Preparation method of rare earth magnesium alloy and sheet thereof

A rare earth magnesium and alloy technology, applied in the field of metal materials, can solve the problems of alloy economy and room temperature deformation ability to be improved, failure to examine alloy thermal stability, etc., to achieve large-scale production and application, reduce metallurgical defects, product Dimensionally accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

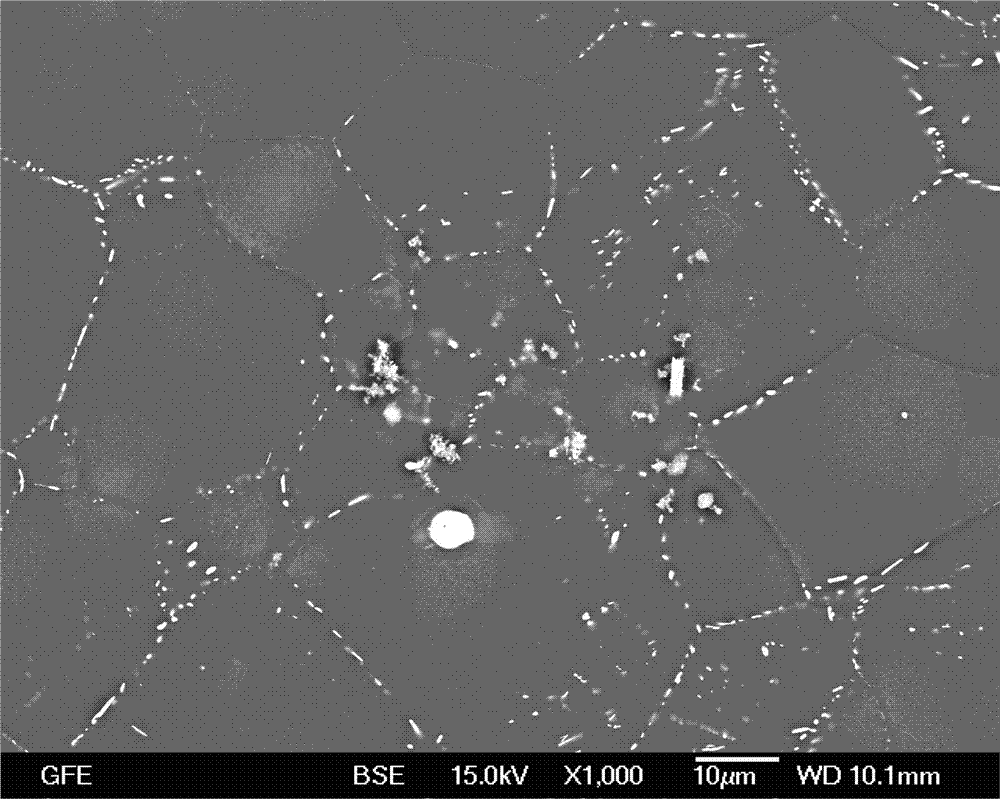

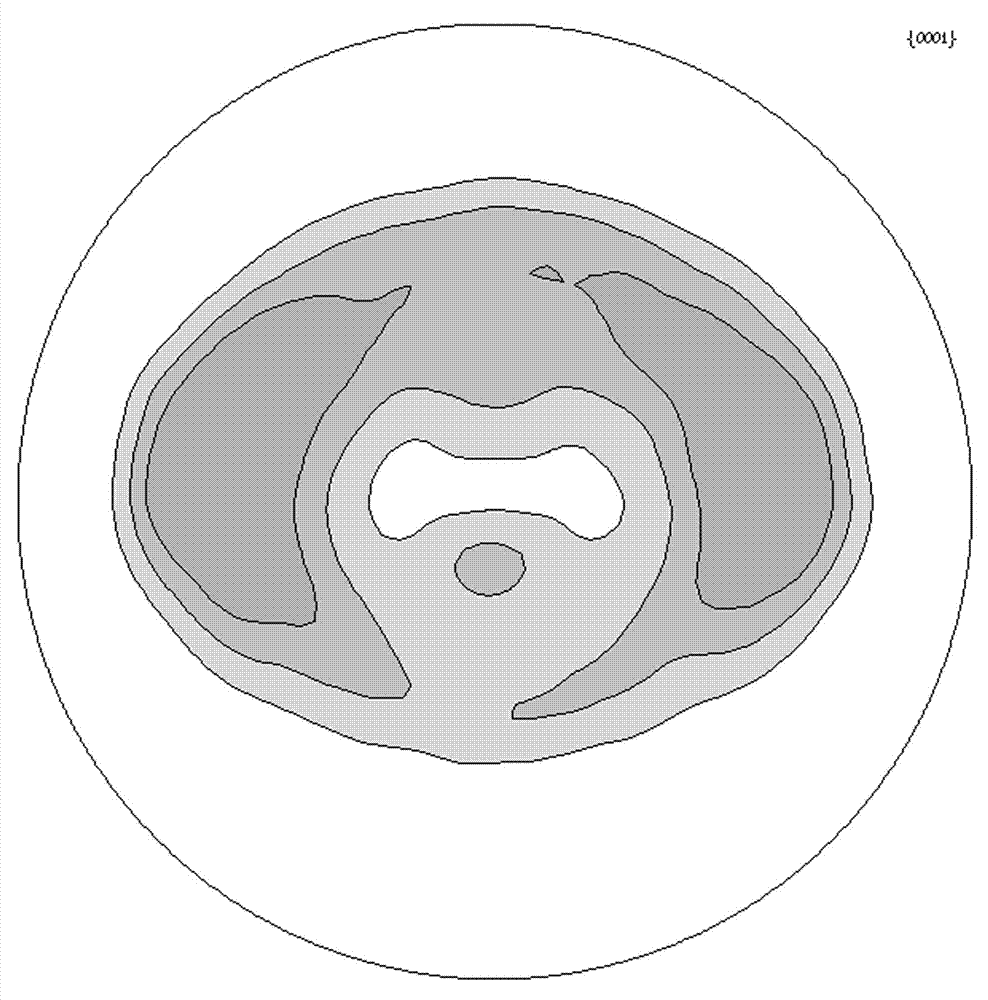

[0032]The square cast ingot with a thickness of 100mm produced by the semi-continuous casting method in this embodiment, the mass percent of the alloy composition is: Zn 1%, Gd 1%, Zr 0.3%, and the rest is Mg;

[0033] 1. The alloy square ingot is homogenized at 400°C for 48 hours, and then cooled with water;

[0034] 2. Keep the milled blank at 400°C for 4 hours; at the same time, preheat the roll to 250°C, and start rolling for 6 passes, with a reduction of 30% for each pass. After the 2nd and 4th passes, return to the furnace and heat to 400°C for 30 minutes and then continue rolling. The reduction in the last pass is 40%, and the total reduction is 90%;

[0035] 3. The plate after hot rolling is annealed at 300°C for 2 hours;

[0036] 4. After hot-rolling, the plate is cold-rolled 4 times at room temperature, with a reduction of 15% in each pass and a total reduction of 52%;

[0037] 5. The cold-rolled sheet is then annealed at 300°C for 30 seconds;

Embodiment 2

[0039] The square cast ingot with a thickness of 100mm produced by the semi-continuous casting method in this embodiment, the mass percent of the alloy composition is: Zn 1%, Gd 2%, Zr 0.6%, and the rest is Mg;

[0040] 1. The alloy square ingot is homogenized at 450°C for 24 hours, and then cooled with water;

[0041] 2. Keep the milled billet at 450°C for 2 hours; at the same time, preheat the roll to 280°C, and start rolling for 6 passes, with a reduction of 35% for each pass. After the 2nd and 4th passes, return to the furnace and heat to 450°C for 45 minutes and then continue rolling. The reduction in the last pass is 30%, and the total reduction is 94%;

