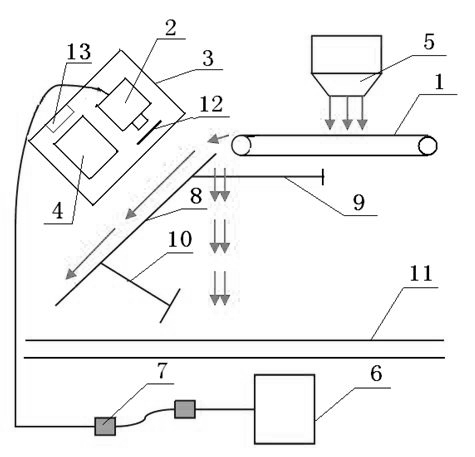

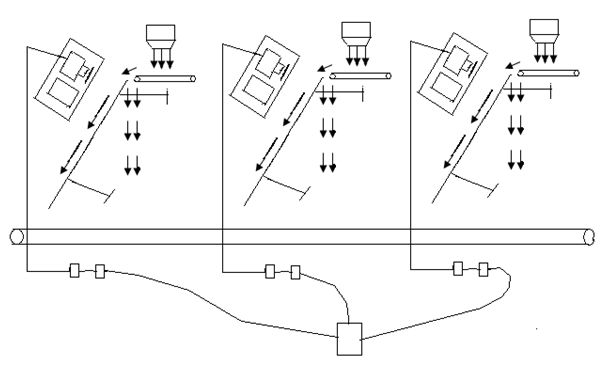

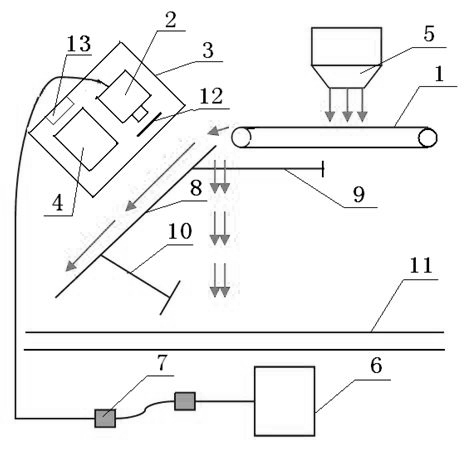

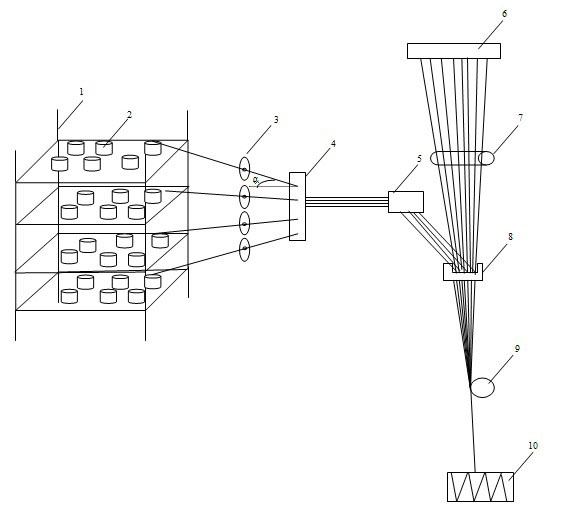

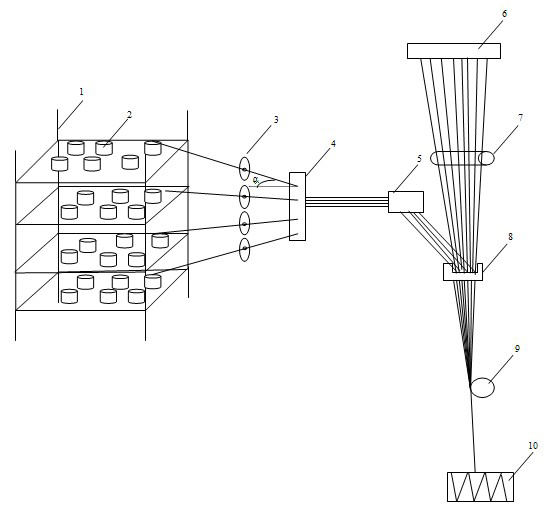

Digital imaging acquisition system for aggregate grading detection and acquisition method thereof

InactiveCN101929943AQuick collectionHigh detection costVolume/mass flow measurementParticle size analysisDigital imagingPoor Quality Image

The invention discloses a digital imaging acquisition system for aggregate grading detection. The system consists of an aggregate sampling device, an image acquiring device, an optical processing optimizer and communication and storage equipment, wherein the aggregate sampling device comprises a material dividing plate, a distance adjusting rod and an angle adjusting rod; the image acquiring device comprises an infrared laser, a linear array camera and an image acquiring card; the optical processing optimizer comprises a filter device and a diffuse coating layer; and the communication and storage equipment comprises a data line and a computer. A digital imaging acquisition method for aggregate grading detection comprises the following steps of: setting the aggregate sampling device; setting the image acquiring device; setting the communication and storage equipment; acquiring an image of a sampled aggregate; and transmitting and storing the image. An aggregate stream is sampled and acquired by arranging the material dividing plate, so the problem that the image of a falling stream of the aggregate must be completely acquired is solved and the defects of poor quality of the acquired image, difficult separation of particles and a large amount of processing data are overcome.

Owner:CHANGAN UNIV

Solvent preparation of cellulose fiber releasing anion and use thereof

InactiveCN101230495ANon-volatileEasy to recycleMonocomponent cellulose artificial filamentWet spinning methodsTotal solid contentCellulose fiber

The invention relates to a method of preparing a cellulose fibre releasing anions by using the solvent method and the application. The method has the following steps: firstly, the comminuted cellulose, tourmaline powder and addition agent are well mixed with an ironic liquid, dissolved at a temperature of 35 to 160 DEG C, deaerated for 1 to 120 hours and a homogeneous and stable spinning solution with a total solid content of 3 to 30 percent is formed, wherein, the mixed mass ratio of the tourmaline powder is 0.01 to 20 percent and the added mass ratio of the addition agent is 0 to 10 percent; secondly, the spinning solution is filtered, deaerated, spinned and solidified through a coagulation bath; and thirdly, a composite fibre of cellulose and tourmaline powder is obtained after the procedures of stretching, water cleaning, bleaching, oiling and drying. The composite fibre has the functions of releasing anions, generating far infrared radiation, generating biocurrent and suppressing bacteria and is applicable to the fields of garments, ornaments and medical textiles. The ironic liquid used in the invention has high production efficiency, is easy for callback and conforms to the requirement of a green production. The prepared composite fibre has excellent mechanical strength and mechanical property, and the fabric made of the composite fibre can release anions, resist bacteria and prevent mildew.

Owner:DONGHUA UNIV

Ceramic tile mould preparation method

ActiveCN103085162ARealistic effectThe pattern is natural and beautifulCeramic shaping apparatusPolymer sciencePolyurethane membrane

The invention discloses a ceramic tile mould preparation method. The ceramic tile mould preparation method includes steps of fixing a material, spraying release agents or parting agents on the surface of the material, uniformly painting silica gel on the surface of the material, taking down the silica gel when the silica gel completely solidifies, and obtaining a silica gel membrane. The surface of the silica gel membrane copies stereoscopic layering textures of the surface of the material. The textures are copied on the surface of a fine carving greasy filth mold, then copied on the surface of a plaster mold, next copied on the surface of the silica gel membrane, and last copied on the surface of a polyurethane membrane, and the obtained polyurethane membrane is a ceramic tile mould. The ceramic tile mould prepared in the ceramic tile mould preparation method has the stereoscopic layering textures of the surface of the material, is vivid and natural in effects, and has the advantages of having clear, natural, concave-convex textures and natural and beautiful patterns like natural stones, wood or fabrics. The ceramic tile mould preparation method solves the problems that an existing ceramic tile mould has surface texture defects which can not be improved, causes resource waste and is time-consuming and labor-consuming in production.

Owner:广东道氏陶瓷材料有限公司

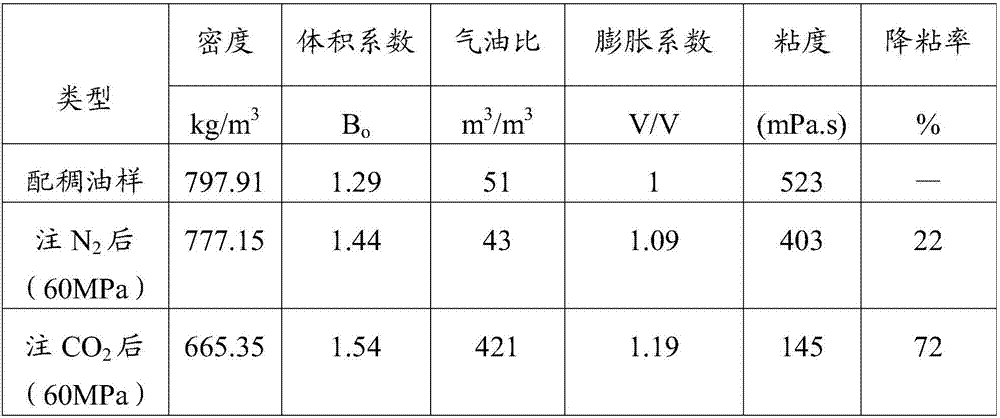

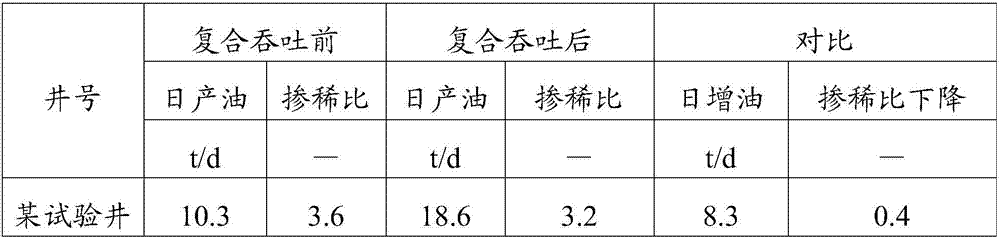

Oil production method of nitrogen and carbon dioxide composite huff and puff

InactiveCN106968651AAchieve solubilityRealize functionDrilling rodsFluid removalDissolutionOil production

The invention discloses an oil production method of nitrogen and carbon dioxide composite huff and puff. The oil production method comprises the following steps that an injection-production integrated pipe column is put downward to a target oil layer in an oil well; the top of the injection-production integrated pipe column is connected with gas injection devices and thin oil injection device on the ground, wherein the gas injection devices comprises the nitrogen injection device and the carbon dioxide injection device; the gas injection devices inject gas into the oil well through the injection-production integrated pipe column; after nitrogen, carbon dioxide and thin oil are injected, shut in well is conducted; when the pressure of an wellhead after shut in well is stable, blow-off is controlled through an oil nozzle; and after the wellhead pressure and the blow-off well liquid amount both are smaller than predetermined values, extracting starts to be conducted through the injection-production integrated pipe column. The nitrogen and the carbon dioxide jointly serve as one-time injection media, the nitrogen replaces attic oil in the high positions of the periphery of the well, the carbon dioxide achieves the functions of dissolution, viscosity reducing and expansion energy increasing on stratum thick oil, and by utilizing the double composite functions of gas cap energy increasing of the nitrogen and stratum viscosity reducing of the carbon dioxide, the recovery efficiency of an ultra-deep fracture-cavity type thick oil reservoir is increased.

Owner:CHINA PETROLEUM & CHEM CORP

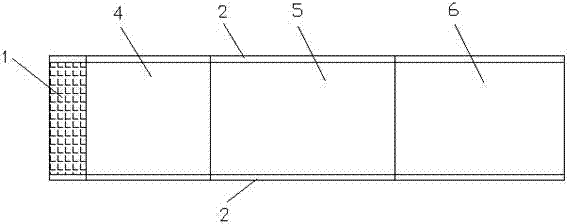

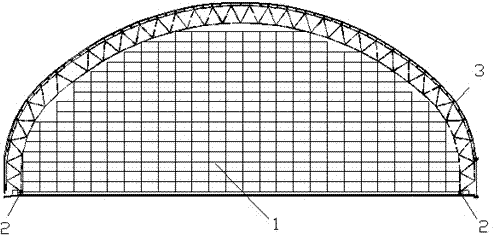

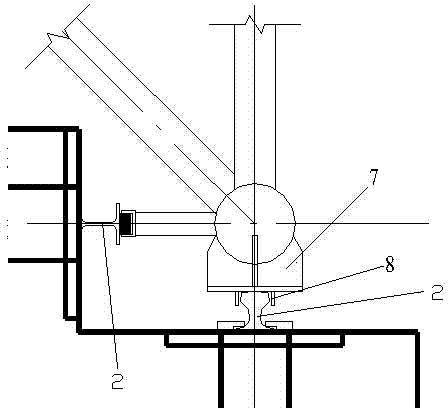

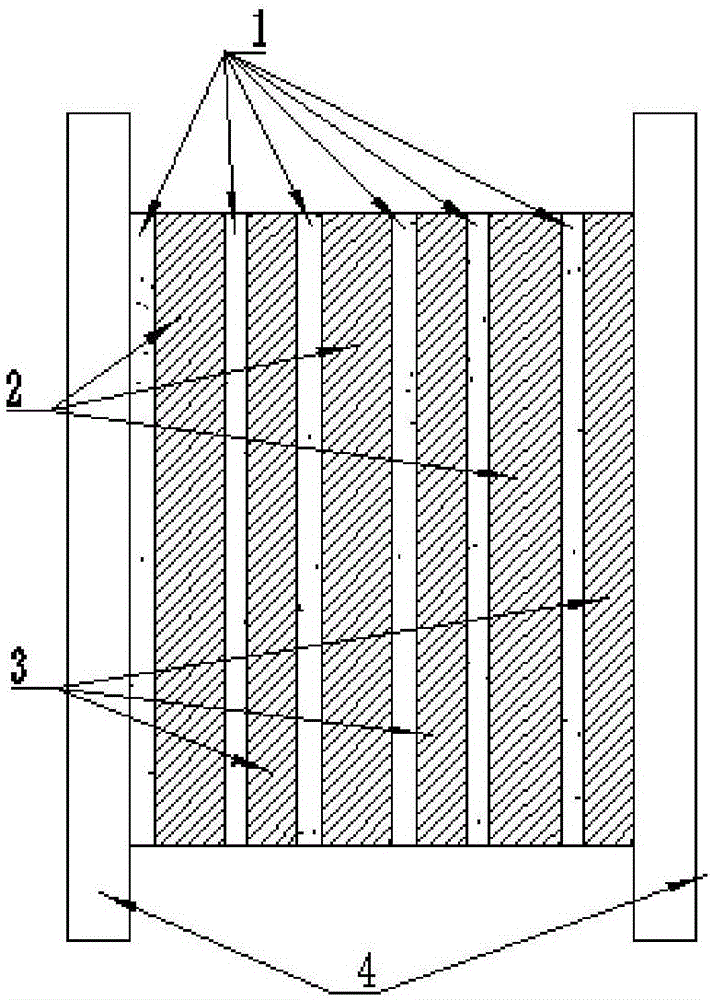

Large roof grid structure assembling and installing method

ActiveCN104264999AGuaranteed stabilityLower requirementBuilding material handlingEconomic benefitsEngineering

The invention provides a large roof grid structure assembling and installing method, and belongs to the technical field of high-altitude and large-span grid structure installing methods. The method is used for assembling and installing a large roof grid structure. An operation platform is arranged outside a grid structure coverage area, grid structure assembling work is conducted on the operation platform, the assembled grid structure slides and is assembled through sliding rails, sliding power is provided through a hydraulic crawl device, and the grid structure can slide in place on the premise that the overall stability of the grid structure is kept. The large roof grid structure assembling and installing method is scientific and reasonable in design and easy and convenient to implement, construction quality is ensured, the construction speed is increased, various construction and production activities in the grid structure coverage area can not be influenced, and the method has remarkable economic benefits and general popularization value.

