Special high-physical-property high-dyeing polyurethane resin for superfine fiber synthetic leather and preparation method of special high-physical-property high-dyeing polyurethane resin

A technology of polyurethane resin and ultrafine fiber, which is applied in the field of high physical properties and high dyeing polyurethane resin and its preparation, can solve the problems of reduced shape and area retention rate, unfavorable performance of ultrafine fiber synthetic leather, and reduced peel strength, so as to achieve shape retention The effect of improving the rate and myogenicity, enhancing the dyeability and coloring rate, and ensuring the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]

[0029] The preparation method of the high physical properties and high dyeing polyurethane resin special for the above-mentioned superfine fiber synthetic leather mainly comprises the following steps:

[0030] a. Put part of MDI and polyester diol CMA-M20 into the reactor at a ratio of R=1.0, a small amount of solvent, and pre-polymerize at 70-75°C for 90 minutes;

[0031] b. Put antioxidant, polyether diol PTMEG-2000 and polycarbonate diol PC-M80, part of chain extender EG and chain extender TMP, part of solvent into the reactor, stir for 30-60 minutes, mix uniform;

[0032] c. Lower the temperature of the reactor to 60°C, put in some MDI, TDI, and some solvents, and react at 70-75°C for 120 minutes;

[0033] d. Lower the temperature of the reactor to 50-60°C, put in the remaining chain extender 1 and chain extender 2, and part of the solvent, continue to put in the remaining MDI and TDI, and react at 70-75°C;

[0034] e. The temperature is controlled at 70-75°C...

Embodiment 2

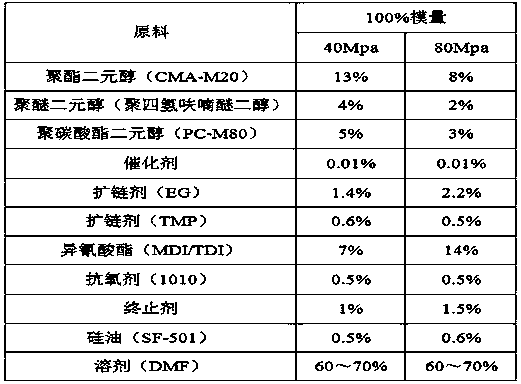

[0039]

[0040] The preparation method of the high physical properties and high dyeing polyurethane resin special for the above-mentioned superfine fiber synthetic leather mainly comprises the following steps:

[0041] a. Put part of MDI and polyester diol CMA-M20 into the reactor at a ratio of R=1.0, a small amount of solvent, and pre-polymerize at 70-75°C for 90 minutes;

[0042] b. Put antioxidant, polyoxypropylene diol and polycaprolactone polyol, part of chain extender EG and chain extender TMP, part of solvent into the reaction kettle, stir for 30-60 minutes, and mix well;

[0043] c. Lower the temperature of the reactor to 60°C, put in some MDI, TDI, and some solvents, and react at 70-75°C for 120 minutes;

[0044] d. Lower the temperature of the reactor to 50-60°C, put in the remaining chain extender EG and chain extender TMP, part of the solvent, continue to put in the remaining MDI and TDI, and react at 70-75°C;

[0045] e. The temperature is controlled at 70-75°...

Embodiment 3

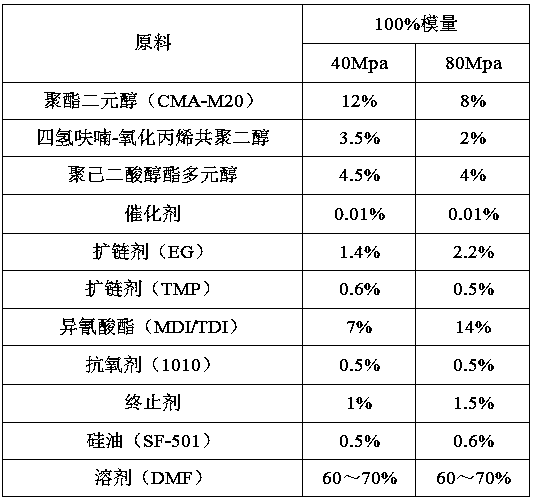

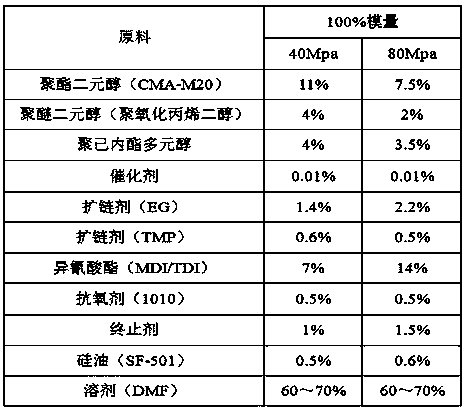

[0049]

[0050] The preparation method of the high physical properties and high dyeing polyurethane resin special for the above-mentioned superfine fiber synthetic leather mainly comprises the following steps:

[0051] a. Put part of MDI and polyester diol CMA-M20 into the reactor at a ratio of R=1.0, a small amount of solvent, and pre-polymerize at 70-75°C for 90 minutes;

[0052] b. Put antioxidant, tetrahydrofuran-propylene oxide copolymerized glycol and polyadipate polyol, part of chain extender EG and chain extender TMP, part of solvent into the reaction kettle, stir for 30-60 minutes, and mix well;

[0053] c. Lower the temperature of the reactor to 60°C, put in some MDI, TDI, and some solvents, and react at 70-75°C for 120 minutes;

[0054] d. Lower the temperature of the reactor to 50-60°C, put in the remaining chain extender EG and chain extender TMP, part of the solvent, continue to put in the remaining MDI and TDI, and react at 70-75°C;

[0055] e. The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com