Laser marking equipment for silicon-based thin-film solar cell

A solar cell and laser scribing technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that laser scribing equipment cannot take into account the cost and scribing complex graphics at the same time, affecting the electrical performance of solar cells, etc. Achieve the effect of avoiding being affected by the external environment, reducing equipment costs, and reducing maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

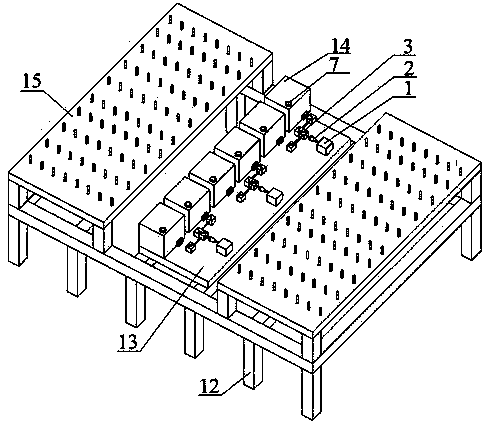

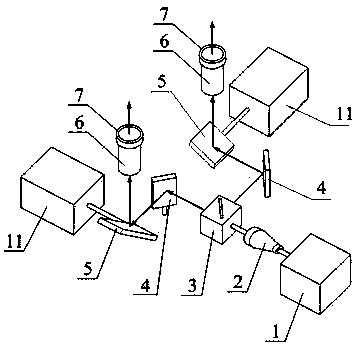

[0027] See figure 1 and figure 2 The laser scribing equipment of this embodiment includes a laser 1, a beam expander 2, a beam splitter 3, a Z-axis galvanometer 4, an X-axis galvanometer 5, a focusing mirror 6, and a protective mirror 7. A beam of laser light emitted by the laser 1 passes through After the beam expander 2, the beam splitter 3 divides the refracted light in the X-axis and the reflected light in the Y-axis. The refracted light is polarized by the Z-axis galvanometer 4 and then passes through the X-axis galvanometer 5, so that the laser goes upward and then passes through the focusing mirror 6 Arrive at the surface of the film layer of the substrate for marking, and at the same time another beam of reflected light is polarized by another Z-axis galvanometer 4 and then passes through the X-axis galvanometer 5, so that the laser goes upward and then reaches the surface of the substrate film layer through the focusing mirror 6 , for scribing, and two laser beams a...

Embodiment 2

[0032] See figure 1 and figure 2 , the laser scribing equipment of this embodiment includes a laser 1, a beam expander mirror 2, a beam splitter 3, a Z-axis vibrating mirror 4, an X-axis vibrating mirror 5, a focusing mirror 6, a protective mirror 7, a Z-axis vibrating mirror 4 and a beam splitting mirror There is also a light blocking device 9 between them. A beam of laser light emitted by the laser 1 passes through the beam expander 2 and is divided into the X-axis refracted light and the Y-axis reflected light by the beam splitter 3. The refracted light passes through the Z-axis vibrating mirror 4 After polarization, it passes through the X-axis galvanometer 5, so that the laser light goes upward and then reaches the surface of the substrate film layer through the focusing lens 6 for marking, while another beam of reflected light is polarized by another Z-axis galvanometer 4 and then passes through the X-axis The vibrating mirror 5 makes the laser upward and then reaches ...

Embodiment 3

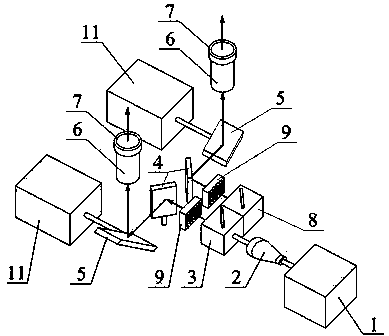

[0035] See figure 1 and Figure 4 , the laser scribing equipment of this embodiment includes a laser 1, a beam expander 2, a beam splitter 3, a Z-axis galvanometer 4, an X-axis galvanometer 5, a focusing mirror 6, a protective mirror 7 and a reflector 8, and the laser 1 emits A beam of laser light passes through the beam expander 2 and is divided into X-axis refracted light and Y-axis reflected light by the beam splitter 3. The refracted light is polarized by the Z-axis galvanometer 4 and then passes through the X-axis galvanometer 5, so that the laser goes upward and then After the focusing mirror 6 reaches the surface of the substrate film layer, it is scored, and at the same time, another beam of reflected light passes through a reflector 8 to reflect the optical path into the X axis consistent with the refracted light, and the reflected light passes through another Z axis. The mirror 4 is polarized and then passes through the X-axis vibrating mirror 5, so that the laser l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com