Owner:河北大河邯钢设计院有限公司

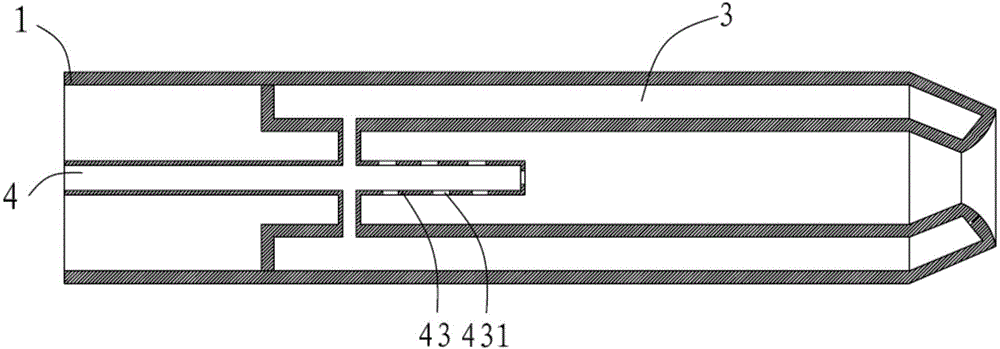

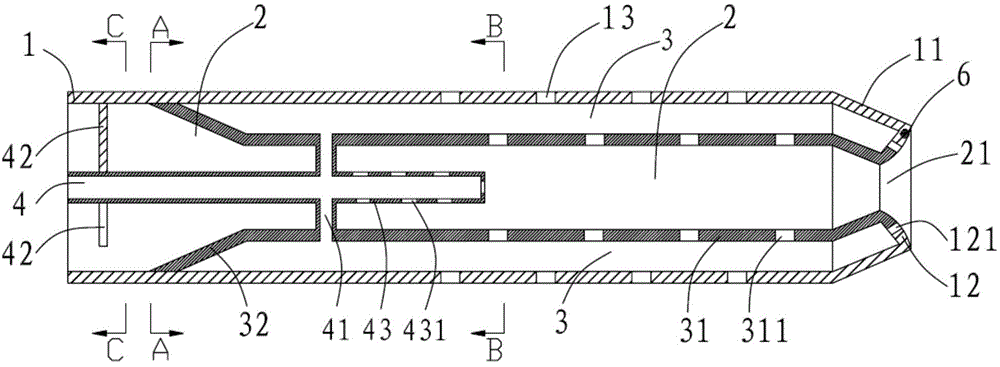

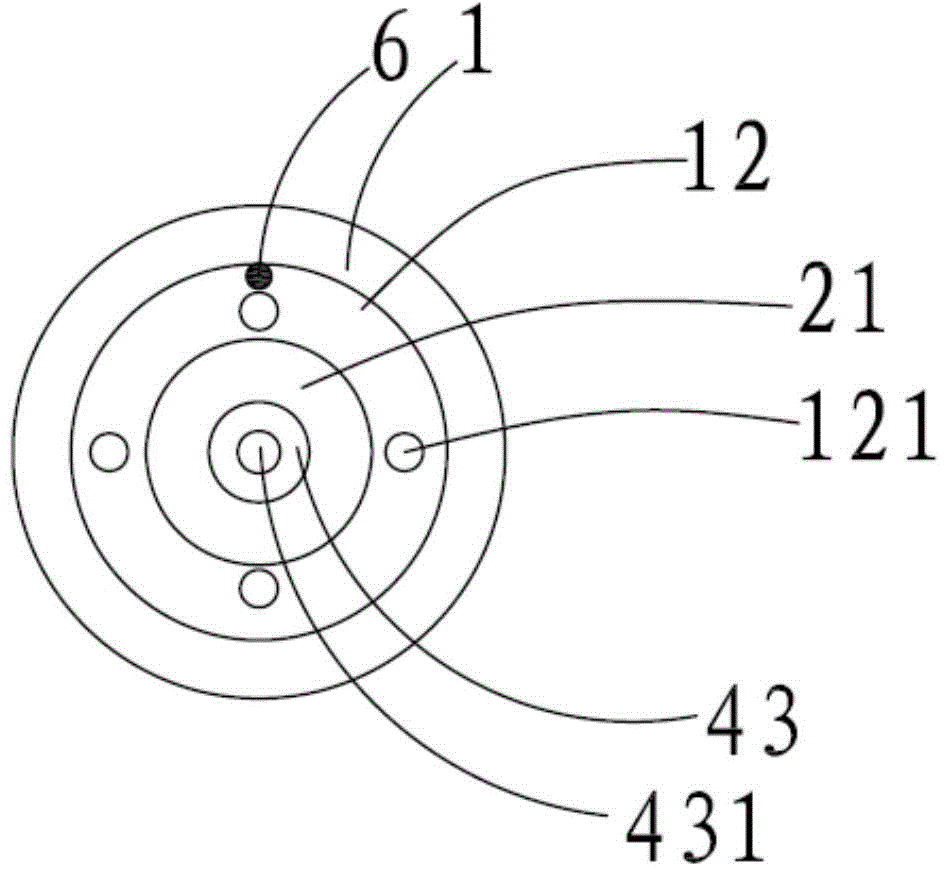

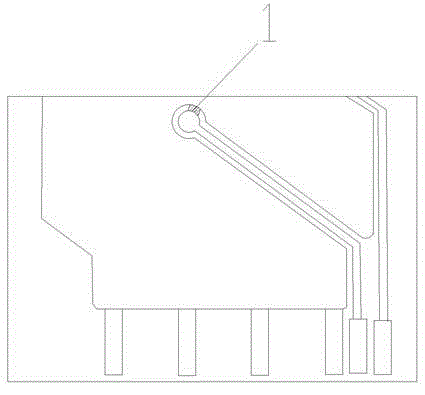

Display device

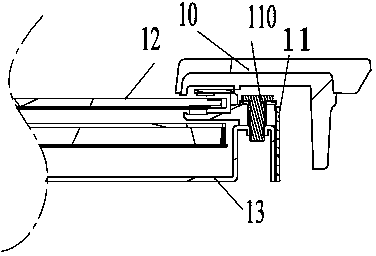

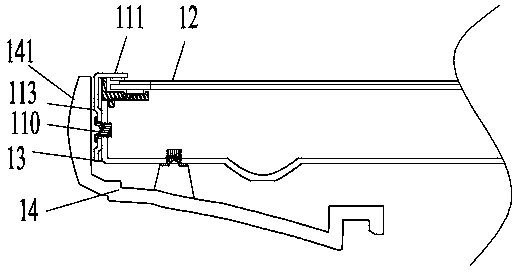

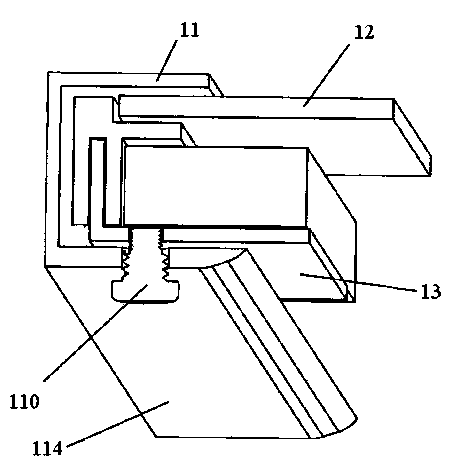

ActiveCN103646622AAvoid breakingAvoid productiveTelevision system detailsColor television detailsDisplay deviceComputer engineering

The invention discloses a display device. The display device comprises a face frame, a panel and a back board, wherein the face frame is formed by splicing a plurality of sections of frame bodies and surrounds the panel and the back board, guiding sliding chutes are formed in a set of opposite edges of the face frame respectively, positioning pieces corresponding to the guiding sliding chutes are arranged at the edges of the back board, and when the frame bodies and the back board are assembled, the positioning pieces correspondingly slide into the guiding sliding chutes to fix the frame bodies, the panel and the back board in advance.

