Patents

Literature

142results about How to "Reduced electrical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multilayer insulated wire and transformers made by using the same

InactiveUS6329055B1Good effectLowered in electric propertyPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsPolymer sciencePolyetherimide

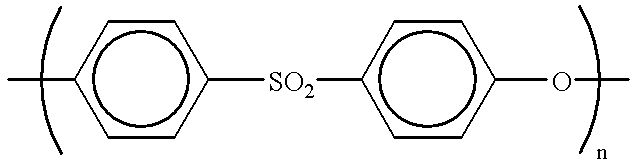

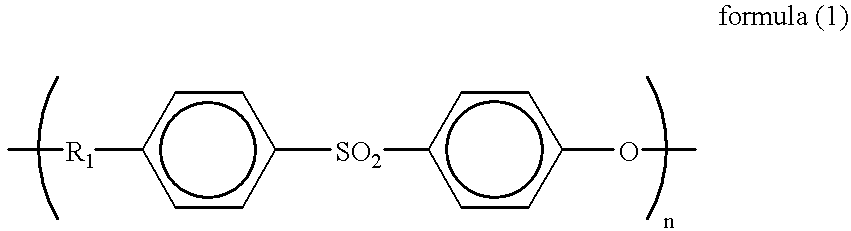

There is disclosed a multilayer insulated wire which comprises a conductor and solderable extrusion-insulating layers made up of two or more layers for covering the conductor, wherein at least one insulating layer is formed by a mixture comprising 100 parts by weight of a resin (A), of at least one selected from the group consisting of polyetherimide resins and polyethersulfone resins, 10 parts by weight or more of a resin (B), of at least one selected from the group consisting of polycarbonate resins, polyarylate resins, polyester resins, and polyamide resin, and 15 to 200 parts by weight of an inorganic filler (C). There is also disclosed a transformer which utilizes the multilayer insulted wire. The multilayer insulated wire is excellent in heat resistance, solderability, high-frequency characteristic, and coilability, and it is favorably suitable for industrial production. Further, the transformer utilizing the multilayer insulated wire is excellent in electrical properties and high in reliability, since when used at high frequencies, electric properties are not lowered and influence by the generation of heat can be prevented.

Owner:FURUKAWA ELECTRIC CO LTD

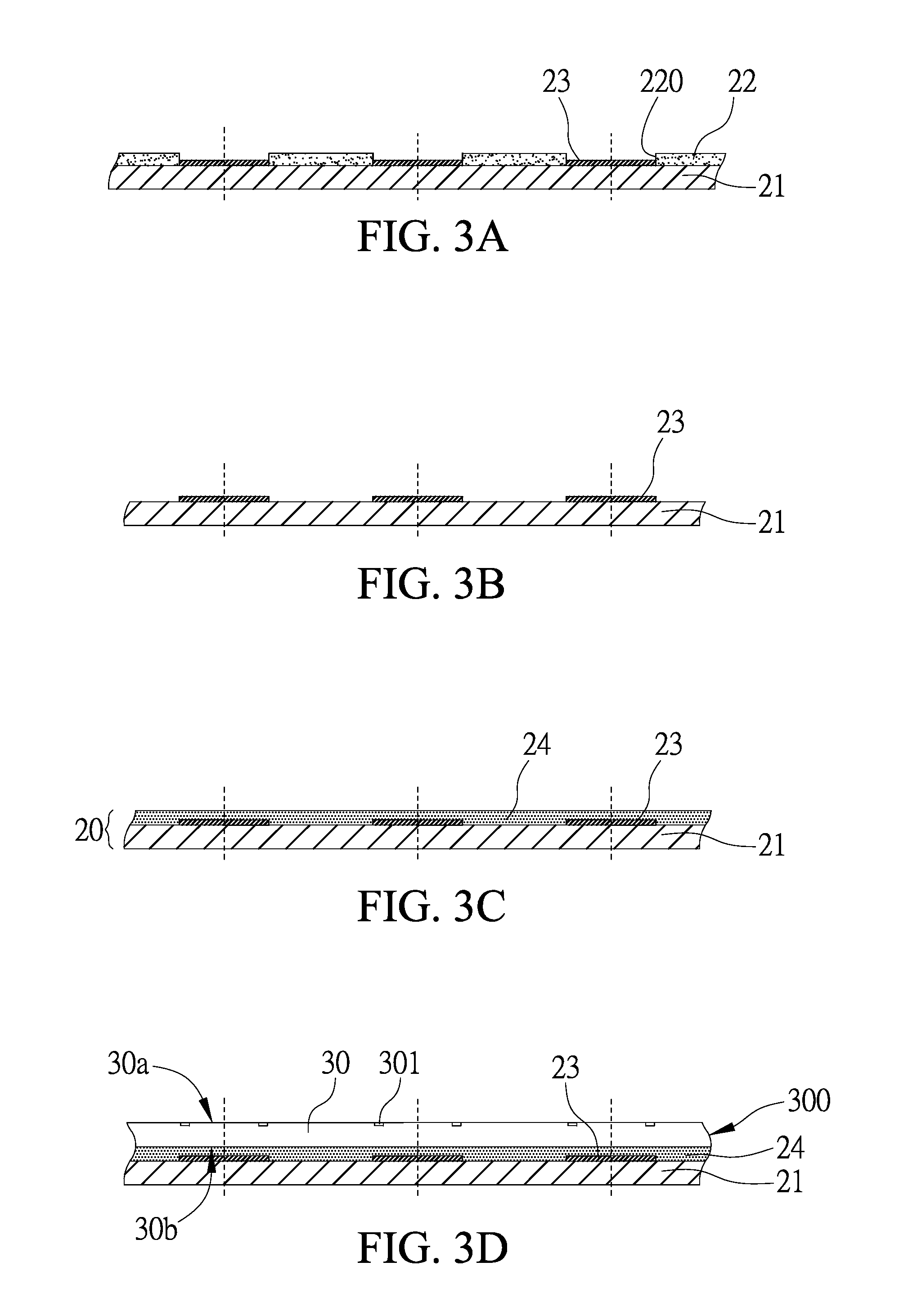

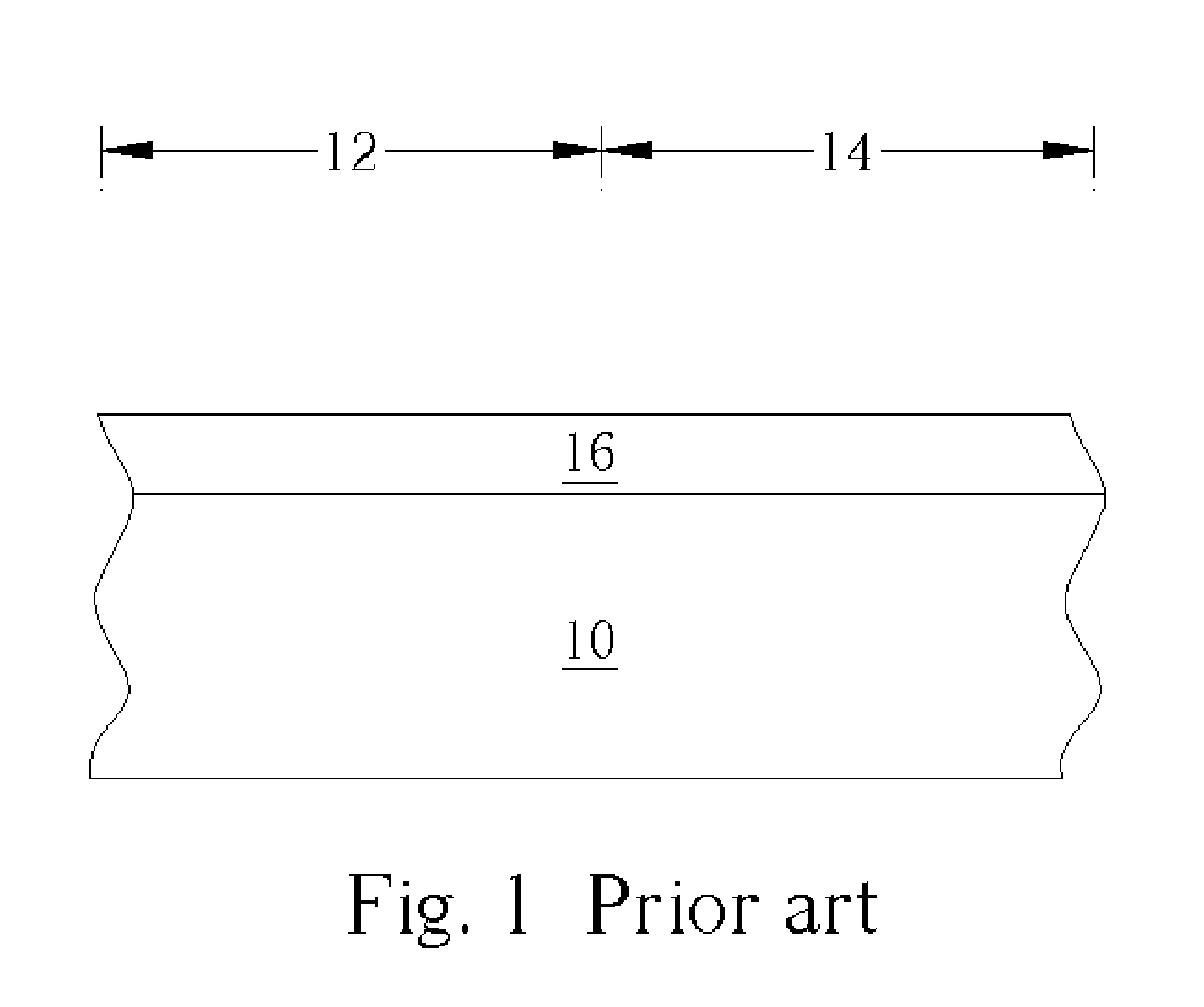

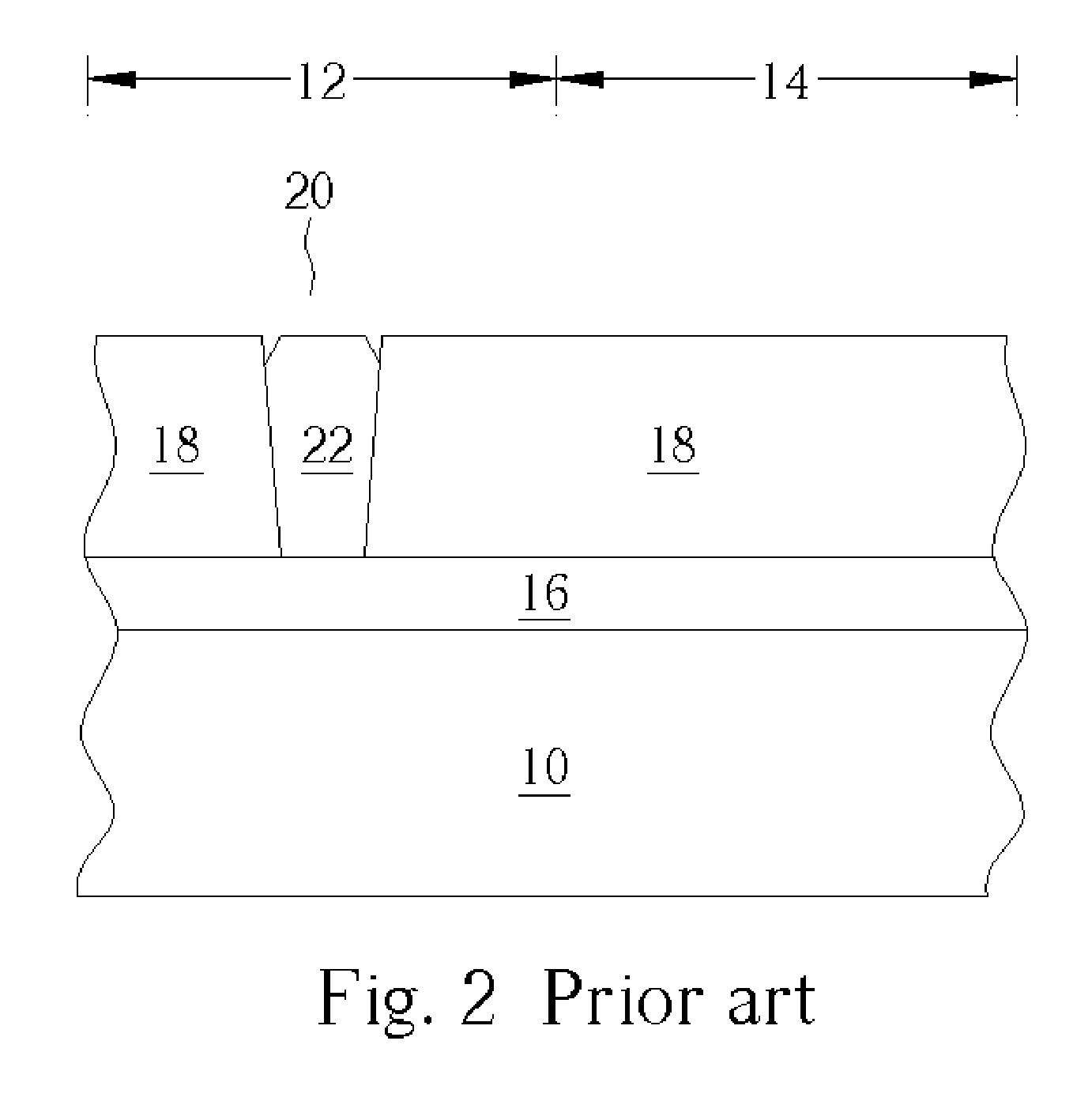

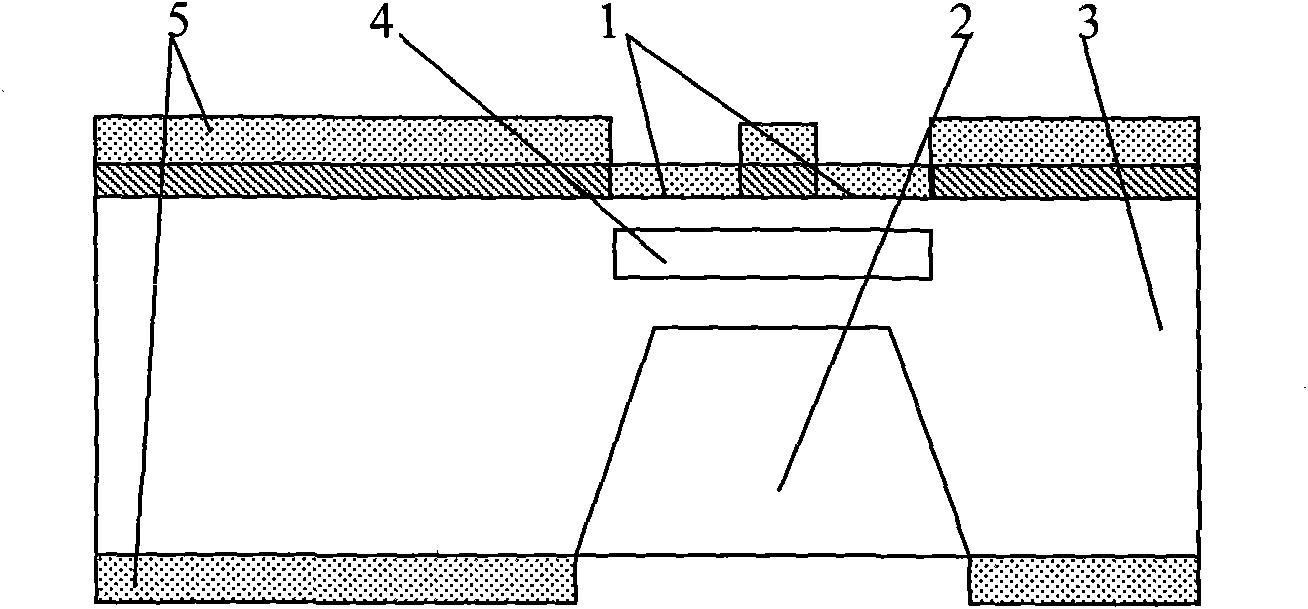

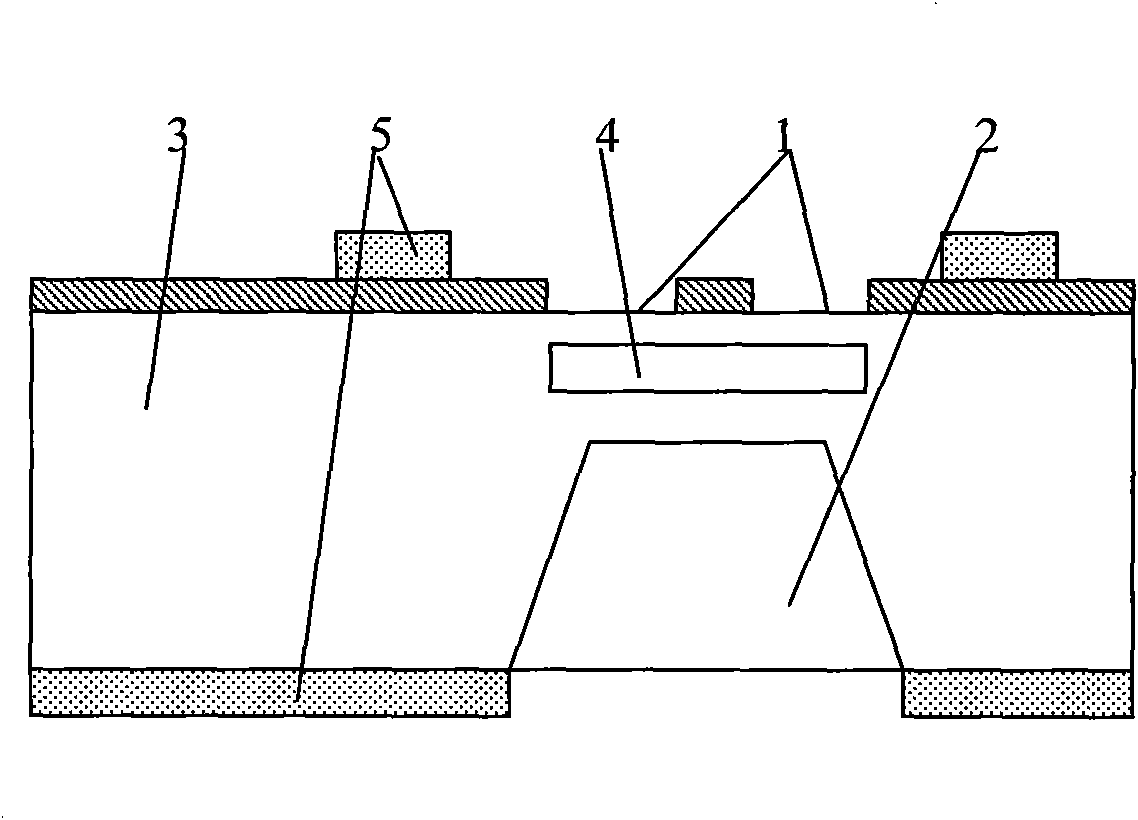

Semiconductor Device and Its Fabrication Method

InactiveUS20080283971A1Easily pickedReduced electrical performanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

