Patents

Literature

50results about How to "Process environment friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

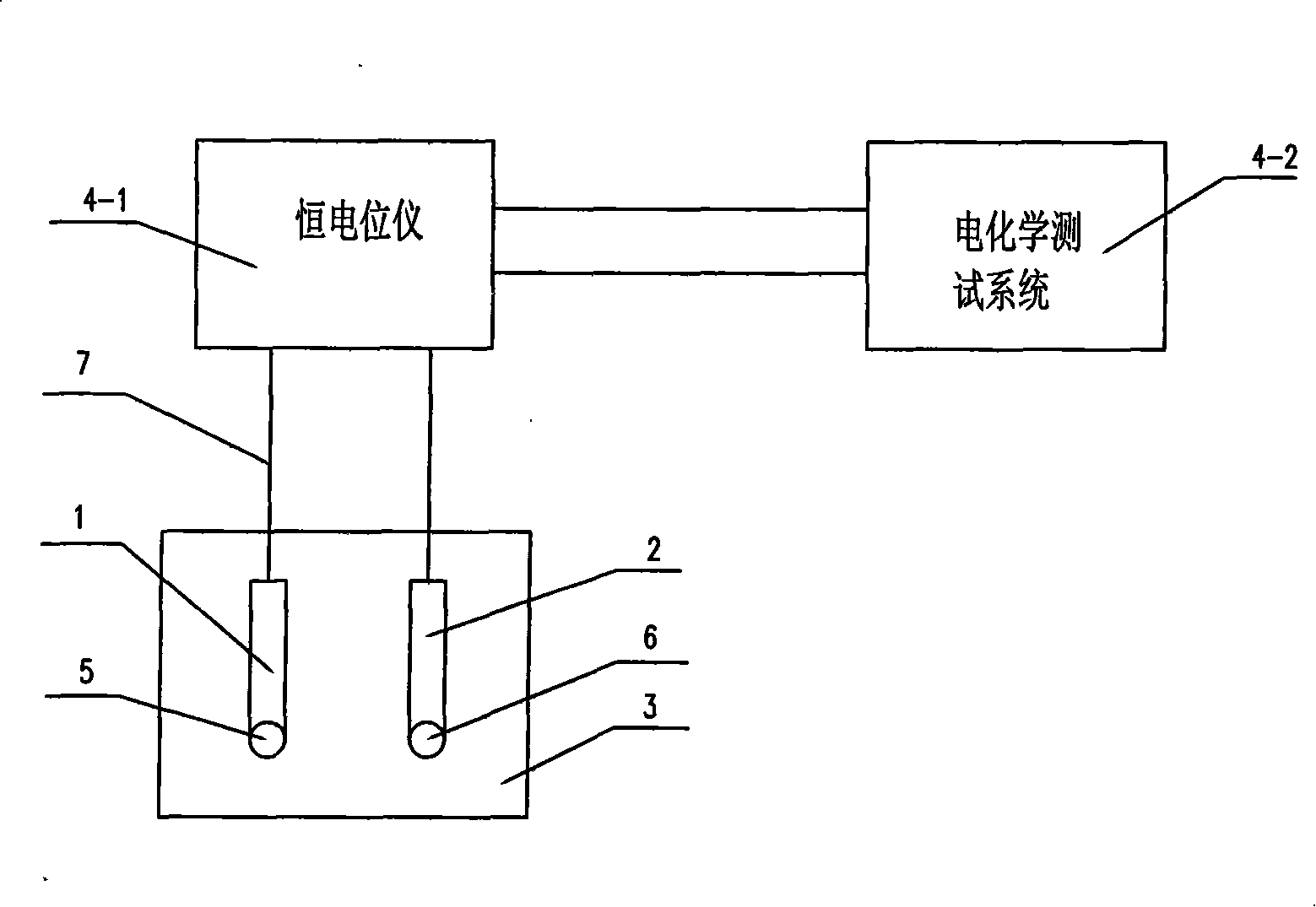