Owner:HISENSE VISUAL TECH CO LTD

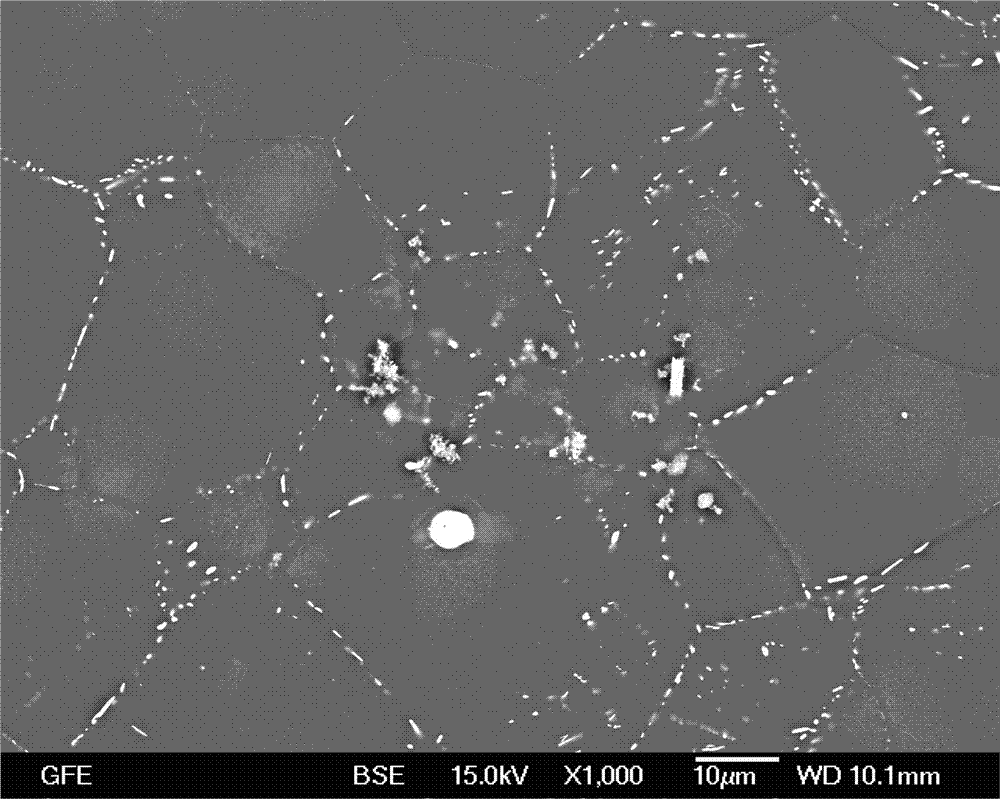

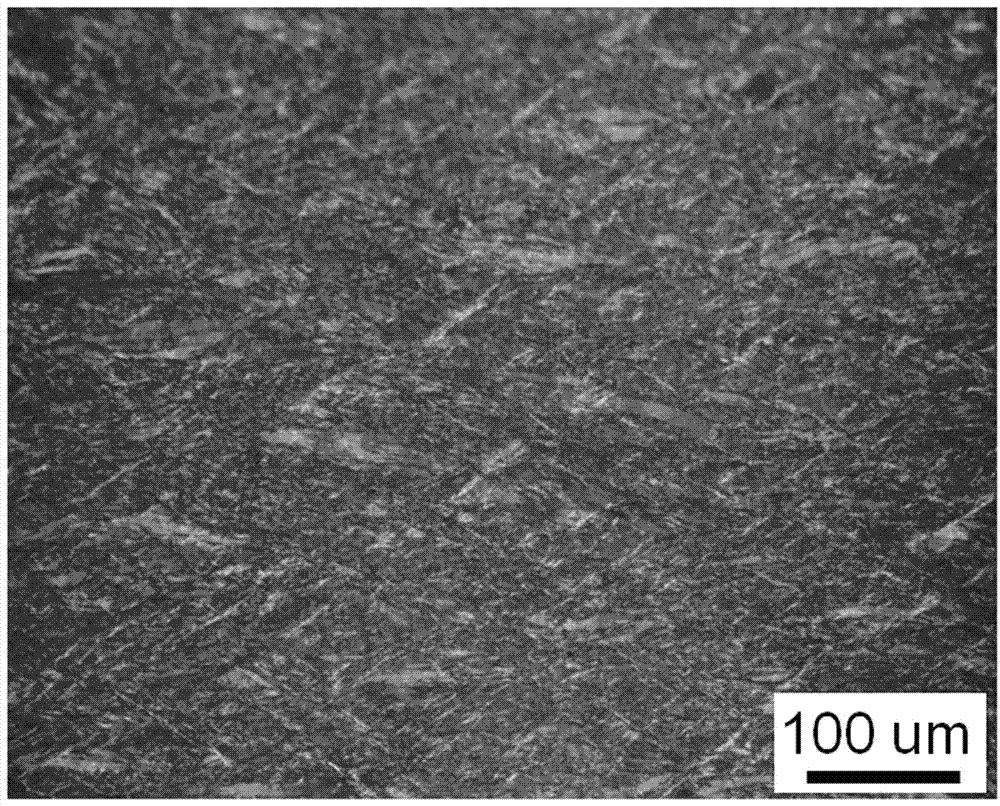

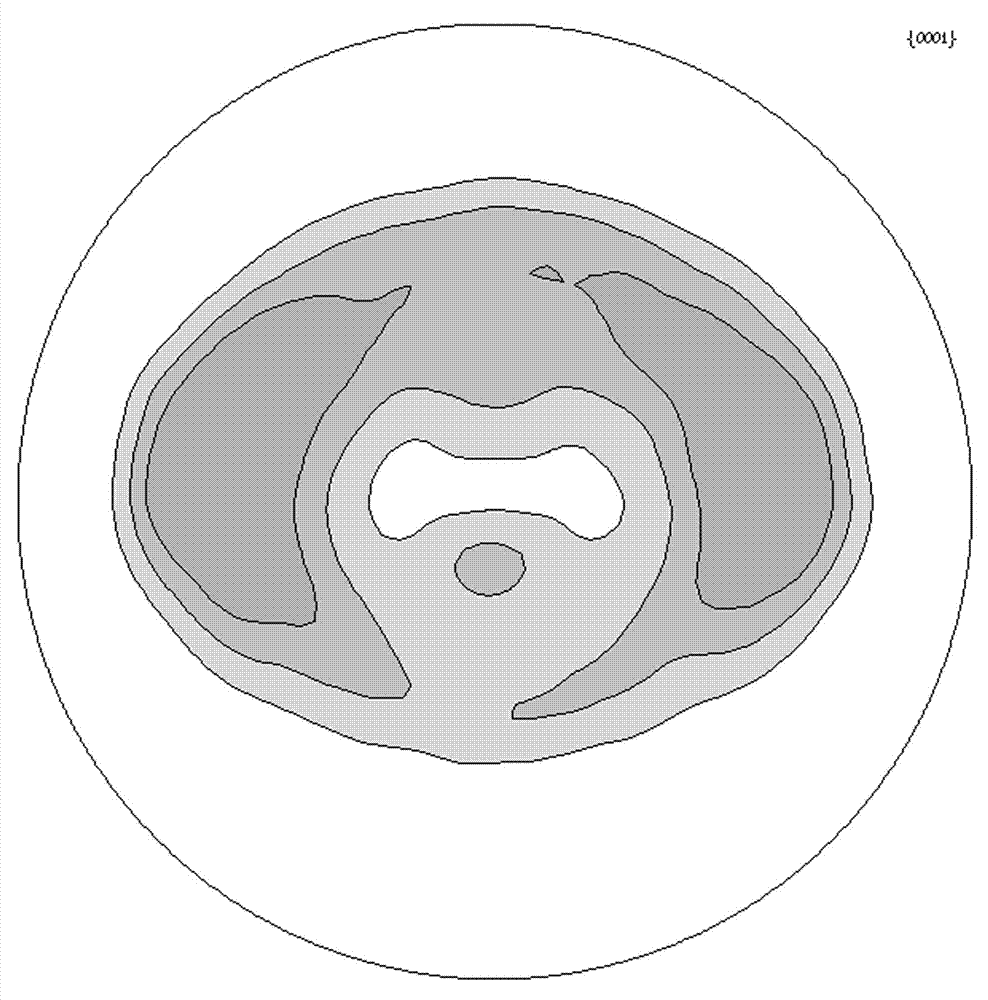

Preparation method of rare earth magnesium alloy and sheet thereof

The invention provides a rare earth magnesium alloy. The rare earth magnesium alloy is characterized by comprising the following components by mass percent: 0.5 to 4.0% of Zn, 0.1 to 2% of Gd, 0.3 to 0.9% of Zr, and the balance of Mg. The preparation method of the rare earth magnesium alloy sheet comprises the following steps of: treating a rare earth magnesium alloy ingot casting by uniform annealing; cooling with water; milling the surface; preheating a milled blank; rolling for four to eight times; melting down and heating once every two to three times after rolling; continuously rolling, wherein the total rolling reduction is 70 to 95%; annealing the sheet subjected to hot rolling; performing cold rolling for a moderate-thickness sheet subjected to hot rolling for two to four times; and then annealing the sheet subjected to cold rolling to obtain the rare earth magnesium alloy sheet. The invention also provides a preparation method of the rare earth magnesium alloy and the sheet thereof. The rare earth magnesium alloy sheet is high in plasticity and high in heat stability. Compared with hot rolling, cold rolling has the advantage that the magnesium alloy can be prevented from being oxidized into a film during heating; in addition, the prepared sheet is accurate in dimension and uniform in thickness; a thin belt which cannot be produced by hot rolling can be obtained; and mass production and application can be realized.

Owner:GUANGDONG INST OF NEW MATERIALS

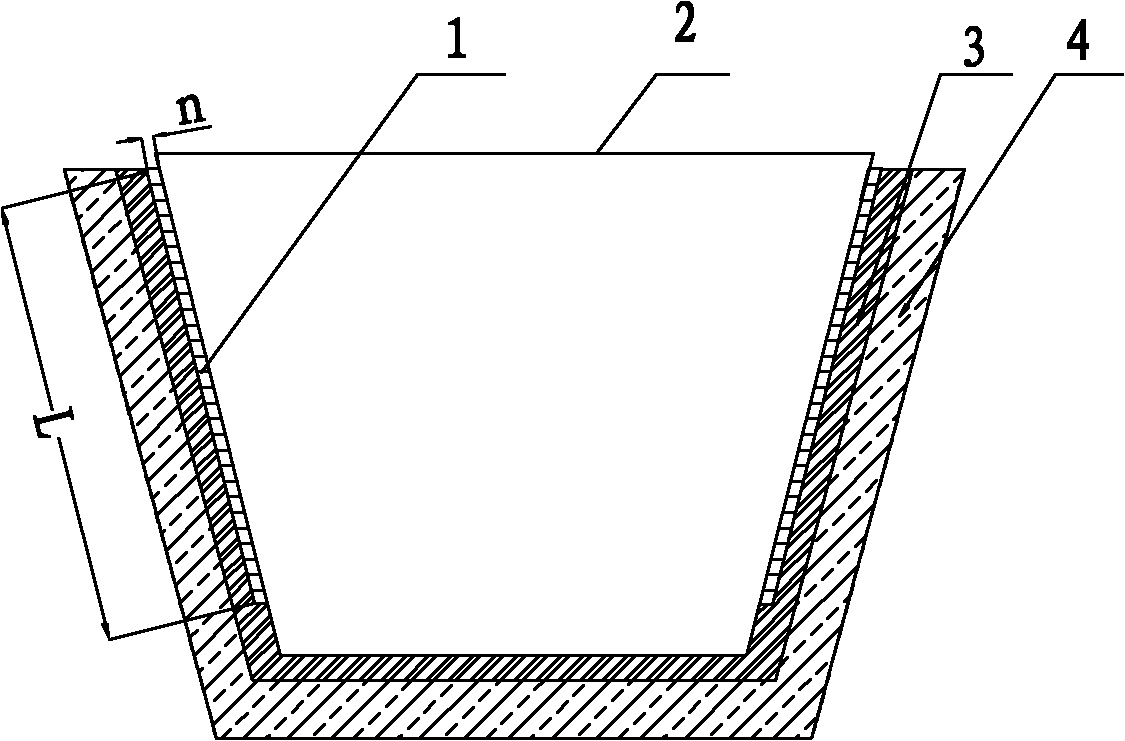

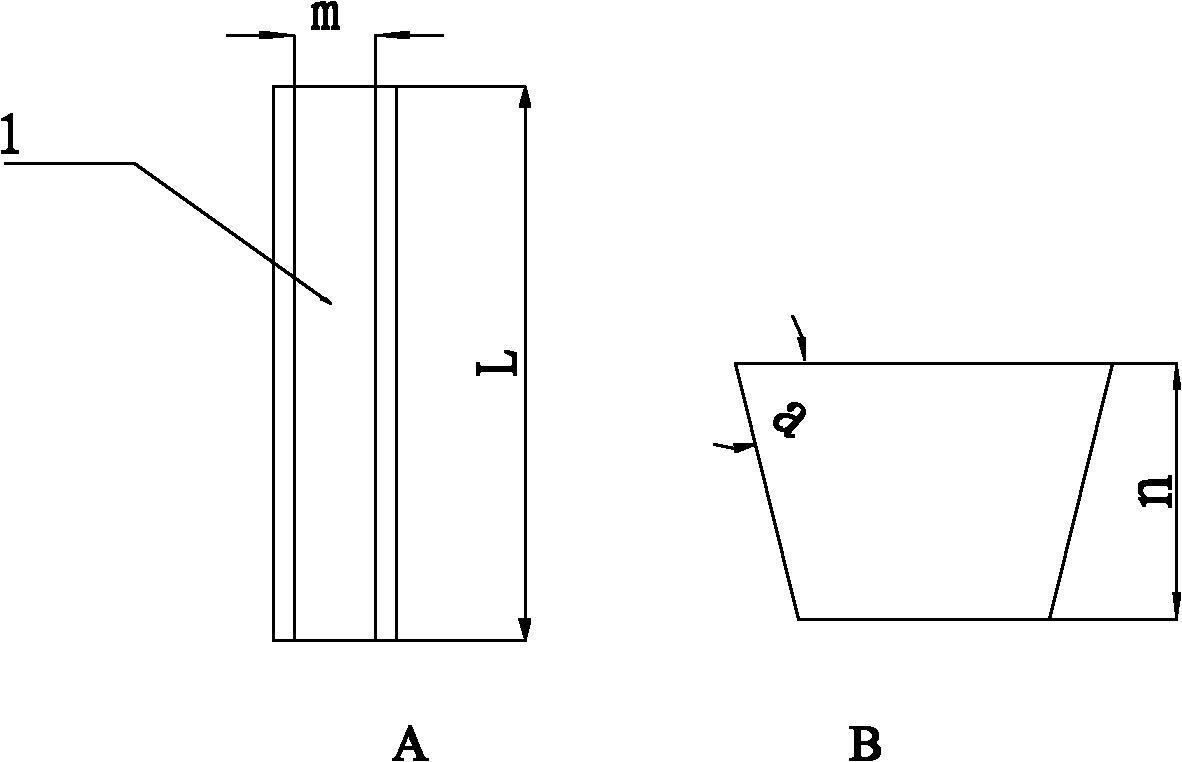

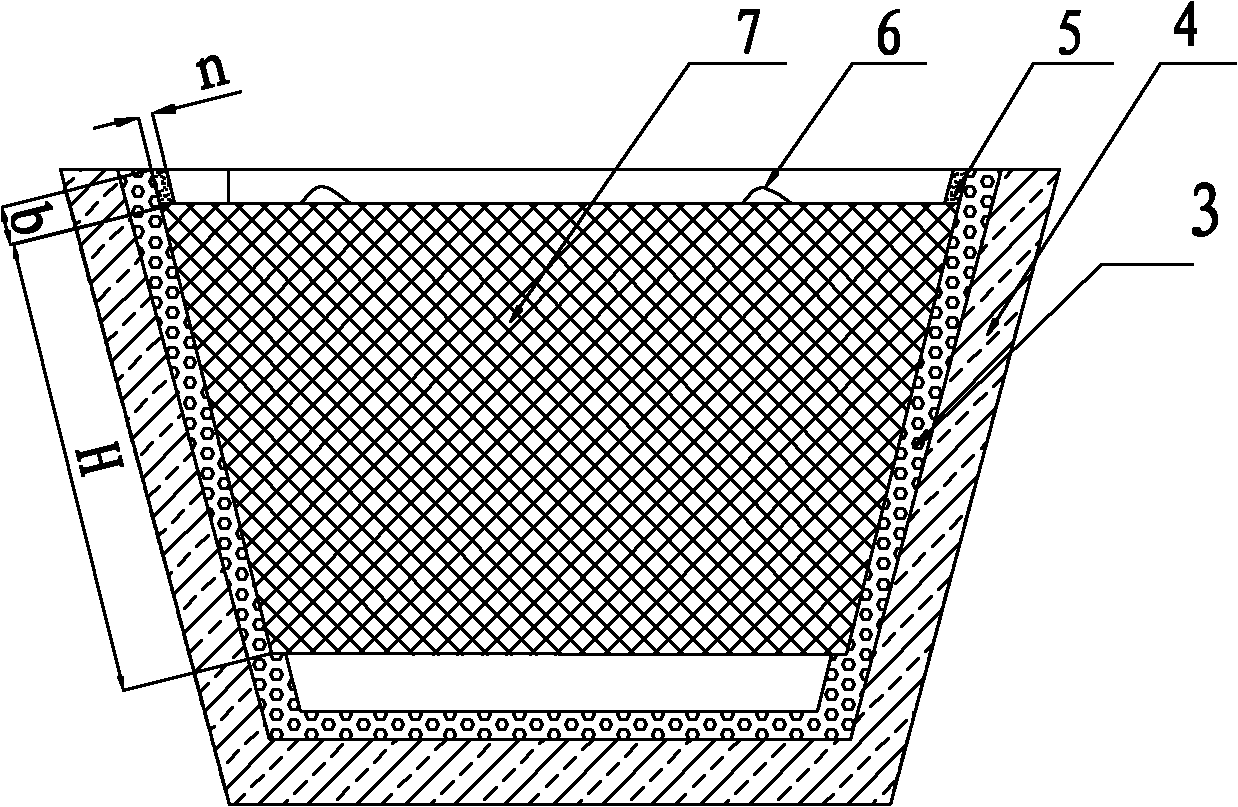

Slag wall inserts of continuous casting tundish and embedded installing method thereof

The invention relates to slag wall inserts of a continuous casting tundish and an embedded installing method thereof. The slag wall inserts of the continuous casting tundish are mainly characterized in that heat-resisting cast steel is used to produce two inserts according to the installing position and size of the slag wall of the tundish; the two inserts are symmetrically welded on the side surface of a dry material working lining construction membrane; when the dry material working lining construction membrane constructs a tundish working lining, the inserts welded on the dry material working lining construction membrane form two grooves at the positions on the tundish working lining for installing the slag wall, and the two side edges of the tundish slag wall are embedded into the twogrooves. The slag wall inserts and the embedded installing method disclosed by the invention are adopted for installing the tundish slag wall, the method is simple, the tundish slag wall is positioned accurately, the technical problem of easy collapsing of a long-service-life tundish slag wall is solved fundamentally, production accidents and quality accidents are avoided, and the service lives of the continuous casting tundish and the slag wall are prolonged.

Owner:LAIWU IRON & STEEL GRP

Lithium ion battery maximum electrolyte injection volume quick evaluation method

ActiveCN106595823AEasy to operateReduced electrical performanceWeighing apparatus for materials with special property/formInjection volumeElectricity

The invention discloses a lithium ion battery maximum electrolyte injection volume quick evaluation method. The electrolyte containing rate of a positive plate, the electrolyte containing rate of a negative plate and the electrolyte containing rate of a diaphragm are measured firstly; the volume of the electrolyte absorbed by each is calculated according to the electrolyte containing rate; the spare volume Vspare of the inner cavity of a battery shell is measured; the correction coefficient eta of the volume of the void for containing the electrolyte of a cathode mix is then detected; and the total electrolyte injection volume m<electrolyte>=( Vspare+Vvoid*eta)*rho of the battery is finally calculated. The evaluation method is simple to operate, the result is accurate, the debugging time is shortened, influences on the device precision and the production by frequent device debugging are avoided, falling of the electric performance of the battery caused by insufficient electrolyte injection volume can be avoided, and accurate design parameters are provided for the electrolyte injection volume of the battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method and equipment for manufacturing composite fiber containing continuous glass fiber

The invention relates to a method for manufacturing a composite fiber containing a continuous glass fiber. The composite fiber is formed by mutually mixing offline terylene and an online continuous glass fiber; the glass fiber is drawn on line, and the terylene is finished yarn; a plurality of bundles of terylene with different yarn feed angles are drawn to be converged into sheet shapes after being subjected to tension adjustment; and the converged terylene yarn bundles are separated and then compounded with the glass fiber processed with an impregnating compound. The invention has the advantages of simplified process equipment and improved production smoothness; and meanwhile, the introduction of chemical fiber yarn-feed tension adjustment ensures that better practicability and better effect on the baked yarn clew moulding effect are achieved.

