Preparation method of intrinsic flame retardant polyphosphazene resin with high/low-temperature resistance and high performance

A high and low temperature resistant, polyphosphazene technology, applied in the field of intrinsic flame retardant polyphosphazene resin, can solve the problems of low flame retardant efficiency, limited amount of flame retardants, influence of additive performance, etc., to overcome inelasticity, volume Small size, the effect of expanding the operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

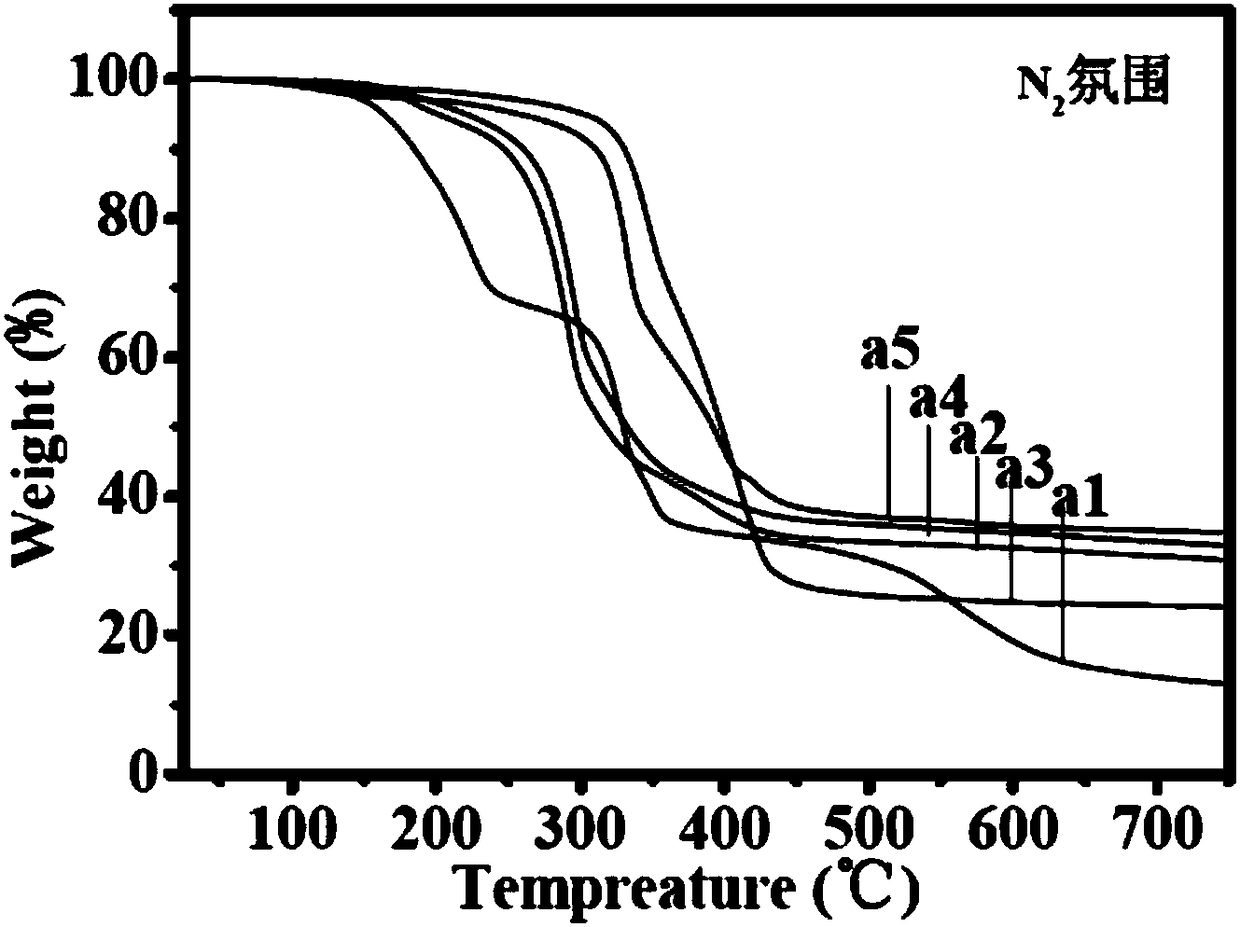

Embodiment 1

[0025] Under the protection of nitrogen, add tetrahydrofuran THF and sodium hydride to a flask connected with a condenser. Place ethanol in a constant pressure dropping funnel and add it dropwise to the flask. The molar ratio of sodium hydride to ethanol is 1.5:1 at room temperature. Stir until the ethanol is completely reacted to obtain a sodium ethoxide solution; under the protection of nitrogen, add THF as solvent and sodium hydride to a flask connected with a condenser, place phenol in a constant pressure dropping funnel and add dropwise to the flask, sodium hydride and The molar ratio of phenol is 1.5:1. Stir at room temperature until the phenol reaction is complete to obtain sodium phenolate solution; at room temperature, take the prepared sodium ethoxide solution and sodium phenate solution in a flask with a condenser. The molar ratio is 100:0, 75: 25, 50: 50, 25: 75, 0: 100; keep stirring, add the polydichlorophosphazene tetrahydrofuran solution through a constant pressu...