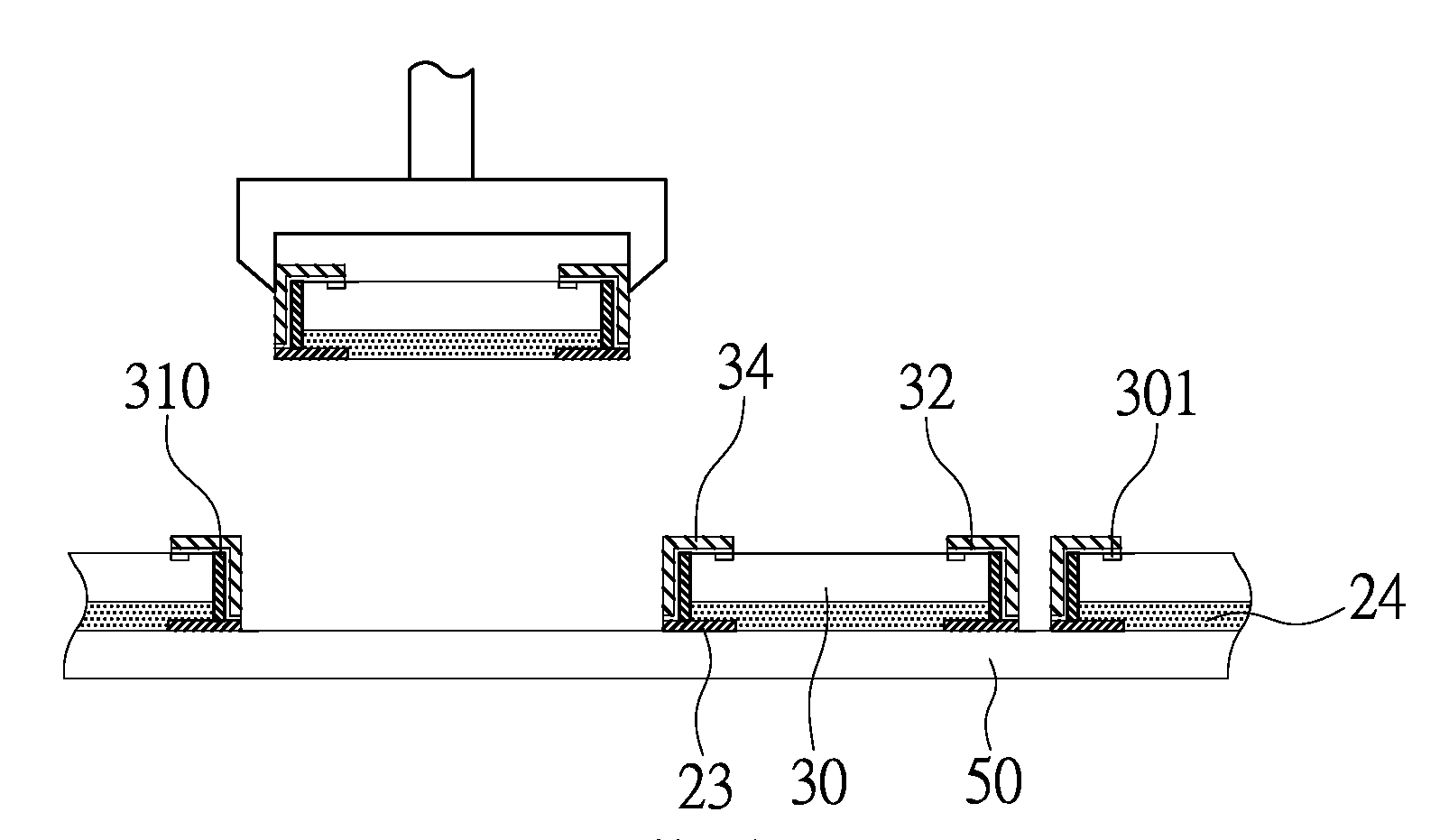

A semiconductor device and a fabrication method thereof are disclosed. The method includes attaching a wafer with a plurality of chips on a carrier board having an insulating layer, a plurality of conductive circuits and a bottom board; forming a plurality of first grooves between solder pads of adjacent chips to expose the conductive circuits, and filling the first grooves with an insulating adhesive layer; forming second grooves in the insulating adhesive layer; and cutting among the chips to separate the chips from one another.

Owner:SILICONWARE PRECISION IND CO LTD

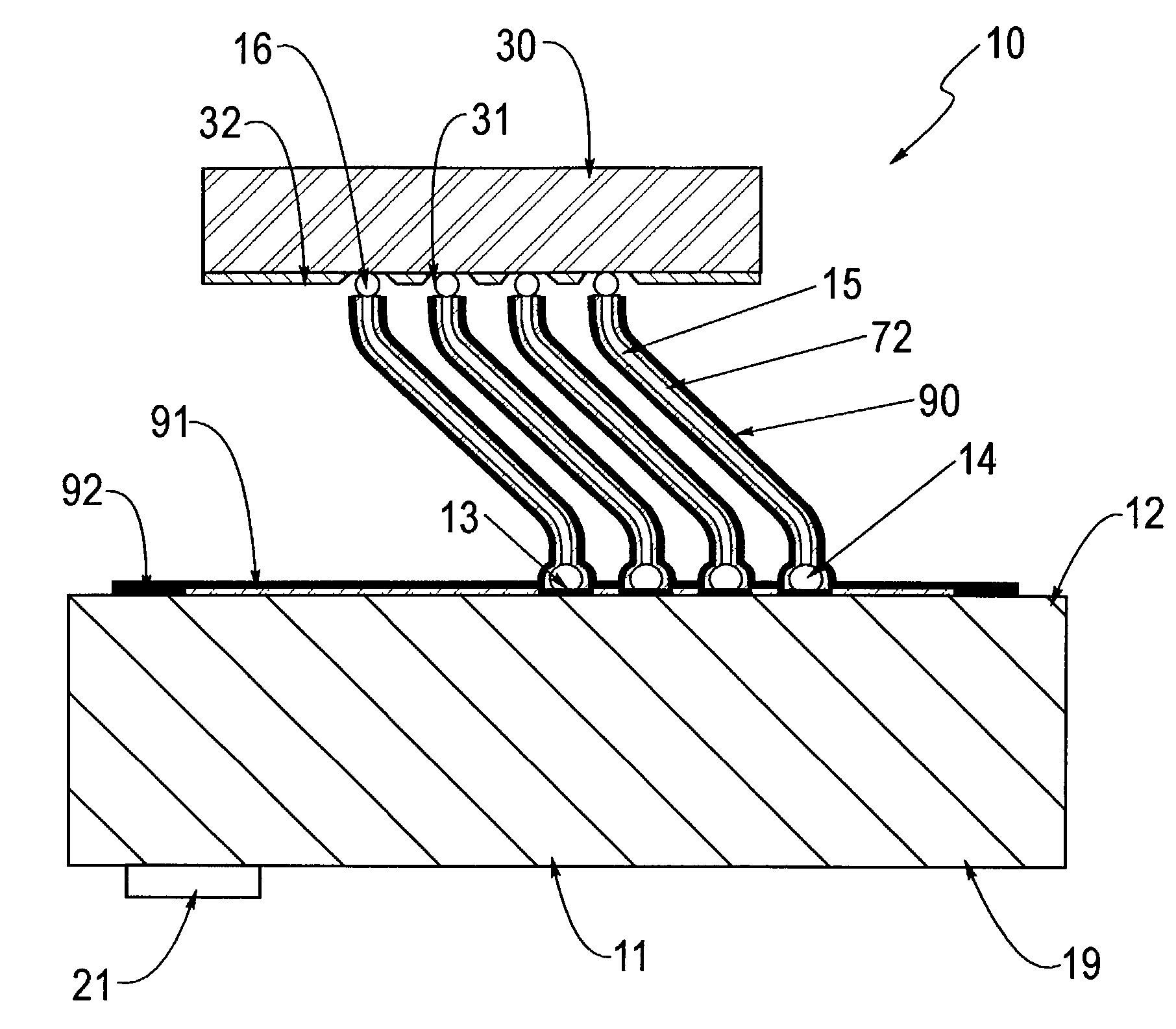

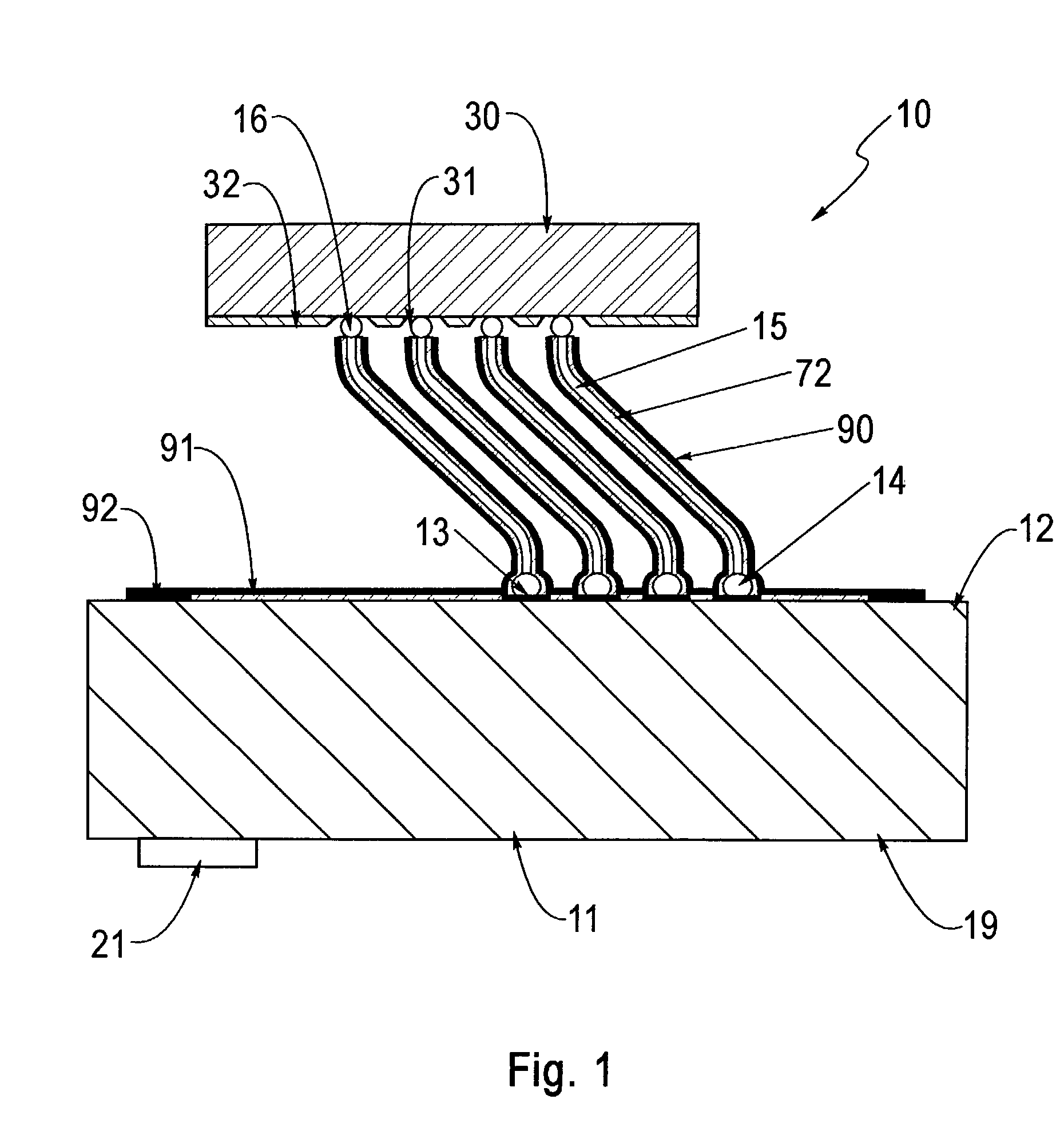

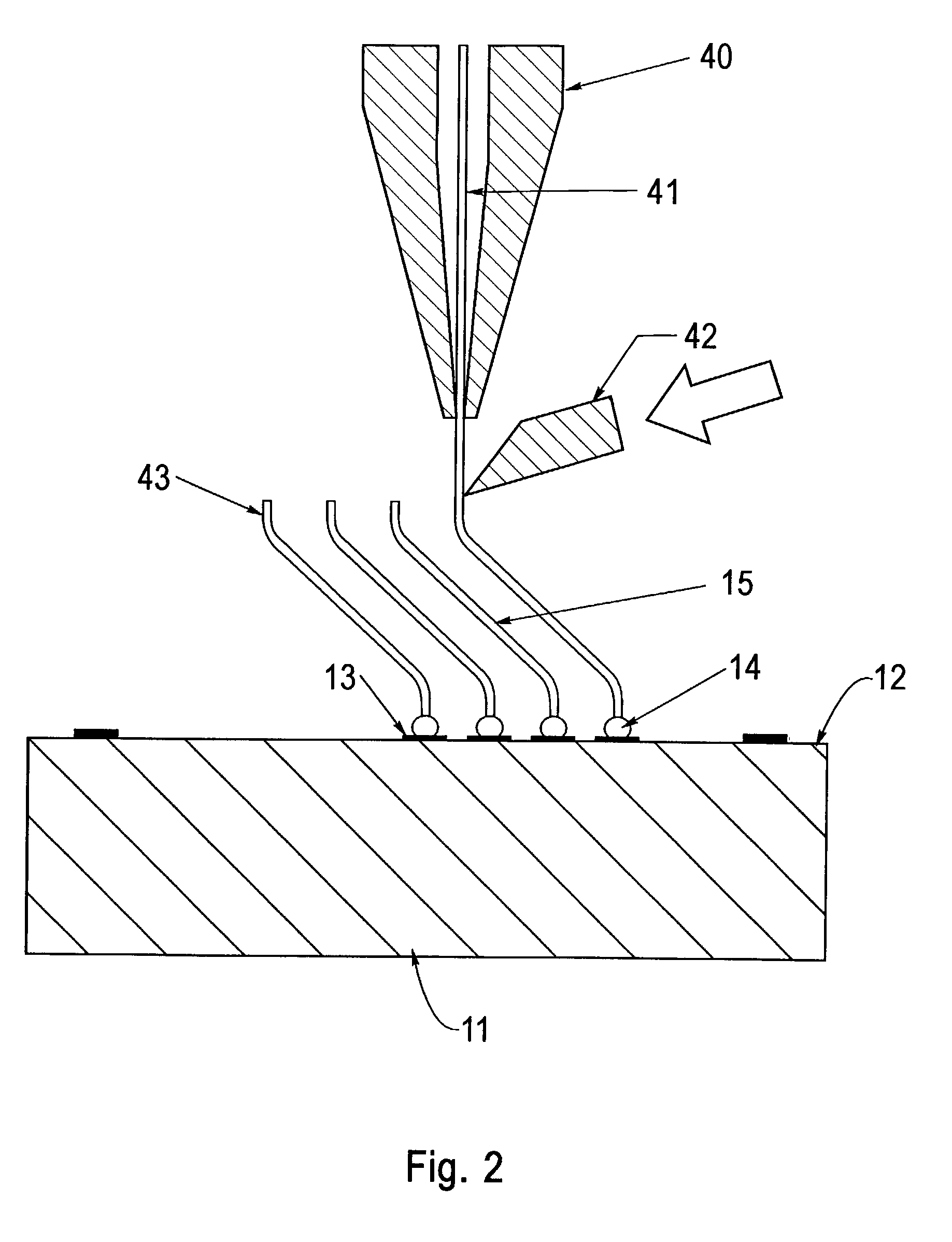

Probe structure having a plurality of discrete insulated probe tips projecting from a support surface, apparatus for use thereof and methods of fabrication thereof

InactiveUS7368924B2Minimize electrical conductor lengthMinimized contact resistanceElectrical measurement instrument detailsSemiconductor/solid-state device detailsCoaxial probeElectricity

The present invention is directed to structures having a plurality of discrete insulated elongated electrical conductors projecting from a support surface which are useful as probes for testing of electrical interconnections to electronic devices, such as integrated circuit devices and other electronic components and particularly for testing of integrated circuit devices with rigid interconnection pads and multi-chip module packages with high density interconnection pads and the apparatus for use thereof and to methods of fabrication thereof. Coaxial probe structures are fabricated by the methods described providing a high density coaxial probe.