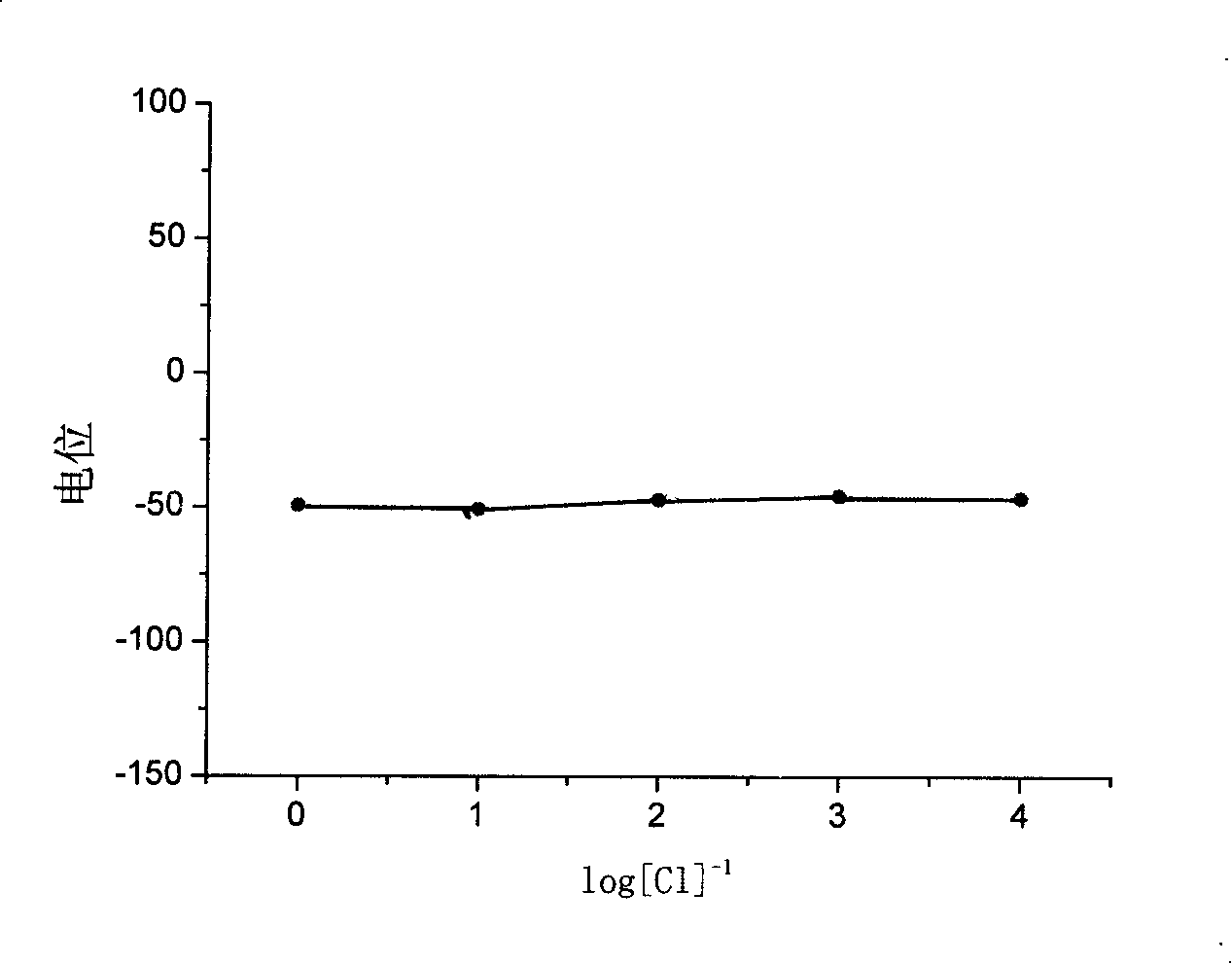

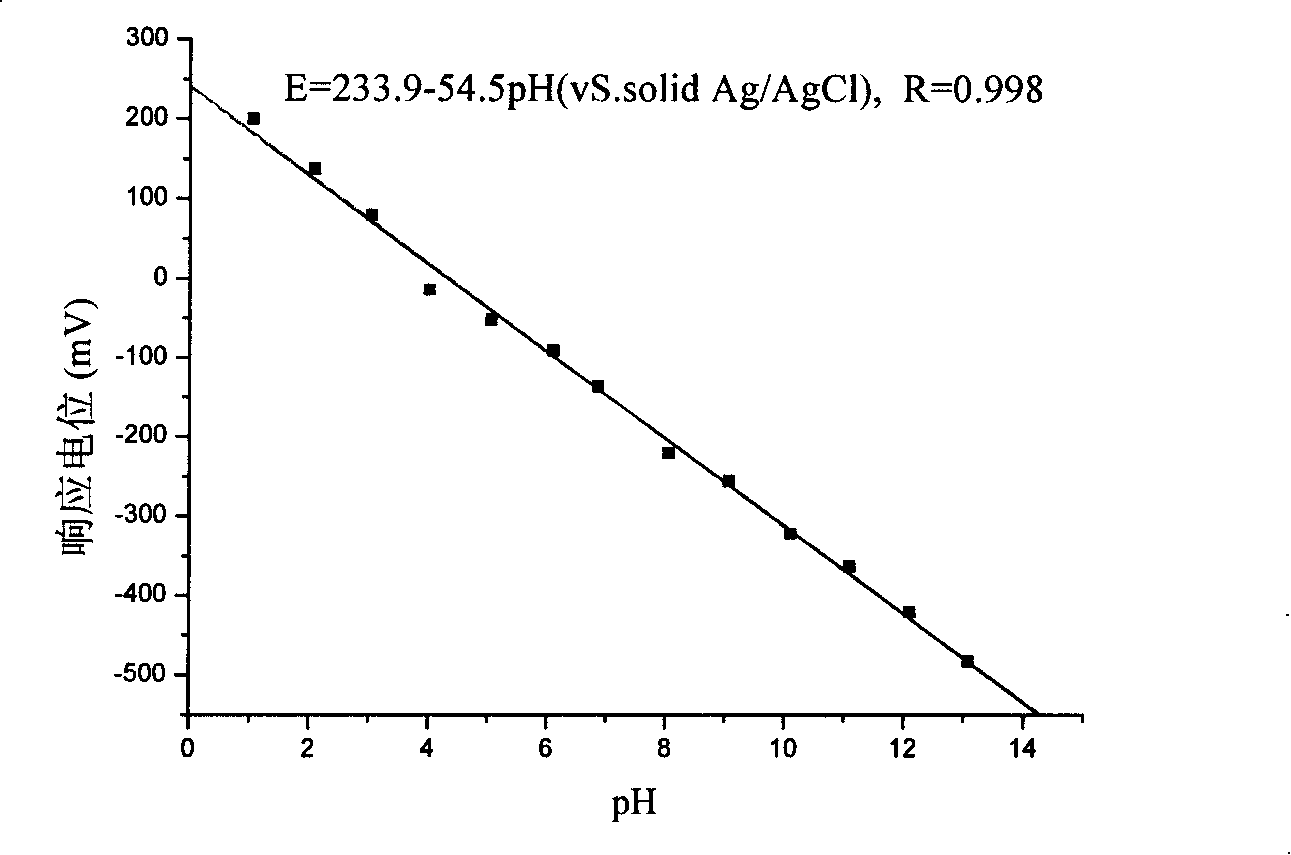

Integrated all-solid-state pH electrochemical sensor based on nanometer tungsten oxide and method for making same

InactiveCN101236170AEasy to prepareProcess environment friendlyMaterial electrochemical variablesAll solid stateMiniaturization

