Slow release fertilizer comprising fly ash gel and preparation method of slow release fertilizer

A slow-release fertilizer and fly ash technology, applied in fertilizer mixtures, layered/coated fertilizers, fertilization devices, etc., can solve the problems of fertilizer nutrient waste, limited nutrient absorption, loss of nitrogen and potassium fertilizers, etc. The speed of decomposition, the increase in specific surface area, the effect of fixing fertilizer nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

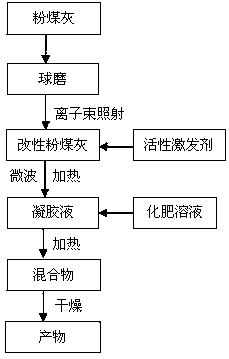

Image

Examples

Embodiment 1

[0030] (1) Put 30 parts by weight of fly ash into a ball mill and grind for 5 minutes, with a particle size of 300 mesh;

[0031] (2) Put the ground fly ash into the ion beam irradiation device, choose energy 5keV, dose 1000×2.0×10 13 ions / cm 2 , select the nitrogen ion beam to irradiate the active fly ash for 10 minutes to obtain the modified fly ash;

[0032] (3) Put the modified fly ash into the microwave reactor, and prepare a mixed solution with 2mol / L sodium carbonate solution at a solid-to-liquid ratio of 2.5. Set the microwave parameters: temperature 60°C, speed 200 r / min , and reacted for 40 min to obtain fly ash gel;

[0033] (4) Dissolve 40 parts by weight of calcium superphosphate and 40 parts by weight of potassium chloride in water to form a saturated solution, add the saturated solution of chemical fertilizer to the gel solution in step (2), control the temperature at 40°C, and Stir at 800 r / min speed for 20 min to obtain a mixture of fly ash gel and chemica...

Embodiment 2

[0036] (1) Put 20 parts by weight of fly ash into a ball mill and grind for 10 minutes, with a particle size of 500 mesh;

[0037] (2) Put the ground fly ash into the ion beam irradiation device, set the energy range to 10keV, and the dose to 900×2.0×10 13 ions / cm 2 , select the nitrogen ion beam to irradiate the active fly ash for 12min to obtain the modified fly ash;

[0038] (3) Put the modified fly ash into the microwave reactor, and prepare a mixed solution with 2mol / L sodium acetate solution at a solid-to-liquid ratio of 2.6, and set the microwave parameters: temperature 70°C, speed 300 r / min , and reacted for 30 min to obtain fly ash gel;

[0039] (4) 40 parts by weight of urea, 20 parts by weight of superphosphate and potassium nitrate of 10 parts by weight are dissolved in water to form a saturated solution, and the saturated solution of chemical fertilizer is added to the gel solution in step (2), and the control Stir at a temperature of 50°C for 15 minutes at a s...

Embodiment 3

[0042] (1) Put 10 parts by weight of fly ash into a ball mill and grind for 15 minutes, with a particle size of 800 mesh;

[0043] (2) Put the ground fly ash into the ion beam irradiation device, set the energy range to 15keV, and the dose to 800×2.0×10 13 ions / cm 2 , select the nitrogen ion beam to irradiate the active fly ash for 15 minutes to obtain the modified fly ash;

[0044] (3) Put the modified fly ash into the microwave reactor, and prepare a mixed solution with 2mol / L sodium phosphate solution at a solid-to-liquid ratio of 2.7, and set the microwave parameters: temperature 80°C, speed 400 r / min , and reacted for 25 min to obtain fly ash gel;

[0045] (4) Dissolve 40 parts by weight of potassium dihydrogen phosphate and 20 parts by weight of potassium sulfate in water to form a saturated solution, add the saturated solution of chemical fertilizers to the gel solution in step (2), control the temperature at 60°C, and Stir at a speed of 600 r / min for 10 min to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com