Owner:GLOBALFOUNDRIES INC

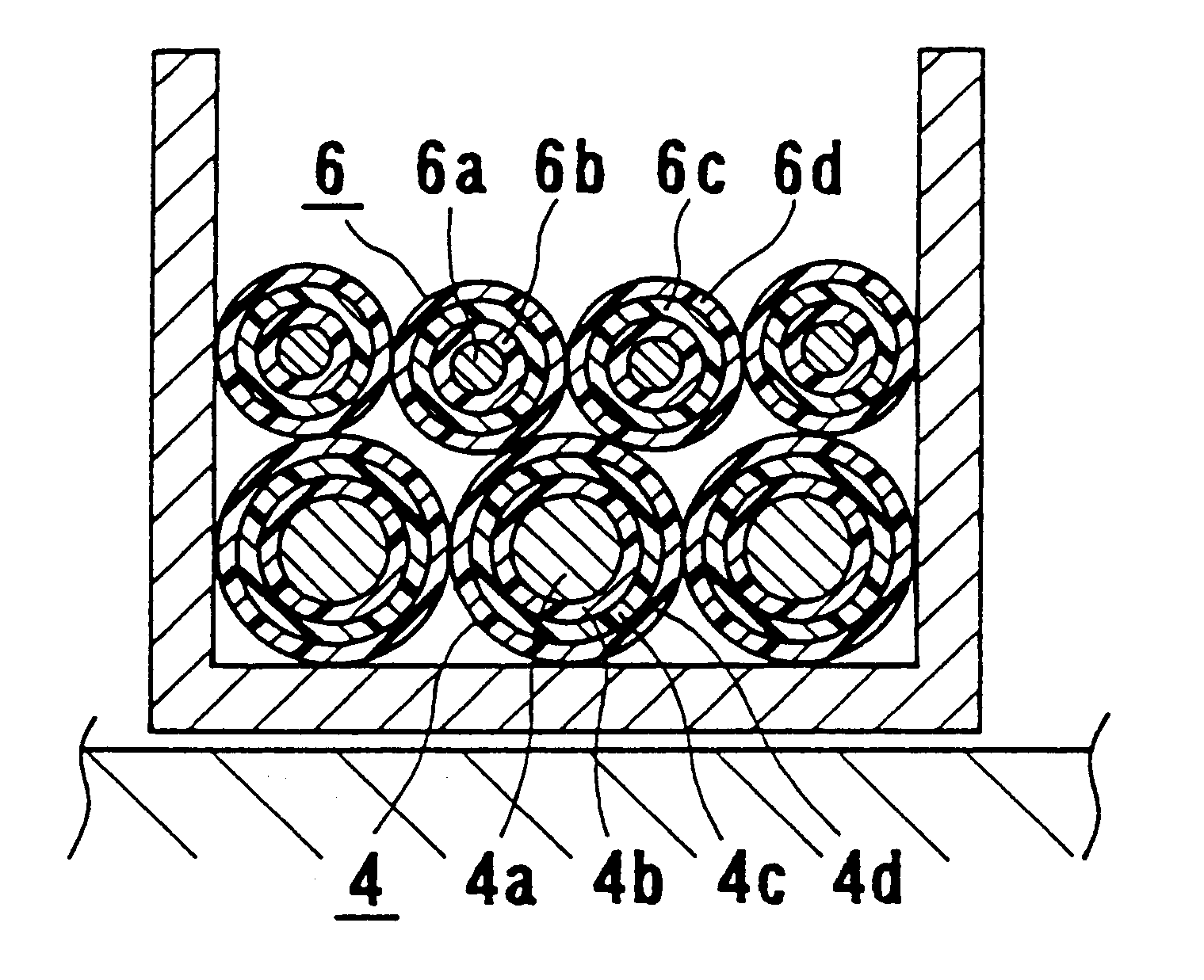

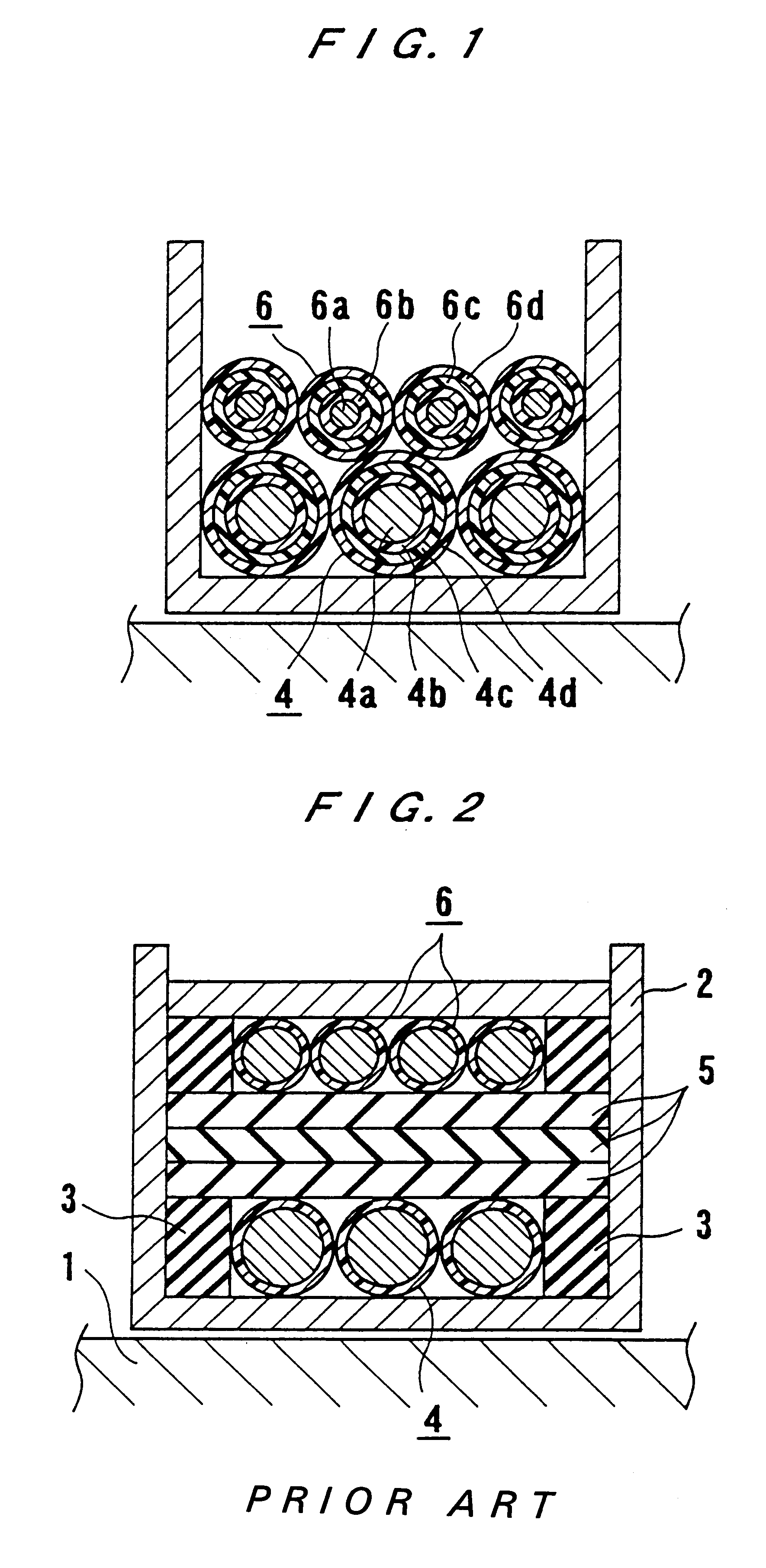

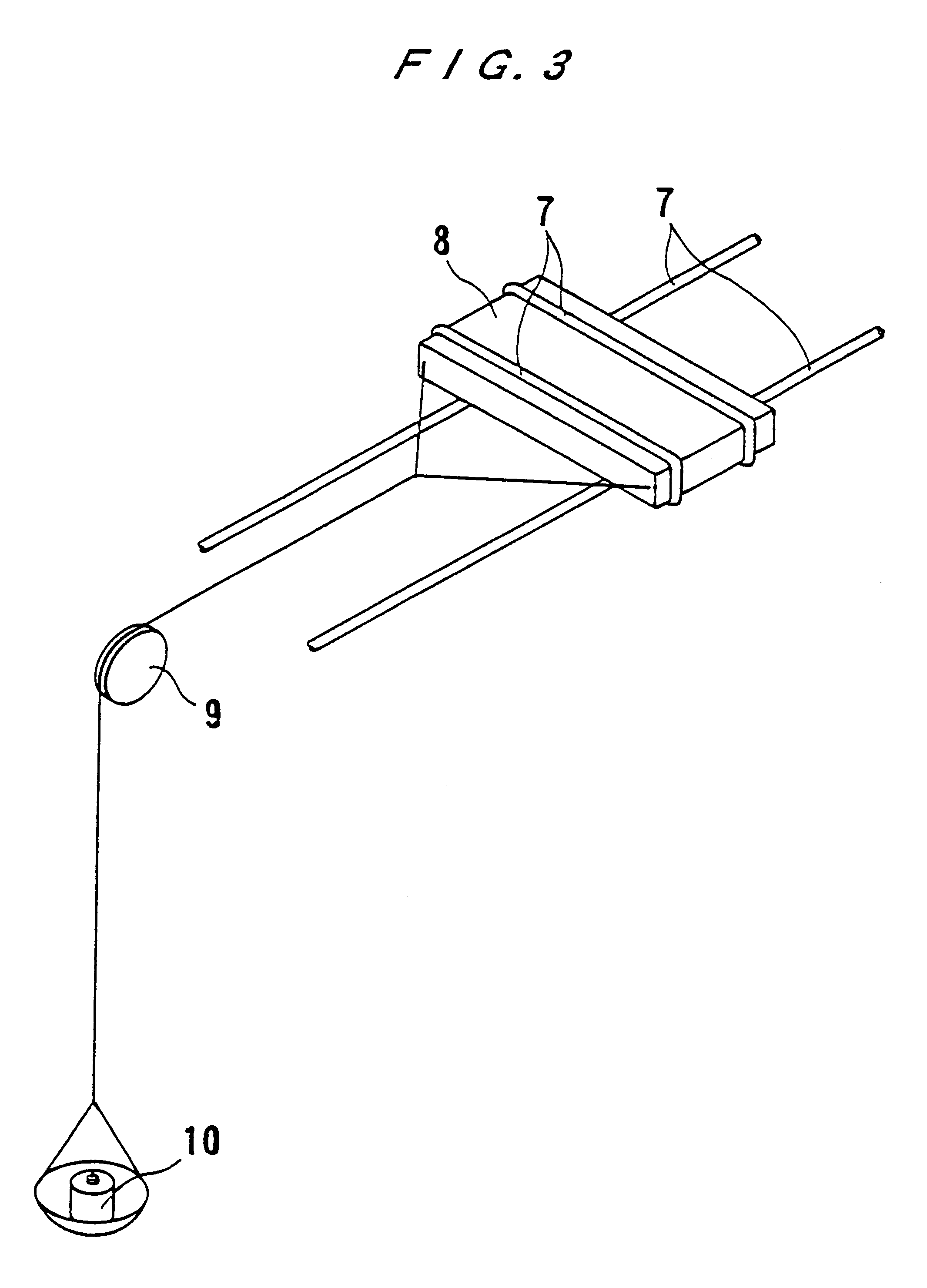

Multilayer insulated wire and transformers using the same

InactiveUS6222132B1Prevent crystallizationSuppress the deterioration with lapse of time of the electrical propertiesPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsPolyesterPolymer science

A multilayer insulated wire has a conductor and solderable extrusion-insulating layer made up of two or more layers for covering the conductor. At least one insulating layer including the outermost layer is formed by a mixture of 100 parts by weight of resin components in which 100 parts by weight of a thermoplastic polyester-series resin (A) is blended with 5 to 40 parts by weight of an ethylene-series copolymer having a carboxylic acid component or a metal salt of the carboxylic acid component in its side chain, and 10 to 80 parts by weight of an inorganic filler (B). A transformer which utilizes the multilayer insulated wire has excellent solderability, high-frequency characteristics, peel resistance under high-voltage and high-frequency, and coilability, and it is favorably suitable for industrial production. A transformer utilizing the multilayer insulated wire has excellent electrical properties and high reliability, because when used at high frequencies, there arises no problem of lowering of electric properties and scraping-off from the wire by corona.

Owner:FURUKAWA ELECTRIC CO LTD

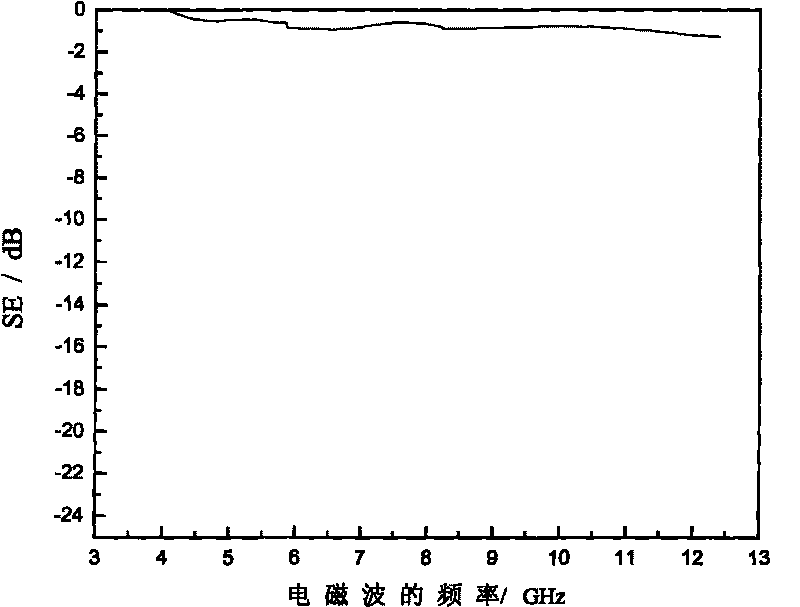

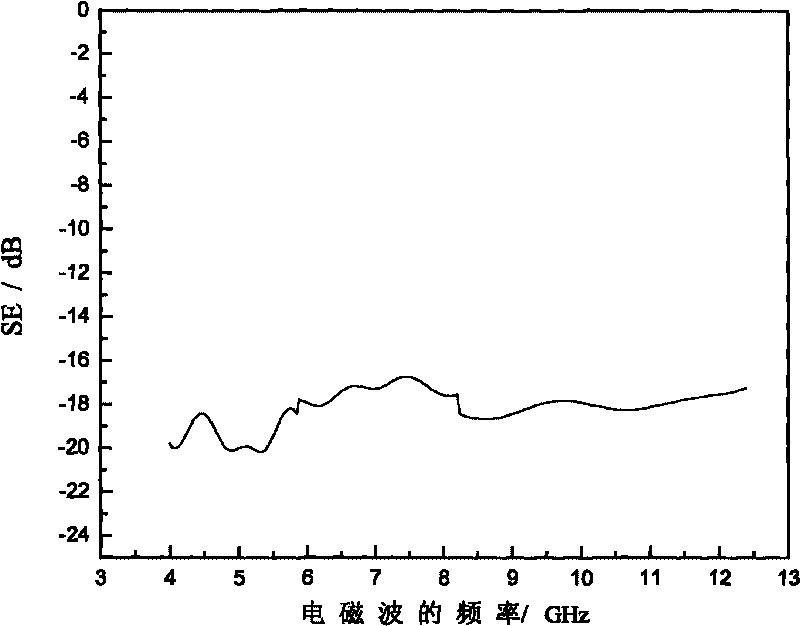

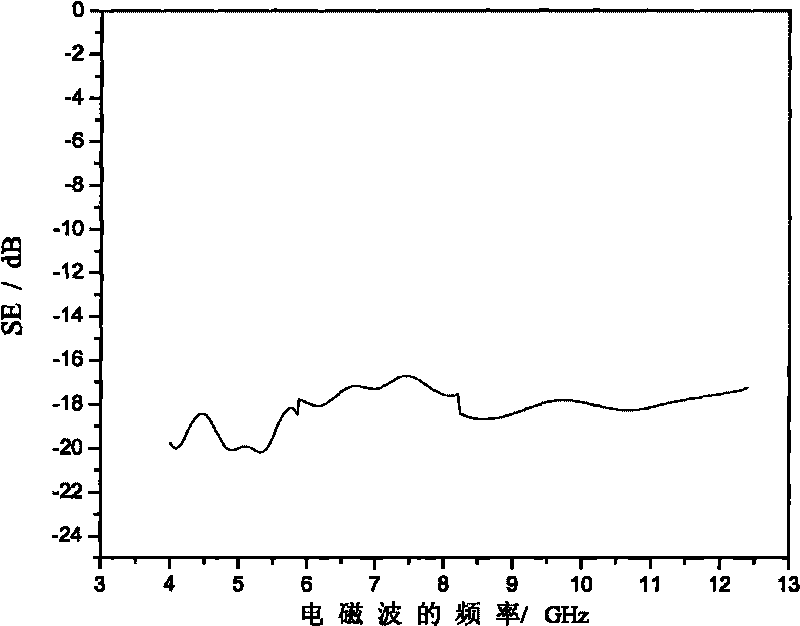

Preparation method as well as application of novel electromagnetic shielding filler

The invention relates to a preparation method as well as an application of novel electromagnetic shielding filler. The preparation method of the novel electromagnetic shielding filler comprises the following steps: by using clean glass microspheres as templates, firstly carrying out sulfhydrylation or amination modification on the surfaces of the templates; then enabling silver nanoparticles to directionally deposit and gradually grow on the surfaces of the templates continuously by using a chemical silvering method to obtain silver-coated glass microsphere compound particles with complete nuclear shell structures; and then, dissolving the templates with a hydrofluoric acid solution, and filtering in a pumping way, washing and drying to obtain hollow silver microspheres with complete structures to be used as the electromagnetic shielding filler. The novel electromagnetic shielding filler prepared by the invention has good conductivity; compared with the traditional conducting aluminum powder, the cost of the novel electromagnetic shielding filler is at least lowered by 65%, and the weight of the novel electromagnetic shielding filler is reduced by more than 80%; the electromagnetic shielding composite material prepared by the novel electromagnetic shielding filler has better shielding effectiveness; and the novel electromagnetic shielding filler has wide application prospects in the aspects of electromagnetic compatibility engineering, information leakage prevention, electromagnetic interference application and the like.

Owner:WUHAN UNIV OF TECH

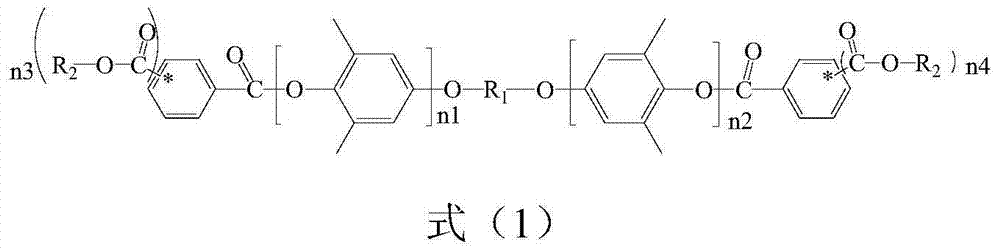

Active ester, thermosetting resin composition containing active ester, prepreg and laminated board

InactiveCN104761719AImprove heat resistanceStrong heat resistanceSynthetic resin layered productsPrinted circuit aspectsEpoxyHeat resistance

The invention provides active ester, a thermosetting resin composition containing the active ester, a prepreg and a laminated board. The active ester is a double-ended polyfunctional active ester containing a PPO main chain, and the thermosetting resin composition comprises epoxy resin and the double-ended polyfunctional active ester containing the PPO main chain. The prepreg, the laminated board and a copper-clad plate prepared from the thermosetting resin composition containing the double-ended polyfunctional active ester containing the PPO main chain has excellent dielectric properties, damp-heat resistance, heat resistance, extremely low water absorption and high bending strength.

Owner:GUANGDONG SHENGYI SCI TECH

Process for preparing high performance copper-clad polytetrafluoroethylene plate

InactiveCN1586876AReduce void volumeLow dielectric dissipation factorSynthetic resin layered productsCopper foilPTFE - Polytetrafluoroethylene

The preparation process of novel high performance copper-clad PTFE plate includes the following steps: preparing inner layer of glass fiber fabric; preparing outer layer of glass fiber fabric; and cladding copper foil on two sides of the outer layer of glass fiber fabric. The copper-clad PTFE plate of the present invention has excellent electric performance, heat performance and mechanical performance, high bending strength, high size stability and high comprehensive performance.

Owner:SOUTH CHINA UNIV OF TECH

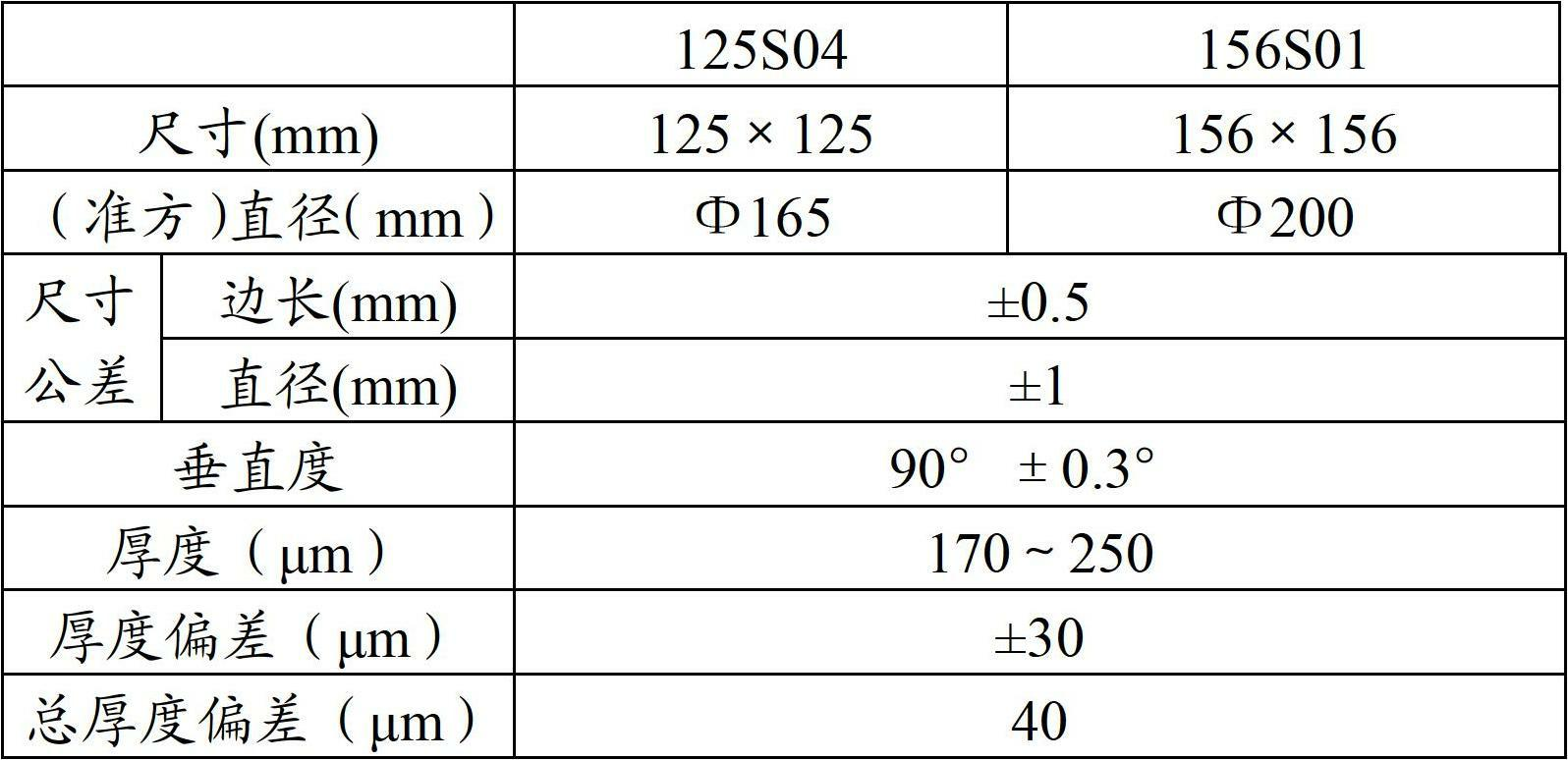

Preparation method and application of monocrystalline silicon sheet

ActiveCN109747055AIncrease profitEfficient use ofPolycrystalline material growthAfter-treatment detailsNanotechnologySingle crystal silicon