[0042] 3. The plate after hot rolling is annealed at 350°C for 12 hours;

[0043] 4. After hot-rolling, the plate is cold-rolled 3 times at room temperature, the reduction of each pass is 15%, and the total reduction is 40%;

[0044] 5. The cold-rolled sheet is then annealed at 400°C for 1 minute;

Embodiment 3

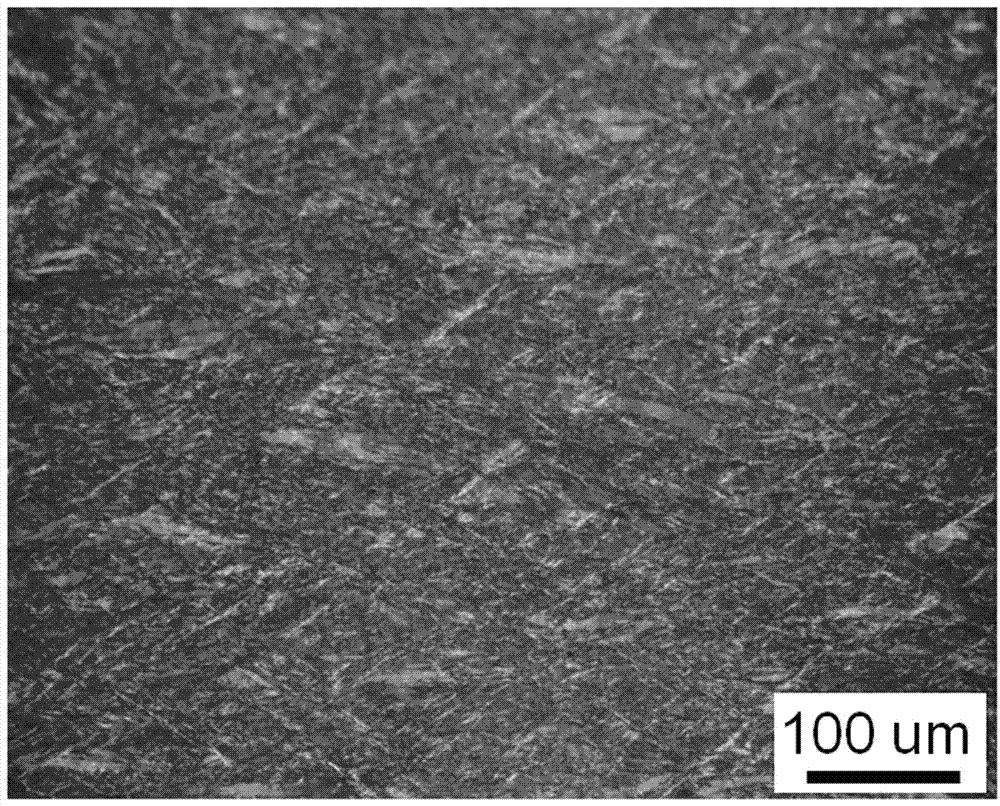

[0046] In this embodiment, a square ingot with a thickness of 100mm is produced by semi-continuous casting method, and the mass percentage of the alloy composition is: Zn 2%, Gd 2%, Zr 0.3%, and the rest is Mg.

[0047] 1. The alloy square ingot is homogenized at 520°C for 10 hours, and then cooled with water;

[0048] 2. Keep the milled blank at 500°C for 1 hour; at the same time, preheat the roll to 300°C, and start rolling for 4 passes, and the reduction in each pass is 40%. After the second pass, return to the furnace and heat to 500°C for 45 minutes and then continue rolling. The reduction in the last pass is 20%, and the total reduction is 85%;

[0049] 3. The plate after hot rolling is annealed at 400°C for 1 hour;

[0050] 4. After hot-rolling, the medium-thick plate is cold-rolled 4 times at room temperature, the reduction of each pass is 10%, and the total reduction is 35%;

[0051] 5. The cold-rolled sheet is then annealed at 450°C for 60 seconds;

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com