Owner:JUSHI GRP CO

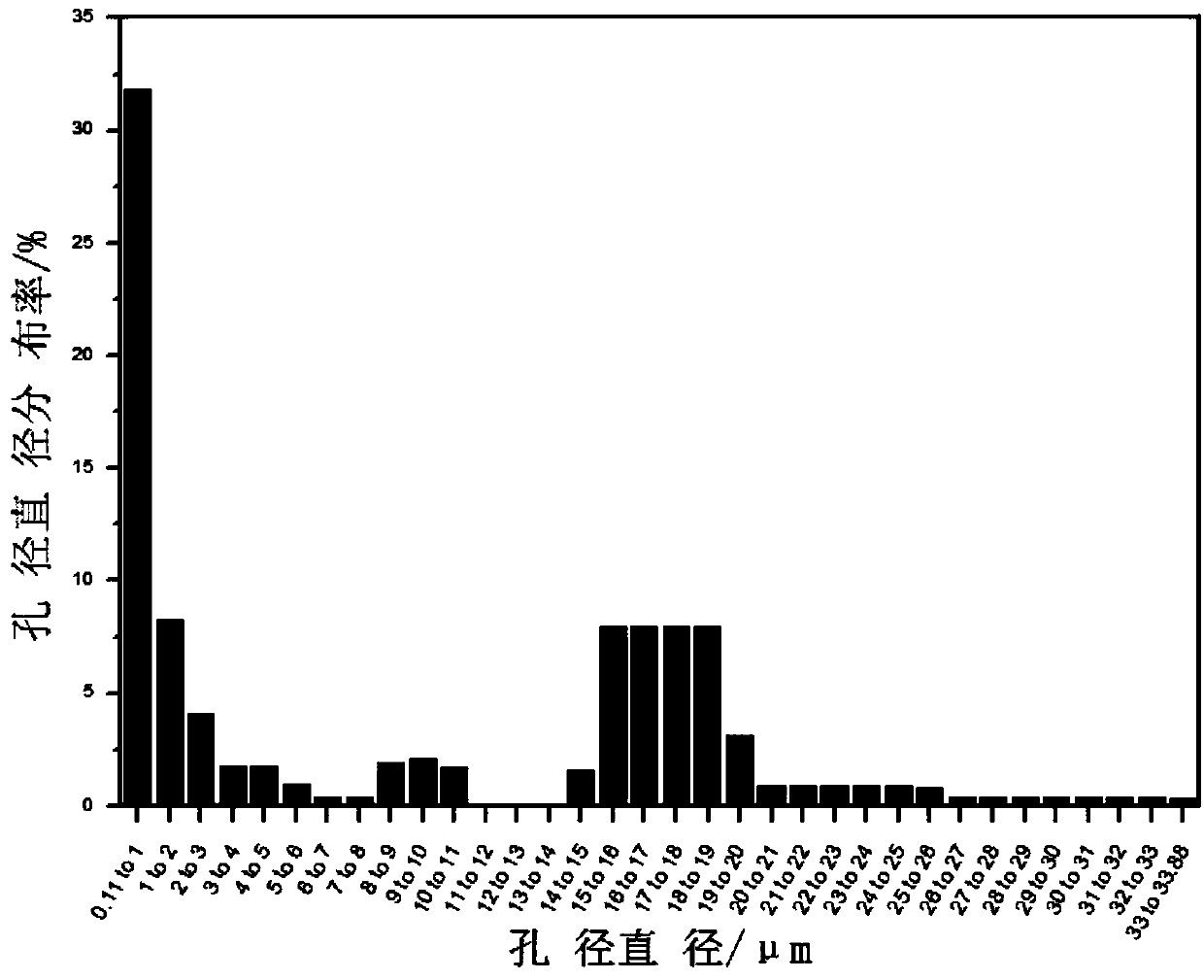

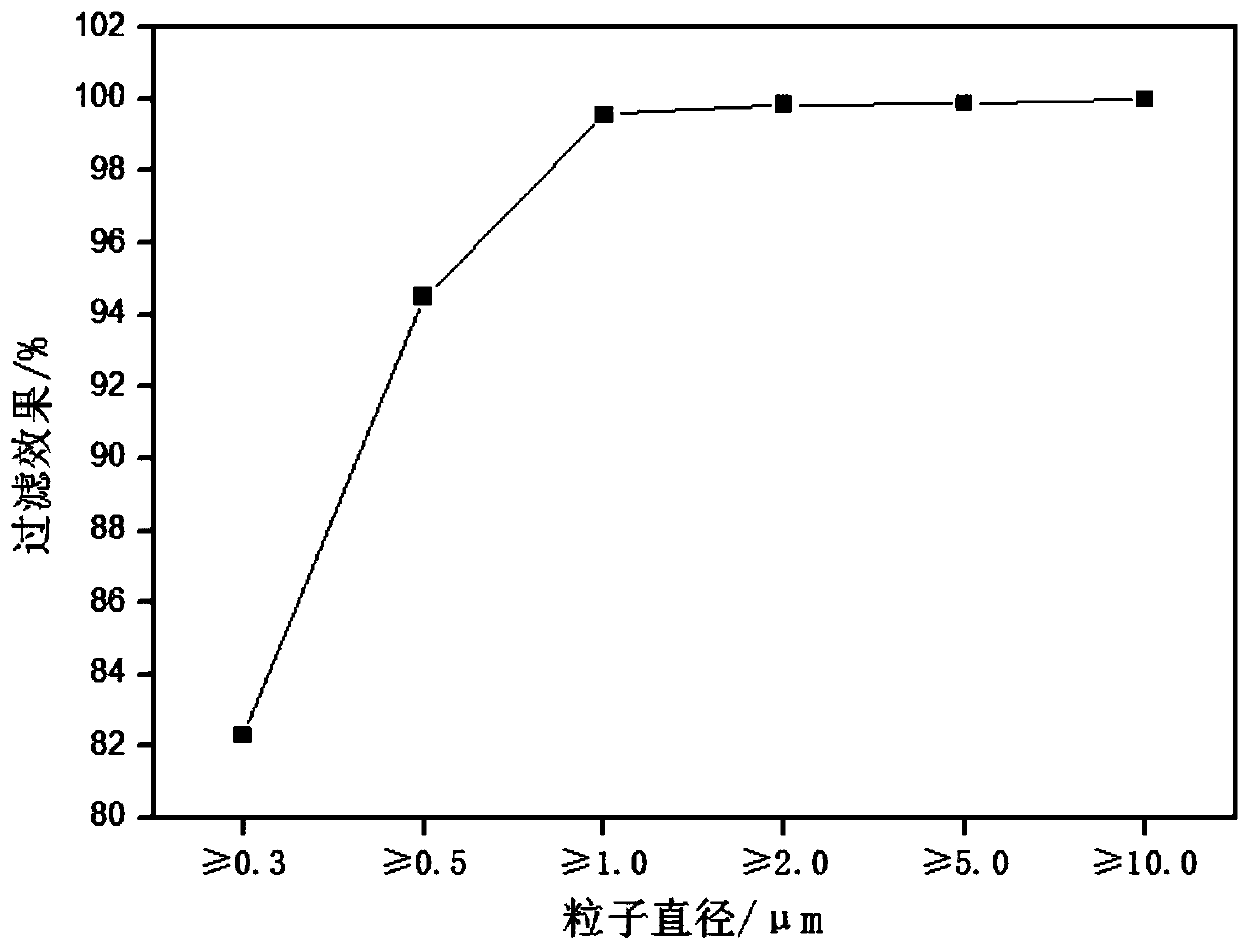

Preparation method of cotton bast fiber and chitosan composite nonwoven fabric for filtering

ActiveCN107604739AAvoid damageEasy to separatePulp beating methodsReinforcing agents additionHigh volume manufacturingElectrospinning

The invention discloses a preparation method of cotton bast fiber and chitosan composite nonwoven fabric for filtering, and belongs to the technical field of fiber materials. Cotton bast is separatedthrough steam flash-explosion pretreatment, formation is conducted by a papermaking method, and chitosan is added to enhance the mechanical property and the filtering efficiency. The preparation method is simple, convenient and environment-friendly in process flow and adapts to industrialized production. The nonwoven fabric adopts lignin-enriched cotton bast fiber and chitosan as raw materials, sothat the nonwoven fabric has high antibacterial property. The cotton bast and the chitosan are biology-based materials and can be degraded in the natural environment after use, so that environmentalburden is reduced and the problem that the electrostatic spinning method is difficult in industrialized and mass production is solved.

Owner:JIANGNAN UNIV

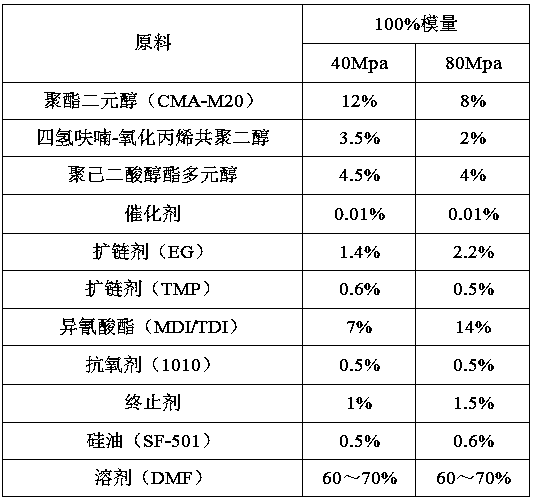

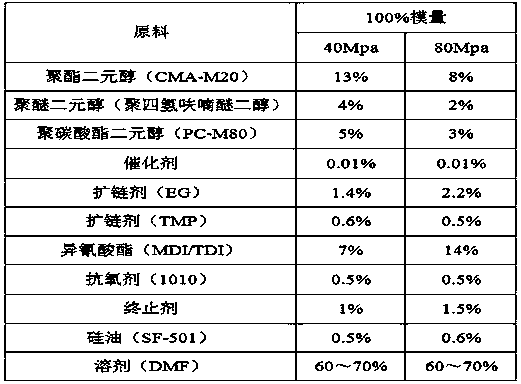

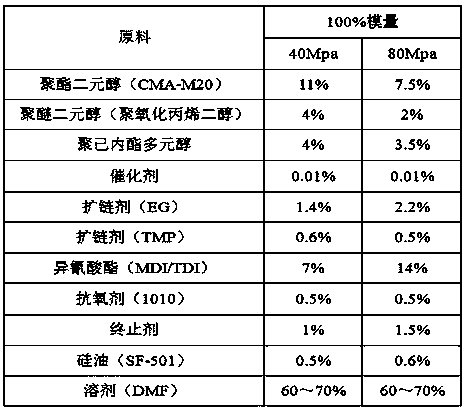

Special high-physical-property high-dyeing polyurethane resin for superfine fiber synthetic leather and preparation method of special high-physical-property high-dyeing polyurethane resin

The invention discloses a special high-physical-property high-dyeing polyurethane resin for superfine fiber synthetic leather and a preparation method of the special high-physical-property high-dyeingpolyurethane resin. The special high-physical-property high-dyeing polyurethane resin for the superfine fiber synthetic leather comprises the following components in percentages by weight: 1-15% of polyether polyol, 1-15% of polyester polyol, 5-10% of isocyanate, 0.5-1% of small molecular polyol, 1-2% of an end-capping agent, 0.1-1% of an antioxidant, 0.5-1% of silicone oil, 0.01% of a catalyst and the balance of a solvent. The polyester polyol comprises a combination of one or more polyester polyols with different structures, and any one of the polyester polyols is mainly formed by polycondensation of a dibasic acid compound and dihydric alcohols or / and a dihydric alcohol derivative; and the glycol derivative is preferably N-methyldiethanolamine. The invention also discloses a preparation method of the polyurethane resin. The polyurethane resin obtained by the method disclosed by the invention has the advantages that the stripping strength and the tearing strength are improved whilethe dyeing property is guaranteed, the setting time is shortened, the myogenicity is high, a large-kettle production process is simple, the reaction can be smoothly carried out, the explosion polymerization is avoided, and the industrialized popularization is facilitated.

