Sn/Au eutectic based chip partial vacuum packaging method of resonance type pressure sensor

A pressure sensor and sensor chip technology, which is applied to the measurement of the properties of piezoelectric devices, etc., can solve the problems of reduced sealing vacuum, shortened service life of sensor chips, and unenvironmental protection, so as to improve vacuum and reduce heat. impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manner of the present invention is not limited to the following description, and the method of the present invention will be further described below in conjunction with the accompanying drawings.

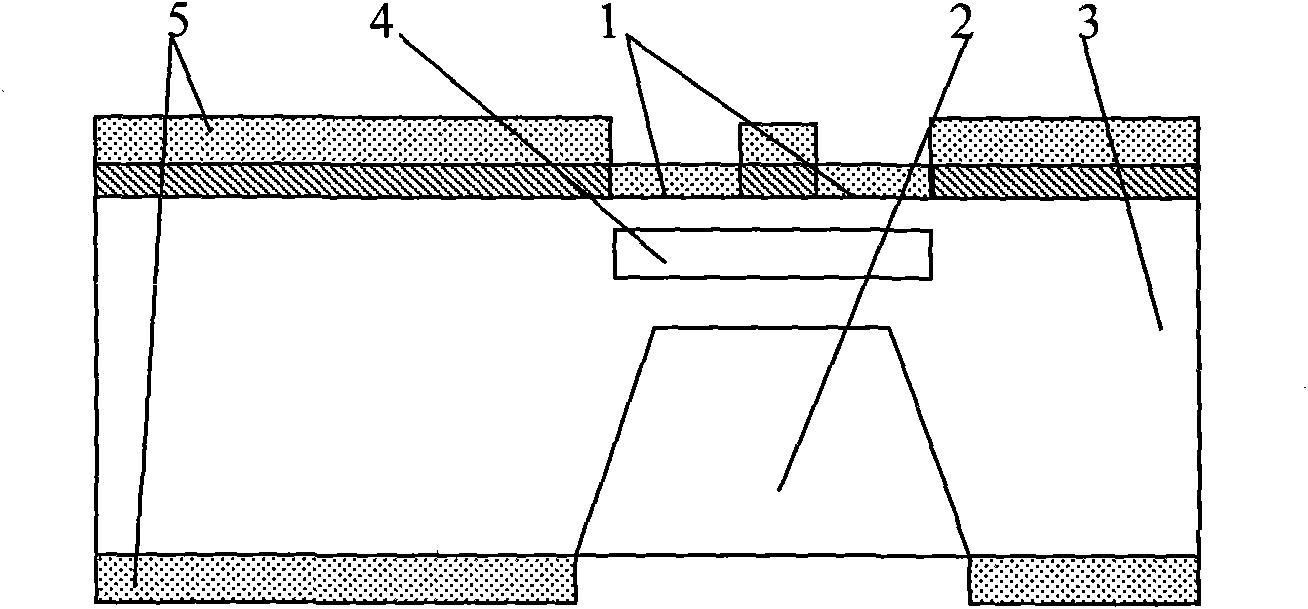

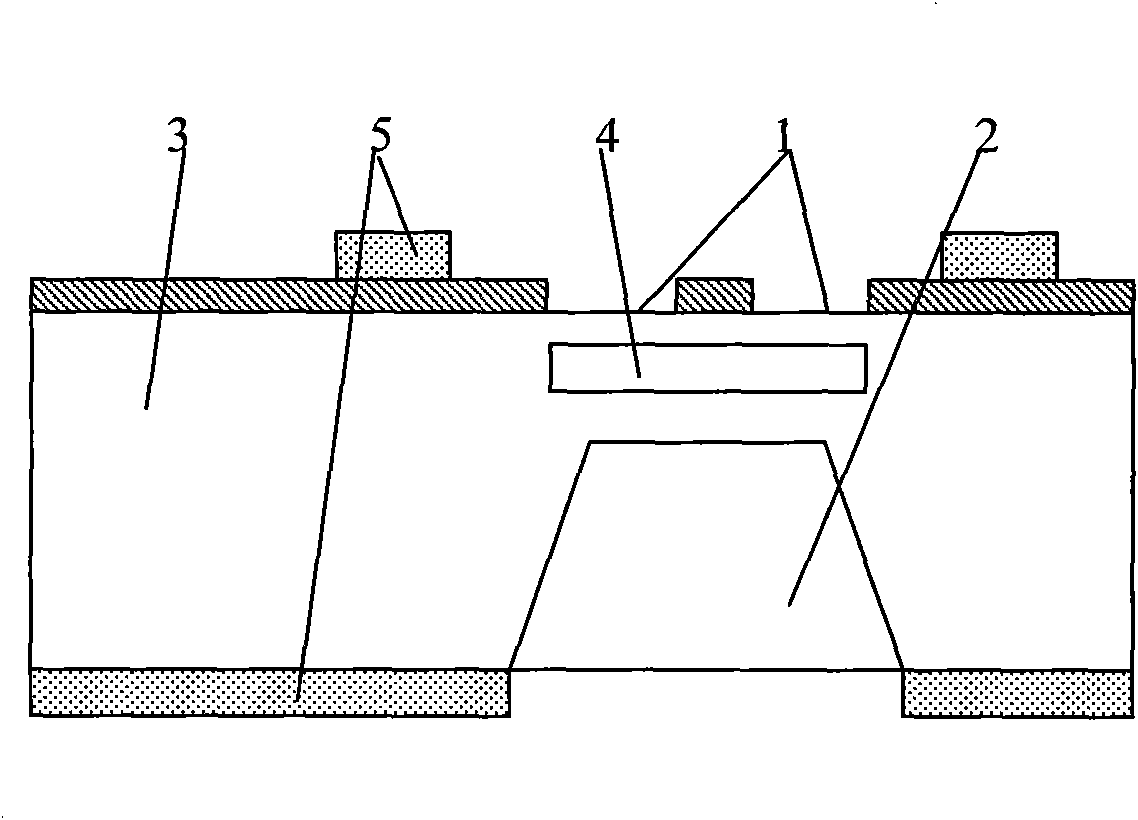