Embodiment 2

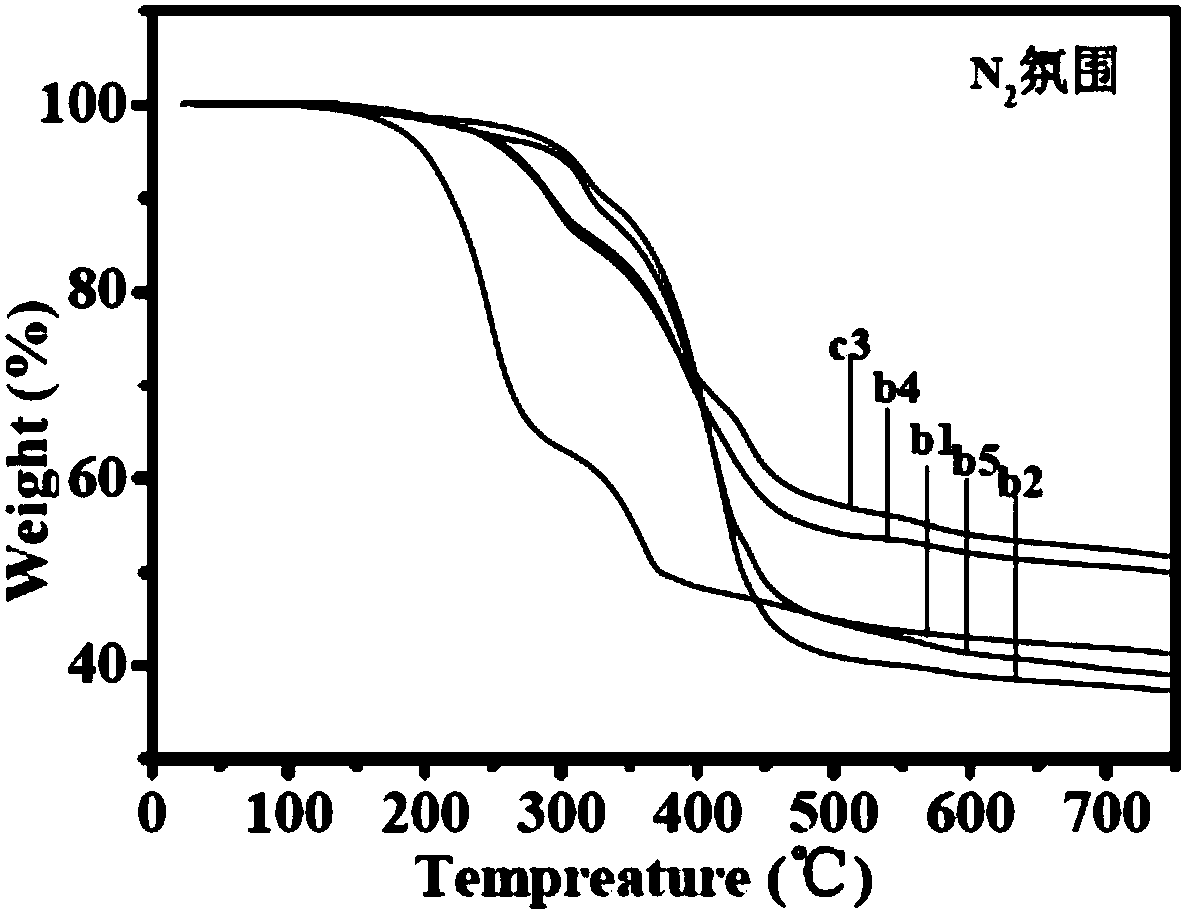

[0028] Under the protection of nitrogen, add THF and sodium hydride to a flask connected with a condenser. Place n-propanol in a constant pressure dropping funnel and add it dropwise to the flask. The molar ratio of sodium hydride to n-propanol is 1.5:1 , Stir at room temperature until the ethanol reaction is complete to obtain the sodium n-propoxide solution; under the protection of nitrogen, add the THF solvent and sodium hydride to the flask connected with the condenser, and place the phenol in a constant pressure dropping funnel and add dropwise to the flask , The molar ratio of sodium hydride to phenol is 1.5:1, stir at room temperature until the phenol reaction is complete to obtain sodium phenate solution; at room temperature, take the prepared sodium n-propoxide solution and sodium phenolate solution in a flask with a condenser, The molar ratios of sodium n-propoxide and sodium phenolate are 100:0,75:25,50:50,25:75,0:100 respectively; keep stirring, pass the tetrahydrofu...