Owner:浙江华大树脂有限公司

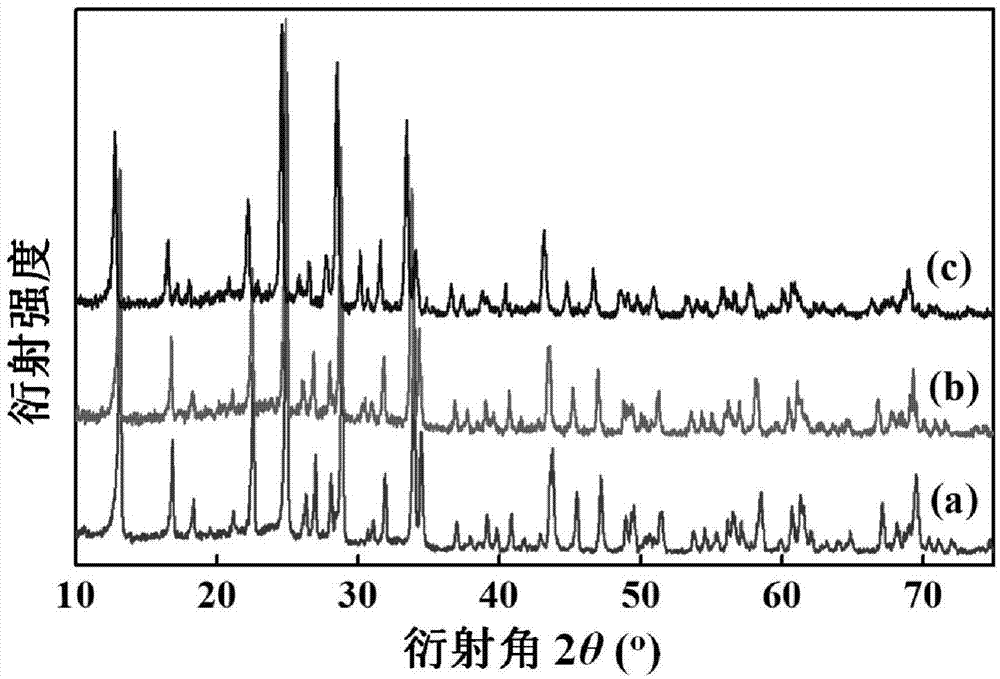

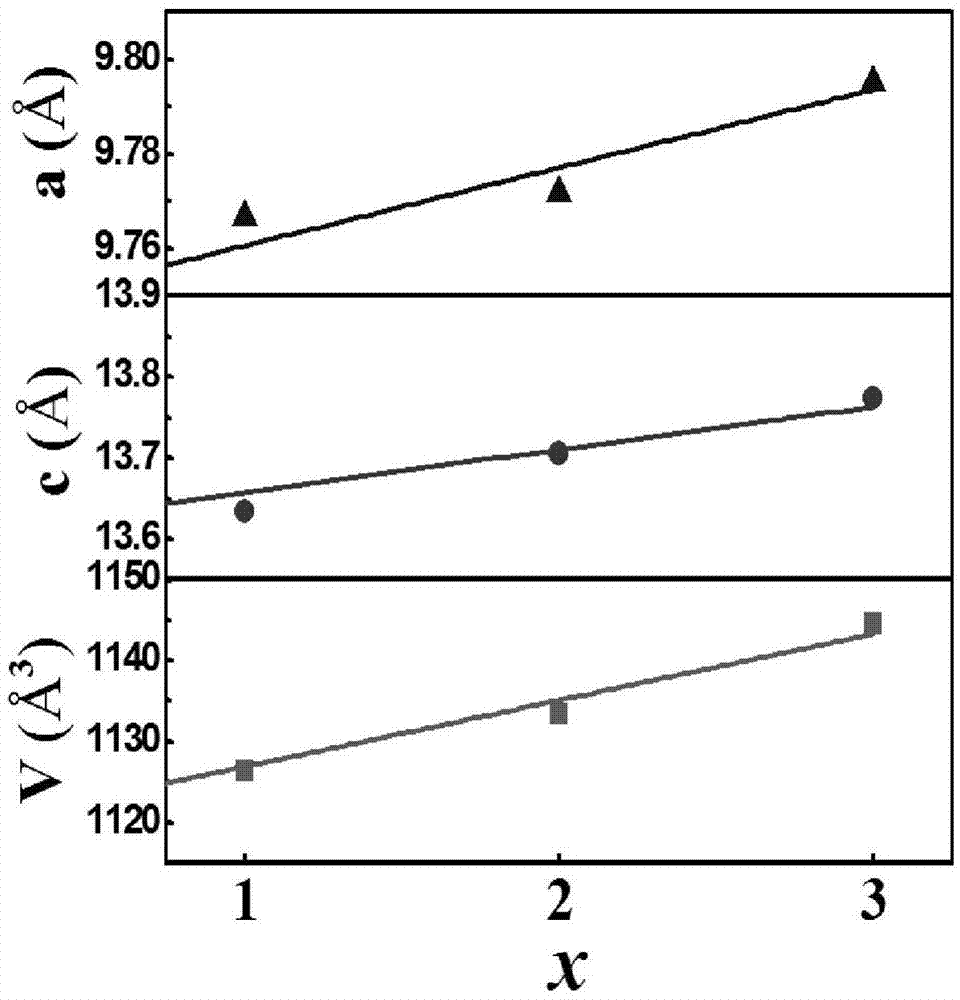

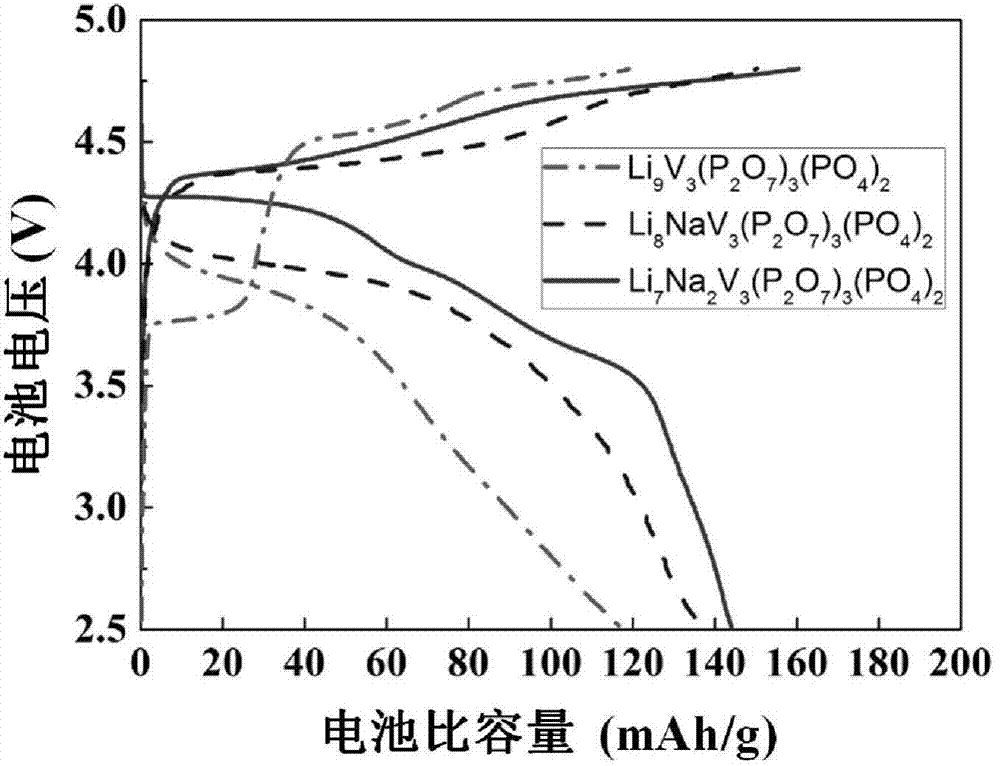

Mixed ion phosphate positive electrode material and preparation method thereof

ActiveCN104752697AHigh discharge specific capacityCell parameter increaseCell electrodesPhosphorus compoundsPhosphateLithium hydroxide

The invention belongs to the technical field of lithium ion battery positive electrode materials and discloses a mixed ion phosphate positive electrode material and a preparation method thereof. The positive electrode material has the chemical formula of Li(9-x)NaxV3(P2O7)3(PO4)2, wherein x is more than 0 and less than 9. The preparation method comprises the following steps: mixing a lithium salt or lithium hydroxide, a sodium salt or sodium hydroxide, a vanadium salt or oxides of vanadium, phosphate or phosphorus pentoxide which are used as raw materials according to a molar ratio (9-x) to x to (2.8-3.2) to 8 of lithium to sodium to vanadium to phosphorus, grinding or performing ball milling, thereby obtaining a precursor mixture; performing heat treatment on the precursor mixture for 2-10 hours at the temperature of 200-450 DEG C in air in a reducing atmosphere or an inert atmosphere; and finally, sintering for 4-72 hours at the temperature of 500-800 DEG C in a reducing atmosphere or an inert atmosphere, thereby obtaining the product. The positive electrode material disclosed by the invention comprises two conduction ions and has high charge and discharge voltage and specific discharge capacity.

Owner:SOUTH CHINA UNIV OF TECH

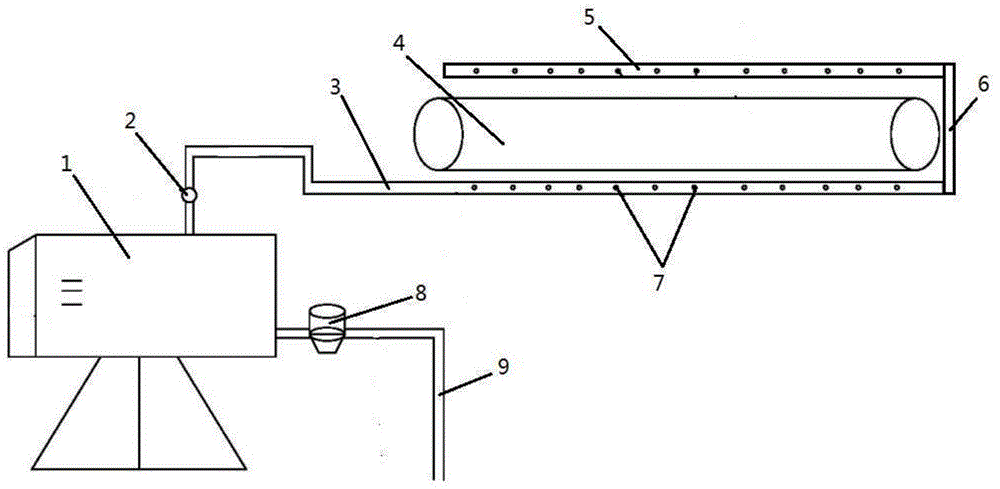

Wallpaper rotary screen printing station with spraying humidification device

InactiveCN104999787APrevent network congestionAvoid missing printsScreen printersPrinting press partsScreen printingWater source

The invention relates to wallpaper production equipment, in particular to a wallpaper rotary screen printing station with a spraying humidification device. The wallpaper rotary screen printing station comprises the spraying humidification device and a rotary screen. The rotary screen is horizontally arranged. The spraying humidification device comprises an atomizer, a draught fan and a first spraying pipe. One end of the atomizer is connected with a water source through a pipeline. The other end of the atomizer is connected with the first spraying pipe. The draught fan is mounted at the end, close to the atomizer, of the first spraying pipe. The end, away from the atomizer, of the first spraying pipe extends below the rotary screen in the axial direction of the rotary screen. The end, away from the atomizer, of the first spraying pipe is further connected with a second spraying pipe through a connecting pipe. The second spraying pipe is located above the rotary screen and extends in the axial direction of the rotary screen. The first spraying pipe and the second spraying pipe are each provided with a plurality of spray holes. Orifices of the spray holes face the rotary screen. The wallpaper rotary screen printing station has the beneficial effect that mesh clogging caused by dry sizing agents is effectively prevented.

Owner:桂林威迈壁纸有限公司

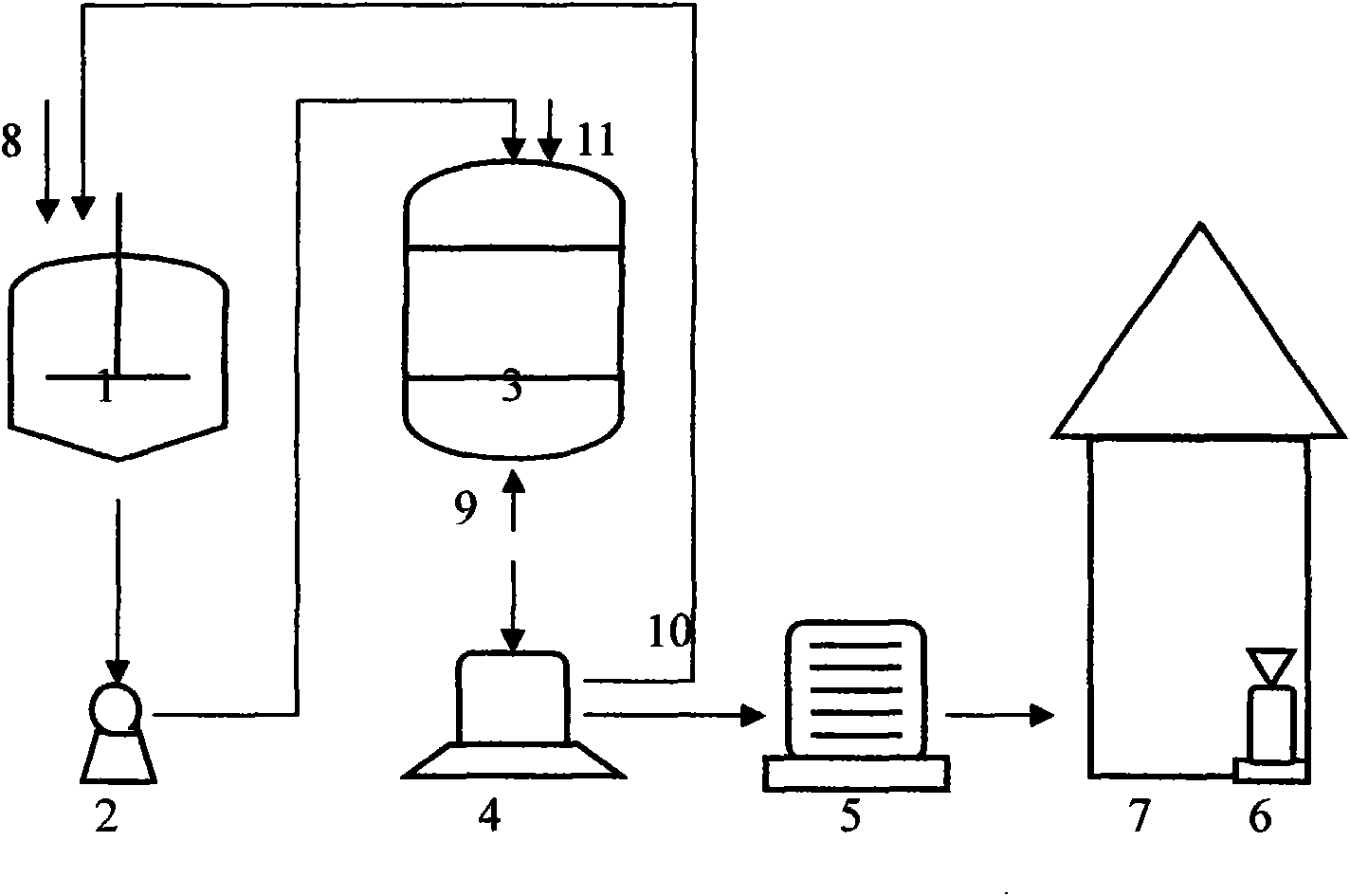

Method for preparing nano active calcium carbonate series products and ammonium chloride by carbide slag

InactiveCN101580258ALow costAvoid productiveCalcium/strontium/barium carbonatesAmmonium halidesCarbon dioxideFilter cake

The invention discloses a method for preparing nano active calcium carbonate series products by carbide slag, which adopts a main technical proposal that: reacting carbide slag and hydrochloric acid to generate calcium chloride and water so as to obtain filter cake and calcium chloride solution; directly putting the filter cake into an incinerator for incineration and deep burying; intensively mixing the calcium chloride, ammonia and a surfactant according to certain proportion in an ammonium carbonizer; introducing carbon dioxide from a reactor until the finish of carbonization to obtain nano active calcium carbonate of various finenesses; and centrifuging, drying and winnowing to obtain calcium carbonate of various grades. The method reasonably avoids the defects of high cost, low productivity, complex production and equipment, and the like of the conventional method, forms the ammonium carbonization method with unique advantages and characteristics, and has the advantages of less investment, low cost, simple production and high yield.

Owner:王嘉兴

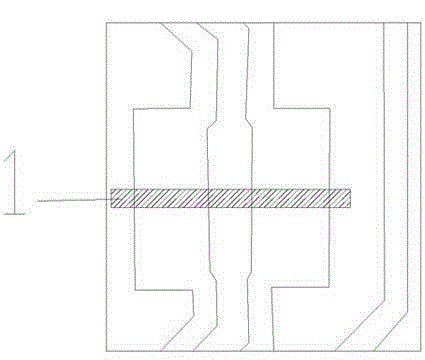

Lithium battery

ActiveCN112563584AStable outputImprove yieldAssembling battery machinesCell seperators/membranes/diaphragms/spacersPole pieceMechanical engineering

The invention discloses a lithium battery which comprises a roll core and tabs, the roll core is formed by stacking and winding an inner diaphragm, a first pole piece, an outer diaphragm and a secondpole piece, and the polarity of the first pole piece is opposite to that of the second pole piece; the inner-layer diaphragm is located on the innermost layer of the roll core, the inner-layer diaphragm and the outer-layer diaphragm are respectively provided with a clamping section, a first straight section connected with the clamping section and located behind the clamping section, and a tail fitting section exceeding the tail end of the first pole piece, the first straight section is located in front of the first pole piece, and the tail fitting section is the tail end of the diaphragm. Theclamping section, the first straight section and the tail fitting section of the inner-layer diaphragm are respectively fitted with the clamping section, the first straight section and the tail fitting section of the outer-layer diaphragm; and the surface friction coefficient of the first straight section of the inner-layer diaphragm is 0.1-0.4. The diaphragm with a specific surface friction coefficient is used, so that the diaphragm is matched with a winding needle material, the production problems of core pulling, poor spacing and the like caused by the diaphragm material can be avoided, andthe product yield and the production efficiency can be improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Water-base gravure ink copolymer emulsion and binder

ActiveCN101575395AMeet environmental protection requirementsReduce usageMonocarboxylic acid ester polymer adhesivesInksWater basedHydrophilic monomer

The invention discloses a water-base gravure ink copolymer emulsion and a binder, allyloxy hydroxypropy sulfonate sodium aqueous solution is added into a mixed solution containing monomers, hydrophilic monomers, molecular weight regulator and ammonium persulfate of carboxyl and carboxyl functional group for preparing the emulsion by copolymerization , alkaline solution is then neutralized and alcohol solubilizing assistant is added to obtain water-base gravure ink copolymer emulsion and the binder. On the one hand, the water-base gravure ink copolymer emulsion and binder save a large amount of food, one the other hand, the water-base gravure ink copolymer emulsion and binder save reduce the use of organic solvents, thereby effectively avoiding the defects that the organic solvent is inevitably combustible and explosive, pollutes environment and jeopardizes health of production worker, and the environment-friendly requirements of the binder are met. The material is widely applied to tipping paper, has viscosity of 90-150 seconds and strong water absorptivity and slow-release function, and can keep the tipping paper from water absorption and deformation and meet the demands of the production of cigarette filter tip.

Owner:毛仕龙

Method for preparing MAX phase material

The invention provides a method for preparing a layered ceramic material MAX phase material. A transition metal source, a main group element source, a carbon source and / or a nitrogen source are mixedto form a solid raw material, the solid raw material itself in a reaction furnace is directly electrified to generate heat and gradually rises to above 900 DEG C, and carbonization and / or nitridation are conducted to form the MAX phase material. The method has the advantages of high thermal efficiency, low power consumption, good product consistency, stable process and large-scale production ofthe MAX phase material.

