Slag wall inserts of continuous casting tundish and embedded installing method thereof

A continuous casting tundish and inlay technology, applied in foundry equipment, casting melt containers, metal processing equipment, etc., can solve the problems of easy collapse of the slag retaining wall of the tundish, avoid production and quality accidents, and solve the problem of easy collapse. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

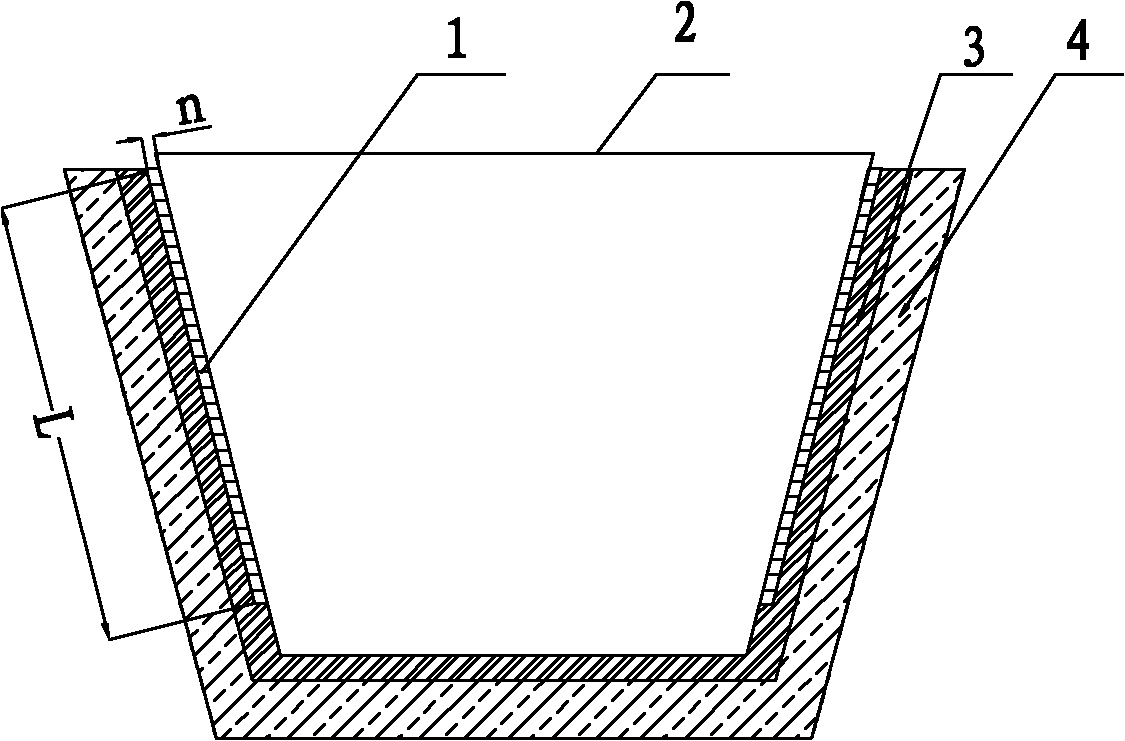

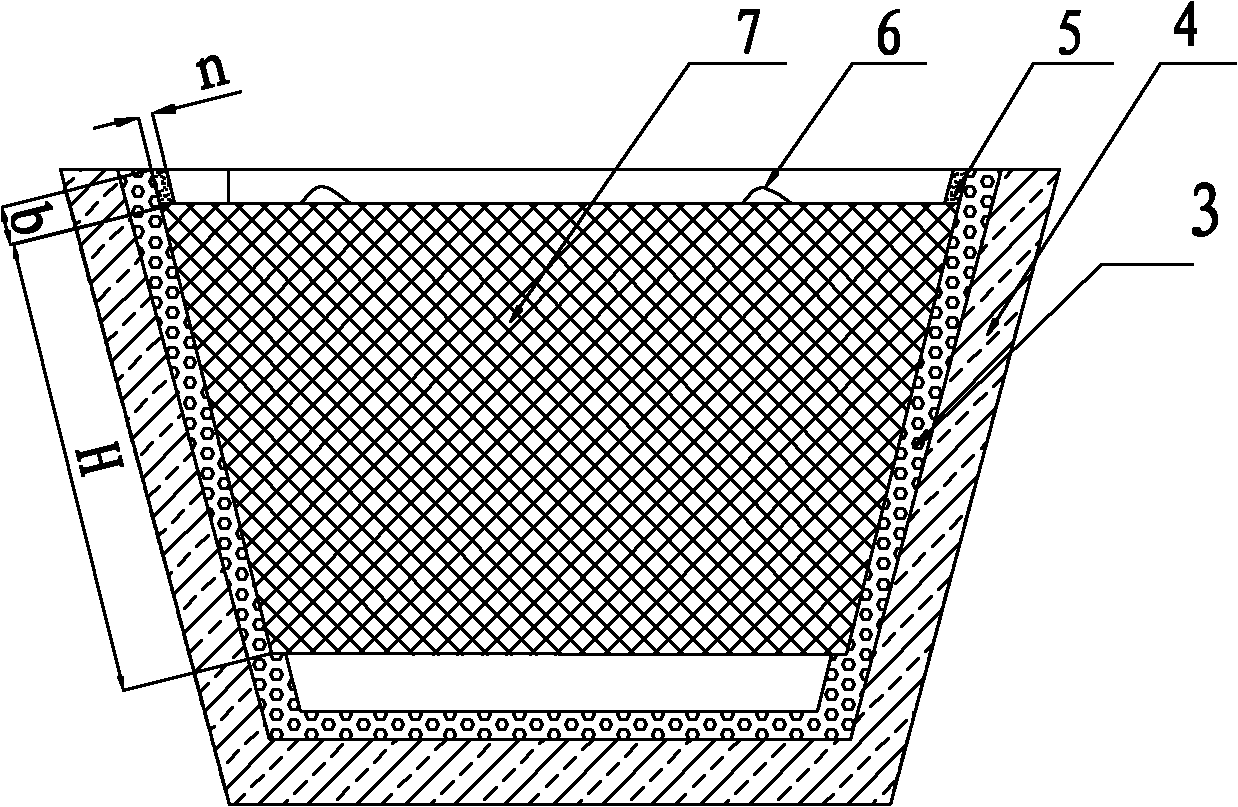

[0025] The technical scheme adopted by the present invention is, according to the installation position and size of the tundish slag retaining wall 7, two inserts 1 are made of heat-resistant cast steel, and they are symmetrically welded on the side of the dry material working lining construction film 2, when When the dry material working lining construction film 2 constructs the