The invention discloses a preparation method and application of a monocrystalline silicon sheet. A monocrystalline silicon rod can be cut to be a strip-shaped right-angle silicon monocrystalline sheetand a monocrystalline silicon quasi square sheet or the strip-shaped right-angle silicon monocrystalline sheet and monocrystalline silicon square sheet, and the using ratio of the monocrystalline silicon rod can be increased.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Grain refinement technology of silver-nickel electrical contact material and grain refinement technology of silver tin oxide electrical contact material

The invention discloses a grain refinement technology of a silver-nickel electrical contact material and a grain refinement technology of a silver tin oxide electrical contact material, belonging to the technical field of a metal-base composite material, which is characterized in that a uniform AgNi wire and a uniform AgSnO2 wire with a certain diameter specification are firstly drawn and thrust into short wires with the length of 1cm-5cm; the thrust wires are pressed into spindles after heat treatment; the spindles are made into the wire through sintering, upsetting and a plurality of hot extrusion, wherein, grain shearing deformation and grain refinement are realized by upsetting before extrusion, so tissue components in an extrusion material (110) are effectively reduced and oxide films on the boundary of powder grains are crushed and dispersed; and a plurality times of extrusion are adopted for extrusion deformation under large hydrostatic pressure, which is beneficial to elimination of tiny holes and combination of material points of the material so that the density and the shaping of the product are enhanced. In the course of extrusion, grain refinement is more obvious, the gross area of the grain boundary is increased, the capability for blocking crack expansion is enhanced, and the concentration of impurities on the grain boundary is reduced, thus avoiding brittle fracture along the grain boundary.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

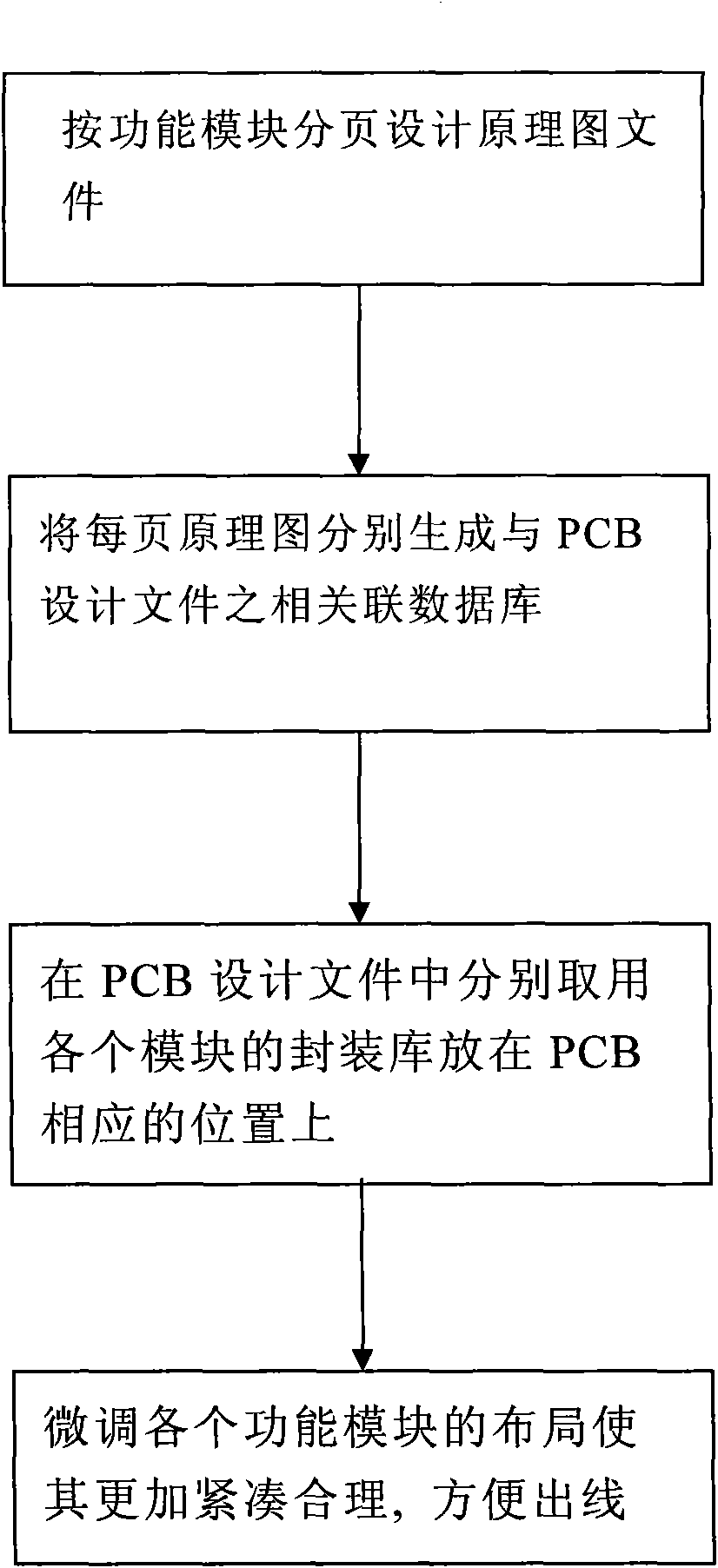

Method for introducing PCB design document from schematic diagram

InactiveCN101639870AReduced electrical performanceShorten the timeSpecial data processing applicationsComputer architectureModular design

The invention discloses a method introducing PCB design document from a schematic diagram. The method comprises: performing modular design according to realized function in a schematic diagram designdocument; according to a schematic diagram functional module, respectively and independently associating to the PCB design document; in the PCB design document, respectively according to relevant document generated by the schematic diagram, calling each corresponding functional module from a packaging library in the PCB design document, and putting to the proper position in the PCB design document; trimming to form component position of each functional module to cause the component to be regular and convenient for routing. The invention can shorten time of laying later-stage circuit board components and lower the ratio of making mistakes in the subsequent process of putting components.

Owner:SHANGHAI WINGTECH ELECTRONICS TECH

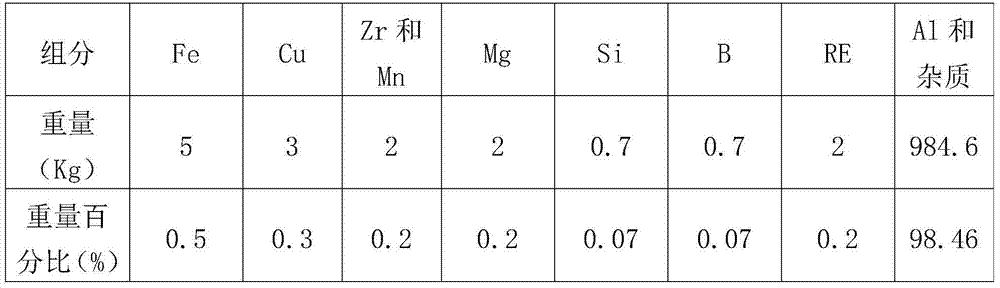

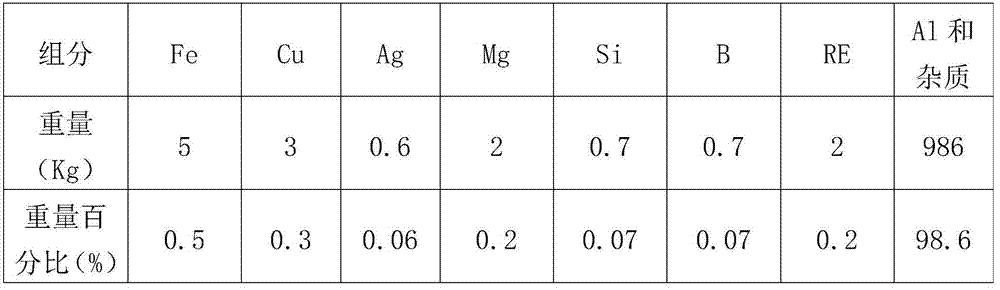

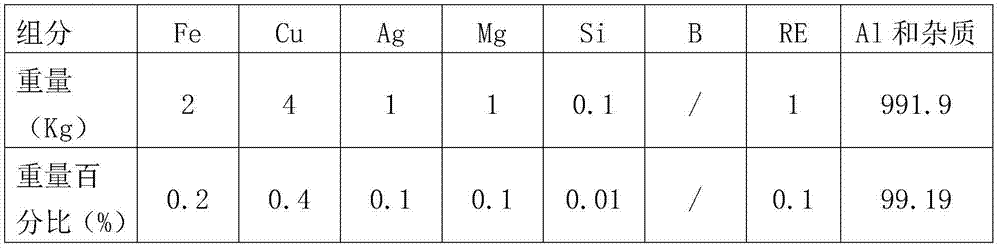

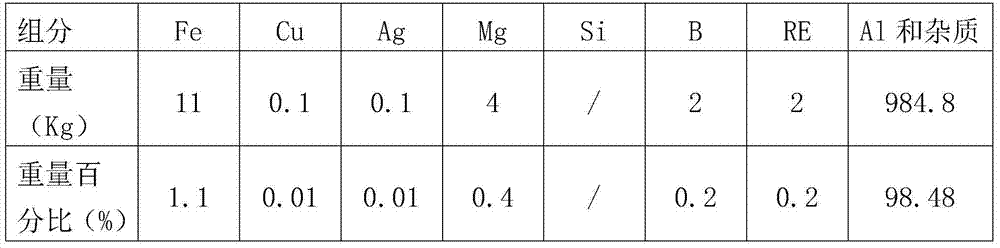

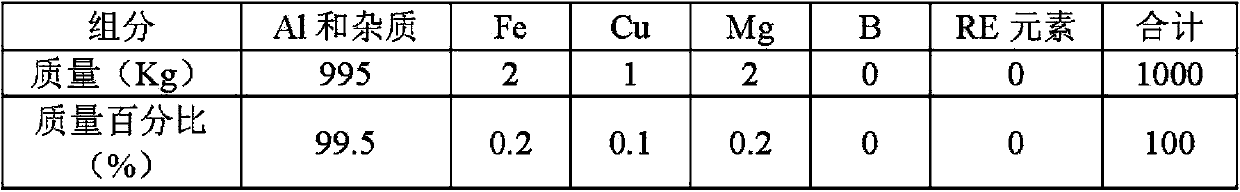

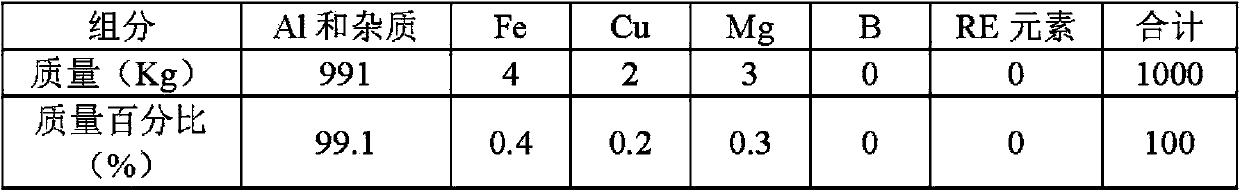

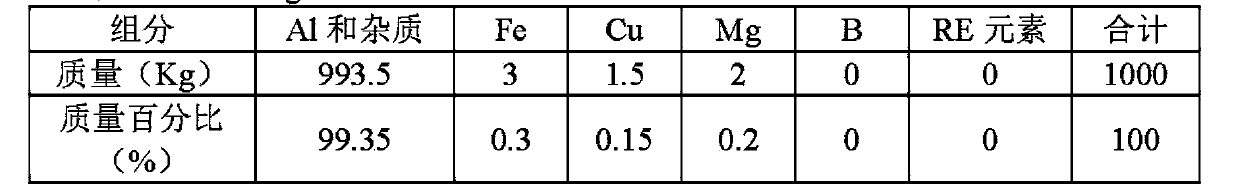

Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, aluminum alloy cable and preparation method of alloy cable

PendingCN104294093AImprove performanceImprove mechanical strength, tensile propertiesMetal/alloy conductorsCable/conductor manufactureCoalOmega

The invention discloses an Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, which comprises 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.01-0.4% of Mg, 0-0.1% of Si, 0-0.2% of B, and the balance of Al and impurities, wherein the electrical resistivity of the aluminum alloy is not greater than 0.028264 Omega.mm<2> / m, the elongation at break is not less than 10%, and the number of times of 90-degree fatigue bending is greater than or equal to 30. An aluminum alloy cable is prepared by the steps of melting, casting and rolling the aluminum alloy material so as to obtain an aluminum alloy rod, carrying out drawing, bunch-stranding and softening on the aluminum alloy rod so as to obtain an aluminum alloy cable core, and carrying out extruded insulation, cabling, extruded sheathing or armoring on the cable core; and the prepared aluminum alloy cable has the characteristics of high strength, high electric conductivity, good bending performance and the like, and can satisfy the requirements on the properties of cables in the field of coal mines.