The invention discloses an integration all-solid-state PH electrochemical sensor and preparing method based on nanometer tungsten oxide. The sensor comprises a basal plate, a sensor and a detection device, wherein the basal plate is provided with a WO3 working electrode and an Ag / AgCl solid state reference electrode, and the two electrodes are externally connected with the detection device through connecting wires. The invention integrates the nanometer tungsten oxide H<+> response working electrode and the Ag / AgCl solid state reference electrode on the basal plate. The metal oxide H<+> response working electrode is characterized in that: the working electrode has easy preparation, quick response and high mechanical strength, thereby being applicable to a special detection environment which a glass PH electrode is not suitable for. In addition, the all-solid-state Ag / AgCl reference electrode which replaces the prior Ag / AgCl reference electrode needing filling reference solution facilitates miniaturization or portability.

Owner:FOSHAN UNIVERSITY +1

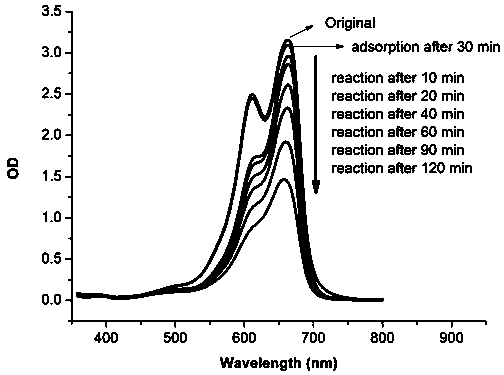

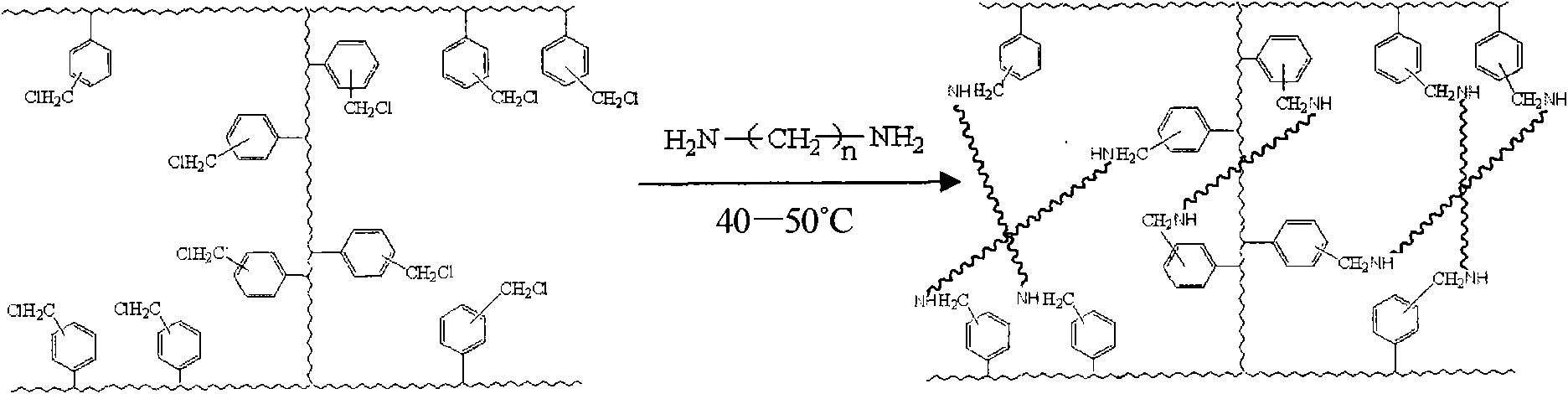

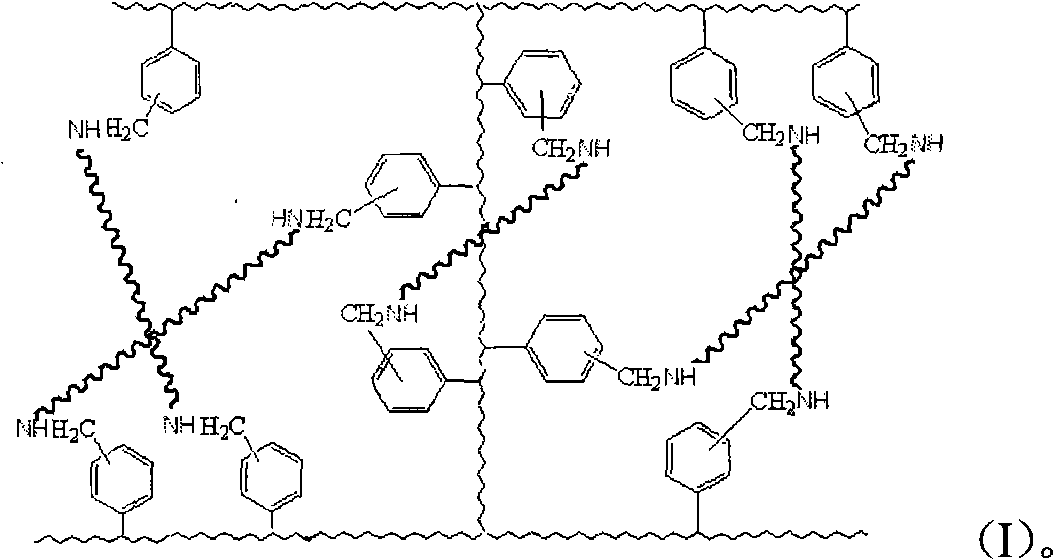

Uniform-hole amine resin and preparation and application method thereof

InactiveCN101829549AIncrease the degree of cross-linkingHigh content of functional groupsOther chemical processesAlkali metal oxides/hydroxidesChemical reactionPolystyrene

The invention discloses a uniform-hole amine resin and a preparation method and an application method thereof, belongs to the technical fields of decoloring resin synthesis of a novel hole structure, active ingredient separation and purification of a natural plant and the like, and in particular relates to a decoloring resin. The appearance characteristic and hole structure parameters of the uniform-hole amine resin are that the resin is spherical, faint yellow and semi-transparent; the grain diameter of the resin is 0.3 to 0.7mm; and the water content of the resin is 50 to 60 percent. The invention also discloses the preparation method and the application method for the uniform-hole amine resin. In the preparation of the uniform-hole amine resin, a non-good solvent serving as a porogen is not needed in the process of synthesizing the traditional macroporous resin; and a creative double-functional-group functional reagent and a polystyrene resin undergo a secondary crosslinking chemical reaction to generate a uniform-hole mesh structure, which has the structure characteristics of high crosslinking degree and high functional group content. For the decolouring application in plant polysaccharide, the decolouring rate of pigment in a plurality of plant polysaccharide extracts is over 95 percent and the recovery rate of the polysaccharide is over 90 percent only by one operation step, namely, adsorption; and the preparation method has the advantages of environmental-friendly process, low production cost, simple and convenient operation, high decolouring efficiency and suitability for large-scale industrial application.

