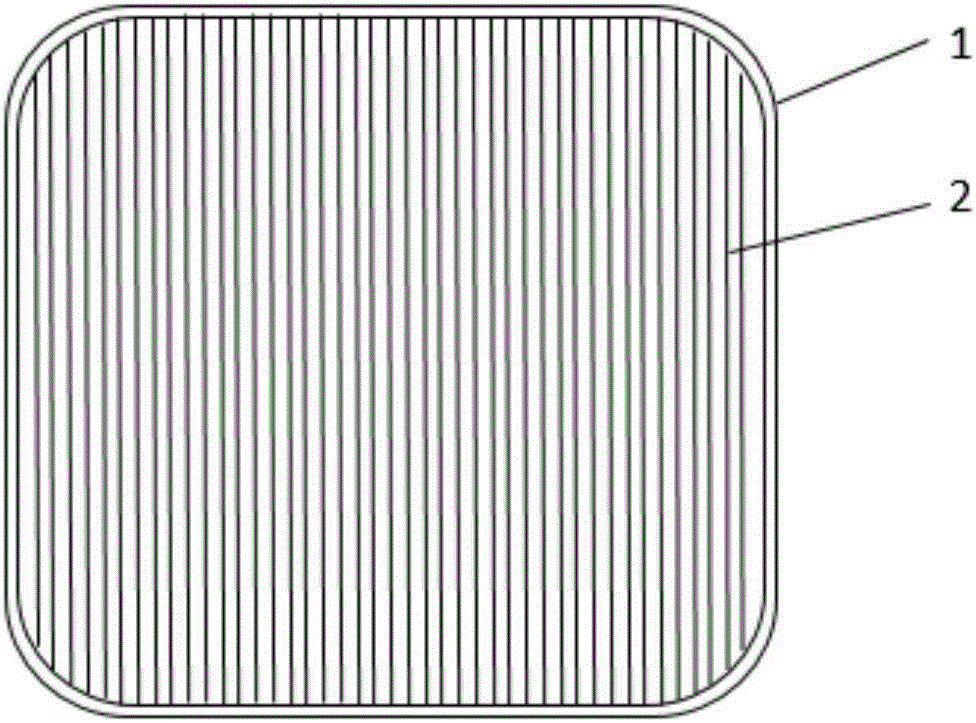

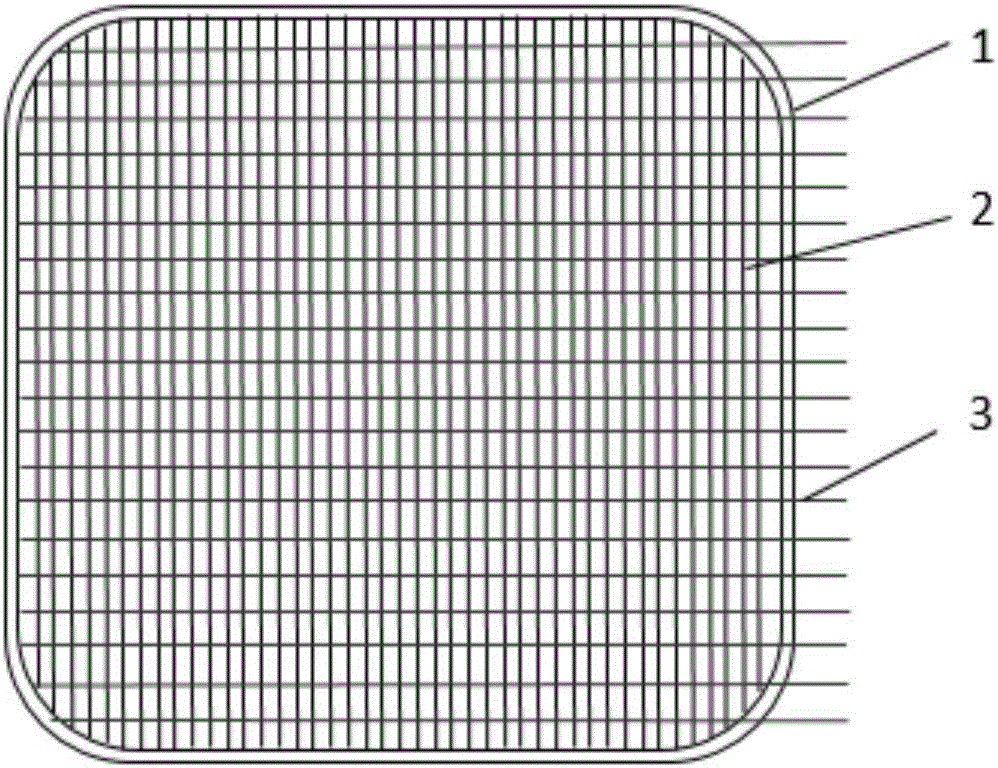

Method for packaging double-faced crystalline silicon heterojunction main-grid-free solar cell piece

A technology of solar cell sheet and packaging method, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., and can solve the problems of poor weldability of batteries and reduce the amount of silver paste used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

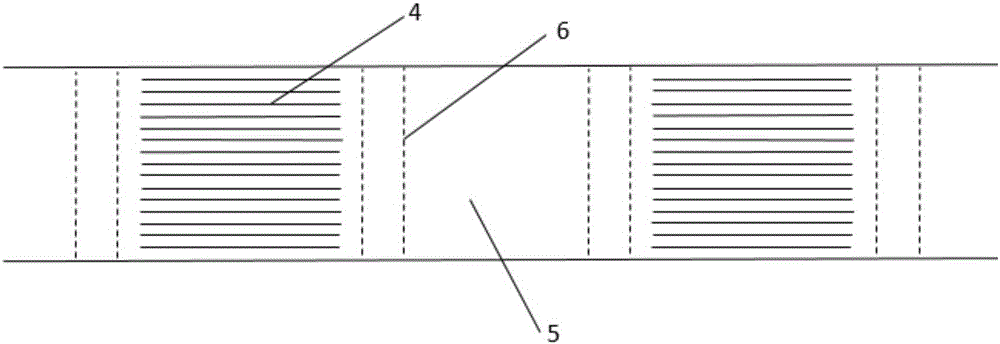

[0044] The silver paste with a silver content of 90% was printed on the battery sheet through a single screen printing process, and then thermally cured at 200° C. to prepare fine grid lines. Copper wires are then laid in a direction perpendicular to the fine grid lines. Through the transfer printing process, the copper wire is fixed on the battery sheet. In the transfer printing method, the acrylic resin type thermal pressure-sensitive adhesive is pre-loaded on the front of the release paper, and the width of the coated glue is 1.5 times the diameter of the copper wire. The back of the release paper is as follows: image 3 As shown, there are reference lines for easy alignment. The reference line can be the width position of the cell, the position of the starting copper wire, the position of the ending copper wire, the width position of the machine, etc., and it is designed according to the actual positioning method. The adhesive release paper is in the form of a roll, whic...

Embodiment 2

[0047]The silver paste with a silver content of 80% is printed on the battery sheet by a single screen printing process, and then thermally cured at 200°C to make a fine grid line, and then continue to pass the screen printing process at the point in contact with the copper wire Print a circular contact point with low-solid conductive silver paste, and the diameter of the contact point is slightly larger than or equal to the diameter of the copper wire. The paste used is low-solid conductive paste. After printing, copper is laid

[0048] Use equipment with a smooth surface and good thermal conductivity to hot press the copper wire and battery sheet at 200°C to solidify the silver paste.

[0049] Table 1 The material parameters and test results of a single SHJ cell are compared in the following table:

[0050]

[0051] Table 2 The comparison of the electrical performance test results of SHJ battery components is shown in the following table:

[0052] Program Vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com