Owner:冯良荣

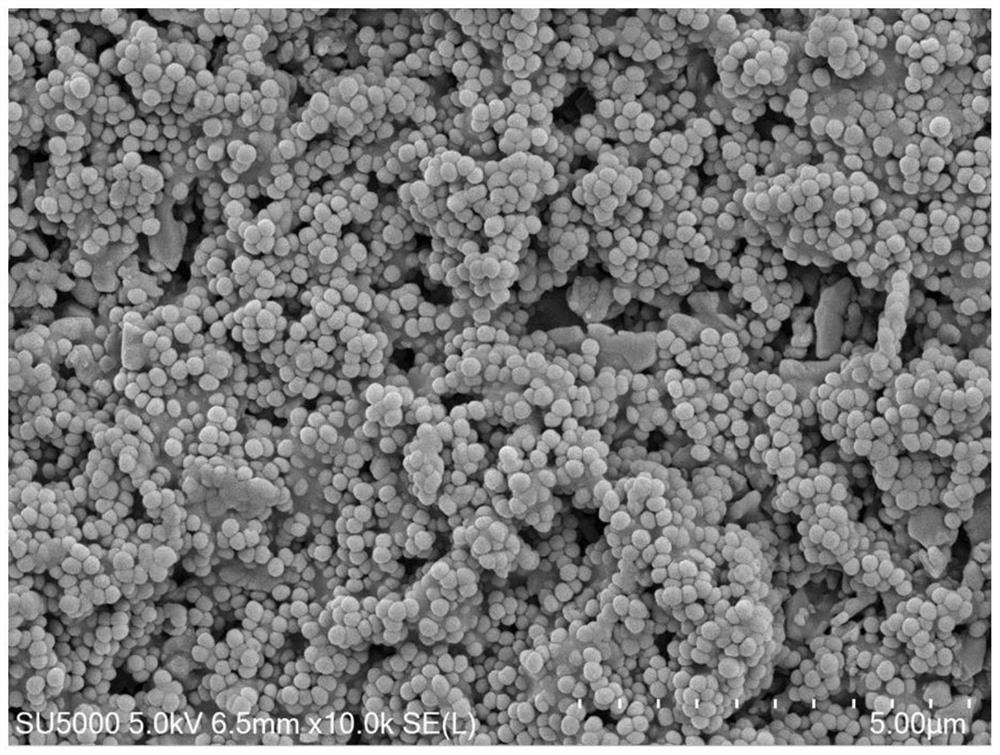

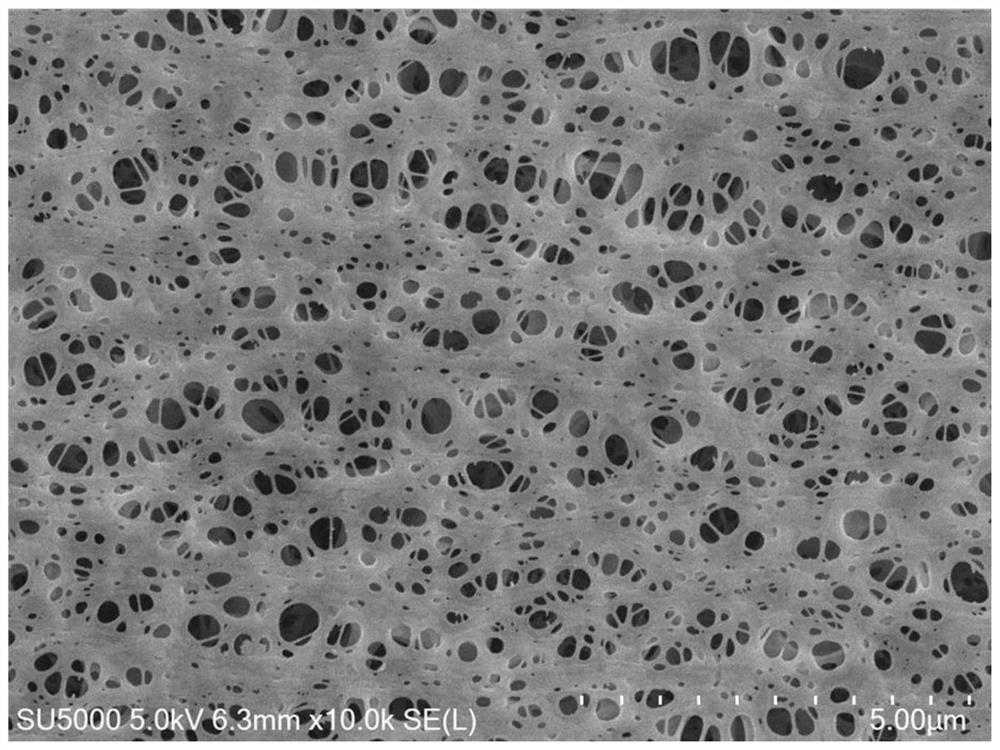

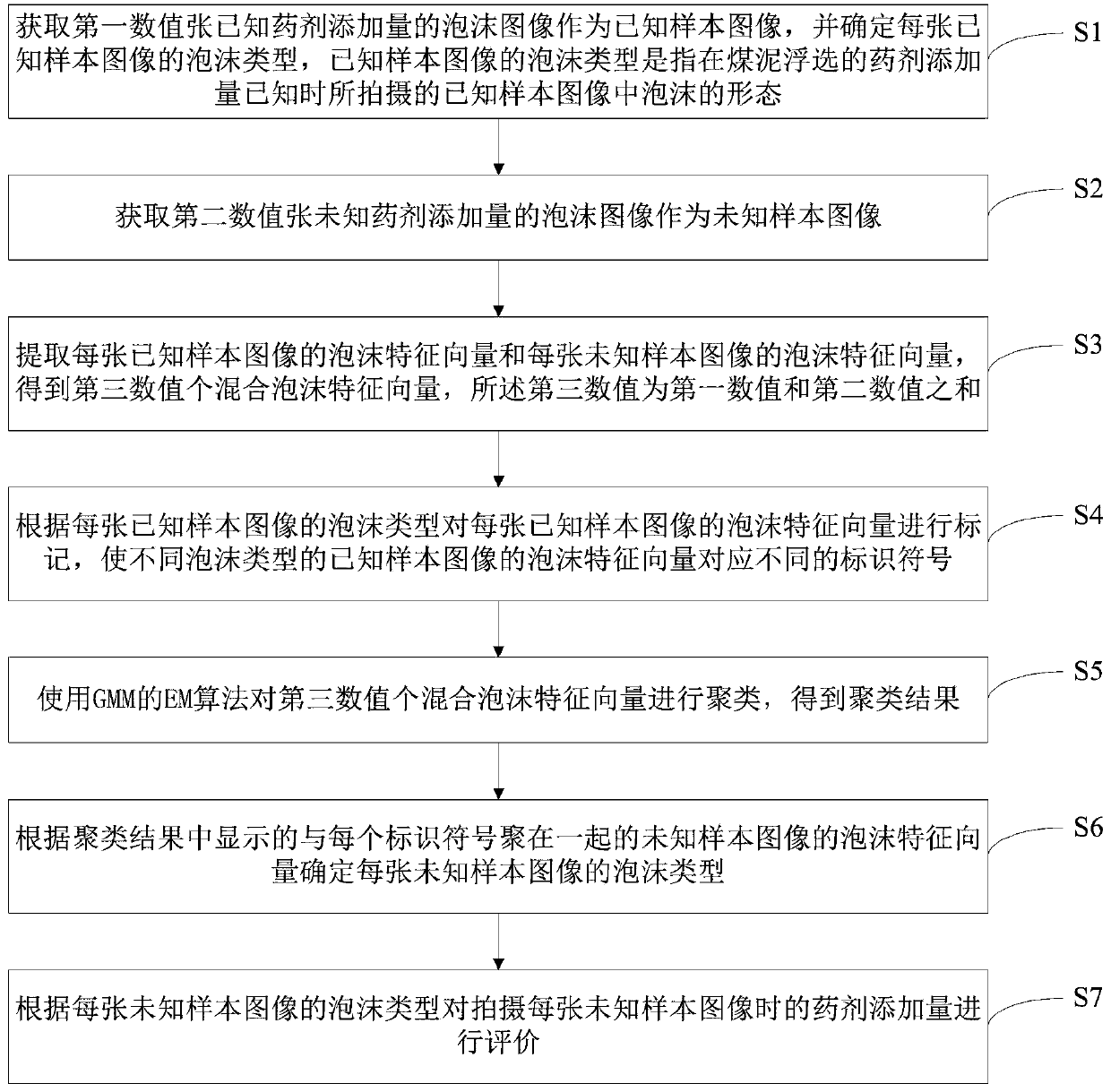

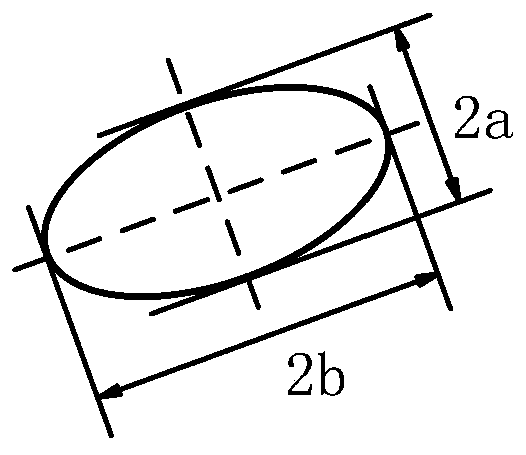

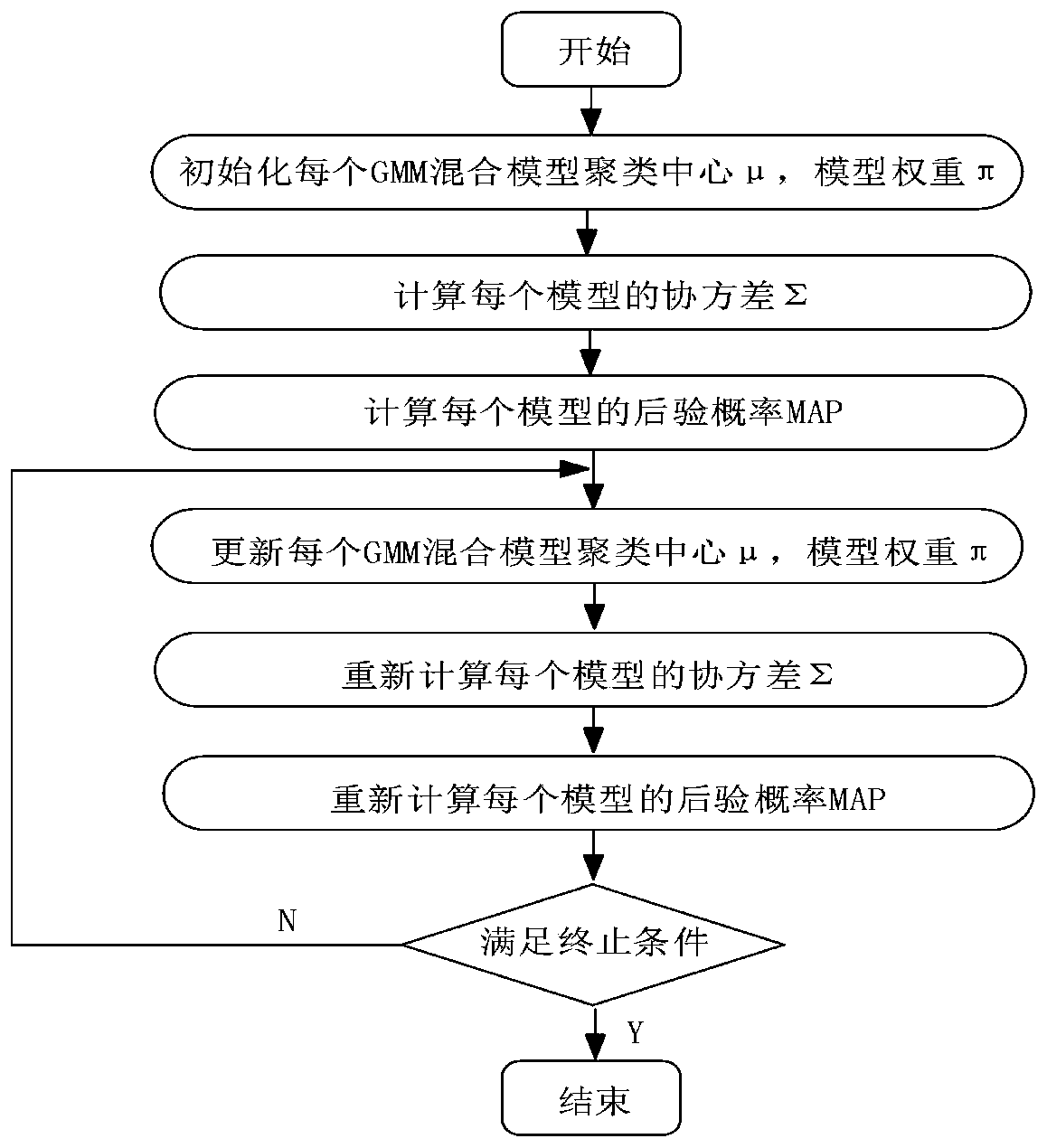

Coal slime flotation reagent adding amount evaluation method based on semi-supervised clustering

ActiveCN110288260AAchieve optimal controlIncrease the level of automationCharacter and pattern recognitionResourcesFeature vectorResource recovery

The invention provides a coal slime flotation reagent adding amount evaluation method based on semi-supervised clustering, belongs to the field of coal slime flotation, and aims at solving the problems that an existing method has subjective randomness and lagging performance, and fluctuation of flotation working conditions is large, the resource recovery rate is low and reagent consumption is large easily. The method comprises the steps of obtaining a first number of known sample images, and determining a foam type of each known sample image; obtaining a second number of unknown sample images; extracting foam feature vectors of each known sample image and each unknown sample image to obtain a third number of mixed foam feature vectors; marking the foam feature vector of each known sample image according to the foam type of each known sample image; clustering the third number of mixed foam feature vectors by using an EM algorithm of GMM to obtain a clustering result; determining a foam type of each unknown sample image according to a clustering result; and determining whether the agent adding amount is appropriate when each unknown sample image is shot according to the foam type.