tundish working lining 3, the inlay piece 1 welded on the dry material working lining construction film 2 will form a two-fold structure at the position where the tundish working lining 3 is installed with the slag retaining wall 7. two grooves, and the two sides of the tundish slag retaining wall 7 are embedded in the two grooves.

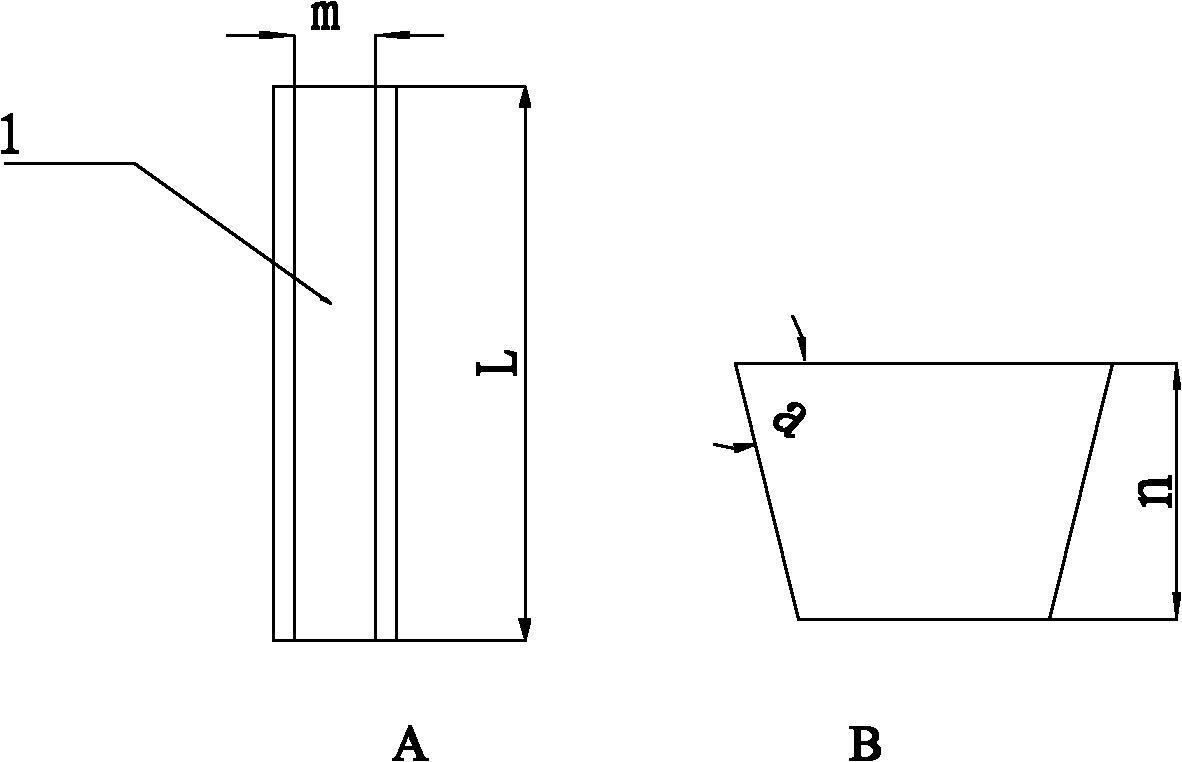

[0026] The present invention provides a continuous casting tundish slag retaining wall insert 1, which is characterized in that the cross section of the insert 1 is trapezoidal, and L is the length of the insert 1, that is, the length H of the tundish slag retaining wall 7...

Embodiment 2

[0036] Others are the same as embodiment 1, the difference is:

[0037] The length L of the mosaic 1 is 950 mm, the width m is 160 mm, the thickness n is 40 mm, and the inclination a is 80°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com