Display device

A display device and frame body technology, which is applied to identification devices, televisions, instruments, etc., can solve problems such as low panel production efficiency, and achieve the effect of reducing the width of the frame and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

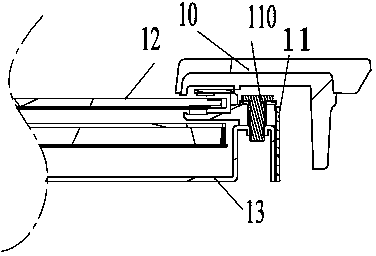

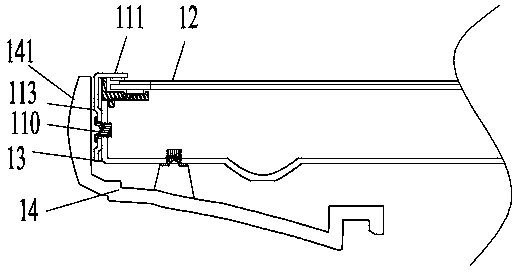

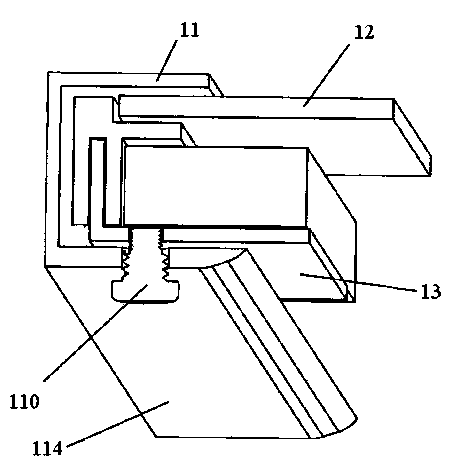

[0031] Figure 3A It is a schematic diagram of the first embodiment of the pre-fixed structure of the surface frame and the backplane of the present invention, Figure 3A Presented is a schematic diagram of the rear pre-fixed structure of the display device. Such as Figure 3A As shown, the surface frame 21 adopts a four-section split type surface frame, including four sections of inline frames 21a, 21b, 21c, and 21d on the upper, lower, left, and right sides. The four corners of the four-section inline frame are spliced to form a rectangular frame. Body structure, the surface frame material is resin or metal material, also can be other materials that can make the surface frame. At least one set of opposite sides in the four-section inline frame of the upper, lower, left and right are respectively provided with at least one guide chute, such as Figure 3AAs shown, guide chute 2121 is provided on the two opposite sides 21c and 21d on the left and right, and a positioning p...

Embodiment 2

[0046] Only the differences between this embodiment and the first embodiment will be described below, and the similarities will not be described repeatedly. Such as Figure 5 As shown, the difference between this embodiment and the first embodiment is that the surface frame 21 adopts two L-shaped frame structures, and the two L-shaped frames are joined diagonally to form a rectangular frame structure. Such as Figure 5 As shown, the surface frame 21 includes two sections of L-shaped frame bodies 21a' and 21b', wherein the frame body 21a' includes a left frame portion 21a1' and a lower frame portion 21a2', and the frame body 21b' includes a right frame portion 21b1' and In an upper frame portion 21b2', at least one pair of opposite sides of the two groups of opposite sides is provided with a guide chute. At least one set of opposite sides of the face frame is provided with guide chute respectively, and the edge of the backboard is provided with a positioning piece correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com