Owner:TAIYUAN UNIV OF TECH

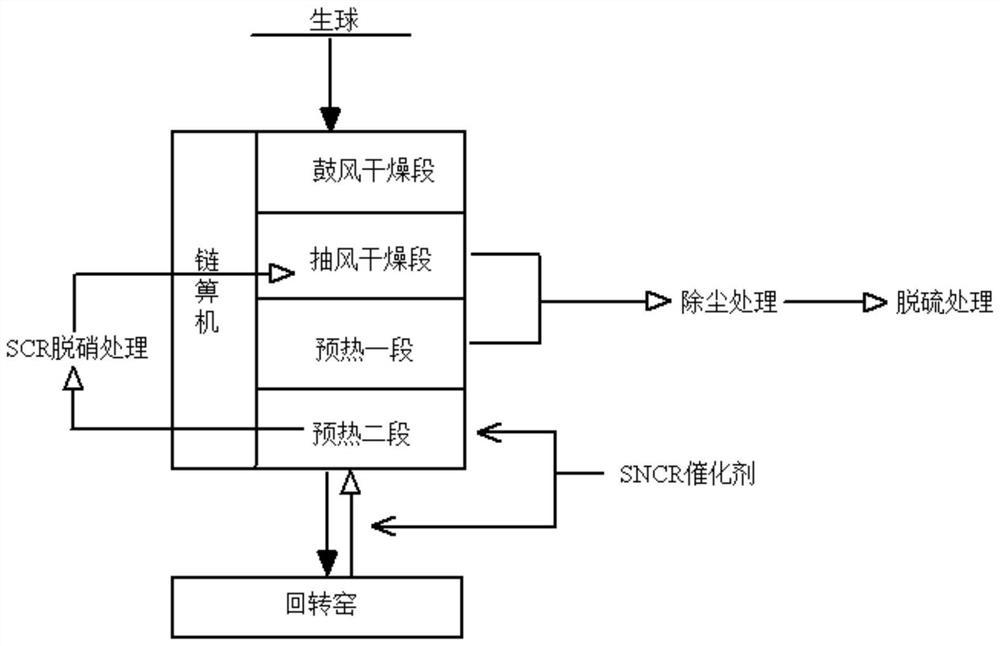

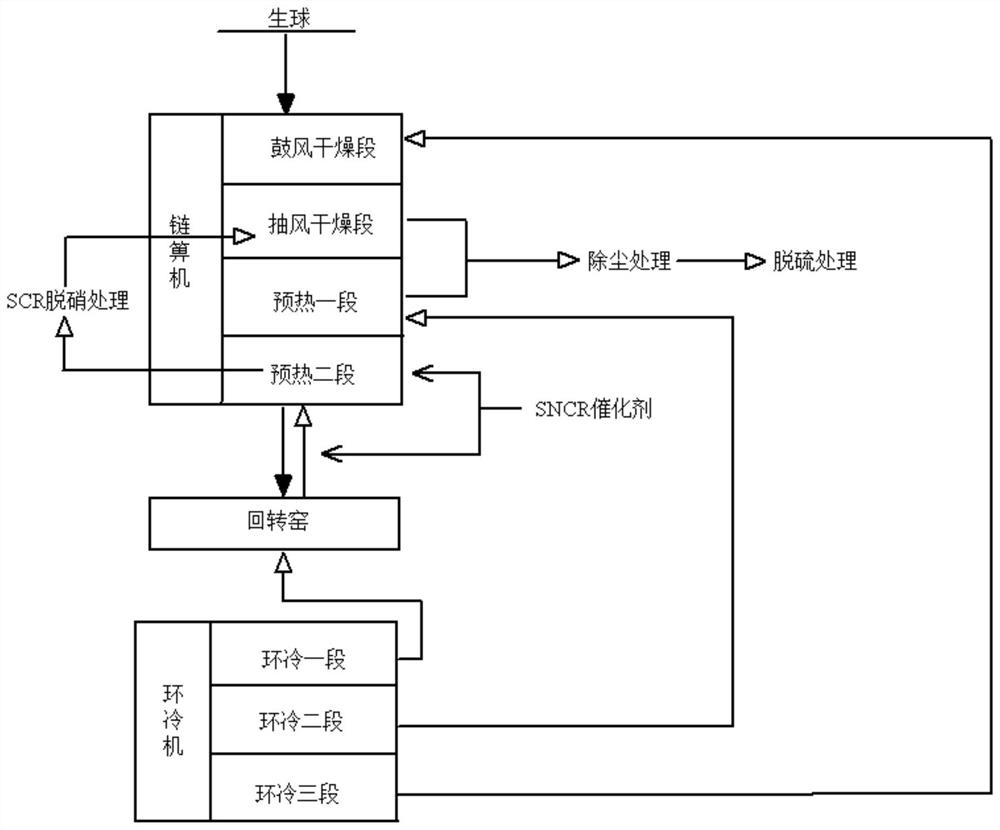

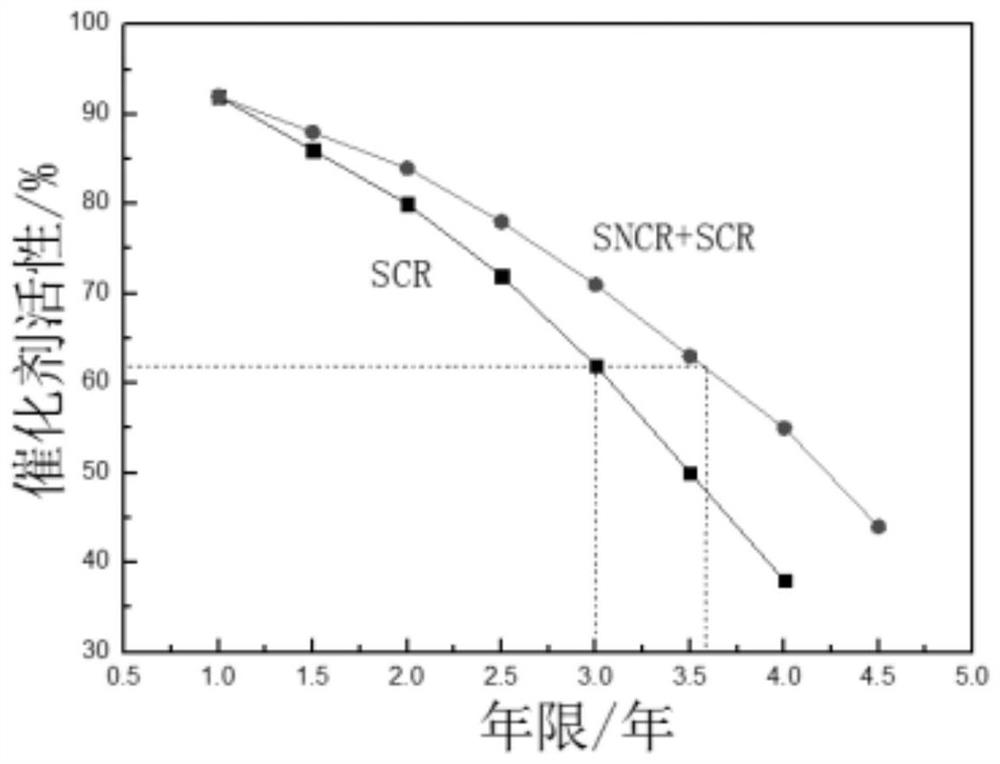

Flue gas treatment process and treatment system

ActiveCN113908677ALow investment costLow running costGas treatmentRotary drum furnacesPtru catalystThermodynamics

The invention discloses a chain grate-rotary kiln flue gas treatment process and treatment system. A control method of an SNCR-SCR coupling denitration system is adopted, a composite additive is added into an SNCR denitration catalyst or a novel SNCR composite ammonia agent is provided; and meanwhile, a movable airflow balance plate is additionally arranged between a PH section and a TPH section of a chain grate, the air pressure of the TPH section is controlled to be larger than or equal to the air pressure of the PH section by utilizing the position change of the airflow balance plate, so that the problem that the content of NOx in flue gas of the TPH section is increased due to the fact that high-NOx-content waste gas of the PH section flees towards the TPH section is prevented. The optimal coupling ultralow NOx emission technology can be formed, the denitration efficiency can be effectively guaranteed on the premise that SNCR ammonia consumption is reduced, meanwhile, the service lifetime of an SCR denitration catalyst can be prolonged, and the denitration operation cost and investment cost of the system are obviously reduced. The utilization efficiency of a flue gas denitration reducing agent is further improved, and the escape amount of NH3 is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Preparation method of surface die pressing film of PVC-based stone-plastic composite board

ActiveCN109306065AAvoid productiveAvoid large investment in equipmentSolid waste managementFilling pastesProduction lineMetallurgy

The invention discloses a preparation method of a surface die pressing film of a PVC-based stone-plastic composite board. The preparation method comprises the steps that the surface of the PVC-based stone-plastic composite board is subjected to activating treatment, specifically, activated putty is prepared, the surface of the base material is crudely roughened, the activated putty is applied, curing is carried out, and the surface of the base material is finely roughened; PMMA slurry is prepared; and film coating and forming is carried out on the surface of the PVC-based stone-plastic composite board, specifically, the board is put in a die, cold-pressing shaping, tightening by a clamp, low-temperature curing, high-temperature treatment and cooling die-release are carried out, and thus the PVC-based stone-plastic composite board with the surface coated with the PMMA film is obtained. According to the PVC-based stone-plastic composite board with the surface coated with the PMMA film, which is prepared by the preparation method provided by the invention, the problems that in a traditional situation of producing floors with surface printing and surface film-sticking technologies, theinvestment of related production lines and equipment is large, and the production cost is high can be avoided; the board provided by the invention can partially replace composite floors, stone materials, acrylic face plates, curtain wall plates and the like, which are popular in the market currently; and a new path is provided for high value-added utilization of waste.

Owner:SHAANXI SCI TECH UNIV +1

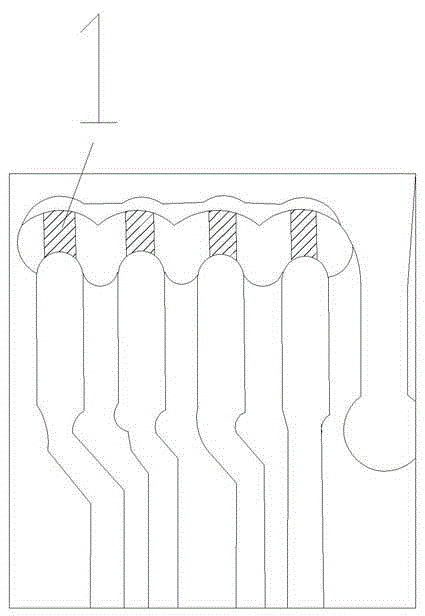

Nozzle

ActiveCN104632181AAvoid stabilityAvoid productiveConstructionsCoal gasificationCombustionWater source

A nozzle comprises a nozzle body. A water jacket and a water conveying pipe communicated with the water jacket are arranged in the nozzle body. Cooling water enters the water jacket through the water conveying pipe to cool the nozzle body, and a plurality of water spraying holes are formed in the rear end of the water conveying pipe. A water source and a water pump continuously convey cooling water into the water conveying pipe, and the cooling water flows to the water jacket and then is drained out. The cooling water in the water jacket cools the nozzle body, and the influence on the stability and the continuous production of a gasifier due to the fact that the nozzle is too hot or even burnt is avoided. The cooling water sprayed out from the water spraying holes of the water conveying pipe and a gasifying agent in an inner cavity of the nozzle are internally mixed and then are sprayed out from an outlet to reach a gasification reaction working face, and the effect of improving the coal bed combustion condition and coal gas quality is achieved.

Owner:ENN SCI & TECH DEV

Method for preparing common-activity calcium carbonate series product and co-producing ammonia chloride

The invention relates to a method for preparing common-activity calcium carbonate series products and co-producing ammonia chloride, belonging to the technical field of the preparation method of inorganic salt filling materials. The main technical scheme is that limestone is used for reacting with ammonia chloride to obtain calcium chloride, carbon dioxide and ammonia water; and the carbon dioxide is fed to ammonium carbonization at a next step for cyclic utilization, the calcium chloride, the ammonia water and surfactant are fully mixed in an ammonium carbonizer according to certain proportions, the carbon dioxide coming from a reactor is simultaneously fed for carbonization till completion to obtain common-activity calcium carbonate, and finally the obtained common-activity calcium carbonate is centrifuged, dried and air-separated to obtain calcium carbonate of various grades. By adopting the ammonium carbonization method and recycling reactants, the invention has the advantages of small investment, low cost, simple production and high yield.

Owner:LIWANG CHEM NANTONG

Golden finger processing method characterized by no lead wire residues

InactiveCN104968163AReduce feedingEasy to PlatingProcessing steps orderPrinted element electric connection formationSolder maskNetwork connection

The invention discloses a golden finger processing method characterized by no lead wire residues. The method comprises the following steps of (S1) internal circuit board making, laminating and boring, and full-plate electroplating; (S2) external pattern transferring for the first time; (S3) circuit board etching and film stripping; (S4) circuit board appearance detecting; (S5) external pattern transferring for the second time; (S6) hard gold layer electroplating on the golden finger part of the circuit board, and film stripping; (S7) external pattern transferring for the third time; (S8) circuit board etching and film stripping; and (S9) solder mask printing and moulding surface processing to make the circuit board. The golden finger network connection point residues are effectively prevented. Copper exposed on the front of the cut golden finger is also prevented. Phenomena of burring, upwarping during a production process are eliminated. Material supplementing on the golden finger part of the circuit board is reduced during the production process. The workload of workers is reduced. The production efficiency is improved. The generated defective products are reduced. The discarded products are also reduced. The production cost is lowered. The yield is further improved.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

