Circuit board and socket assembly

A technology for printed circuit boards and sockets, applied in the direction of circuits, electrical components, parts of connecting devices, etc., can solve problems such as damage to device performance, no overall satisfactory solution found, disadvantage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

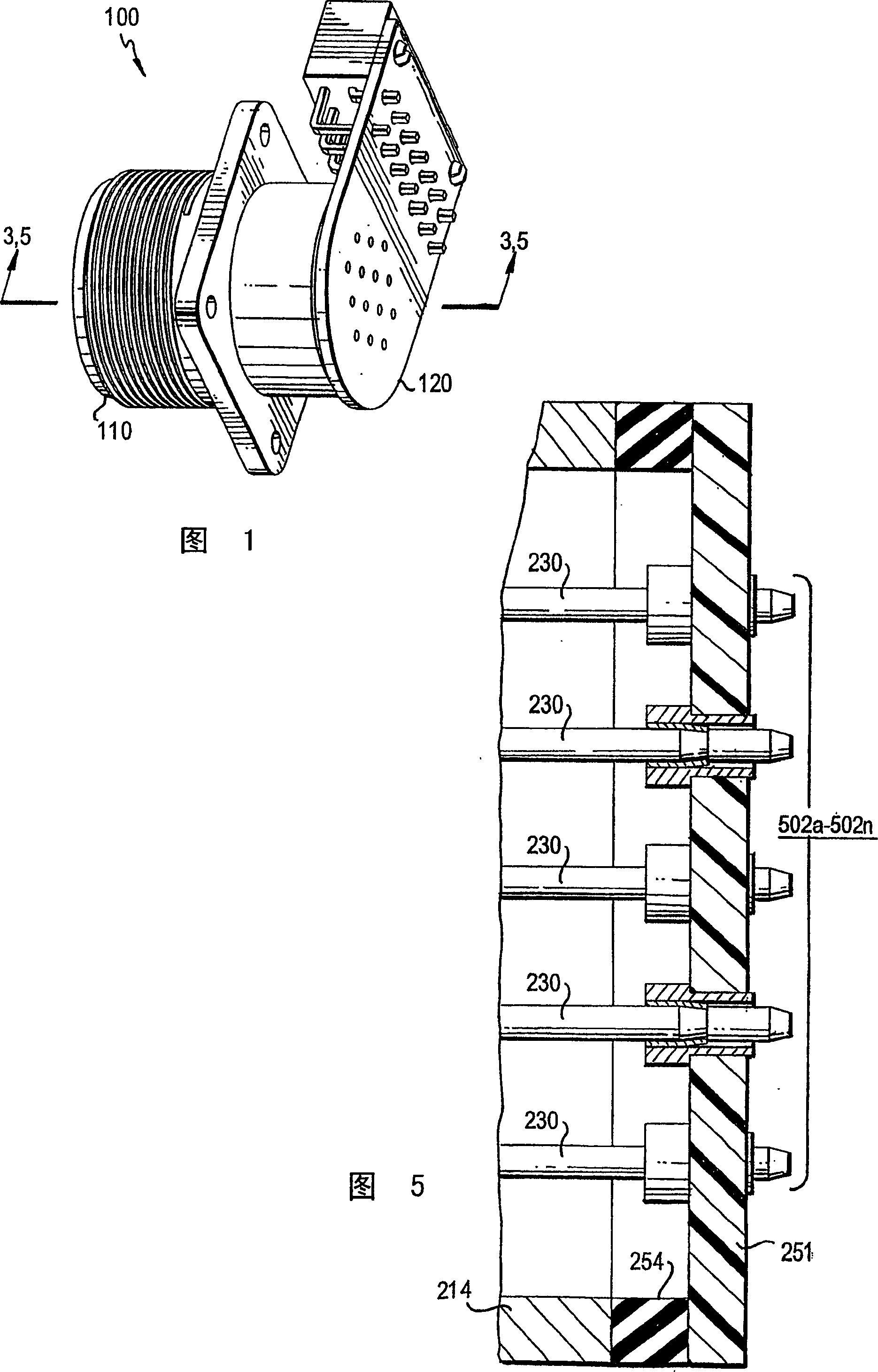

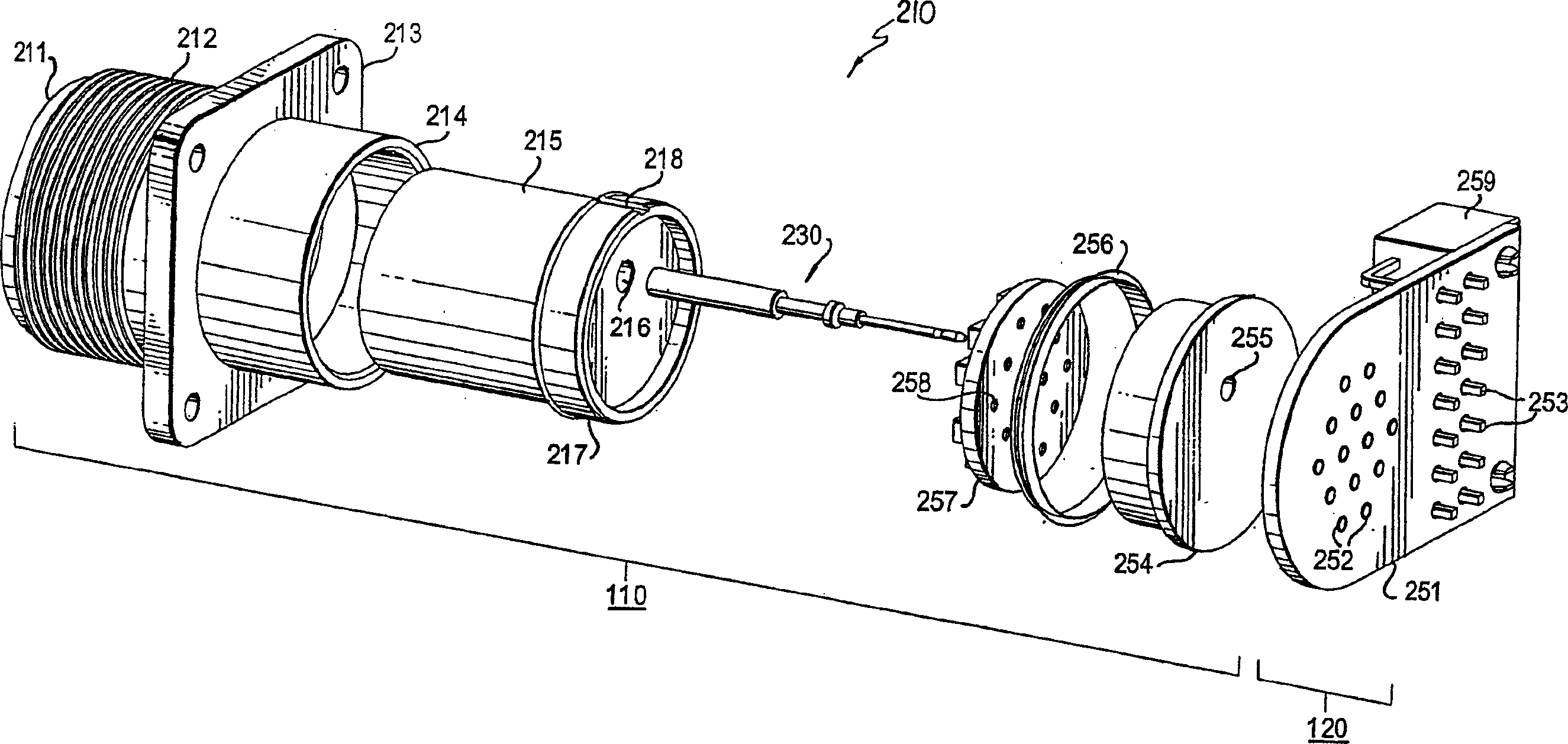

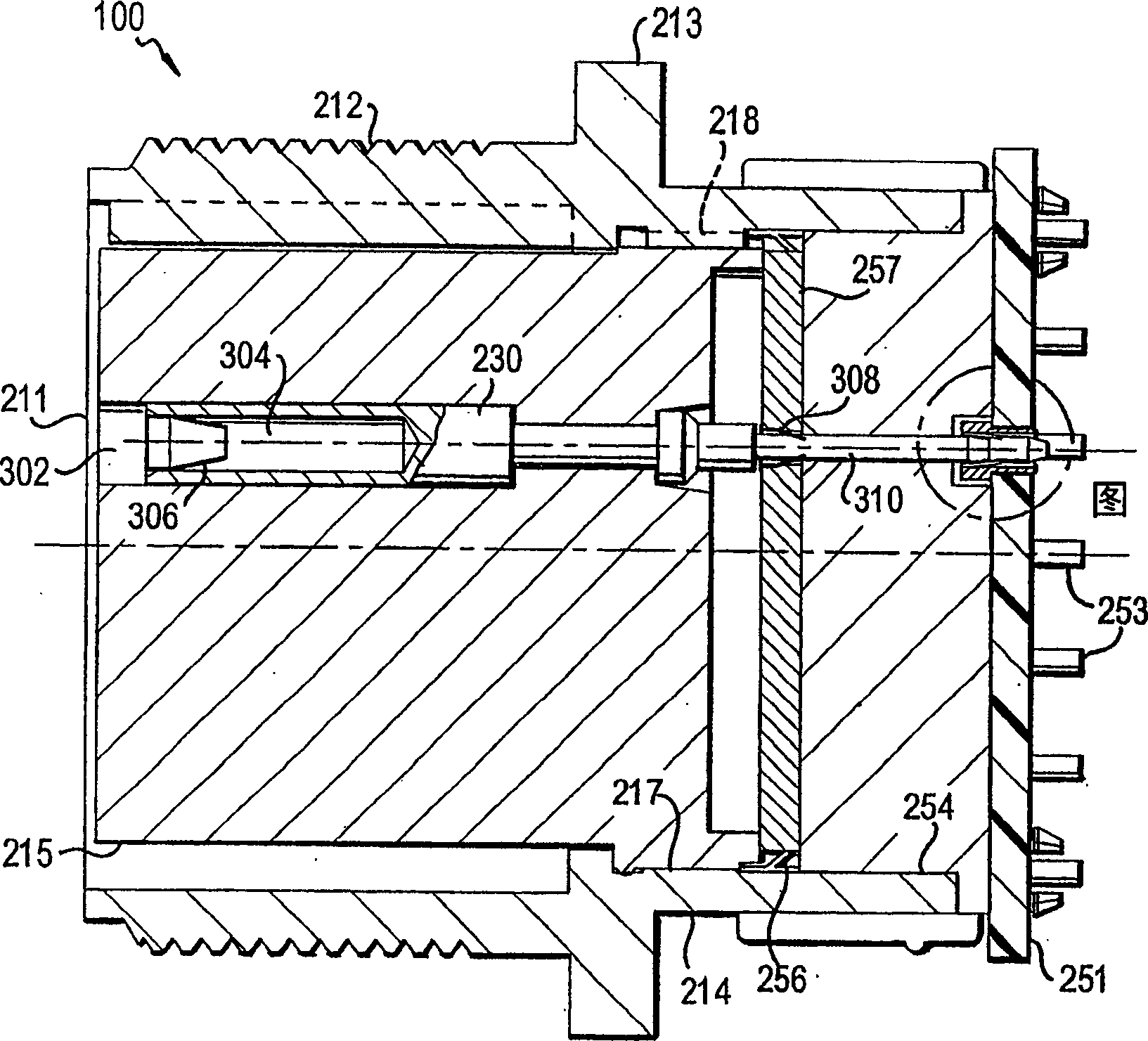

[0027] Referring now to the detailed description of the drawings, wherein like parts are indicated by like reference numerals, a perspective view of an electrical connector 100 of the present invention is shown in FIG. . Connector 100 in FIG. 1 illustrates how the receptacle and printed circuit board embodiment of the present invention may be used in a typical application. However, those skilled in the art will appreciate that any connector including a receptacle receiver, a pin receiver, or the interconnection of a plug and a printed circuit board can be implemented with the present disclosure, and that the invention can be used well in many contexts or used in aircraft. For example, the jack receiver embodiment shown in FIG. 1 may be adapted to accept plugs of any shape, not just round.

[0028] In the context of the present invention, the term "socket" may be interchanged with "adapter" or "receiver". These terms, and others commonly used in the art, generally refer to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com