Owner:ANHUI JOY SENSE CABLE

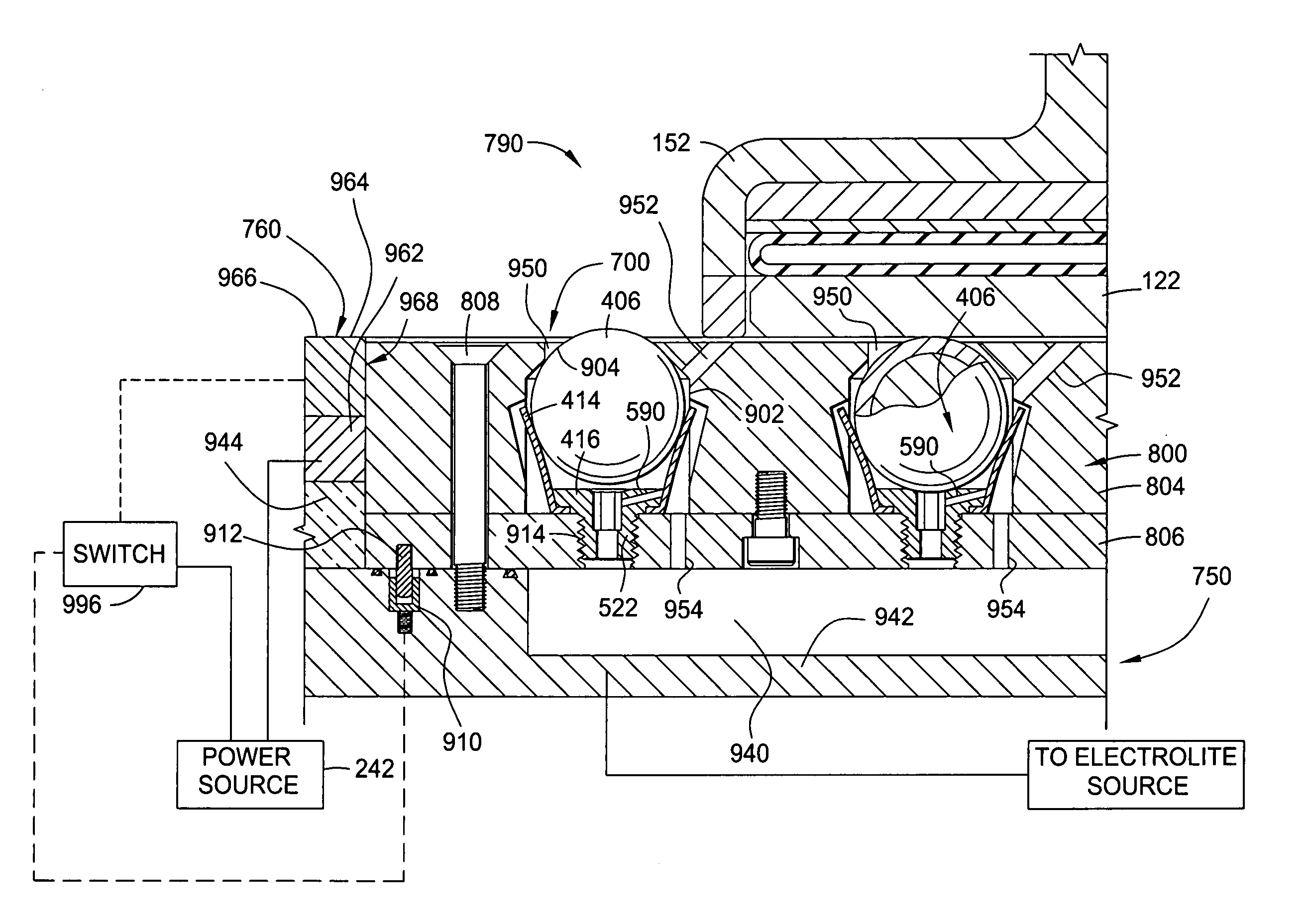

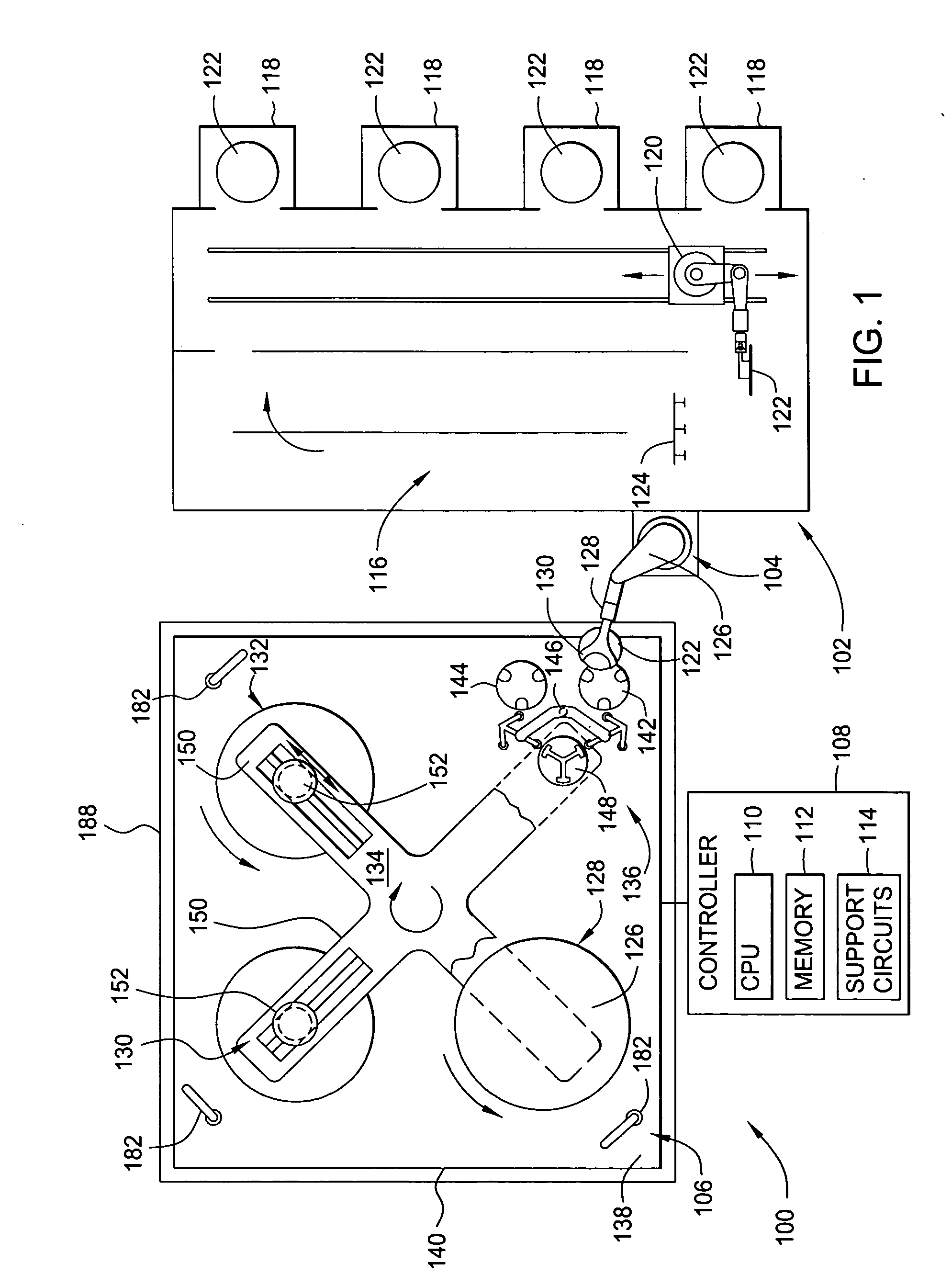

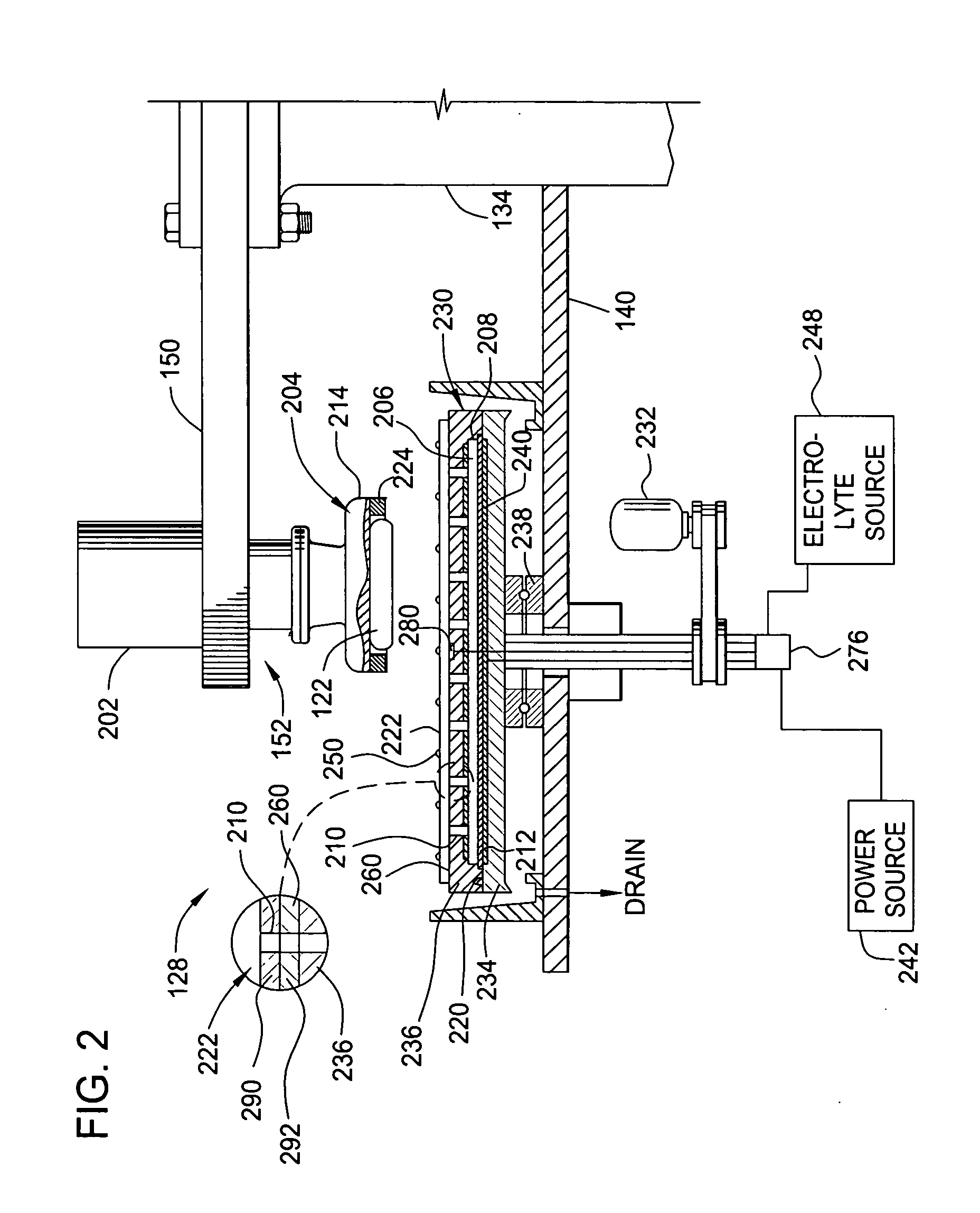

Contact assembly and method for electrochemical mechanical processing

InactiveUS20060032749A1Reduced electrical performanceCellsLiquid separation by electricityElectricityElectrochemistry

Embodiments of the invention generally provide a method and apparatus for processing a substrate in an electrochemical mechanical planarizing system. In one embodiment, a contact assembly for electrochemically processing a substrate includes a housing having a ball disposed in a passage formed through the housing. The ball is adapted to extend partially from the housing to contact the substrate during processing. The housing includes a fluid inlet that is positioned to cause fluid, entering the housing through the inlet, to sweep the entire passage. In another embodiment, a method for electrochemically processing includes flowing a processing fluid through a passage retaining a conductive element. The flow sweeps the entire passage of the housing. A first electrical bias is applied to the conductive element in contact with the substrate relative an electrode electrically coupled to the substrate by the processing fluid. After the substrate is separated from the conductive element, flow of processing fluid is continued through the passage past the conductive element.

Owner:APPLIED MATERIALS INC

Manufacturing method of corona-resistant polyimide film sintered enamelled copper strap wires

ActiveCN102800423AHigh corona resistance strengthHigh temperature resistanceInsulating conductors/cablesPolyesterCopper conductor

The invention relates to a manufacturing process of enamelled copper strap wires, and particularly relates to a manufacturing method of corona-resistant polyimide film sintered enamelled copper strap wires. The manufacturing method comprises the following steps of: processing a copper conductor into a copper strap wire; making the copper strap wire to a 200-grade polyester-imine / polyamide-imide compound type enamelled copper strap wire; and covering a corona-resistant polyimide film on the enamelled copper strap wire and then heating, baking and sintering the enamelled copper strap wire. The manufacturing method combines an enameling process and a glass-coating process, overcomes the limitation of the conventional process, makes up single performance of the existing process, and well combines the enameling process and the glass-coating process; and the product has high corona resistance strength and reaches a high temperature resistance level.

Owner:SICHUAN JINRUI ELECTRIC

Single-component silver filled conductive glue capable of being stored and transported at normal temperature

InactiveCN1931946APlay its due roleAdhesive response is fastAldehyde/ketone condensation polymer adhesivesEpoxy resin adhesivesEpoxyPrinted circuit board

The single-component silver filled conductive glue capable of being stored and transported at normal temperature consists of flaky silver powder as the main component in 70-75 wt%, and supplementary material including organic carrier comprising epoxy resin and phenolic resin 10-15 wt%, curing agent dicyan diamine 0.5-1 wt%, curing promoter carbamide 0.1-0.3 wt%, and diluent mixture of dimethyl adipate, dimethyl glutarate and dimethyl succinate 9-15 wt%. The conductive glue of the present invention is used as the connecting material to replace solder for adhering printed circuit board as well as SMT, quartz resonator, chip, etc. It has excellent conducting performance, high adhesion, easy transportation and storing, and capacity of forming bright and fine cured spot.

Owner:贵州振华亚太高新电子材料有限公司

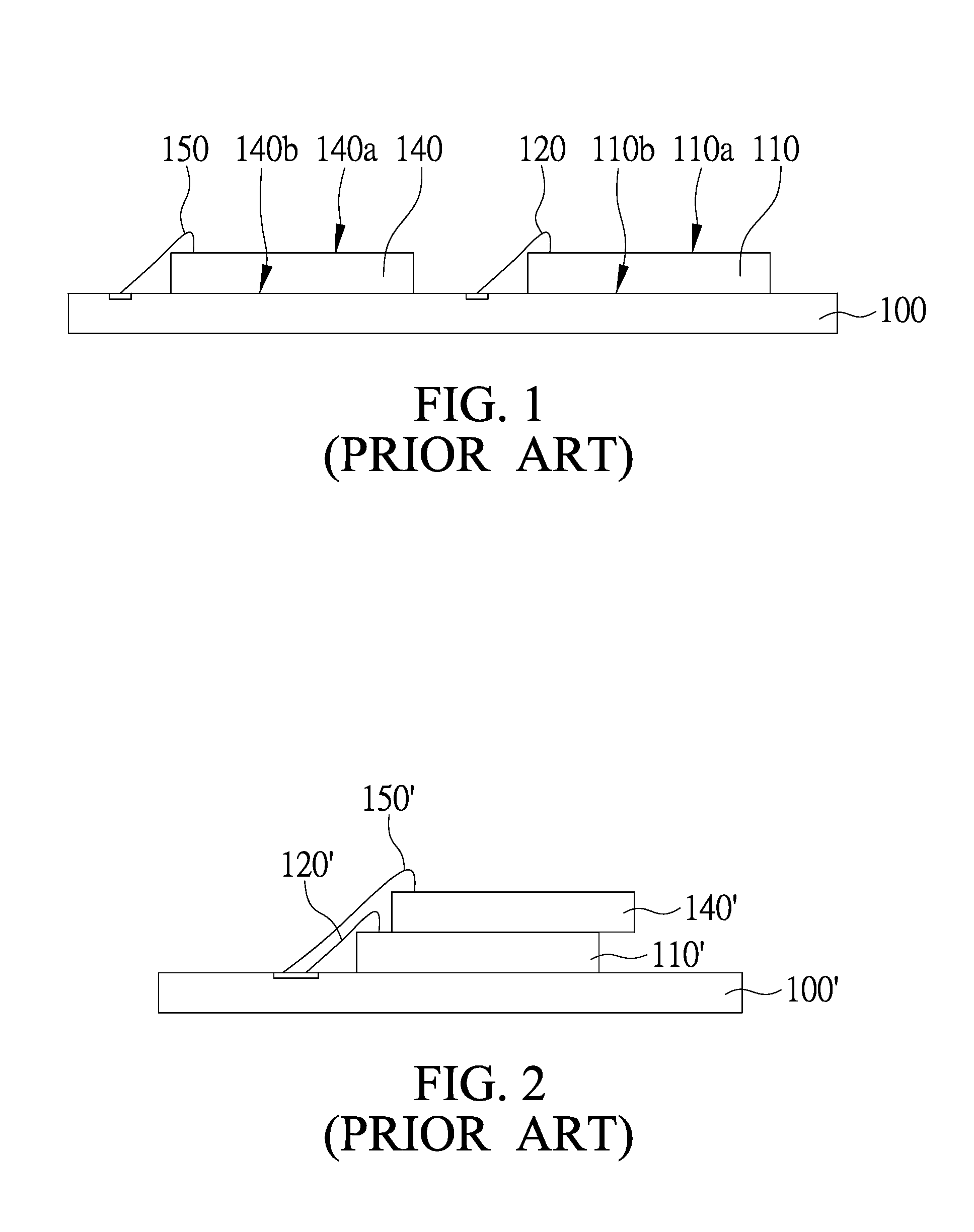

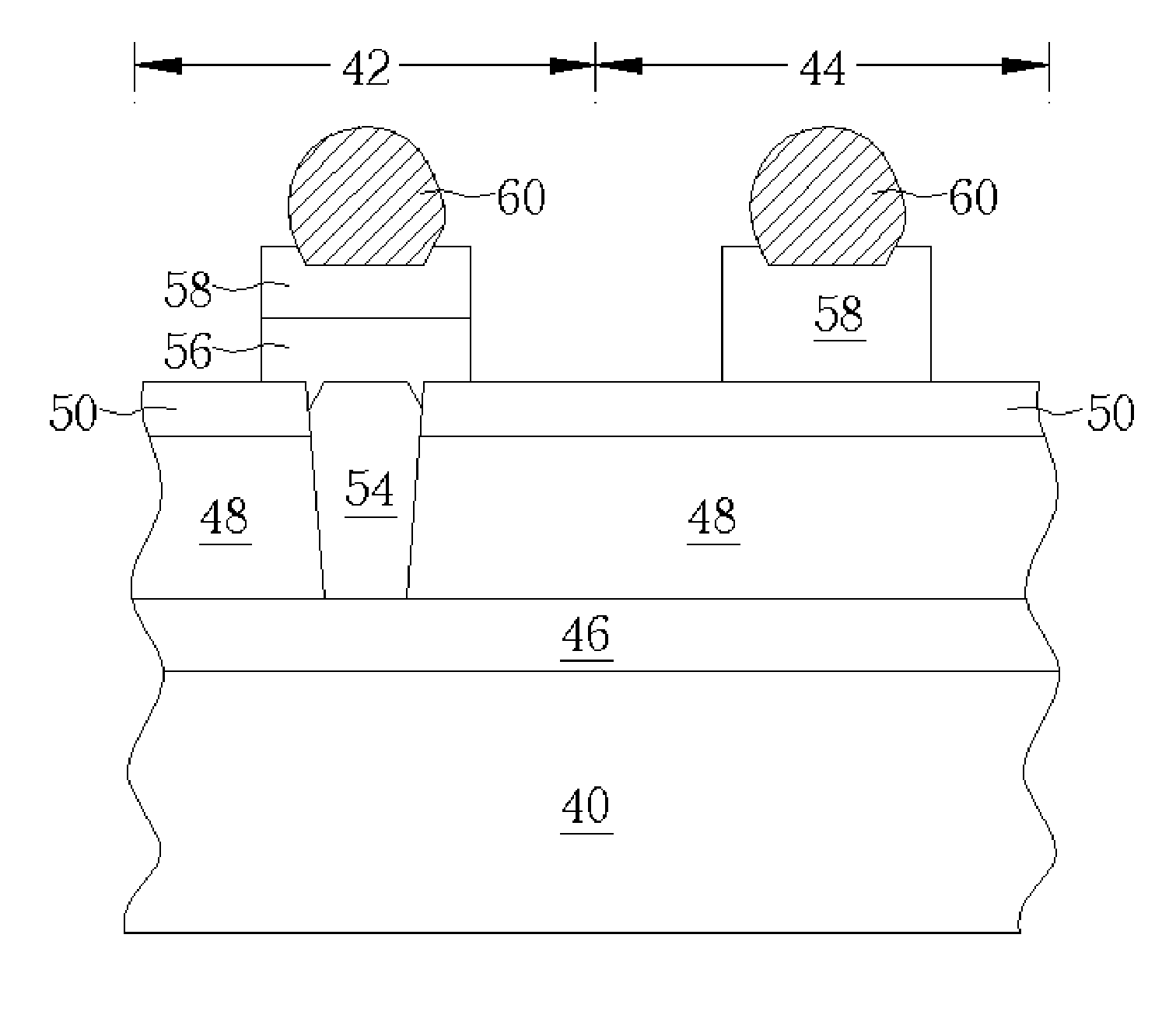

Parasitic capacitance-preventing dummy solder bump structure and method of making the same

ActiveUS7026234B2Reduced electrical performanceImprove liquiditySemiconductor/solid-state device detailsSolid-state devicesParasitic capacitanceUnder bump metallurgy

A parasitic capacitance-preventing dummy solder bump structure on a substrate has at least one conductive layer formed on the substrate, a dielectric layer employed to cover the conductive layer, an under bump metallurgy layer (UBM layer) formed on the dielectric layer, and a solder bump formed on the UBM layer.

Owner:UNITED MICROELECTRONICS CORP

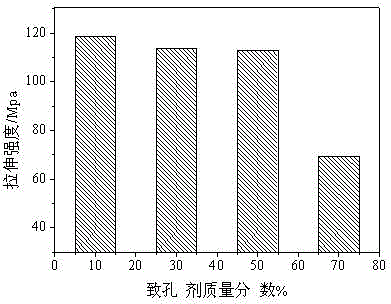

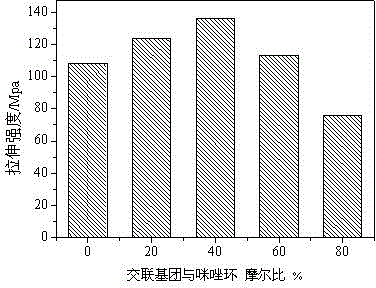

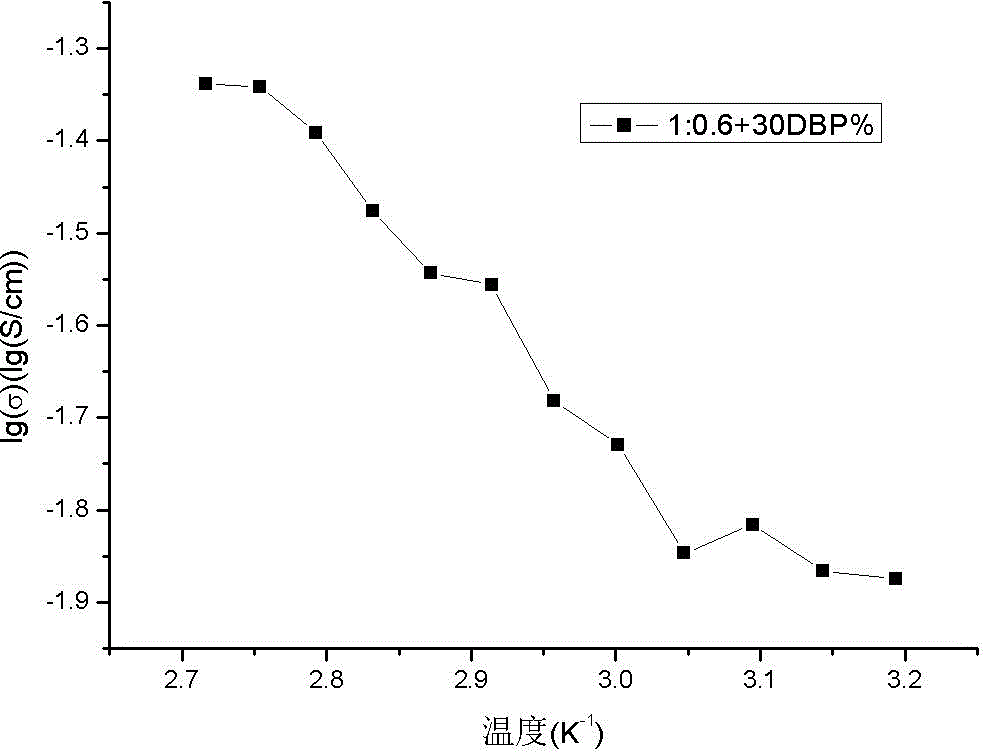

Preparation method of pore-filing type proton exchange membrane taking double ether crosslinked porous polybenzimidazole imide as base

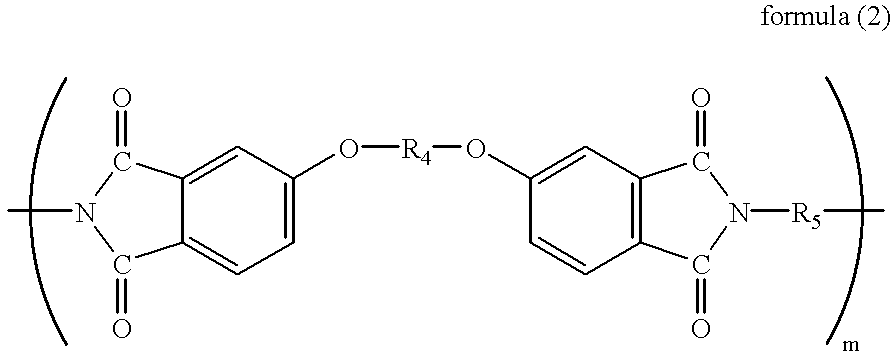

InactiveCN104629081AExcellent thermal stabilityImprove mechanical strength and poor dimensional stabilitySolid electrolyte fuel cellsFunctional polymersEther

The invention belongs to the technical fields of functional polymer materials and electrochemistry and in particular relates to a preparation method of a pore-filing type proton exchange membrane taking double ether crosslinked porous polybenzimidazole imide as a base. The preparation method of the pore-filing type proton exchange membrane taking the double ether crosslinked porous polybenzimidazole imide as the base comprises the following steps: firstly synthesizing polybenzimidazole imide provided with a cross-linkable imidazole group on a main chain, preparing the synthesized polybenzimidazole imide into a membrane solution, adding a double ether crosslinking agent, reacting with the imidazole group, a crosslinking sulfonated polyimide polymer in a membrane forming process, adding a pore-forming agent at the same time to form a crosslinked porous polybenzimidazole imide membrane, and finally compounding the crosslinked porous polybenzimidazole imide membrane with perfluorosulfonate resin, so that the pore-filling type proton exchange membrane is obtained. A basement membrane gives good mechanical properties to the pore-filling type membrane, and the pore-filling type membrane has high dimensional stability; meanwhile, the proton conductivity of a perfluorosulfonate membrane is not greatly reduced. The preparation method of the pore-filing type proton exchange membrane taking the double ether crosslinked porous polybenzimidazole imide as the base has the advantages that the preparation technology controllability is good; and compared with the traditional perfluorosulfonate membrane, the obtained pore-filling type proton exchange membrane has high mechanical strength and good dimensional stability and has broad application prospect in a polymer electrolyte membrane fuel cell.

