Large roof grid structure assembling and installing method

A technology of grid structure and installation method, which is applied in building structure, processing of building materials, construction, etc., can solve the problems of slow construction progress, influence of normal operation of construction or production facilities, and long construction period, so as to improve construction speed, Ease of implementation and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention takes the following steps to carry out:

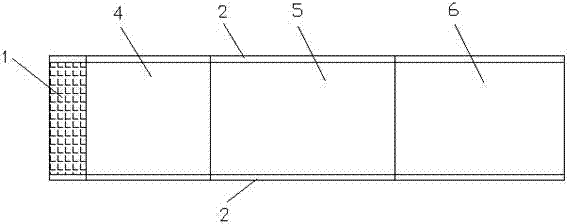

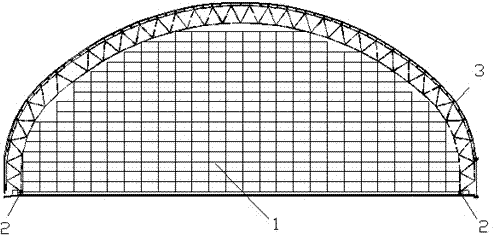

[0025] a. An operation platform 1 with a steel structure frame is erected at one end of the longitudinal axis of the grid structure outside the area covered by the grid structure. The outer contour of the operation platform 1 matches the lower surface of the grid structure 3, and the width of the operation platform 1 is the width of a small unit grid;

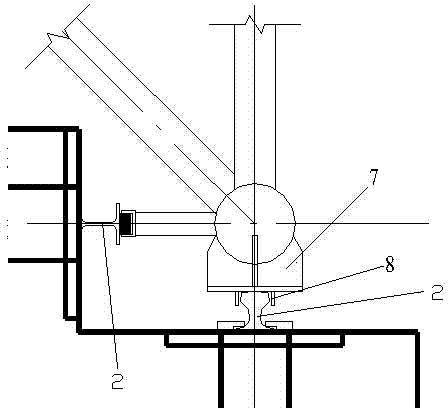

[0026] b. Lay the sliding track 2 along the length direction of the grid structure on the top surface of the independent foundation on both sides of the installation grid structure 3, and lay the sliding track 2 on the outside of the operating platform 1 at the same time, so that the sliding on the outside of the operating platform 1 The track 2 is connected with the sliding track 2 on the top surface of the independent foundation;

[0027] c. Use a crane to lift the grid material of the assembled grid structure 3 to the operation platform 1, install the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com