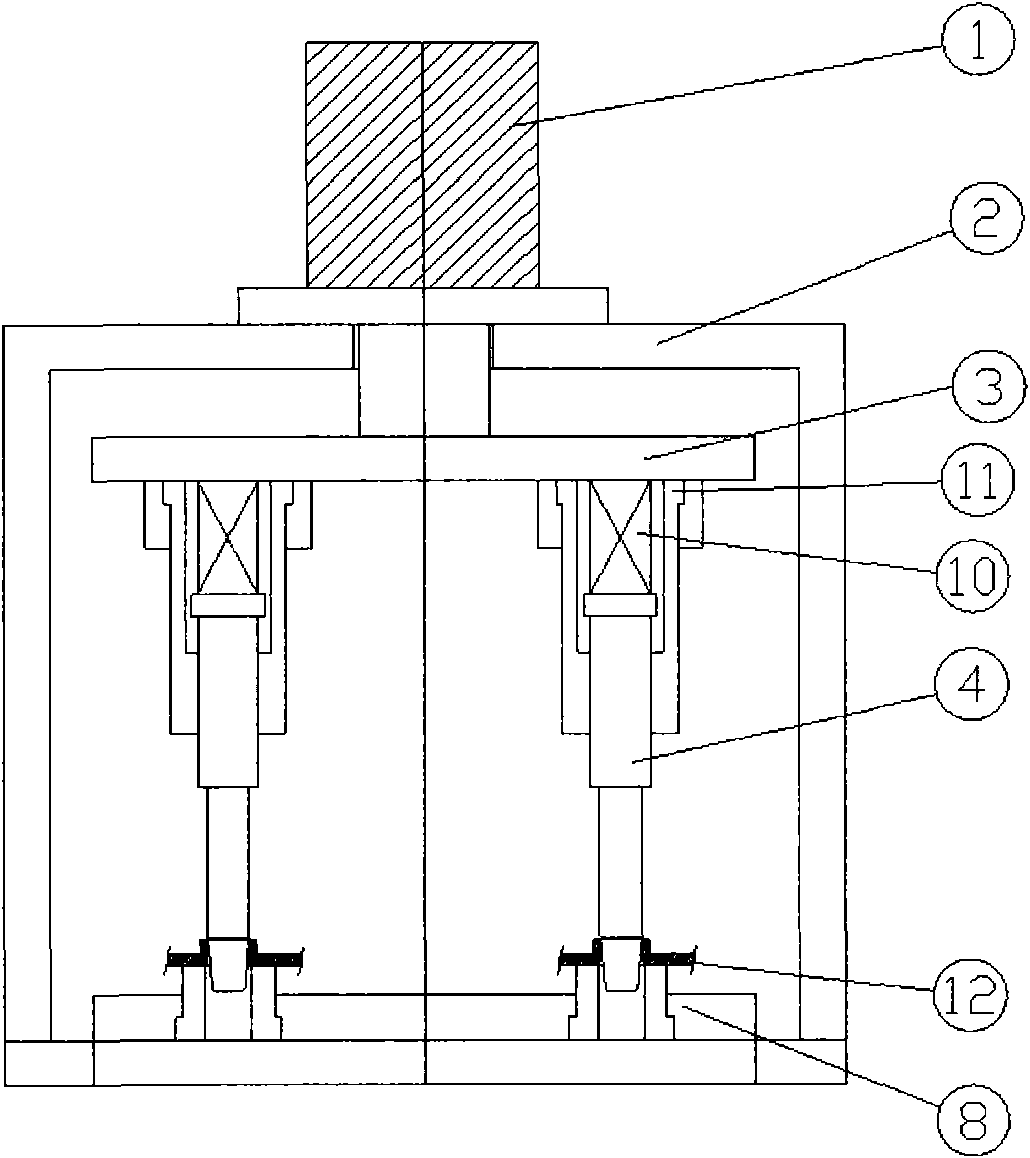

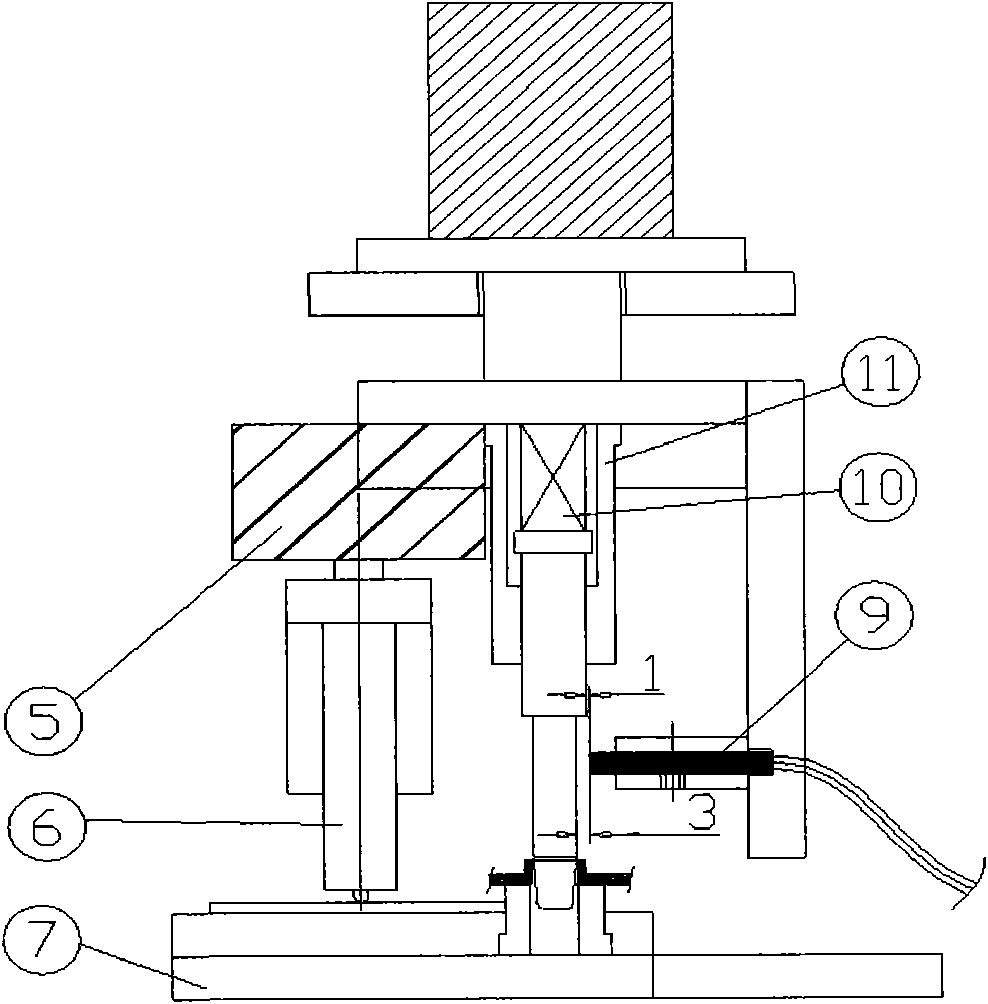

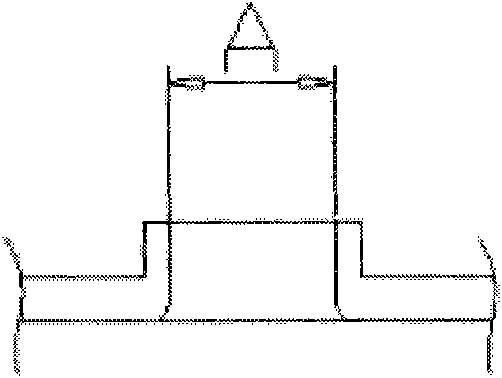

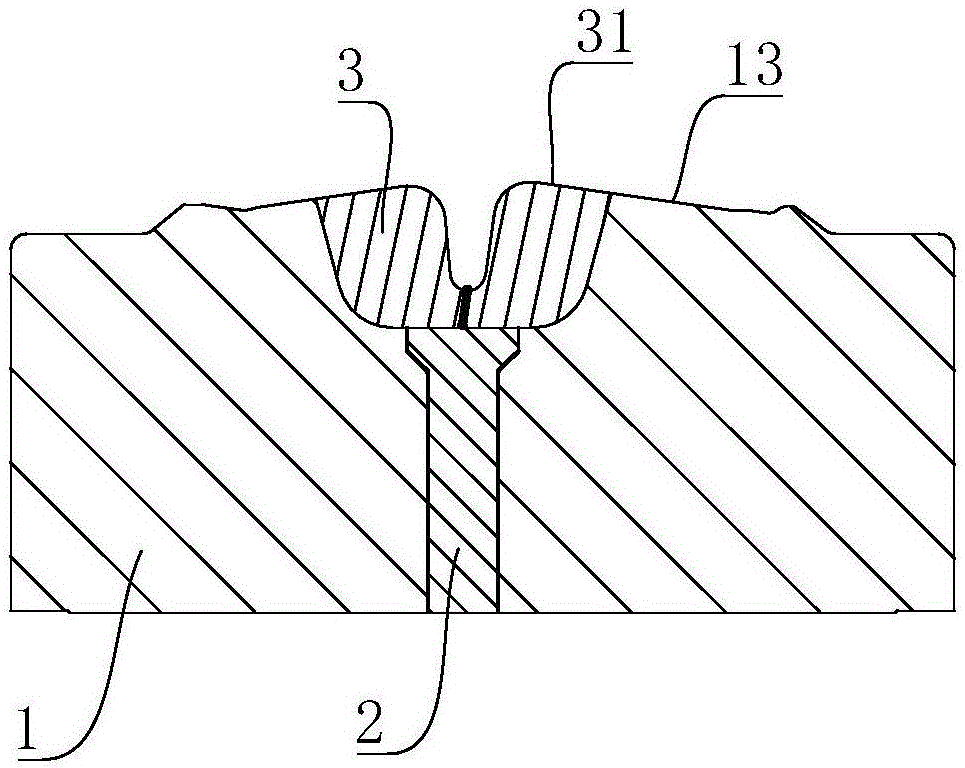

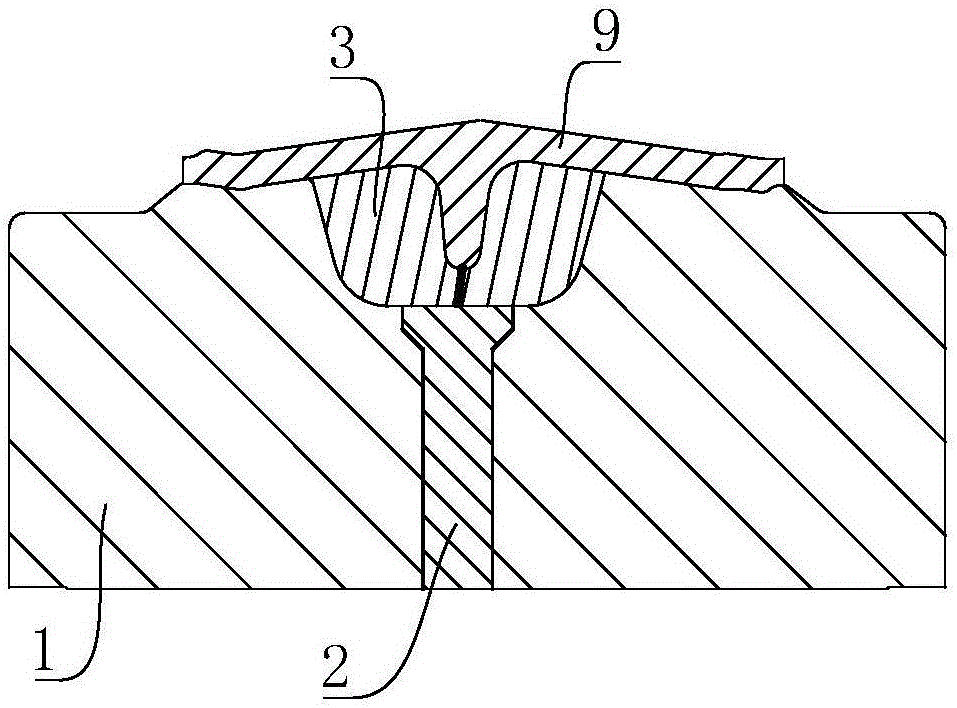

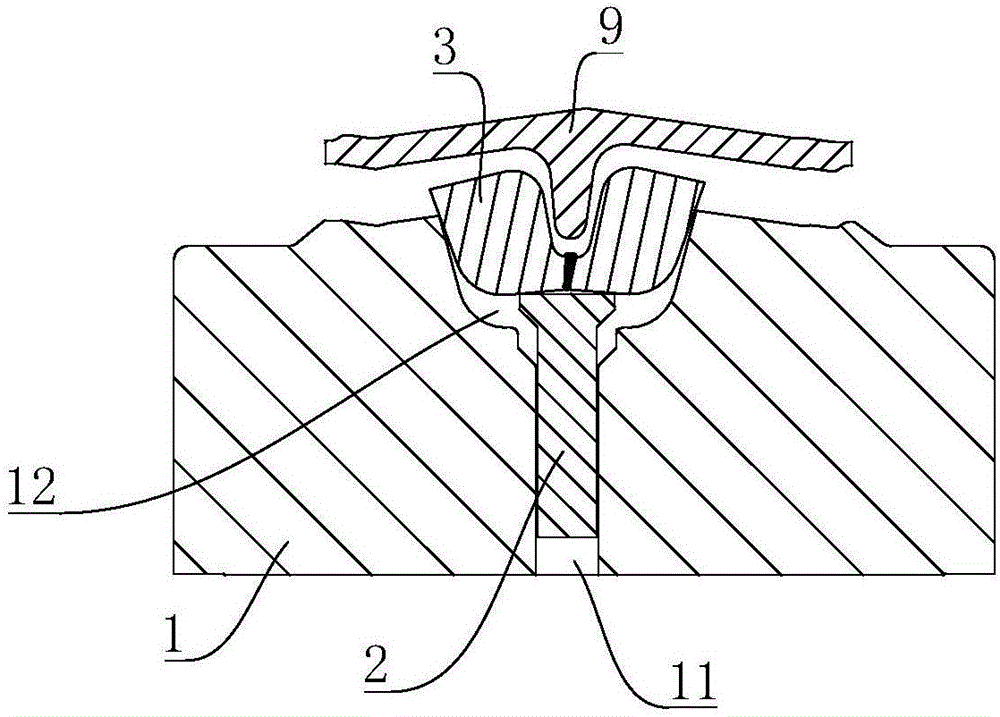

Core-embedded mold facilitating ejection-out of forging

ActiveCN106670369ASmooth disengagementAvoid damageForging/hammering/pressing machinesEmbedded coreMaterials science

The invention relates to a core-embedded mold facilitating ejection-out of a forging. The core-embedded mold facilitating ejection-out of the forging comprises a mold body. A first mold cavity face is arranged on the surface of the mold body. A material ejection-out rod for ejecting out the forging is arranged in the mold body in a movable fit manner. An embedding cavity is formed in the mold body. An embedding core is embedded into the embedding cavity. The surface, exposed from the embedding cavity, of the embedding core is provided with a second mold cavity face. The second mold cavity face and the first mold cavity face are spliced into a preset mold cavity. The embedding cavity is in movable fit with the embedding core. The embedding core is located on the ejection-out path of the material ejection-out rod. The end, close to the ejection-out end of the material ejection-out rod, of the embedding core is smaller than the opposite end in size. The embedding core is formed by splicing at least two embedding core sections, and a splicing seam is matched with the second mold cavity face in shape. By the adoption of the core-embedded mold, the embedding core can be ejected out by the material ejection-out rod along with the forging, the embedding core can be easily separated along the splicing seam after being disengaged from the embedding cavity, the forging is subject to demolding smoothly, and damage and production interruption caused by the fact that the mold is stuck by the forging can be avoided.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

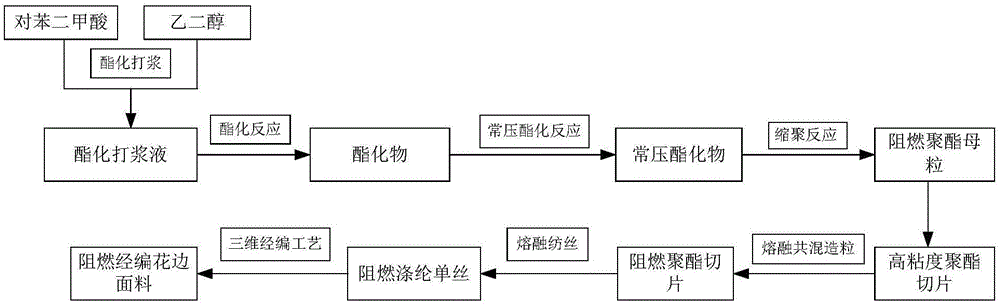

Anti-flaming tricot lace fabric and production method thereof

ActiveCN106350892AImprove flame retardant performanceGood anti-drip effectFlame-proof filament manufactureWarp knittingPolymer scienceWater vapor

The invention relates to anti-inflaming tricot lace fabric and a production method thereof. The anti-inflaming tricot lace fabric is characterized in that a flame resistance limit oxygen index is 30 to 34 percent, the vertical combustibility UL-94 is V0 class, and the residual carbon content by calcining the anti-inflaming tricot lace fabric under 500 DEG C for 30 minutes is 25 percent. The anti-inflaming tricot lace fabric comprises a flame retardant structure with a free radical capturing function, the carbon forming performance of the anti-inflaming tricot lace fabric is further increased through a benzene ring structure in flame retardant molecules, the flame retardant effect is increased, the effects of flame retarding and carbon forming are increased by utilizing the synergistic effect of bromine-containing functional groups and the benzene ring structure, and the melt dripping resistance is further enhanced; meanwhile, the molecules contain methoxyl functional groups capable of carrying out transesterification, methyl alcohol in a transesterification process is in a micromolecule form, the boiling point of the methyl alcohol is lower than that of water molecules, the volatility is good, and saturated vapor pressure is far below that of water vapor molecules, so that the methyl alcohol formed through transesterification is beneficial for removing of micromolecules in a polycondensation process, particularly, chain segments in a later period are lengthened, the removing of the micromolecules is difficult during a viscosity increment process, and a chain segment lengthening process is difficult to achieve; the anti-inflaming tricot lace fabric is applied to the fields of textile, decorative fabric and the like, and the application prospect is wide.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com