Al-Fe-Cu-Mg aluminum alloy and electric wire made of the same

An al-fe-cu-mg, aluminum alloy technology, used in metal/alloy conductors, circuits, electrical components, etc., can solve the problems of fatigue resistance and creep resistance not being improved, and achieve improved mechanical strength and Tensile properties, improved creep resistance, improved electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

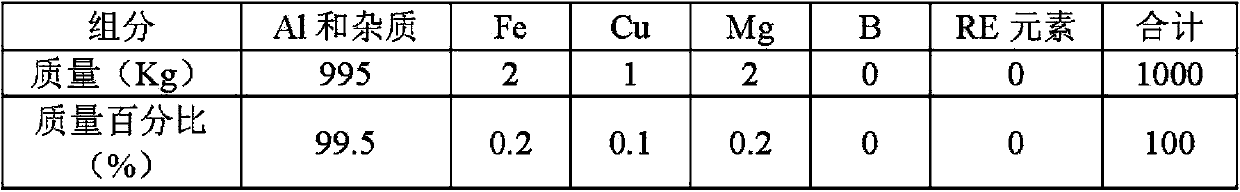

[0062] An Al-Fe-Cu-Mg aluminum alloy, wherein the components and component contents are shown in the following table

[0063]

[0064] The specific method for preparing the aluminum alloy conductor material by using the above aluminum alloy formula is as follows:

[0065] a) Melting is carried out by adding various components according to the above proportions in a constant temperature cupola at 800°C.

[0066] b) The molten metal after smelting is added to the 750°C holding furnace in proportion to the refining agent, and the high-temperature-resistant alloy steel double-blade stirrer is used to stir at a rate of 20 rpm for 10 minutes. After the stirring, the temperature is raised to 820°C and kept for 30 minutes. minute;

[0067] c) The alloy liquid is cooled to below 650°C through the constant temperature diversion tank and then enters the casting room for casting;

[0068] d) The cast bar obtained in step c) is kept at 500°C for 3 hours, and then cooled to 400°C for 4...

Embodiment 2

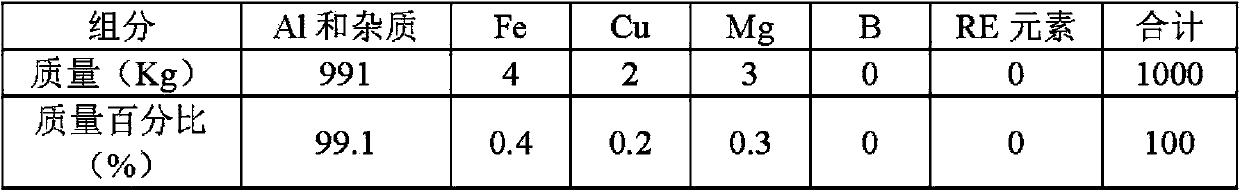

[0078] An Al-Fe-Cu-Mg aluminum alloy, wherein the components and component contents are shown in the following table

[0079]

[0080] The specific method for preparing the aluminum alloy conductor material by using the above aluminum alloy formula is as follows:

[0081] a) In a constant temperature cupola at 780°C, various components are added in the above proportions for smelting.

[0082] b) The molten metal after smelting is added to the 750°C holding furnace in proportion to the refining agent, and the high-temperature-resistant alloy steel double-blade stirrer is used to stir at a rate of 20 rpm for 10 minutes. After the stirring, the temperature is raised to 820°C and kept for 30 minutes. minute;

[0083] c) The alloy liquid is cooled to below 650°C through the constant temperature diversion tank and then enters the casting room for casting;

[0084] d) The cast bar obtained in step c) is kept at 500°C for 3 hours, and then cooled to 400°C for 4 hours.

[0085] e...

Embodiment 3

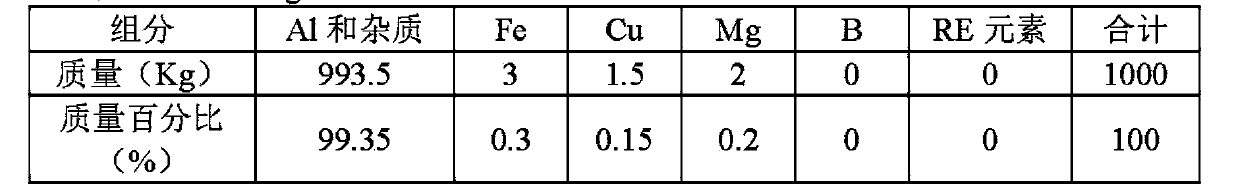

[0094] An Al-Fe-Cu-Mg aluminum alloy, wherein the components and component contents are shown in the following table

[0095]

[0096] The specific method for preparing the aluminum alloy conductor material by using the above aluminum alloy formula is as follows:

[0097] a) Melting is carried out by adding various components according to the above proportions in a constant temperature cupola at 800°C.

[0098] b) The molten metal after smelting is added to the 750°C holding furnace in proportion to the refining agent, and the high-temperature-resistant alloy steel double-blade stirrer is used to stir at a rate of 20 rpm for 10 minutes. After the stirring, the temperature is raised to 820°C and kept for 30 minutes. minute;

[0099] c) The alloy liquid is cooled to below 640°C through the constant temperature diversion tank and then enters the casting room for casting;

[0100] d) The cast bar obtained in step c) is kept at 500°C for 3 hours, and then cooled to 400°C for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Average creep speed | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com