Chemical crosslinking low-smoke and halogen-free flame-retardant polyolefin cable material and preparation method thereof

A polyolefin cable material and chemical cross-linking technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as complex production processes, and achieve the effect of improving the temperature resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

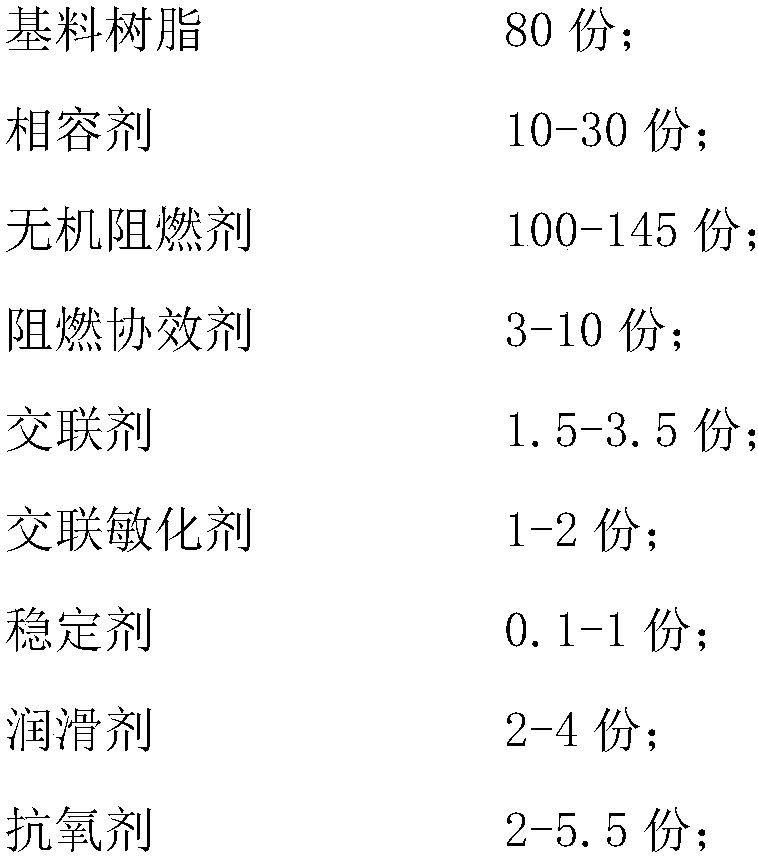

[0036] The formula is as follows:

[0037]The mass % content of methyl acrylate monomer is 24% and 40 parts of ethylene-methyl acrylate copolymers whose DSC melting point is less than 85°C, 40 parts of ethylene-butylene copolymer elastomers whose DSC melting point is less than 85°C, maleic anhydride Branched ethylene-octene copolymer elastomer 20 parts, magnesium hydroxide 90 parts, calcium magnesium carbonate 10 parts, zinc borate 3 parts, 2,5-dimethyl-2,5-bis(tert-butylperoxy)- 3.5 parts of 3-hexyne, 1.5 parts of triallyl isocyanurate, 1 part of p-benzoquinone, 3 parts of silicone, 1 part of long-chain alcohol polyester, 4,4'-thiobis(6-tert Butyl-3-methylphenol) 1.5 parts, 1,3,5, three (3,5-di-tert-butyl, 4-hydroxybenzyl) s-triazine 2 parts, bis(3,5-di-tert-butyl 2 parts of base-4-hydroxyphenylpropionoyl) hydrazine.

[0038] The preparation method is as follows: Put the above-mentioned weighed materials into a high-speed mixer, stir and mix them at high speed for 2 minutes...

Embodiment 3

[0041] The formula is as follows:

[0042] The mass % content of ethyl acrylate monomer is 35% and 70 parts of ethylene-ethyl acrylate copolymer whose DSC melting point is less than 85°C, 10 parts of ethylene-hexene copolymer elastomer with DSC melting point less than 85°C, grafted with maleic anhydride 30 parts of ethylene-methyl acrylate copolymer, 110 parts of magnesium hydroxide, 35 parts of calcium magnesium carbonate, 5 parts of carbon nanotubes, 2,5-dimethyl-2,5-bis(tert-butylperoxy)-3 - 1.5 parts of hexyne, 2 parts of triallyl isocyanurate, 0.1 part of tetramethylbenzoquinone, 1 part of long-chain alcohol polyester, 3 parts of polyhydroxy magnesium stearate, 4,4'-thio 1 part of bis(6-tert-butyl-3-methylphenol), 1 part of tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester, bis( 1 part of 3,5-di-tert-butyl-4-hydroxyphenylpropionyl)hydrazine.

[0043] The preparation method is as follows: put the above-mentioned weighed materials into a ...

Embodiment 4

[0046] The formula is as follows:

[0047] The mass % content of butyl acrylate monomer is 30% and 60 parts of ethylene-butyl acrylate copolymers whose DSC melting point is less than 85°C, 20 parts of ethylene-butylene copolymer elastomers whose DSC melting point is less than 85°C, maleic anhydride 15 parts of ethylene propylene rubber, 75 parts of magnesium hydroxide, 50 parts of calcium magnesium carbonate, 8 parts of aluminum hypophosphite, 2,5-dimethyl-2,5-bis(tert-butylperoxy)-3-hexyne 3.5 parts, 1.5 parts of triallyl isocyanurate, 0.8 parts of 2-methyl-2-nitrosomethane, 2 parts of silicone, 1 part of long-chain alcohol polyester, three (2,4-di-tert 2 parts of butylphenyl) phosphite, 1 part of 1,3,5, tris(3,5-di-tert-butyl, 4-hydroxybenzyl)-s-triazine, 1 part of tetrakis[β-(3',5' -2.3 parts of di-tert-butyl-4'-hydroxyphenyl)propionic acid]pentaerythritol ester.

[0048] The preparation method is as follows: put the above-mentioned weighed materials into a high-speed mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com