Anti-torsion data power composite cable and manufacturing method thereof

A composite cable, anti-torsion technology, used in cable/conductor manufacturing, insulated cables, cables with double-stranded/quad-stranded, etc., can solve problems such as cable damage, production line shutdown, etc., to improve performance, The effect of high tensile strength and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

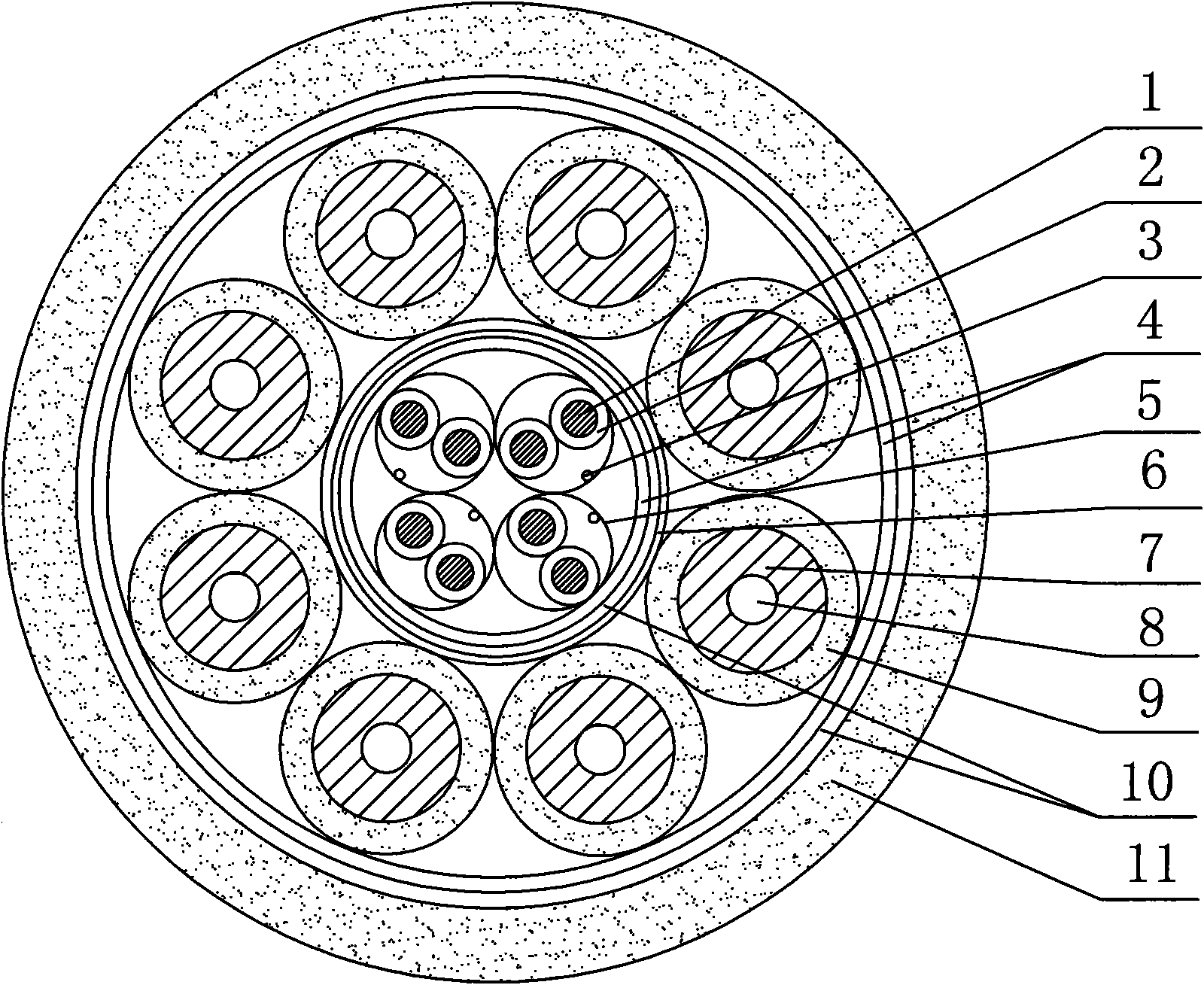

[0024] (1) The oxygen-free copper wire is used as the solid conductor 1, and the physical foamed polyethylene insulating material co-extruded with three layers of skin-foam-skin is used to extrude the insulating layer 2 on the oxygen-free copper wire to form an insulated wire core. The physical foaming insulation technology of skin-foam-skin three-layer co-extrusion is adopted, which is carried out on the Rosenthal series production line imported from Germany, and the material is selected from the physical foaming material imported from Dow Chemical. In the production process, adopt reasonable mold design and appropriate nitrogen injection pressure to ensure the thickness and concentricity of the inner and outer skins, the diameter of the insulated core and the foaming degree of the intermediate insulating layer in the process design, so that the insulation The single wire has electrical and mechanical properties suitable for the finished cable.

[0025] (2) Two insulated wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com