Owner:NANKAI UNIV

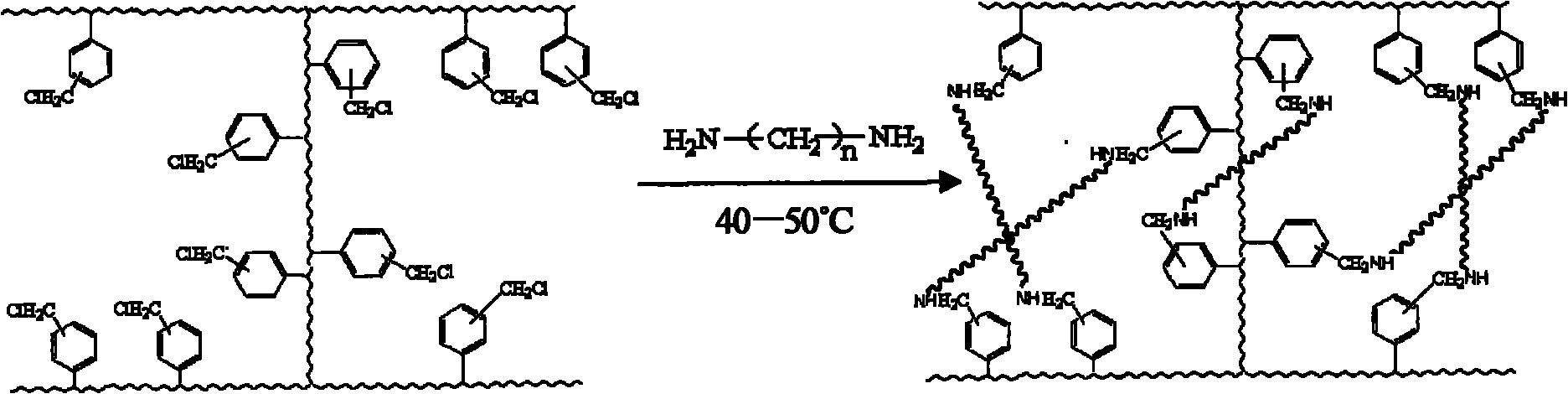

Method for extracting and recovering precious metal and rare metal from wastes

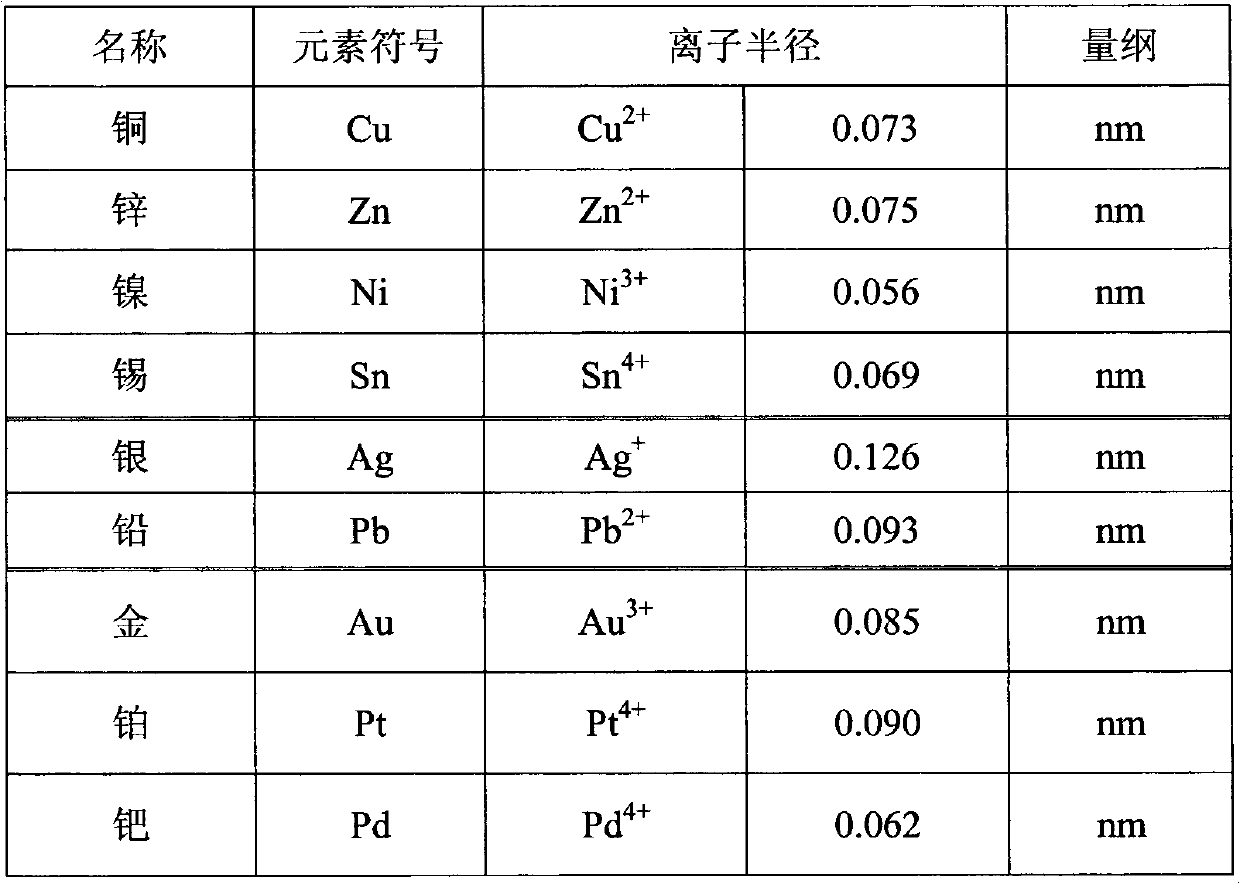

ActiveCN103374659AReduce utilizationHigh purityProcess efficiency improvementPhysical chemistryNanofiltration

The invention relates to a method for extracting and recovering precious metal and rare metal from wastes, in particular relates to a method for extracting precious metal and rare metal from wastes generated from electronic products and in the production process of the electronic products. According to the method, Comprehensive ionization equipment is adopted and different acid liquors are used for ionizing according to the chemical properties of different metals, thus realizing the continuous operation; aiming at the mixture liquor of metal ions, sectional nanofiltration membrane permeation is adopted according to the particle size difference of metal ions, and therefore the separation of metal ions with different particle sizes can be realized and the following refined purification technique can be simplified. By the method, the precious metal elements in the wastes can be extracted, the remaining waste plastic and water after extraction can both be recovered, and the resource utilization rate is high.

Owner:XINGUANG RECYCLING SHANGHAI

Comprehensive utilization method for iron and steel smelting dust washing wastewater

