Titanium alloy fine casting melting method

A titanium alloy and precision casting technology, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problems affecting the application of titanium alloy, difficulty in manufacturing casting blanks, poor alloy performance, etc., and achieve excellent corrosion resistance. , to solve the surface accuracy problem, the effect of structural refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

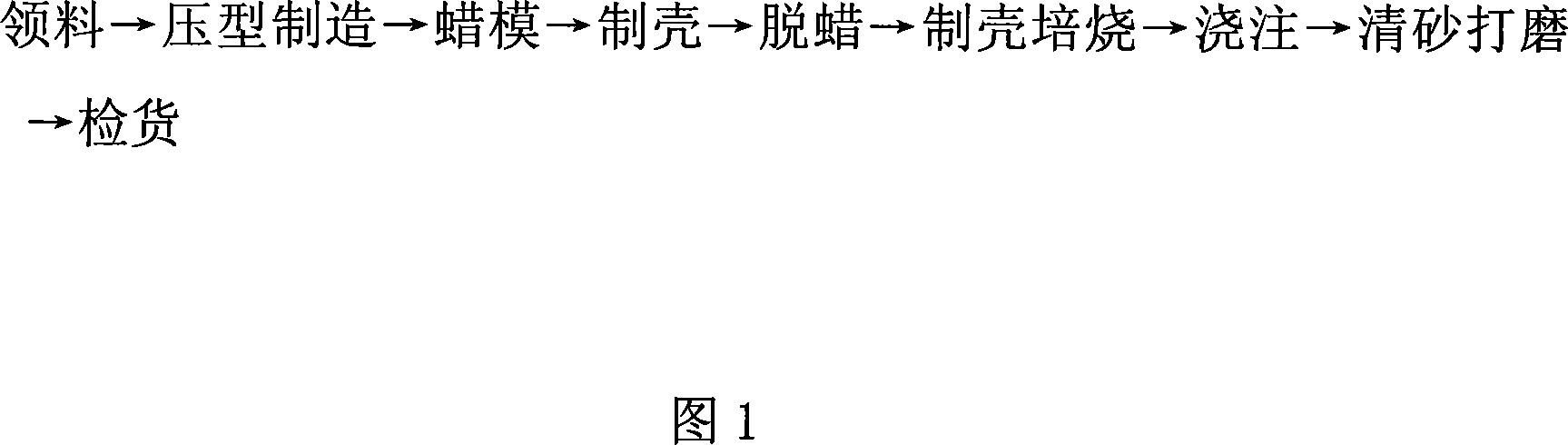

[0021] As shown in Figure 1, the titanium alloy precision casting and smelting method is mainly to make the shell after the wax mold, and then go through dewaxing, shell firing, pouring and post-processing steps:

[0022] Shell making and firing: NaLcog1130 silica sol is used as the binder: Si02=30%PH=10 Average particle size 8μm Average surface area 275m 2 / , 1.214g / cm 3 , Viscosity: less than 10CP (1CP=10 -3 )Pa.S)Na20=0.70%. The refractory filler is mixed with 95% yttrium oxide and 5% zirconia through electric fusion processing, and then crushed into 325 mesh powder, yttrium oxide-silica sol coating, adding a certain amount of base ion source to adjust the pH value of the coating to PH≥ 11. This kind of paint can guarantee that it will not gel for 6 days or more, and the viscosity of the paint should be controlled at 36-42 seconds. The temperature requirement of the shell-making operation room during shell-making: 26°C±1°C. The first and second layers use fused Zr02, wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com