Method for identifying foam working condition on copper flotation site based on wavelet multi-scale binaryzation

A copper flotation and foam technology, applied in the field of image processing technology and pattern recognition, can solve the problems that affect the accurate judgment of working conditions, and it is difficult to describe the appearance of foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The specific embodiment of the present invention is described below in conjunction with accompanying drawing, there are three kinds of foams of different working conditions in a certain copper flotation site, are respectively normal foam, hydration foam and viscous foam, the foam images of these three kinds of different working conditions are as follows figure 1 shown.

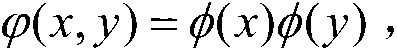

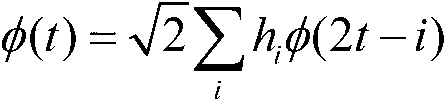

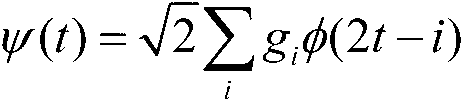

[0064] In the first step, according to the foam video obtained at the copper flotation site, the foam image is obtained, and the three-dimensional image is grayscaled. Then wavelet decomposition is performed on the two-dimensional grayscale image to obtain wavelet subgraphs on different scales. Ignore the characteristics of each order detail subgraph, and only perform single-branch reconstruction on each order approximation subgraph to obtain the reconstructed approximation subgraph.

[0065] Step 1: Grayscale the original foam image;

[0066] Raw 3D RGB foam image K (X×Y×3) After grayscale, it beco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com