Preparation method of pore-filing type proton exchange membrane taking double ether crosslinked porous polybenzimidazole imide as base

A technology of benzimidazole imide membrane and proton exchange membrane is applied in the fields of functional polymer materials and electrochemistry, which can solve problems such as poor resistance to free radical oxidation, improve mechanical strength and poor dimensional stability, and improve fuel permeability. The effect of high, excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

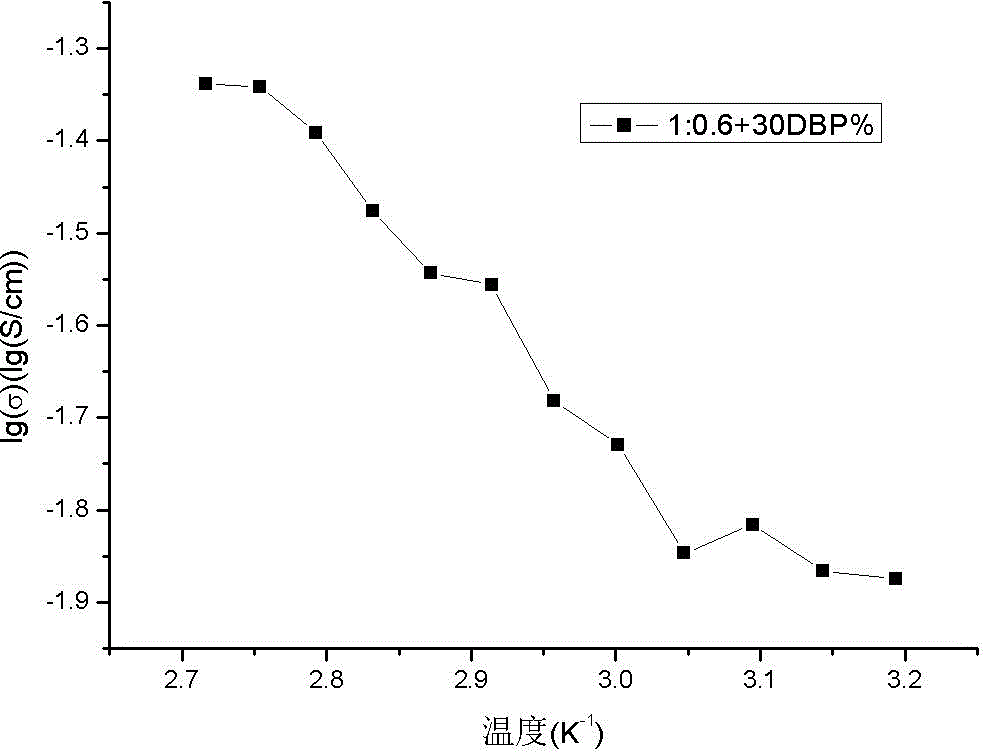

[0021] The CPIBI-20- 50-Nafion preparation.

[0022] (1) The preparation process of polybenzimidazole imide PIBI is as follows. Add 3mmol (0.6796g, 99%) 2-(4-aminophenyl)-5aminobenzimidazole (APBIA ) and 10mL of N-methylpyrrolidone (NMP), connect the gas inlet, drying tube, gas outlet, reflux condenser and mechanical stirrer, feed inert gas and start stirring, when APBIA is completely dissolved, add 3mmol (1.3599g , 98%) 4,4'-hexafluoroisopropylidene-phthalic anhydride (6FDA) and 0.78mL of catalyst isoquinoline, after the reactants are completely dissolved, heat up to 80°C and keep the temperature for 4h , then raise the temperature to 215°C to reflux the solvent NMP, and react for 20 hours. After the reaction, cool down to about 100°C. Drying in an oven at 60°C to obtain polybenzimidazole imide PIBI;

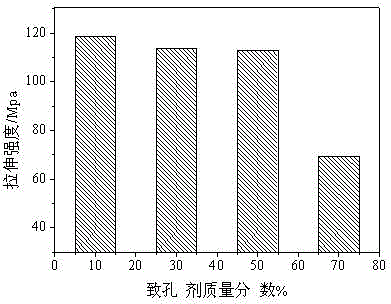

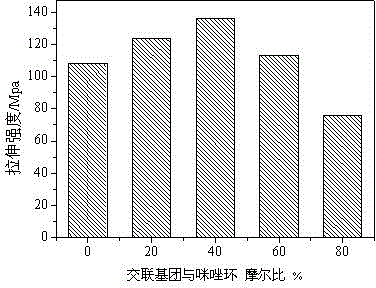

[0023] (2) The preparation process of the cross-linked polybenzimidazole imide film substrate CPIBI-20-50 is as follows. Weigh 0.3g of PIBI obtained in (1), dissolve it in 1...

Embodiment 2

[0026] The CPIBI-40- 50-Nafion preparation.

[0027] (1) The preparation process of polybenzimidazole imide PIBI is the same as step (1) in Example 1;

[0028] (2) The preparation process of the cross-linked polybenzimidazole imide film substrate CPIBI-40-50, except that the mass of TMBP was changed to 0.034g, other steps and the type and quality of the reagents added were the same as those in Example 1 Step (2) is the same;

[0029] (3) The preparation process of Nafion pore-filling membrane, except that the basement membrane was changed to CPIBI-40-50, other steps and the types and quality of reagents added were the same as step (3) in Example 1.

Embodiment 3

[0031] The CPIBI-60- 50-Nafion preparation.

[0032] (1) The preparation process of polybenzimidazole imide PIBI is the same as step (1) in Example 1;

[0033] (2) In the preparation process of the cross-linked polybenzimidazolium imide film substrate CPIBI-60-50, except that the mass of TMBP was changed to 0.051g, other steps and the types and qualities of reagents added were the same as in Example 1 Step (2) is the same;

[0034] (3) The preparation process of Nafion pore-filling membrane, except that the basement membrane was changed to CPIBI-60-50, other steps and the types and quality of reagents added were the same as step (3) in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com