Owner:TONGJI UNIV

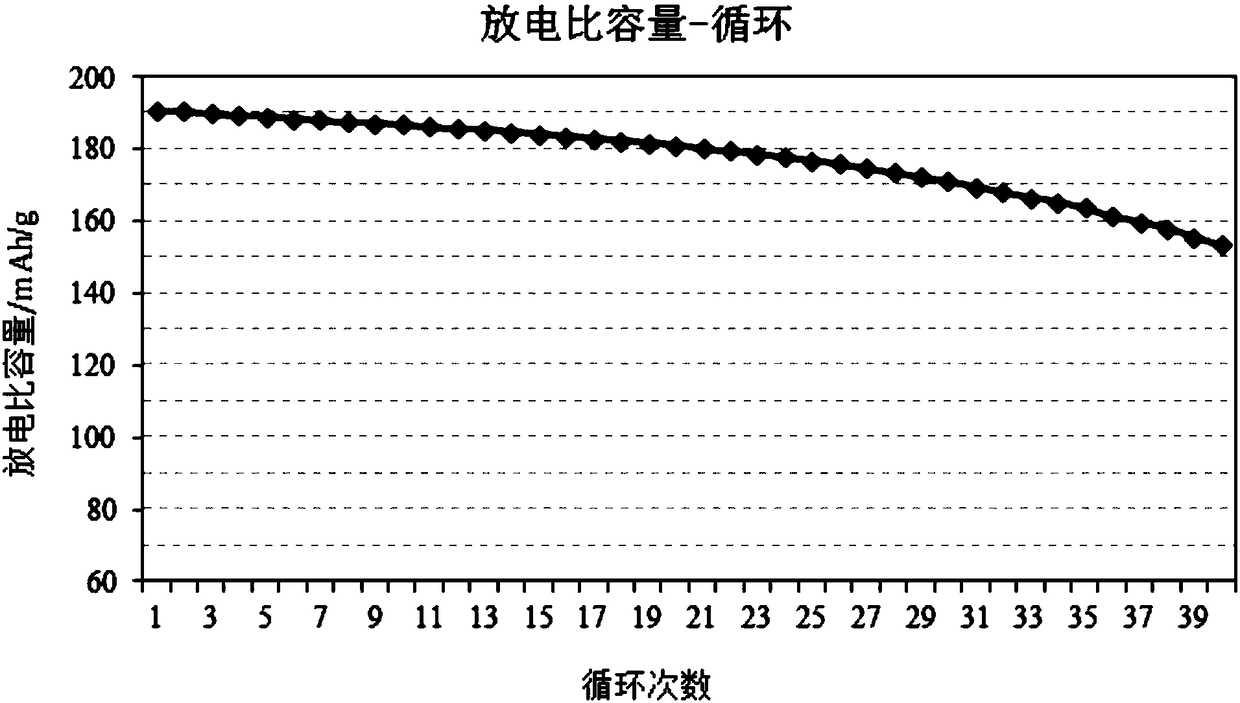

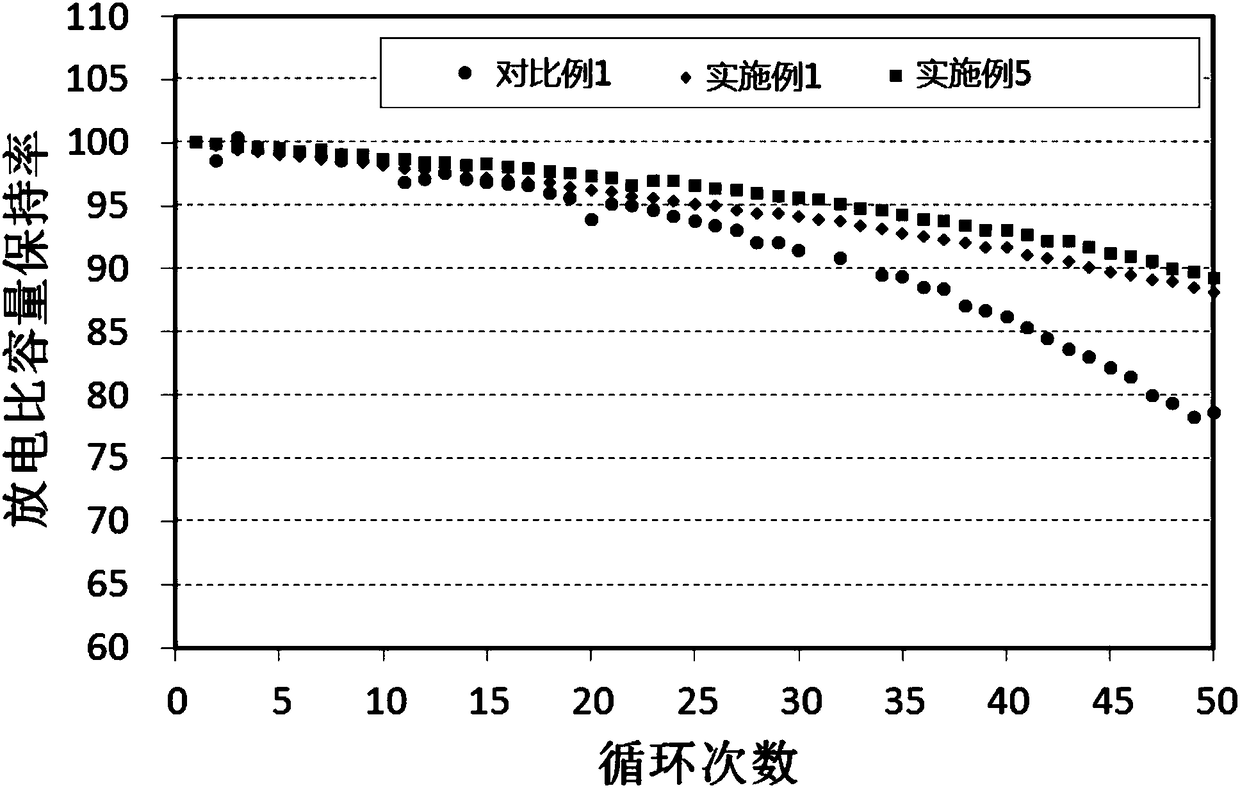

A high-nickel positive electrode material and a preparation method thereof

InactiveCN109148875AEasy to handleReduce residual alkali contentCell electrodesSecondary cellsSolventMaterials science

The invention discloses a high-nickel positive electrode material and a preparation method thereof. The method comprises weighing the positive electrode material, adding a solvent and stirring; solid-liquid separation is carried out to obtain the washed cathode material. Then the washed cathode material is dried and sintered twice to obtain the cathode material with low residual alkali content. Ahigh-nickel cathode material is prepared by washing or pickling the high-nickel cathode material with water or acid at a set time and temperature, strictly controlling conditions such as time and solid-liquid ratio, and the like, so that the high-nickel cathode material has low residual alkali content and good discharge performance. The preparation method has simple and controllable conditions, has low requirements for production equipment, and is a practical method capable of popularization and application.

Owner:北京盟固利新材料科技有限公司

Chemical crosslinking low-smoke and halogen-free flame-retardant polyolefin cable material and preparation method thereof

ActiveCN107857932AHigh temperature resistanceHigh decomposition temperaturePlastic/resin/waxes insulatorsElastomerLow smoke zero halogen

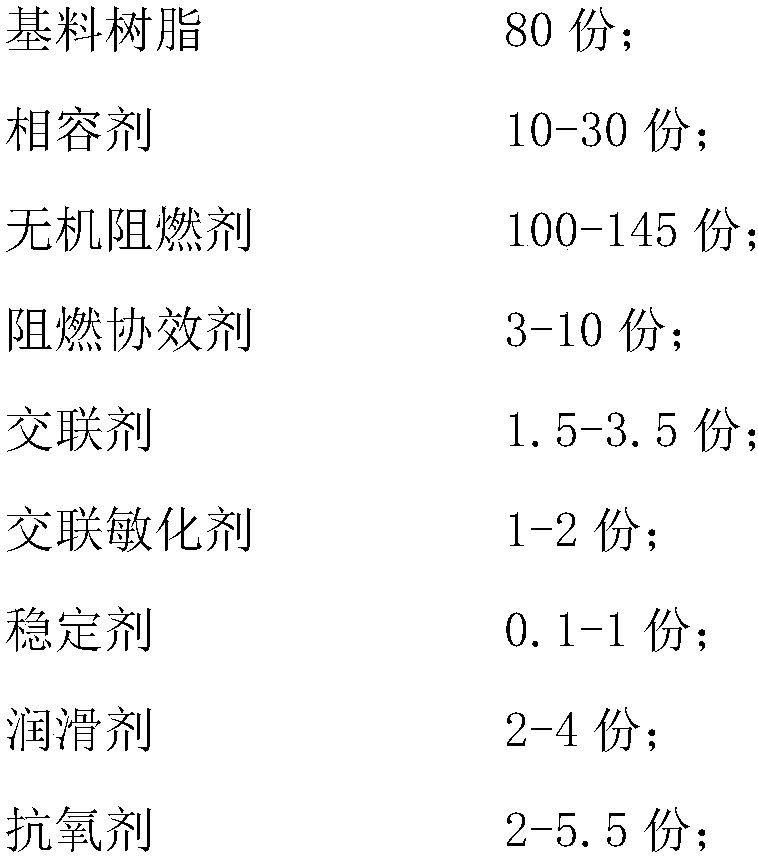

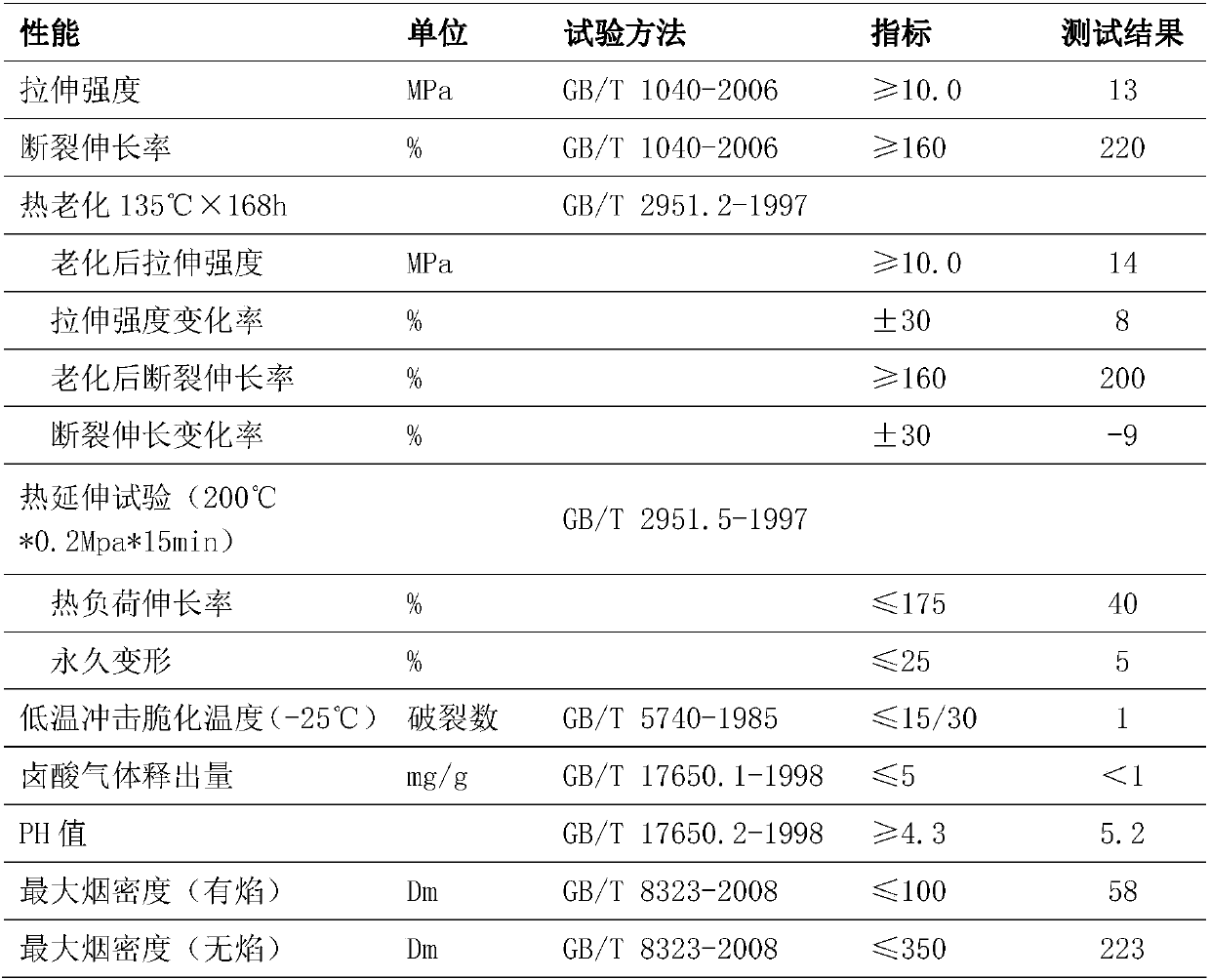

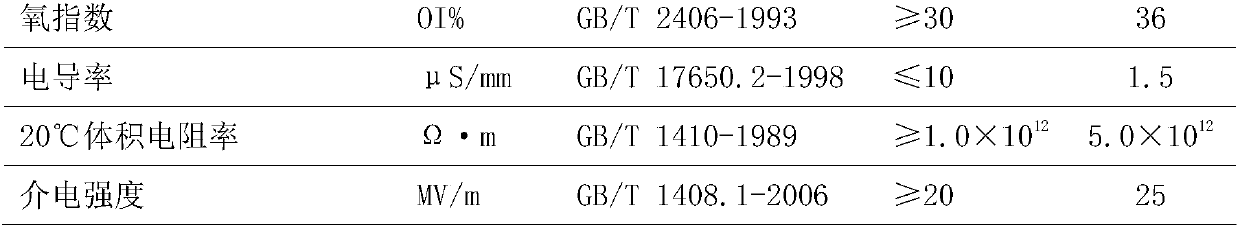

The invention relates to a chemical crosslinking low-smoke and halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The preparation method comprises the following steps of firstly, weighing the following raw materials in parts by weight: 80 parts of base resin, 10 to 30 parts of compatilizer, 100 to 145 parts of inorganic flame-retardant agent, 3 to 10 parts offlame-retardant synergist, 1.5 to 3.5 parts of crosslinking agent, 1.0 to 2.0 parts of crosslinking sensitizer, 0.1 to 1 part of stabilizer, 2 to 4 parts of lubricant, and 2.0 to 5.5 parts of antioxidant; feeding into a high-speed mixer, stirring at normal temperature, sending into a internal mixer to smelt; feeding the material into a single-screw extruder in a forced conical feeding way, extruding by a single-screw extruder, and sequentially pelletizing, cooling and packaging, so as to obtain the chemical crosslinking low-smoke and halogen-free flame-retardant polyolefin cable material, wherein the base resin is prepared from the following raw materials in parts by weight according to a proportional ratio: 40 to 70 parts of vinyl copolymer and 10 to 40 parts of polyolefin elastomer. Thechemical crosslinking low-smoke and halogen-free flame-retardant polyolefin cable material and the preparation method have the advantages that the temperature-resistant class is improved, and the pre-crosslinking is avoided; the technology is concise, and the preparation efficiency is high.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF

Electric wire and cable for high-speed train and production method

InactiveCN104183305AWith high and low temperature resistanceHalogen freeInsulated cablesMetal/alloy conductorsLow smoke zero halogenPolyolefin

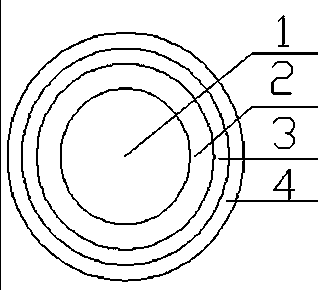

The invention discloses an electric wire and cable for a high-speed train and a production method. The electric wire and cable have the advantages that high-low temperature resistance is achieved, the structure is stable, oil resistance is good, low smoke zero halogen flame retarding is achieved, and electrical performance and mechanical physical performance are good. The electric wire and cable for the high-speed train comprise a conductor. An isolation layer is arranged outside the conductor. An inner insulation layer and an outer insulation layer are arranged outside the isolation layer in a double-layer-co-squeezing mode. The inner insulation layer is formed by 150 DEG C irradiation crosslinked polyethylene. The outer insulation layer is formed by 150 DEG C irradiation crosslinked oil-resisting low smoke halogen-free flame retardant polyolefin. The production method of the electric wire and cable for the high-speed train comprises the steps that the conductor is subjected to lapping to form the isolation layer; insulation layer squeezing is carried out, and irradiation crosslinking processing is carried out, wherein the inner insulation layer is formed by 150 DEG C irradiation crosslinked polyethylene, the outer insulation layer is formed by 150 DEG C irradiation crosslinked oil-resisting low smoke halogen-free flame retardant polyolefin, and insulation materials of the inner insulation layer and the outer insulation layer are subjected to modification processing by radiation crosslinking.

