Coal slime flotation reagent adding amount evaluation method based on semi-supervised clustering

A semi-supervised clustering and slime flotation technology, which is applied in the direction of instruments, character and pattern recognition, data processing applications, etc., can solve the problems of large fluctuations, low resource recovery rate, and large consumption of chemicals, so as to avoid flotation Large fluctuations in working conditions, the effect of improving the level of automation and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

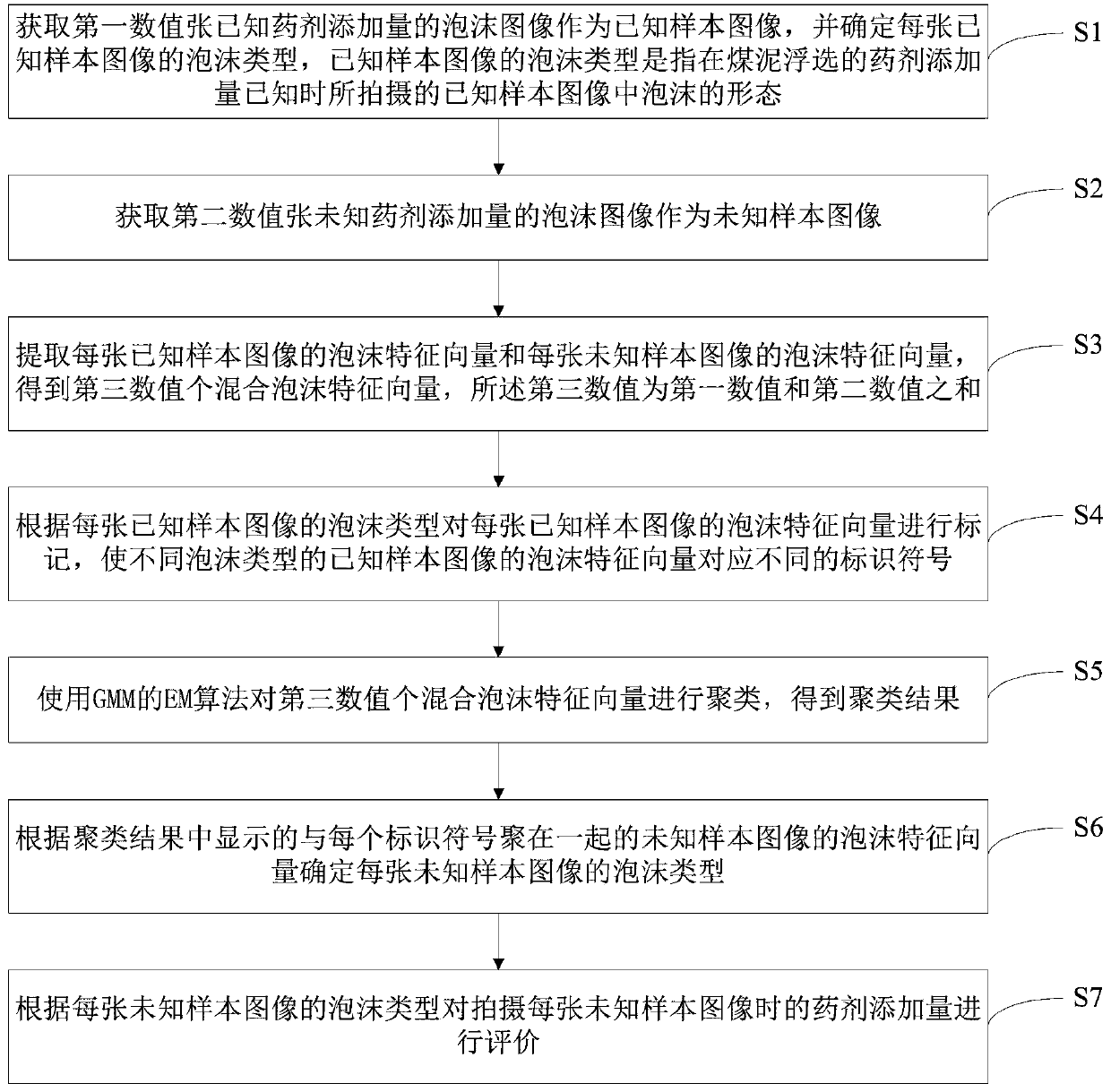

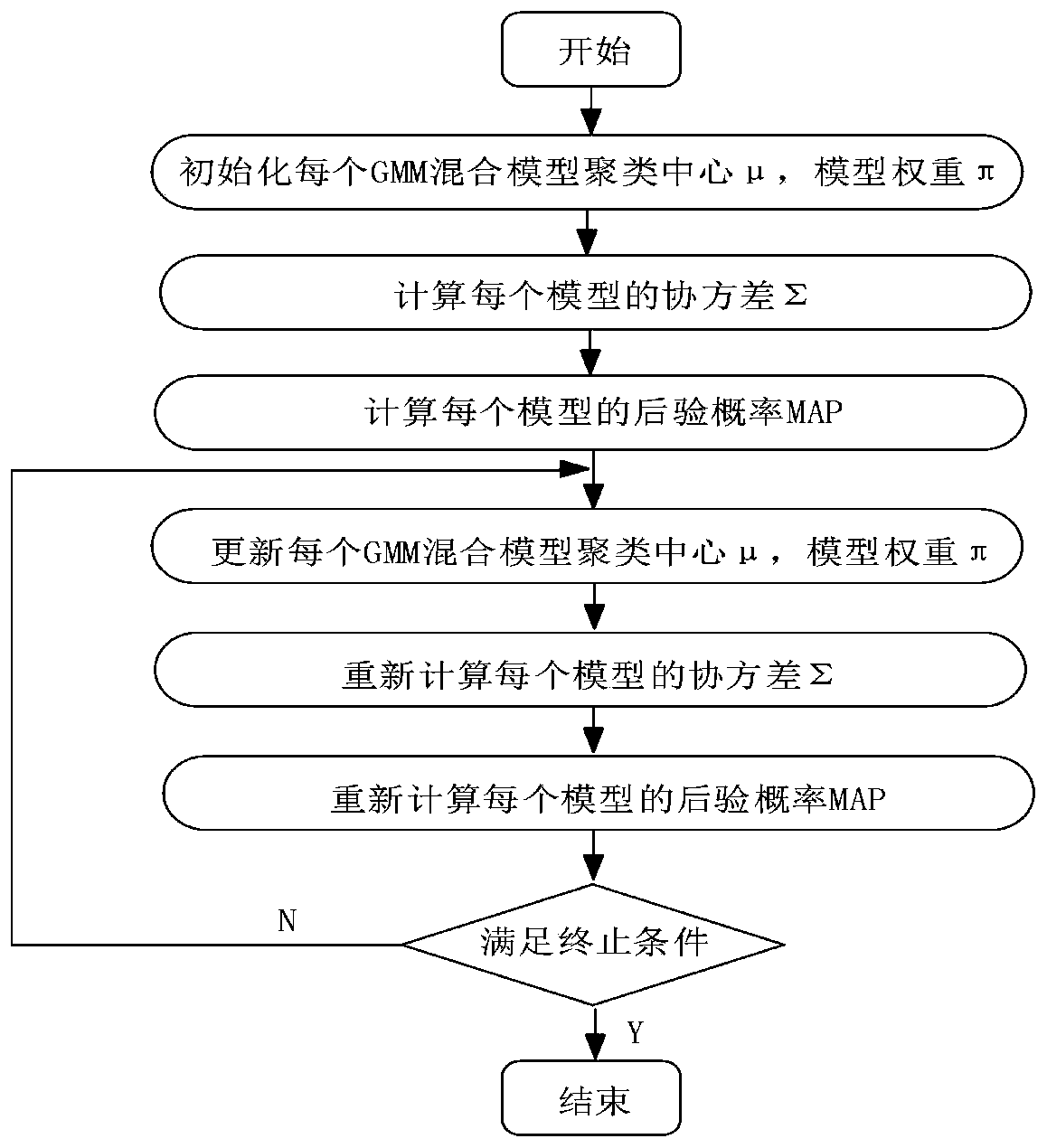

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0029] The implementation environment of the present invention is composed of foam generating equipment, light source, camera, image storage and calculation processing server and its auxiliary components. The foam generating equipment is a flotation machine, which can be an XJX-20 mechanically agitated self-priming flotation machine, and the foam generating equipment is used to provide pollution-free and stable air bubbles. The light source is a special LED ring light source for machine vision, which can provide lighting with high brightness and stable color temperature for the camera, and the light intensity can be adjusted according to the change of the environment. The camera has an infrared supplementary light function, which can clearly capture the foam surface and obtain foam images. The output image is of high quality, and its interface is easy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com