Electric wire and cable for high-speed train and production method

A technology for wires and cables and high-speed trains, applied in the fields of wires and cables for high-speed trains and production, can solve the problems of low smoke, unable to reach the operating temperature, unable to meet the electrical insulation performance at the same time, achieve good flexibility, improve mechanical and physical properties and The effect of temperature resistance and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] First of all, it should be pointed out that what is described in this section is only a preferred embodiment for implementing the present invention, and those skilled in the art can make modifications to the technical solutions described here without changing the principle of the present invention. These modifications will also fall within the scope of the present invention.

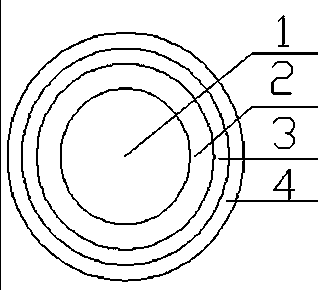

[0022] Reference attached figure 1 , a wire and cable for high-speed trains, comprising a conductor 1, an isolation layer 2 is arranged on the outside of the conductor 1, an inner insulating layer 3 and an outer insulating layer 4 are formed by double-layer co-extrusion outside the insulating layer 2, and the inner insulating layer 3 is radiated at 150°C. It is made of cross-linked polyethylene, and the outer insulating layer 4 is made of irradiated cross-linked oil-resistant, low-smoke, halogen-free, and flame-retardant polyolefin at 150°C.

[0023] In this embodiment, the conductor 1 is formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature class | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com