[0043] 1. Form a TiW / Au ring 5 with a thickness of 3-10 μm and a ring width of 100-200 μm on the sensor silicon wafer 3 to be subjected to deep groove etching on the back side and release movable parts on the front side, and perform deep groove etching and release movable parts The steps in part 6 include:

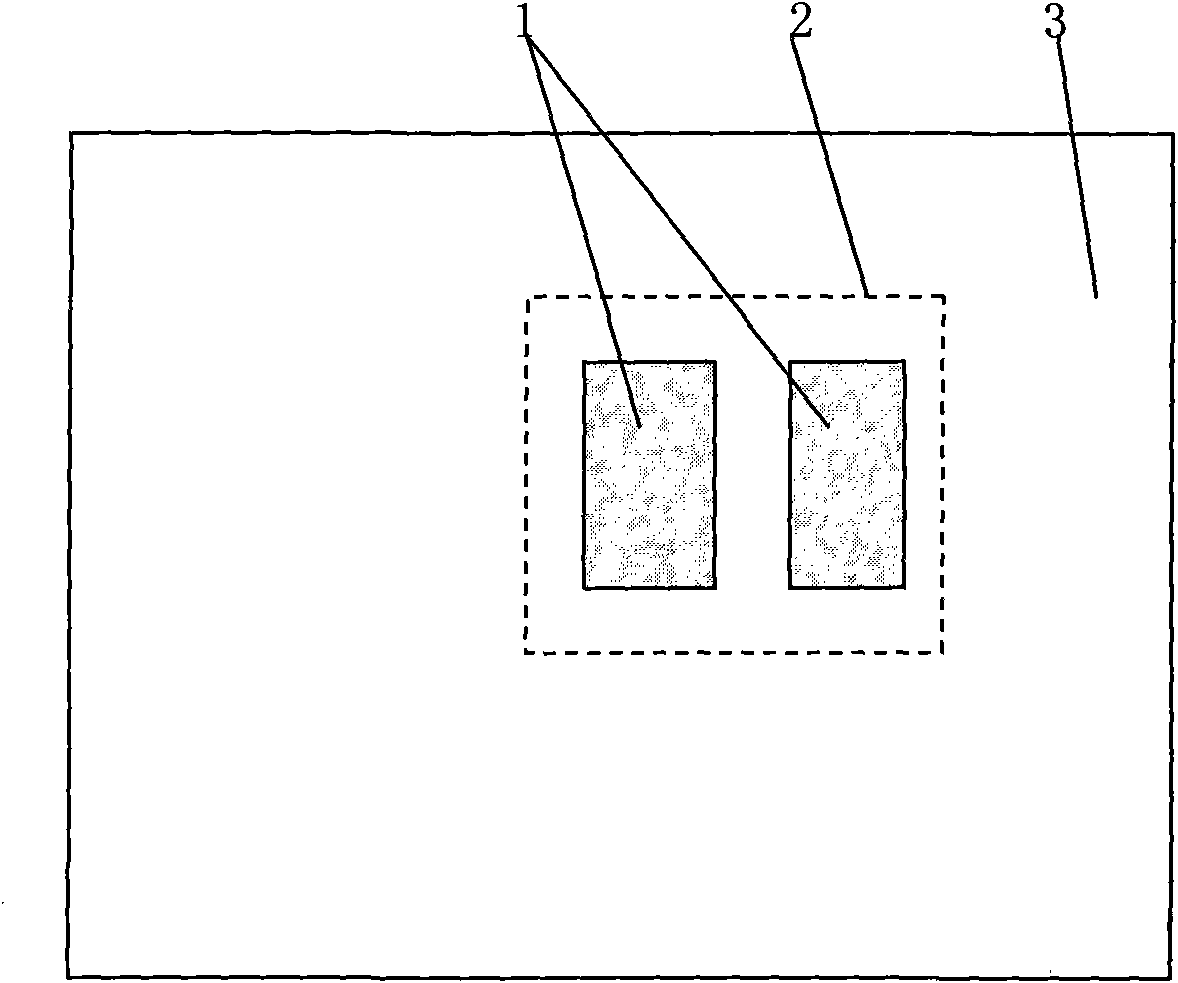

[0044] (1) The sensor silicon wafer 3 to be subjected to deep groove etching on the back and release of movable parts on the front figure 1 as shown, figure 1 1 indicates that silicon is prepared to be etched on both sides of the resonant beam of the sensor to release the area forming the resonant beam, and 2 indicates the area on the back of the silicon chip of the sensor where silicon is prepared to be etched in deep grooves. Use the genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com