Owner:SHANGDONG HUALING CABLE

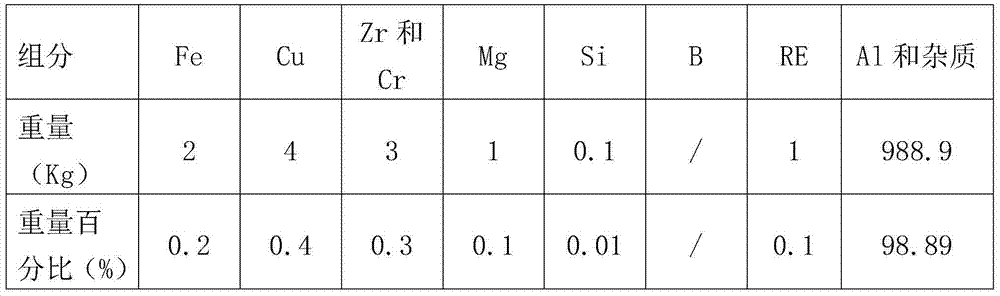

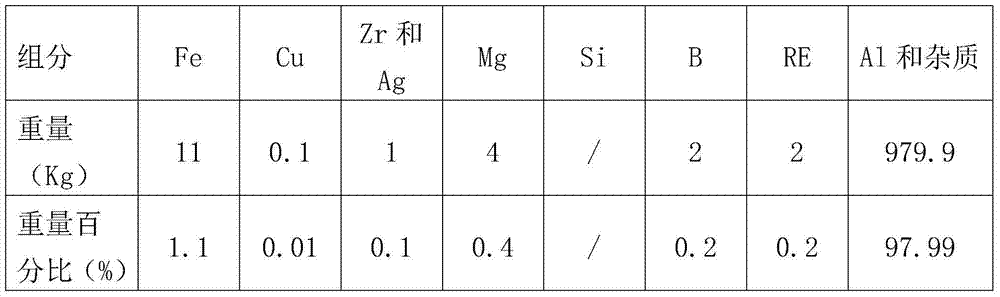

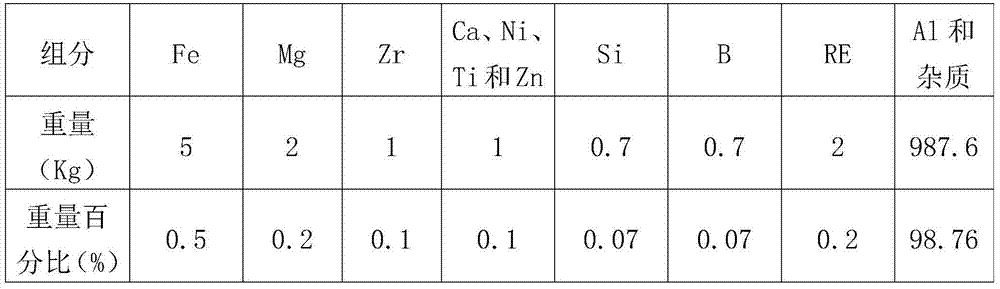

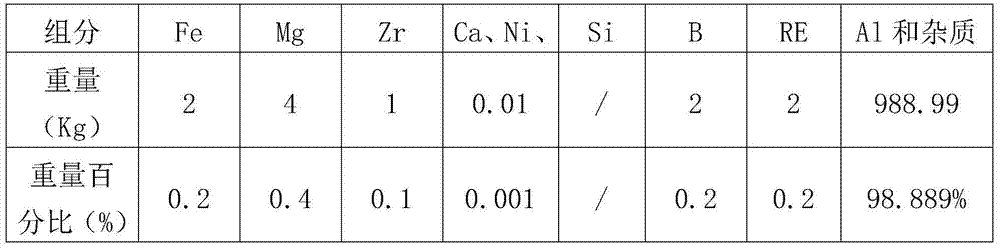

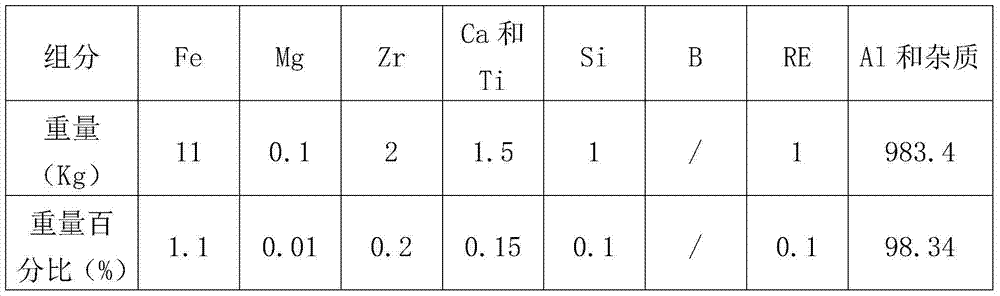

Al-Fe-Mg-Zr aluminum alloy used for coal mine cables, aluminum alloy cable and manufacturing method

PendingCN104299673AImprove performanceHigh mechanical strengthNon-insulated conductorsMetal/alloy conductorsCoalAluminium alloy

The invention discloses Al-Fe-Mg-Zr aluminum alloy used for coal mine cables. The Al-Fe-Mg-Zr aluminum alloy comprises 0.2 percent-1.1 percent of Fe, 0.01 percent-0.4 percent of Mg, 0.001 percent-0.2 percent of Zr, 0 percent-0.1 percent of Si, 0 percent-0.2 percent of B and the balance being Al and impurities, wherein the resistivity of the aluminum alloy is not larger than 0.028164 omega*mm<2> / m, the elongation at break is not lower than 10 percent, and ninety-degree fatigue bending frequency is larger than or equal to thirty. The aluminum alloy material is smelted, cast and rolled, so that an aluminum alloy rod is obtained; afterwards, the aluminum alloy rod is subjected to pulling, bunch stranding and softening, so that an aluminum alloy cable core is formed; next, the cable core is subjected to extruded insulation, cabling, sheath extrusion or armoring, so that an aluminum alloy cable is manufactured. The manufactured aluminum alloy cable has the advantages of being high in strength, high in electric conductivity, good in bending performance and the like, and therefore the requirements for cable performance in the field of coal mines can be satisfied.

Owner:ANHUI JOY SENSE CABLE

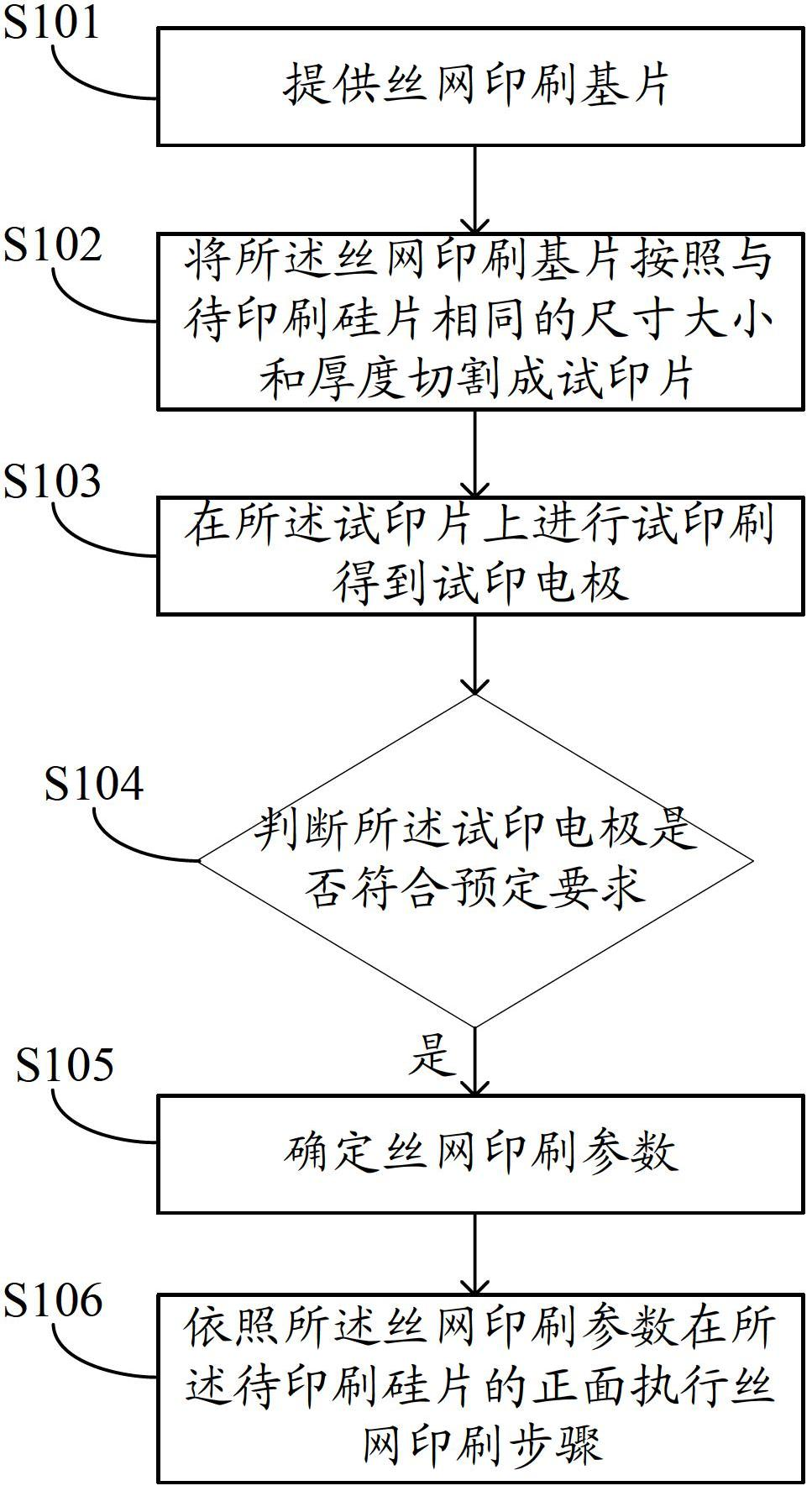

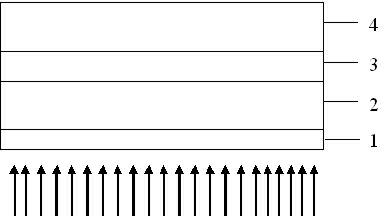

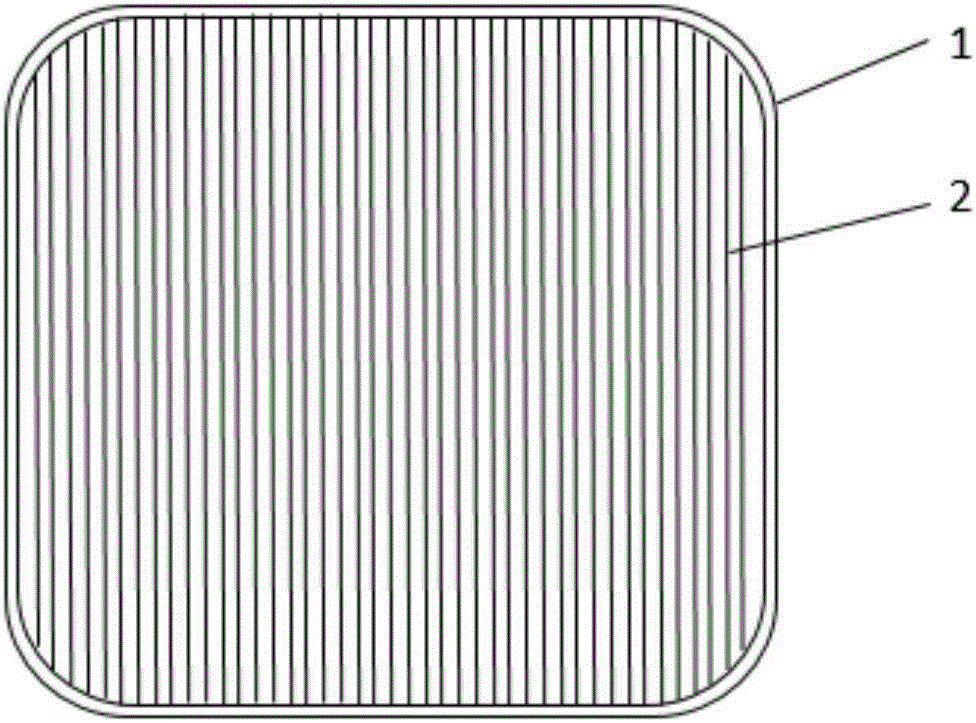

Silk-screen printing method for positive electrode of solar battery

ActiveCN102689534AAvoid electrical performance degradationImprove overall performanceOther printing apparatusSemiconductor devicesElectrical batteryElectricity

The embodiment of the invention provides a silk-screen printing method for a positive electrode of a solar battery, comprising the steps of: providing a silk-screen printing substrate; cutting the silk-screen printing substrate into a proof printing sheet according to the same size and thickness with a silicon wafer to be printed; performing proof printing on the proof printing sheet to obtain a proof printing electrode; judging whether the proof printing electrode obtained by performing proof printing on the proof printing sheet meets the predetermined demand; if so, determining a parameter which is used in the process of performing proof printing on the proof printing sheet to obtain the proof printing electrode, as a silk-screen printing parameter; and performing a silk-screen printing operation on a front side of the silicon wafer to be printed according to the silk-screen printing parameter. Compared with the prior art, the method avoids reduction of electrical properties caused by performing the silk-screen printing operation on the silicon wafer to be printed directly or performing multiple silk-screen printing operations, therefore, the overall property of the solar battery formed with the positive electrode is improved.

Owner:JETION SOLAR HLDG

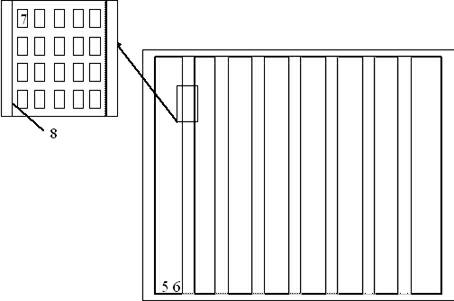

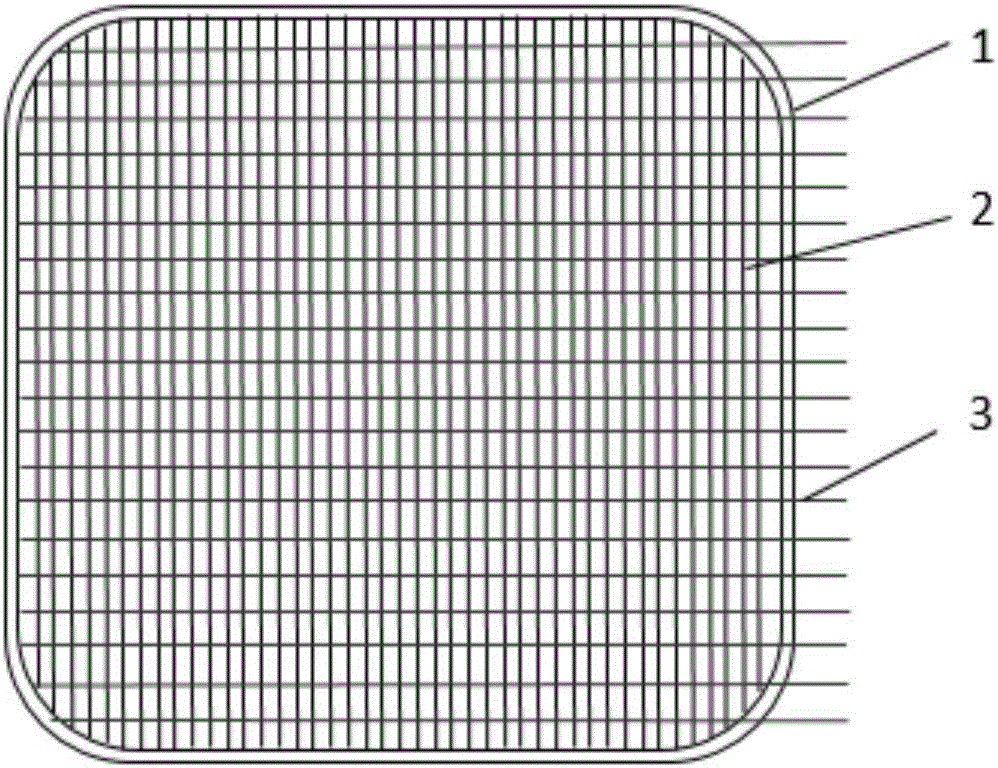

Method for realizing light transmission of thin film solar module by using vibrating mirror laser equipment

InactiveCN102237441ARealize the function of power generationRealize point-by-point scanning and scribingFinal product manufactureLaser beam welding apparatusElectrical batteryEngineering

The invention relates to a method for realizing the light transmission of a thin film solar module by using vibrating mirror laser equipment and belongs to the technical field of thin film solar batteries. The technical scheme is that: the method comprises the following steps of: depositing a front transparent conductive electrode, a thin film photoelectric conversion layer and a back conductive electrode on an insulation light transmission substrate; cutting off the three layers of thin films by adopting laser devices having different wavelengths so as to form insulation regions having different sizes and length-to-width ratios; and removing the three layers of thin films from the insulation regions by using laser scribing equipment with a vibrating mirror system, and scribing a pattern by changing an angle of a vibrating mirror and the magnitude of laser energy and switching laser on / off in real time, wherein film layers outside the insulation regions can realize a power generation function; at positions, where front glass is exposed out of, inside the insulation regions, light rays can be transmitted through the battery directly, so that a light transmission function of the module is realized. By the method, the preparation of a novel light transmission solar module is realized; the output electric performance and the light transmission performance of the thin film solar module are higher than those of the thin film solar module prepared in the prior art; and the method has the characteristics of low cost, high working efficiency, simple operation, diversified light transmission images, simple implementation and the like.

Owner:BAODING TIANWEI GRP CO LTD +1

Al-Fe-Cu-Mg-Ag aluminum alloy for coal cables, aluminum alloy cable and preparation method thereof

InactiveCN104294090AImprove performanceHigh mechanical strengthConductive materialManufacturing wire harnessesHigh intensityHigh conductivity

The invention discloses Al-Fe-Cu-Mg-Ag aluminum alloy for coal cables. The aluminum alloy comprises the following components in percentage by weight: 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.01-0.4% of Mg, 0.001-0.1% of Ag, 0-0.1% of Si, 0-0.2% of B and the balance of Al and impurities, wherein the electrical resistivity of the aluminum alloy is no greater than 0.028264ohm.mm<2> / m, the breakage elongation of the aluminum alloy is no less than 10%, and the fatigue bending times of the aluminum alloy at 90 degrees is greater than or equal to 30; the aluminum alloy material is smelted, cast and rolled, thereby obtaining an aluminum alloy rod; the aluminum alloy rod is pulled, bunch-stranded and softened, thereby obtaining an aluminum alloy cable core; the cable core is subjected to extruded insulation, cabling and extruded sheathing or armoring, thereby obtaining an aluminum ally cable. The prepared aluminum ally cable has the characteristics of high strength, high conductivity, good bending property and the like, and the requirements of the coal field on the property of cables can be met.

Owner:林泽民

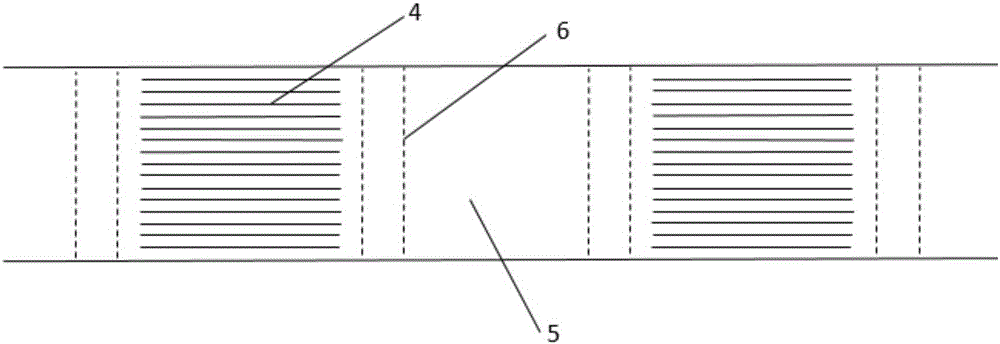

Laser marking equipment for silicon-based thin-film solar cell

ActiveCN103521926AReduce usageLow costFinal product manufactureWelding/soldering/cutting articlesBeam splitterEngineering

The invention relates to laser marking equipment for a silicon-based thin-film solar cell, and belongs to the technical field of solar cell equipment. The laser marking equipment solves the technical problem that according to existing laser marking equipment, low cost and complicated graphs cannot be achieved simultaneously. The laser marking equipment comprises an optical system and a substrate work table, wherein the optical system and the substrate work table are installed on a support. The optical system mainly comprises laser devices, beam expanders and focus lenses, wherein the output end of each laser device is provided with one beam expander. The optical system further comprises beam splitters and galvanometers, wherein the beam splitters and the galvanometers are sequentially installed between the corresponding beam expanders and the corresponding focus lenses, laser emitted by the laser devices enters the beam splitters through the beam expanders to be divided into reflective light and refracted light, the reflective light and the refracted light enter the corresponding galvanometer and the corresponding focus lens respectively to form parallel laser beams, and a film layer is marked. According to the laser marking equipment, a large-size cell with complicated graphs can be marked, the use quantity of the laser devices can be reduced, equipment cost is effectively reduced, and production efficiency is improved.

Owner:SHEN ZHEN TRONY SCI & TECH DEV CO LTD

Preparation method of polyanion cathode material of lithium ion battery

The invention relates to a preparation method of a polyanion cathode material of a lithium ion battery. The cathode material is a polyanion compound expressed by LiMx(XOy)z (Formula I). The preparation method comprises the following steps: uniformly stirring and mixing a lithium source, an M source, an X source and an electric conduction additive in a solvent under the protection of an inert atmosphere to obtain slurry; drying the slurry under the protection of an inert atmosphere to obtain a precursor material; sintering the precursor material under the protection of an inert atmosphere to obtain the polyanion compound; and crushing the obtained polyanion compound under the protection of an inert atmosphere. The overall processes of the preparation method are finished under the protection of the inert atmosphere, thus the oxidation of the prepared polyanion compound in the preparation process is effectively prevented, the generation of a mixed phase of the material is inhibited, and the declining of the electrical property of the material is avoided.