Embodiment 3

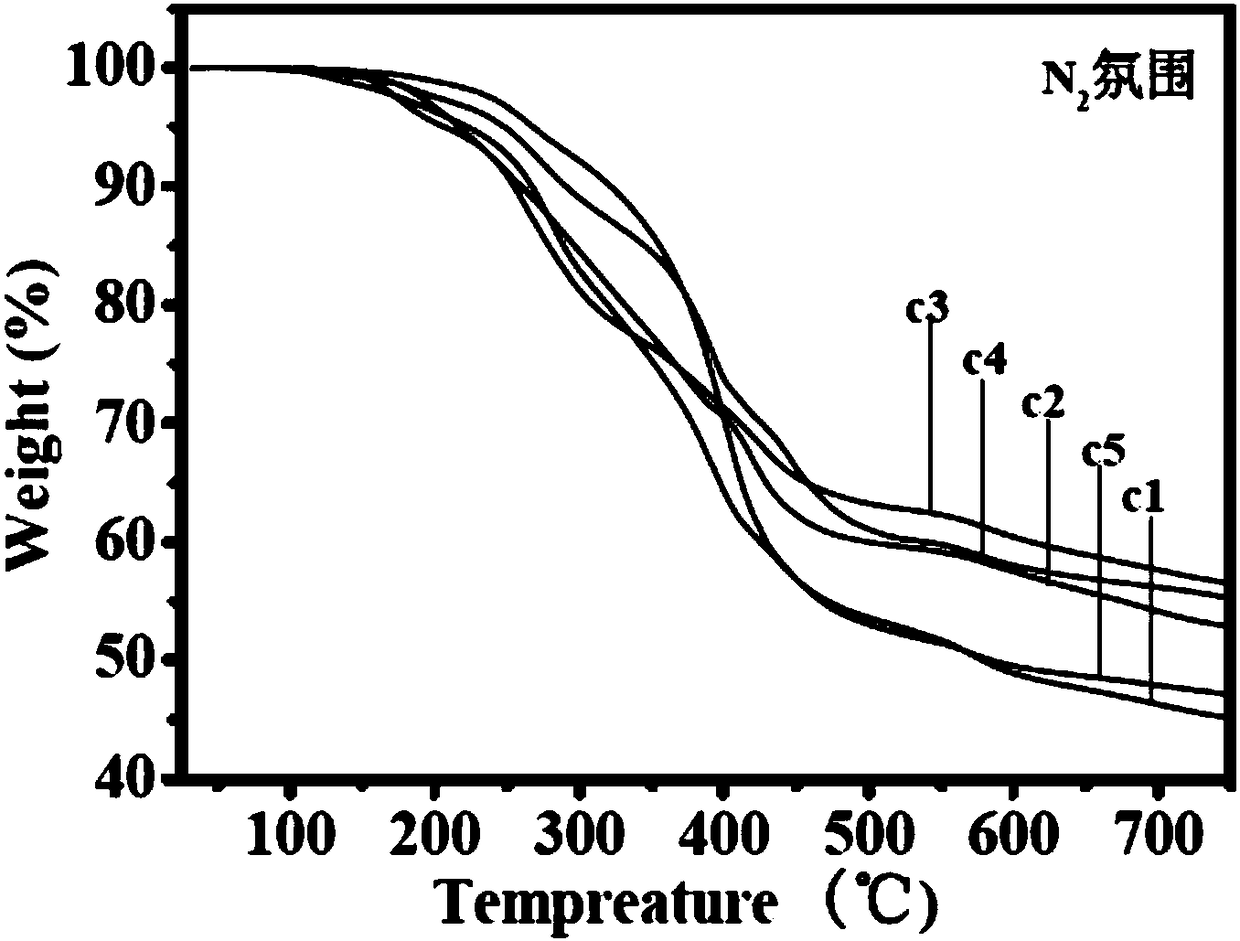

[0031] Under the protection of nitrogen, add THF and sodium hydride to a flask connected with a condenser. Place n-butanol in a constant pressure dropping funnel and add it dropwise to the flask. The molar ratio of sodium hydride to n-butanol is 1.5:1 , Stir at room temperature until the n-butanol reaction is complete to obtain the sodium n-butoxide solution; under the protection of nitrogen, add the THF solvent and sodium hydride to the flask connected with the condenser, and place the phenol in a constant pressure dropping funnel and add dropwise In the flask, the molar ratio of sodium hydride to phenol is 1.5:1. Stir at room temperature until the phenol reaction is complete to obtain sodium phenolate solution; at room temperature, take the prepared sodium n-butoxide solution and sodium phenolate solution in a flask with a condenser Among them, the molar ratios of sodium n-butoxide and sodium phenolate are 100:0, 75:25, 50:50, 25:75, 0:100 respectively; keep stirring, pass the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com