Mixed ion phosphate positive electrode material and preparation method thereof

A positive electrode material and mixed ion technology, which is applied in the field of mixed ion phosphate positive electrode material and its preparation, can solve problems such as hindering the extraction and insertion of Li ions, reducing theoretical capacity, and reducing Li ions, so as to improve conductivity and electrochemical activity , Improve the discharge specific capacity, and the effect of easy control of the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method of mixed ion phosphate cathode material of the present embodiment, specific preparation steps are as follows:

[0038] (1) Mixed grinding: LiOH, NaOH, VO 2 and (NH 4 ) 3 PO 4 Weigh according to the elemental molar ratio of Li:Na:V:P=8:1:3:8 (LiOH: 1.155g, NaOH: 0.241g, VO 2 : 1.500g, (NH 4 ) 3 PO 4 -: 7.190g), using a planetary ball mill for 4 hours to obtain a precursor mixture;

[0039] (2) Pretreatment: Pretreat the precursor mixture in step (1) at 400°C for 10 hours in an air atmosphere, and then grind it again after cooling in the furnace to obtain a powdery intermediate product;

[0040] (3) Sintering reaction: The powdery intermediate product in step (2) was sintered at 700°C for 72 hours in a hydrogen atmosphere to obtain the mixed ion phosphate cathode material Li 8 NaV 3 (P 2 o 7 )3 (PO 4 ) 2 .

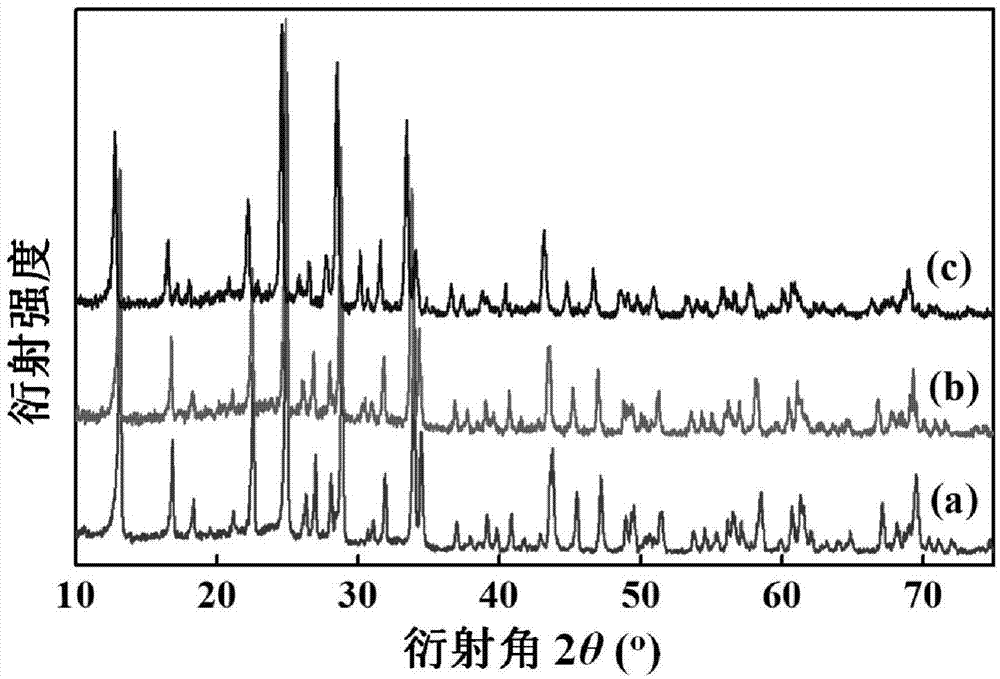

[0041] The XRD pattern of the product is shown in figure 1 In (a), it can be seen from the figure that the pure-phase mixe...

Embodiment 2

[0043] A kind of preparation method of mixed ion phosphate cathode material of the present embodiment, specific preparation steps are as follows:

[0044] (1) Mixing and grinding: Li 2 CO 3 、Na 2 CO 3 , NH 4 VO 3 and (NH 4 ) 2 HPO 4 Take by weighing the element molar ratio of Li:Na:V:P=7:2:3:8 (Li 2 CO 3 : 2.211g, Na 2 CO 3 : 0.906g, NH 4 VO 3 : 1.500g, (NH 4 ) 2 HPO 4 : 4.5156g), the raw material is ball-milled for 4h in a planetary ball mill to obtain a precursor mixture;

[0045] (2) Pretreatment: pretreat the precursor mixture in step (1) in an argon atmosphere at 300° C. for 5 hours, and after natural cooling, ball mill again to obtain a powdery intermediate product;

[0046] (3) Sintering reaction: The powdery intermediate product in step (2) was sintered at 600°C for 20 hours under a hydrogen atmosphere to obtain the mixed ion phosphate cathode material Li 7 Na 2 V 3 (P 2 o 7 ) 3 (PO 4 ) 2 .

[0047] The XRD pattern of the product is shown in ...

Embodiment 3

[0049] A kind of preparation method of mixed ion phosphate cathode material of the present embodiment, specific preparation steps are as follows:

[0050] (1) Mixing and grinding: CH 3 COOLi, CH 3 COONa, V 2 o 5 and NH 4 h 2 PO 4 Weigh (CH 3 COOLi: 2.177g, CH 3 COONa: 1.353g, V 2 o 5 : 1.500g, NH 4 h 2 PO 4 : 5.0594g), the raw material is ball milled in a planetary ball mill for 4h to obtain a precursor mixture;

[0051] (2) Pretreatment: the precursor mixture of step (1) is mixed in Ar-H with a volume ratio of 93:7 2 In a mixed gas atmosphere, pretreatment was carried out at 350°C for 2 hours, and after natural cooling, ball milling was performed again to obtain a powdery intermediate product;

[0052] (3) Sintering reaction: the powdery intermediate product of step (2) is mixed with Ar-H at a volume ratio of 93:7 2 In a mixed gas atmosphere, sintering at 650 °C for 4 h, the mixed ion phosphate cathode material Li 6 Na 3 V 3 (P 2 o 7 ) 3 (PO 4 ) 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com