Owner:北京宏福源科技有限公司

Lithium ion battery maximum electrolyte injection volume quick evaluation method

ActiveCN106595823AEasy to operateReduced electrical performanceWeighing apparatus for materials with special property/formInjection volumeElectricity

The invention discloses a lithium ion battery maximum electrolyte injection volume quick evaluation method. The electrolyte containing rate of a positive plate, the electrolyte containing rate of a negative plate and the electrolyte containing rate of a diaphragm are measured firstly; the volume of the electrolyte absorbed by each is calculated according to the electrolyte containing rate; the spare volume Vspare of the inner cavity of a battery shell is measured; the correction coefficient eta of the volume of the void for containing the electrolyte of a cathode mix is then detected; and the total electrolyte injection volume m<electrolyte>=( Vspare+Vvoid*eta)*rho of the battery is finally calculated. The evaluation method is simple to operate, the result is accurate, the debugging time is shortened, influences on the device precision and the production by frequent device debugging are avoided, falling of the electric performance of the battery caused by insufficient electrolyte injection volume can be avoided, and accurate design parameters are provided for the electrolyte injection volume of the battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

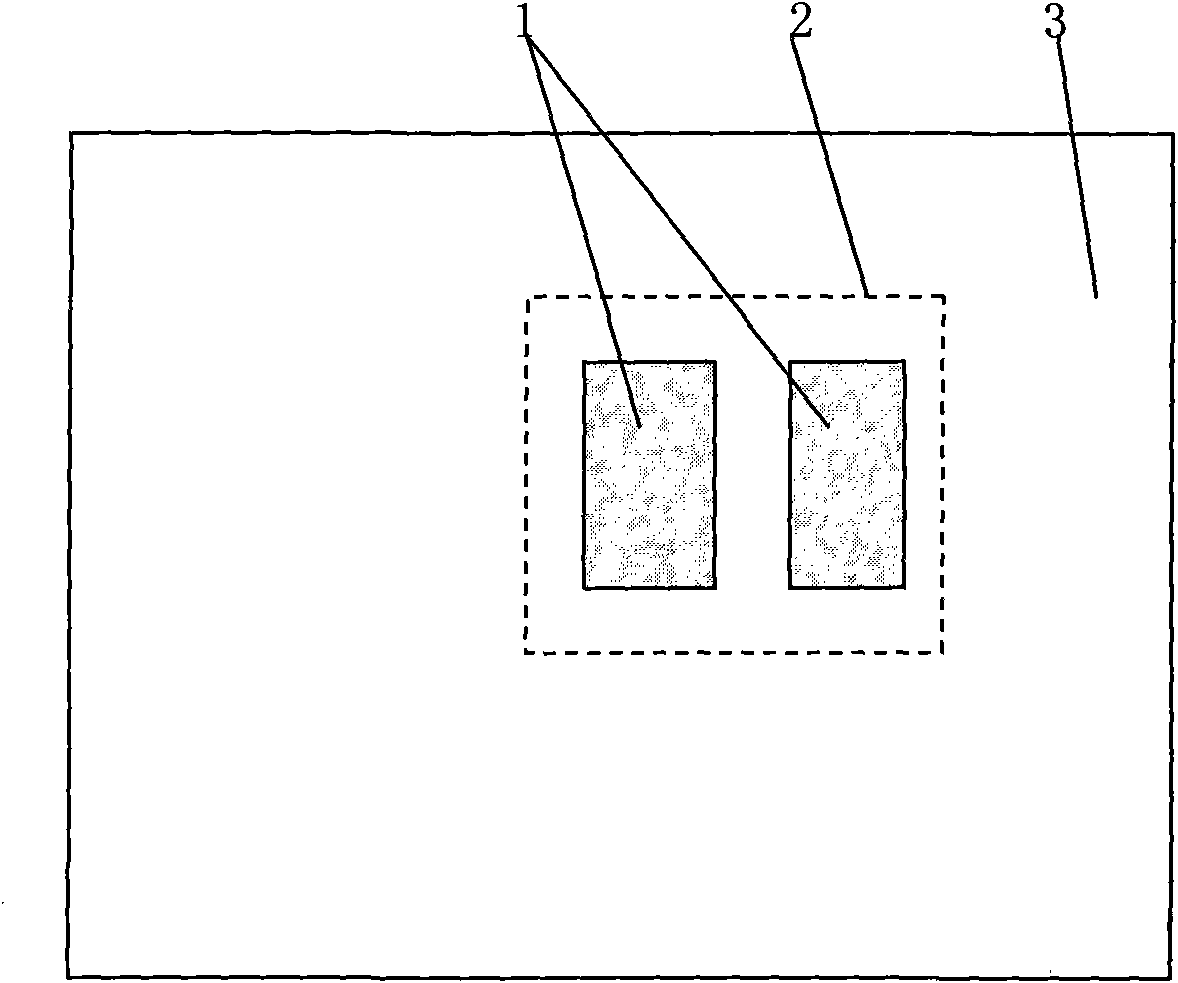

Method for packaging double-faced crystalline silicon heterojunction main-grid-free solar cell piece

InactiveCN106847968ANo secondary printing requiredReduce silver usagePhotovoltaic energy generationSemiconductor devicesHeterojunctionSilver paste

The invention relates to a packaging method for a double-sided HIT busbar-free battery sheet, which mainly includes: laying a 10-80 μm-diameter plated battery on a self-made or outsourced busbar-free HIT battery sheet with once-printed thin grid lines. Copper wire with metal anti-oxidation layer; when the height of the thin grid wire is greater than the diameter of the copper wire, first lay the copper wire in the direction perpendicular to the thin grid wire, and the contact point between the copper wire and the grid wire is a node, and the heat and pressure sensitive After the glue or photosensitive glue is covered on the copper wire and the battery sheet along the direction of the copper wire, the colloid is cured; when the height of the thin grid line is less than or equal to the diameter of the copper wire, a circular pattern is pre-dotted at the junction of the copper wire and the grid line The cured conductive paste or conductive tape is pasted, copper wire is laid, and hot-pressed and cured below 200°C; then the copper wire and the cell are hot-pressed to complete the packaging of the double-sided busbar-free HIT cell. The invention greatly reduces the amount of silver paste used, reduces production costs, and solves the problem of poor weldability of batteries.

Owner:EAST CHINA UNIV OF SCI & TECH

Sn/Au eutectic based chip partial vacuum packaging method of resonance type pressure sensor

ActiveCN101819076ALiquidGuaranteed uniformityForce measurement using piezo-electric devicesResonanceAlloy

The invention relates to a Sn-Au eutectic based chip partial vacuum packaging method of a resonance type pressure sensor. In the method, a Sn / Au layer is deposited by electroplating and sputtering, isothermy solidification and eutectic reaction of gold-tin alloy when heated are used to realize partial vacuum packaging, and the yield of the partial vacuum packaging can be raised to 99%. Compared with conventional tin-lead eutectic sintering and silicon glass partial vacuum packaging methods, the method has the advantages of excellent thickness uniformity of the Sn / Au layer, improved service life of a sensor chip and the like and is a novel chip partial vacuum packaging method. The invention is applicable to the field of a movable part partial vacuum packaging of a microelectro mechanical system (MEMS).

Owner:NO 24 RES INST OF CETC

Al-Fe-Cu-Mg aluminum alloy and electric wire made of the same

PendingCN103730185AHigh mechanical strengthImprove tensile propertiesMetal/alloy conductorsCable/conductor manufactureStress concentrationElectrical conductor

The invention discloses Al-Fe-Cu-Mg aluminum alloy and an electric wire made of the same. The aluminum alloy comprises the components of 0.2-0.4wt% of Fe, 0.3-0.5wt% of Cu and Mg and the allowance of Al and impurities. The specific resistance of the aluminum alloy is not larger than 0.02800 omega*mm<2> / m, the breaking elongation is not lower than 10%, and the average creep speed within 1-100 hours is 5 * 10-2(% / h) or lower under the condition of the temperature of 120 DEG C and the pressure stress of 120 MPa. Stress concentration cannot happen during a cold-drawing micro-pulling machining process so that an aluminum alloy rod cannot be broken, and after wire drawing, the diameter of an aluminum alloy conductor single wire can reach 0.3mm.

Owner:ANHUI JOY SENSE CABLE

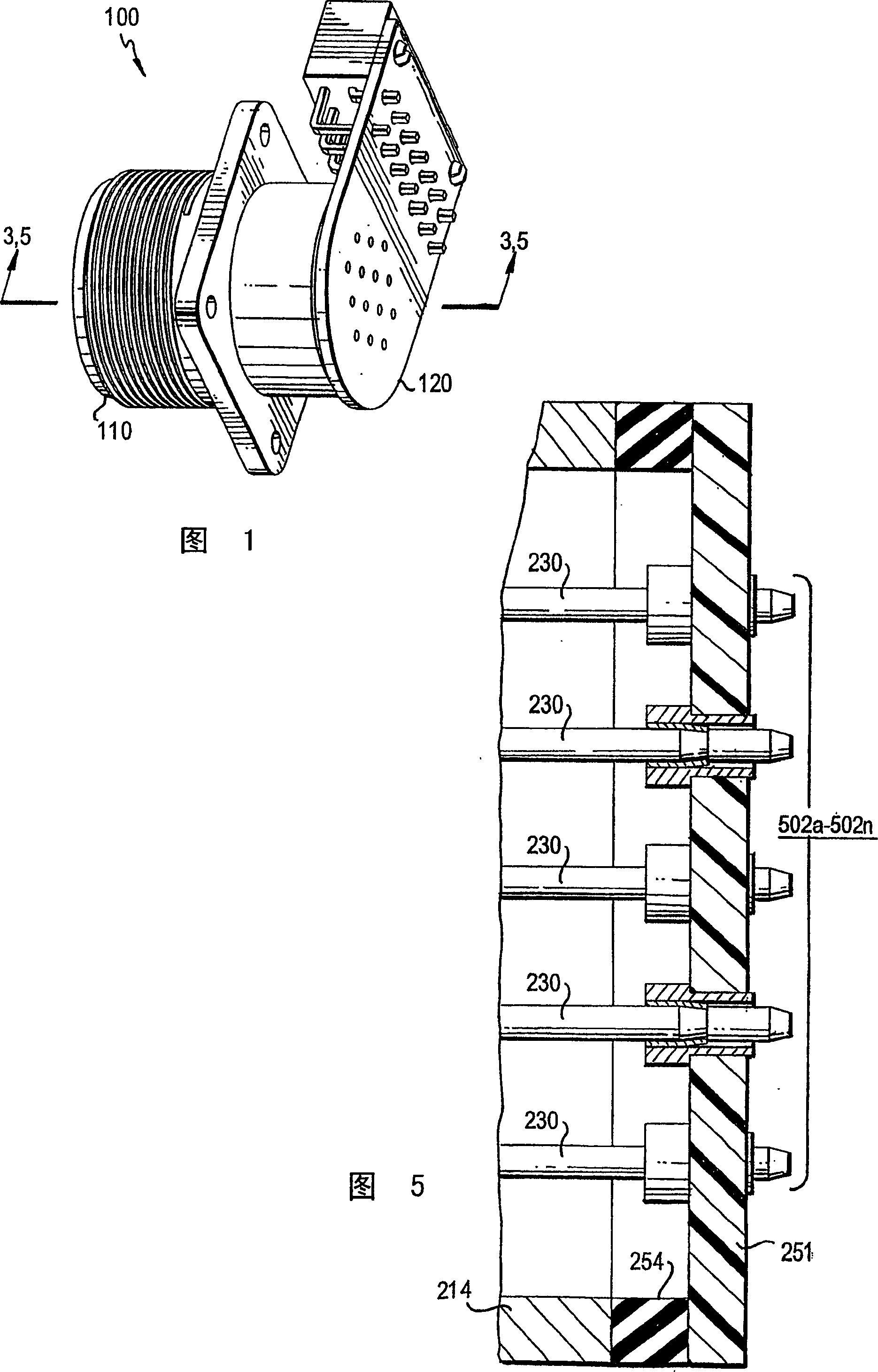

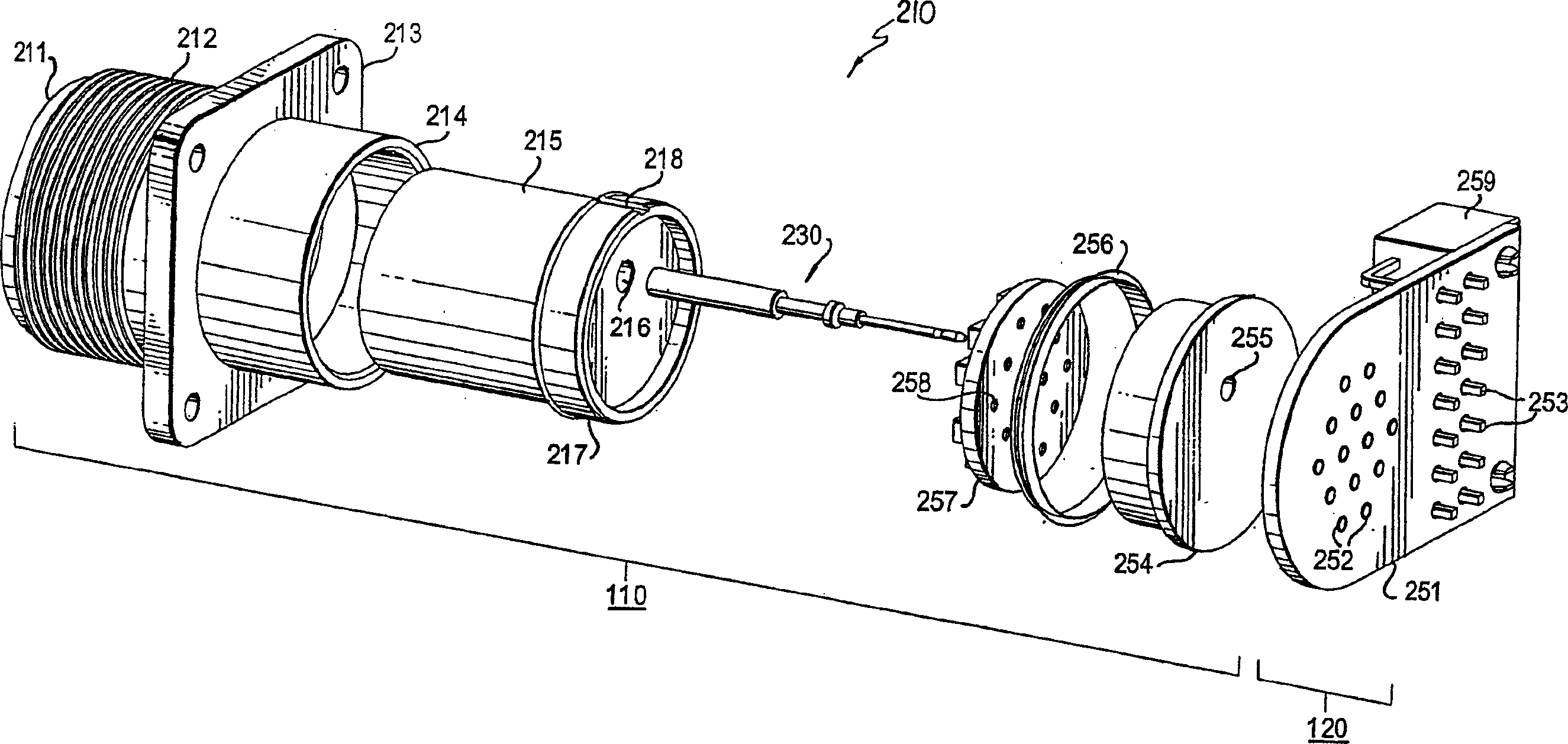

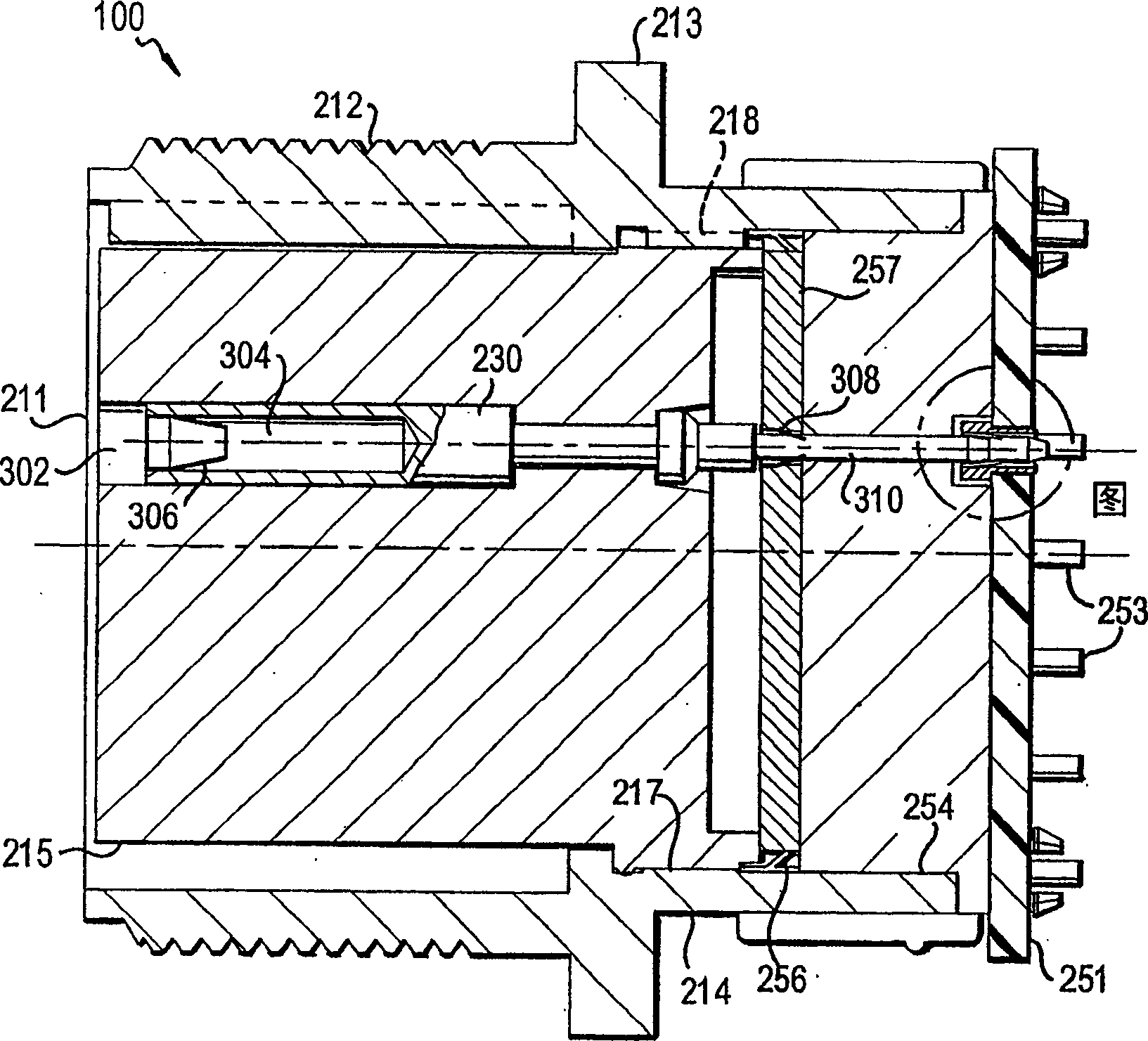

Circuit board and socket assembly

InactiveCN1842941AImprove conductivityImprove retentionCoupling device detailsFixed connectionsElectrical conductorSoldering

An interconnect device and electrical signal filtering connector is disclosed that does not require soldering. The interconnect device is an electrical contact that has a proximate or forward end with a cavity for receiving an electrical conductor of a first plug, and a distal or rear end, also called a tail, formed with a circumferentially-arranged undercut that engages the ends of one or more electrically conducting flanges that extend radially inward in a contact receptacle of a printed circuit board. The connector can be a male plug or female receptacle, including a receptacle with front and rear shells and an insert slidably engaged inside the shells, the receptacle adaptable for receiving a round, 14-conductor plug. The printed circuit board assembly includes a printed circuit board with one or more contact receptacles.

Owner:AMPHENOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com