Solar cell fabrication method and solar cell

A technology of solar cells and manufacturing methods, which is applied to circuits, electrical components, photovoltaic power generation, etc., can solve the problems of solar cell performance degradation and increase, and achieve the effect of reducing the amount of silver used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

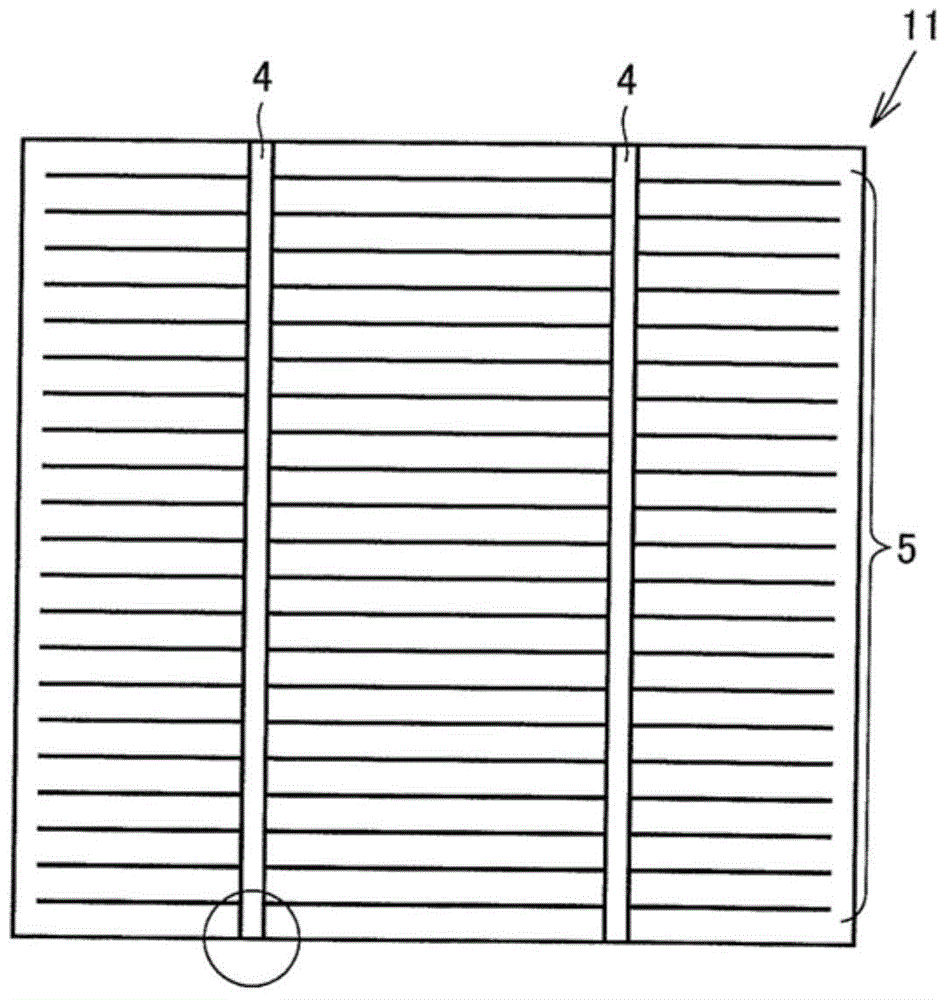

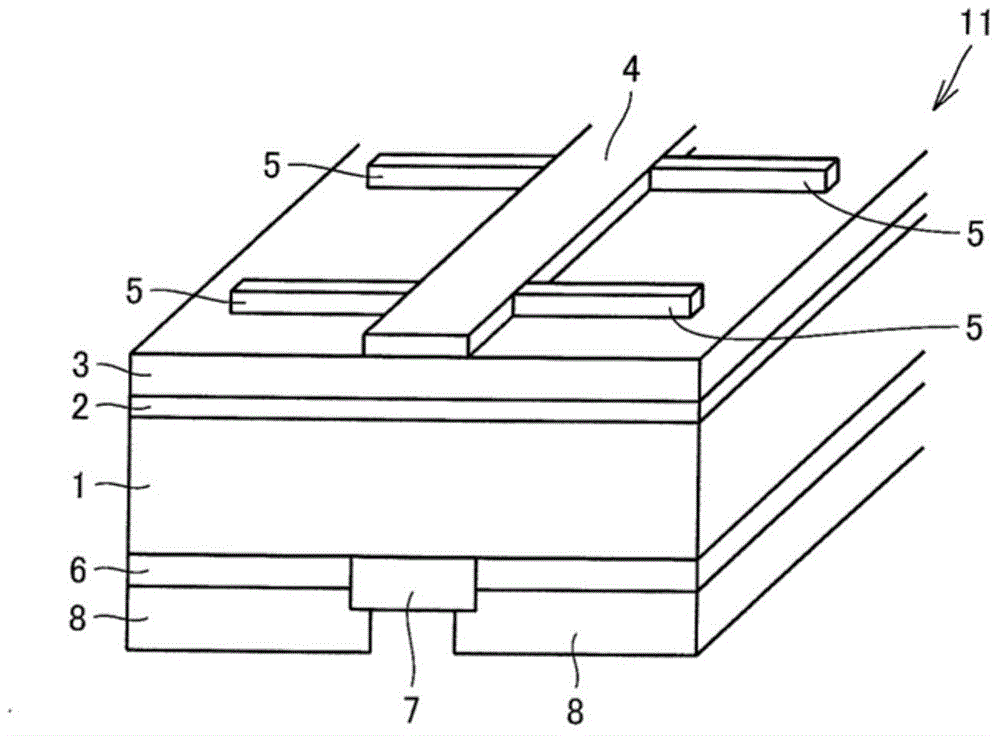

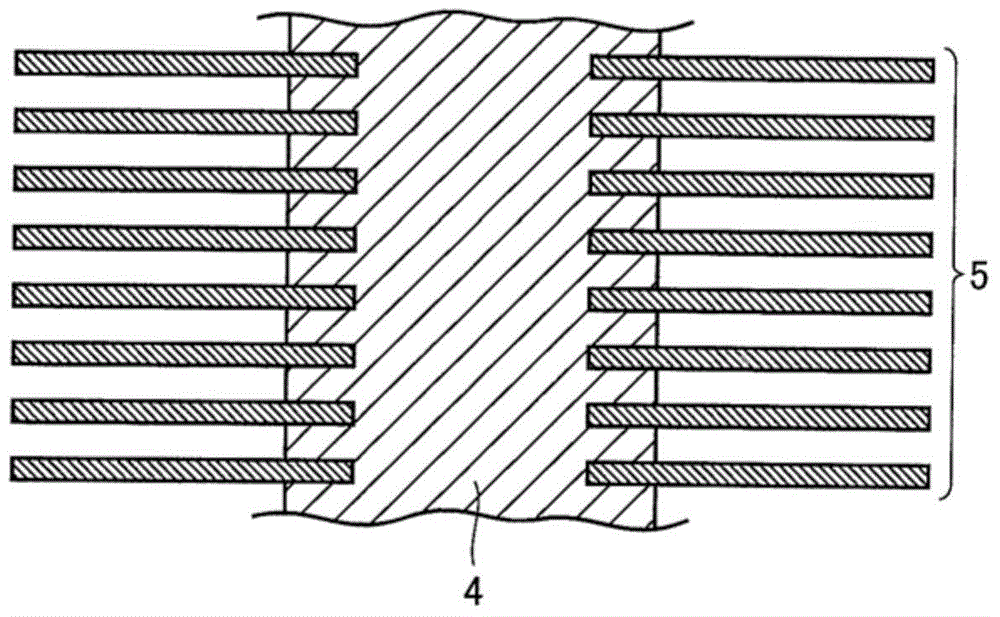

[0050] Next, embodiments of the present invention will be described in detail.

[0051] In the following examples, the same silver paste was used to form the sub-gate electrode 5 , and the silver paste used to form the main gate electrode 4 was variously changed, and its characteristics were investigated. The silver paste used to form the sub-gate electrode 5 was used as a reference silver paste. In addition, all the silver pastes used in the following examples have burn-through properties.

[0052]

[0053] In the first to fourth examples, the solar cells of the first to fourth examples were produced using silver pastes having different silver content and glass frit content in the silver paste used for forming the busbar electrode 4 . Also, in the first to fourth embodiments, as described above, the sub-gate electrode 5 is formed using the reference silver paste. In addition, as a reference, a reference solar cell in which both the main grid electrode 4 and the sub-gate e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com