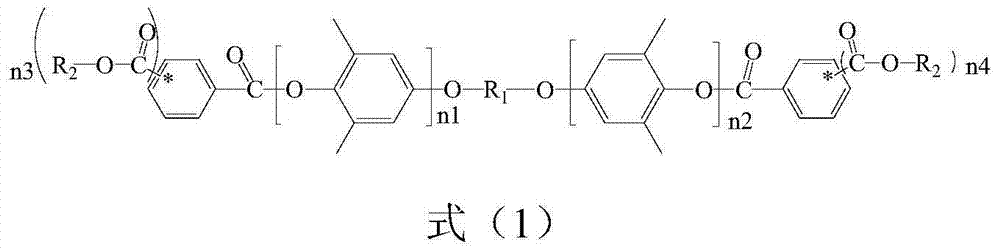

Active ester, thermosetting resin composition containing active ester, prepreg and laminated board

A resin composition, thermosetting technology, applied in the field of prepregs, laminates, and thermosetting resin compositions, can solve the problems of difficulty, heat resistance and low water absorption, and achieve low heat resistance, low water absorption, excellent The effect of dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] (1) Redistribution of PPO

[0045] Stir and heat 4000g of toluene in a three-necked flask equipped with a stirrer, condensing reflux tube and thermometer to 100°C, then add 2000g of PPO resin with a number average molecular weight of 20000, and add 600g of diallyl bis Phenol A (DABPA), stirred for 30min, then added 150g of benzoyl peroxide (BPO) dissolved in toluene, and kept the temperature at 92°C, and reacted for 360min. Then the product was cooled to room temperature and then 4000ml of methanol was added, and vigorously stirred, filtered and dried to obtain 2400g of small molecule bifunctional PPO resin (A1).

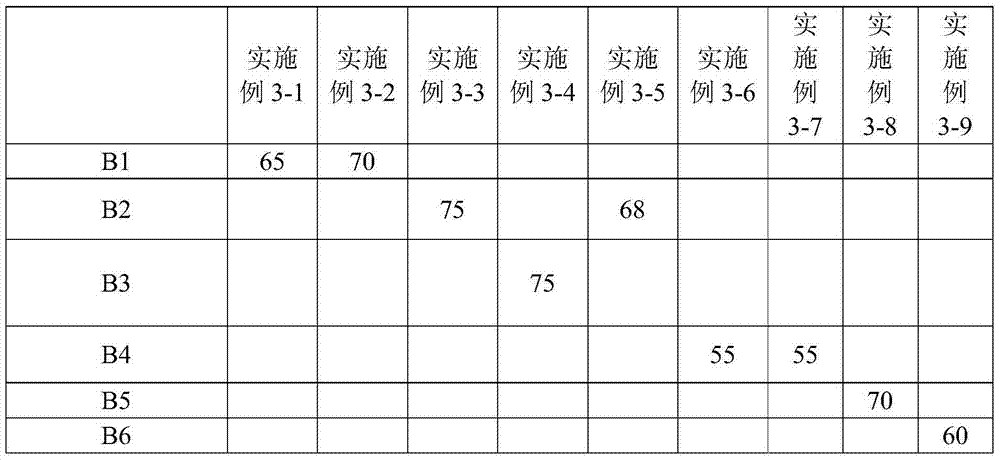

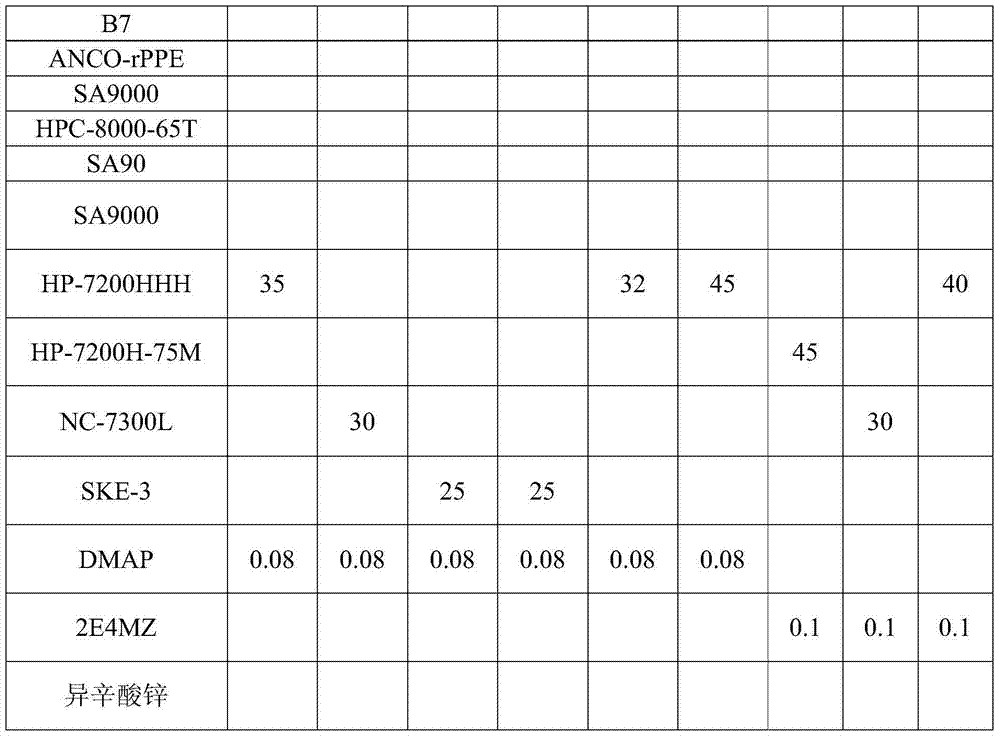

[0046] Repeat the above operations, change the ratio of various reactants in the redistributed PPO resin, and change the reaction temperature and reaction time to obtain difunctional PPO resins with different number average molecular weights, as shown in the following table:

[0047]

A1

A2

A3

A4

A5

A6

PPOs

2000 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com