Lithium ion battery maximum electrolyte injection volume quick evaluation method

A lithium-ion battery and evaluation method technology, which is applied in the field of rapid evaluation of the maximum liquid injection volume of lithium-ion batteries, can solve the problems of complicated and inaccurate parameters, large equipment dependence, and large deviation of liquid injection volume, so as to avoid equipment accuracy and production, avoiding electrical performance degradation, and the effect of accurate design parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

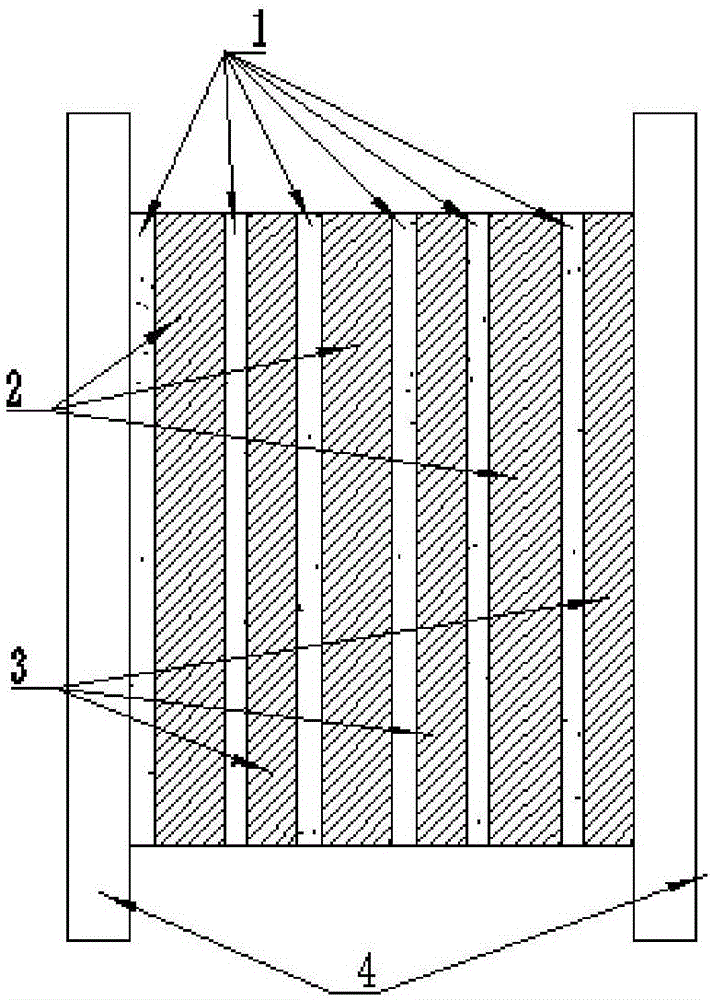

Image

Examples

Embodiment 1

[0027] A method for rapidly evaluating the maximum liquid injection volume of a lithium-ion battery, comprising the following steps:

[0028] (1) First measure the weight and volume of the positive electrode sheet, then completely soak it in the electrolyte at a temperature of 30°C and leave it sealed for 3 hours. After taking it out, wipe it quickly from the surface with blotting paper once and weigh it immediately; use the positive electrode The ratio of the electrolyte volume that the sheet can hold to its own volume is used to calculate the liquid capacity of the positive electrode sheet α 正 =(m 1 -m 0 ) / ρ / V, where m 1 is the mass of the positive plate after absorbing liquid, m 0 is the mass of the positive electrode sheet before liquid absorption, ρ is the density of the electrolyte, V is the volume of the positive electrode sheet,

[0029] Then calculate the liquid capacity α of the negative plate in the same way 负 and the liquid capacity α of the diaphragm 膜 ;

...

Embodiment 2

[0041] A method for rapidly evaluating the maximum liquid injection volume of a lithium-ion battery, comprising the following steps:

[0042] (1) First measure the weight and volume of the positive electrode sheet, then completely soak it in the electrolyte solution at a temperature of 55°C and leave it sealed for 0.5 hours. After taking it out, wipe it quickly from the surface once with blotting paper and weigh it immediately; The ratio of the electrolyte volume that the sheet can hold to its own volume is used to calculate the liquid capacity of the positive electrode sheet α 正 =(m 1 -m 0 ) / ρ / V=0.08, where the mass of the positive plate after absorbing liquid m 1 =315.3g, the mass of the positive electrode sheet before liquid absorption m 0 =306.6g, electrolyte density ρ=1.2g / cm 3 , positive plate volume V = 94.3cm 3 ,

[0043] Then calculate the liquid capacity α of the negative plate in the same way 负 =0.16 and the liquid capacity of the diaphragm α 膜 =0.59; the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com