Method for preparing nano active calcium carbonate series products and ammonium chloride by carbide slag

A technology of active calcium carbonate and series products, which is applied in the field of preparation of inorganic salt nanomaterials, can solve the problems of high cost, complex production and equipment, and low yield, and achieve the effect of low cost, small investment, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

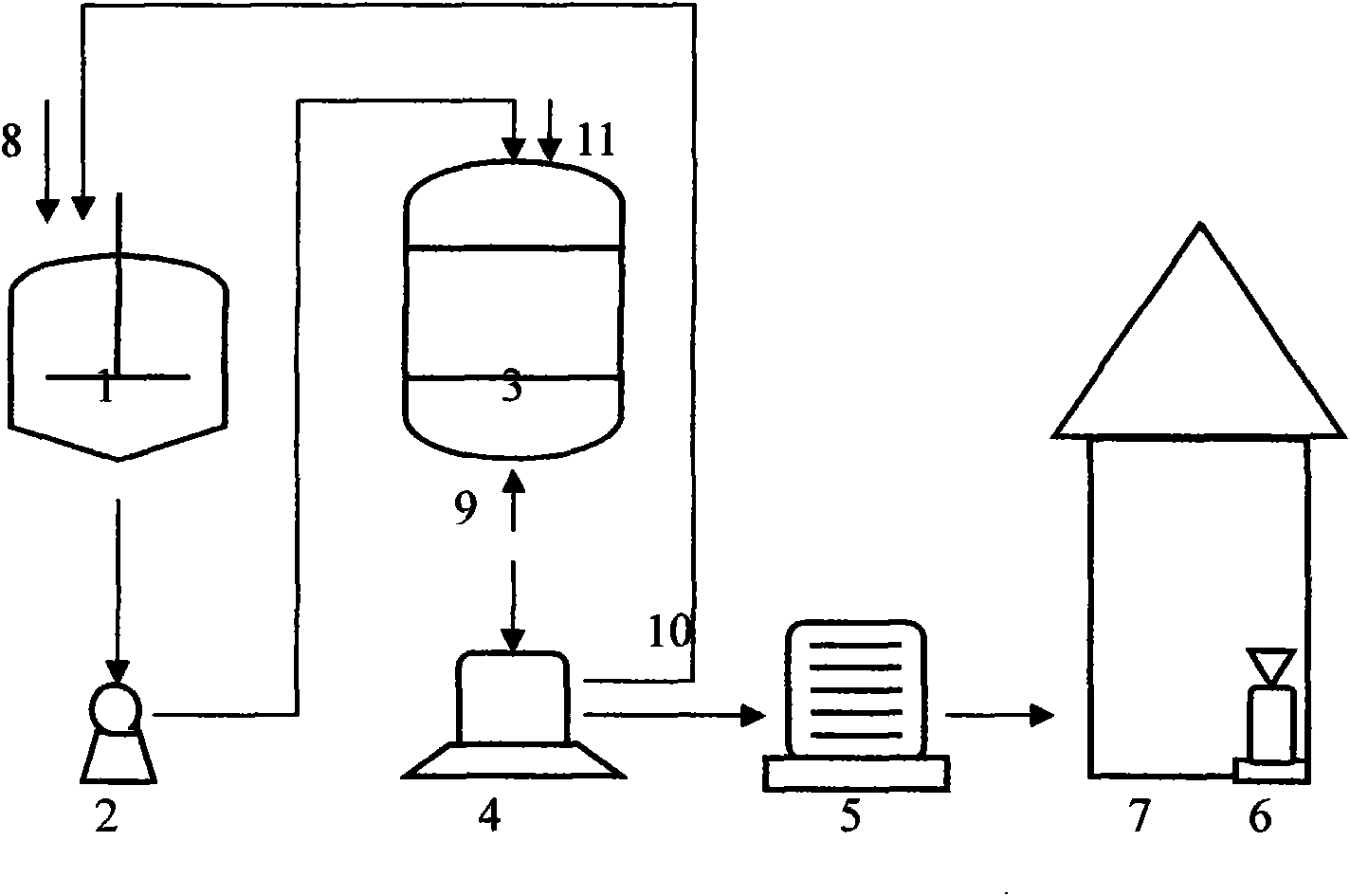

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Use 200 kilograms of calcium carbide slag (8) to mediate into emulsion and dilute hydrochloric acid (10) according to the mass ratio of pure substance 1: 0.98 and mix in reactor (1), react to generate calcium chloride and water, suction filter Obtain filter cake and calcium chloride solution, filter cake is directly thrown into incinerator after incineration and buries deeply, obtains 298.03 kilograms of calcium chloride solution and injects in the ammonium carbonizer (3) as mother liquor after evenly mixing with 6% tensio-active agent, the inside has Ammonia water prepared in advance at a mass ratio of 1:0.95. Start the stirrer to mix the solution evenly at a speed of 400 rpm, and then carry out ammonium carbonization, that is, to slowly introduce carbon dioxide (9) gas with a mass ratio of 1:0.39 under stirring. The end point of carbonization is when the reaction liquid becomes neutral to slightly alkaline. Suction filtration (4) obtains 264.16 kilogram...

Embodiment 2

[0015] Example 2: 200 kg of calcium carbide slag and hydrochloric acid are mixed in the reactor according to the mass ratio of 1:0.68, the reaction generates calcium chloride and water, and the filter cake and calcium chloride solution are obtained by suction filtration, and the filter cake is directly thrown into the incinerator Deep bury after incineration, obtain 206.79 kilograms of calcium chlorides and inject in the ammonium carbonizer as mother liquor after uniformly mixing with 3% surfactant, there is the ammoniacal liquor that the mass ratio 1: 0.75 is configured in advance in the inside. Start the stirrer to mix the solution evenly at a speed of 300 rpm, and then carry out ammonium carbonization, that is, slowly introduce carbon dioxide gas with a mass ratio of 1:0.19 under the condition of stirring. The end point of carbonization is when the reaction liquid becomes neutral to slightly alkaline. Suction filtration obtained 89.29 kg of nano-active calcium carbonate, dr...

Embodiment 3

[0016] Embodiment 3: Mix 200 kilograms of calcium carbide slag and hydrochloric acid in the reactor according to the mass ratio of 1: 1.03, react to generate calcium chloride and water, filter cake and calcium chloride solution by suction filtration, and directly throw the filter cake into the incinerator Deep bury after incineration, get 300 kilograms of calcium chlorides and inject in the ammonium carbonizer as mother liquor after uniformly mixing with 10% surfactant, there is the ammoniacal liquor that the mass ratio 1: 1.15 is configured in advance in the inside. Start the stirrer to mix the solution evenly at a speed of 500 rpm, and then carry out ammonium carbonization, that is, slowly introduce carbon dioxide gas with a mass ratio of 1:0.59 under the condition of stirring. The end point of carbonization is when the reaction liquid becomes neutral to slightly alkaline. 270.27 kg of nano-active calcium carbonate was obtained by suction filtration, and various levels of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com