Nozzle

A technology of nozzles and water spray holes, which is used in coal gasification, underground mining, construction, etc., can solve the problems of gas quality limitation, easy to be affected by high temperature, nozzle burnout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

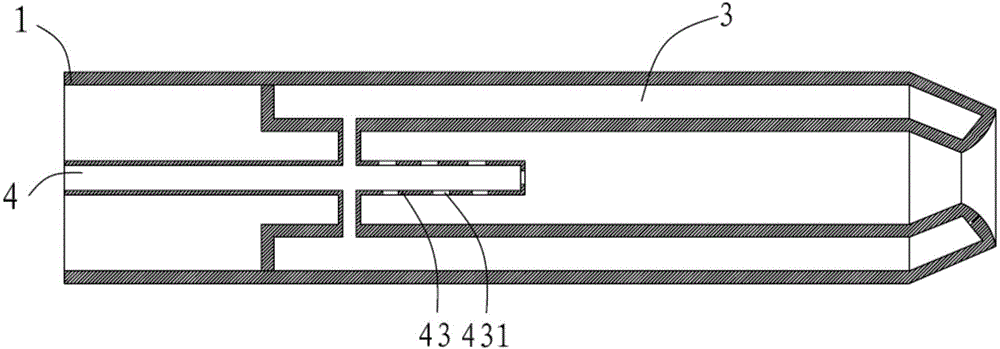

[0029] see figure 1 The first embodiment of the nozzle of the present invention includes a nozzle main body 1, a water jacket 3 and a water delivery pipe 4 communicating with the water jacket 3 are arranged in the nozzle main body 1, and cooling water enters the water jacket 3 through the water delivery pipe 4 to The nozzle main body 1 is cooled, and the rear end of the water delivery pipe 4 is provided with several water spray holes 431 .

no. 2 example

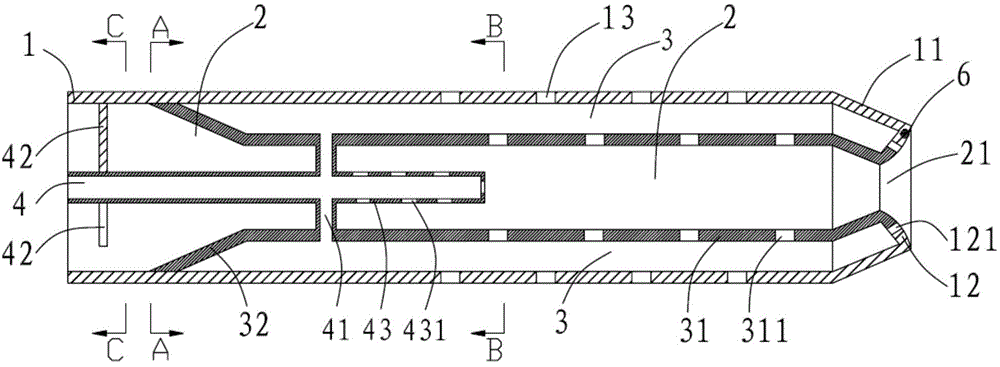

[0031] see figure 2 , The second embodiment of the nozzle of the present invention includes a nozzle body 1 , a nozzle cavity 2 , a water jacket 3 and a water delivery pipe 4 . The nozzle main body 1 is approximately tubular and encloses a nozzle cavity 2 . The inner cavity 2 of the nozzle is the conveying channel of the gasification agent. The water jacket 3 is arranged on the inner wall of the rear end of the nozzle body 1 (towards the coal seam combustion zone), and the water pipe 4 is arranged on the inner side of the nozzle body 1 away from the end of the coal seam combustion zone, and communicates with the water jacket 3 . When the nozzle is in use, cooling water enters the water jacket 3 through the water delivery pipe 4 to cool the nozzle main body 1 .

[0032] The length and outer diameter of the nozzle body 1 are determined according to the inner diameter of the underground gasifier well and the process requirements. In this embodiment, the length of the nozzle bo...

no. 3 example

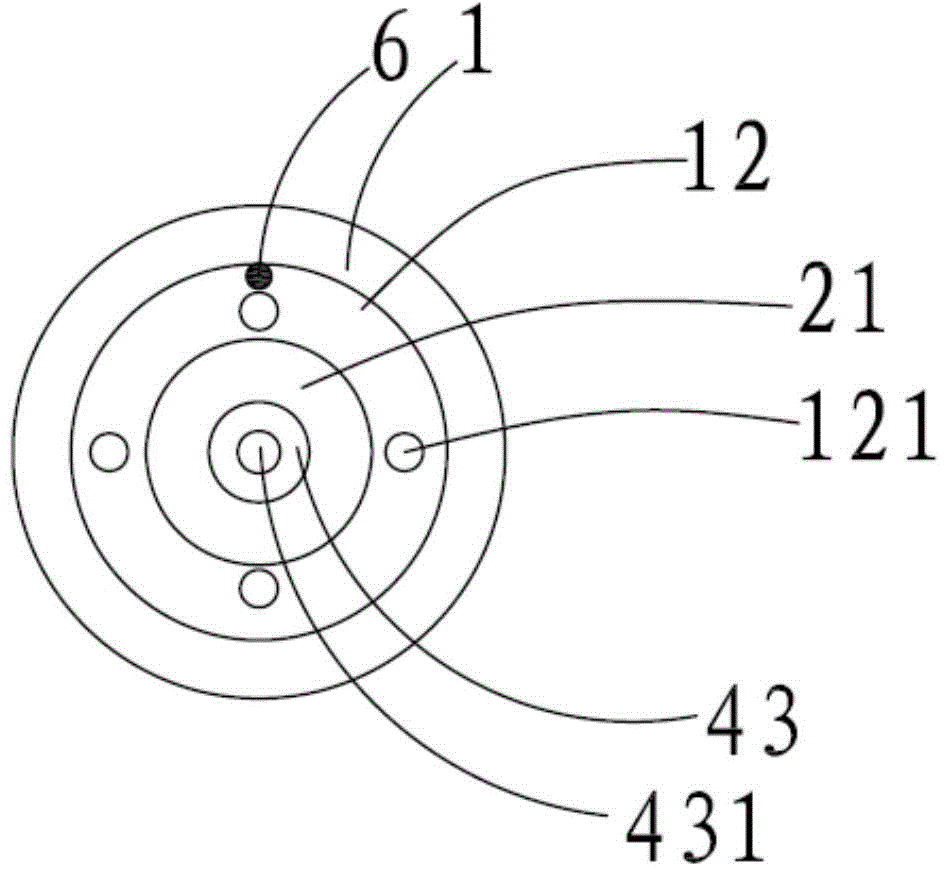

[0049] see Figure 7 , The third embodiment of the nozzle of the present invention includes a nozzle body 1 , a nozzle cavity 2 , a water jacket 3 and a water delivery pipe 4 . The inner cavity 2 of the nozzle is the conveying channel of the gasification agent. The water jacket 3 is arranged on the inner wall of the rear end of the nozzle body 1 (towards the coal seam combustion zone), and the water pipe 4 is arranged on the inner side of the nozzle body 1 away from the end of the coal seam combustion zone, and communicates with the water jacket 3 . When the nozzle is in use, cooling water enters the water jacket 3 through the water delivery pipe 4 to cool the nozzle main body 1 . The rear end of the water pipe 4 is extended to form an extension section 43 , and the extension section 43 is provided with a plurality of water spray holes 431 . The cooling water sprayed from the spray hole 431 is internally mixed with the gasification agent in the nozzle inner cavity 2 and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com