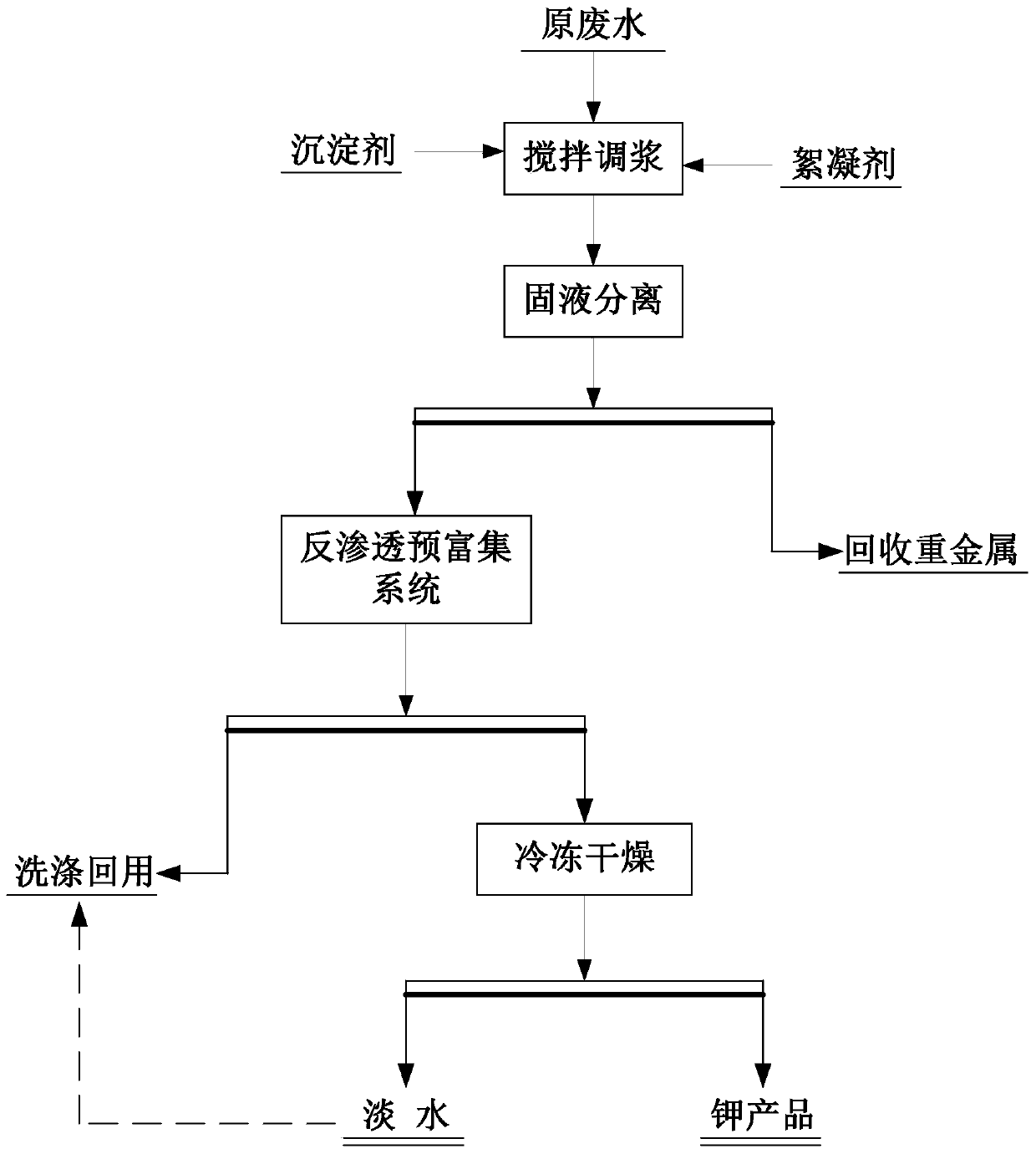

InactiveCN103991995ARealize comprehensive utilizationReduce energy consumptionWaste water treatment from metallurgical processMultistage water/sewage treatmentFreeze-dryingReverse osmosis

The invention relates to the field of comprehensive utilization of resources, and in particular relates to a comprehensive utilization method for iron and steel smelting dust washing wastewater. The method comprises the following steps: a) adding a precipitating agent and a flocculating agent into the iron and steel smelting dust washing wastewater to form a suspension; b) performing solid-liquid separation on the suspension, and collecting a solid phase and a liquid phase respectively; c) delivering the liquid phase to a reverse osmosis pre-enrichment system to complete pre-enrichment of alkali metals and chlorine ions and then obtain low salt water and a concentrated salt solution for washing smelting dust; and d) performing freeze drying on the concentrated salt solution to obtain a potassium salt and fresh water. The method realizes comprehensive utilization of the iron and steel smelting dust washing wastewater; the alkali metals and the chlorine ions can be pre-enriched through the reverse osmosis pre-enrichment system and freeze-dried, so that the energy consumption is reduced greatly compared with high salt water evaporation; meanwhile, the pre-enrichment manner has a relatively wide application prospect in the high salt wastewater treatment; the whole process is environment-friendly, economic and efficient.

Owner:孙伟

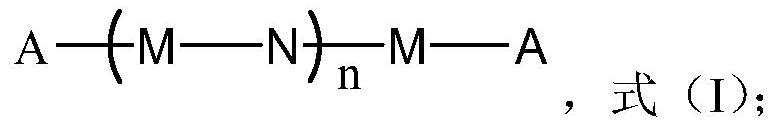

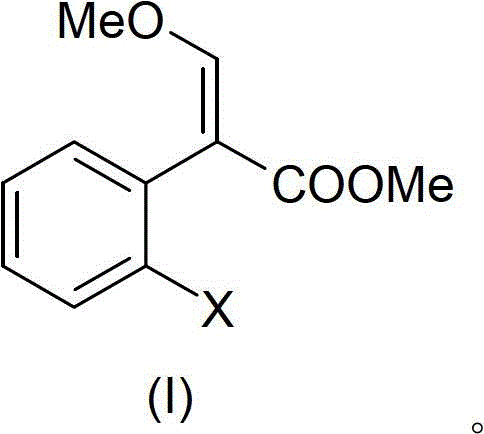

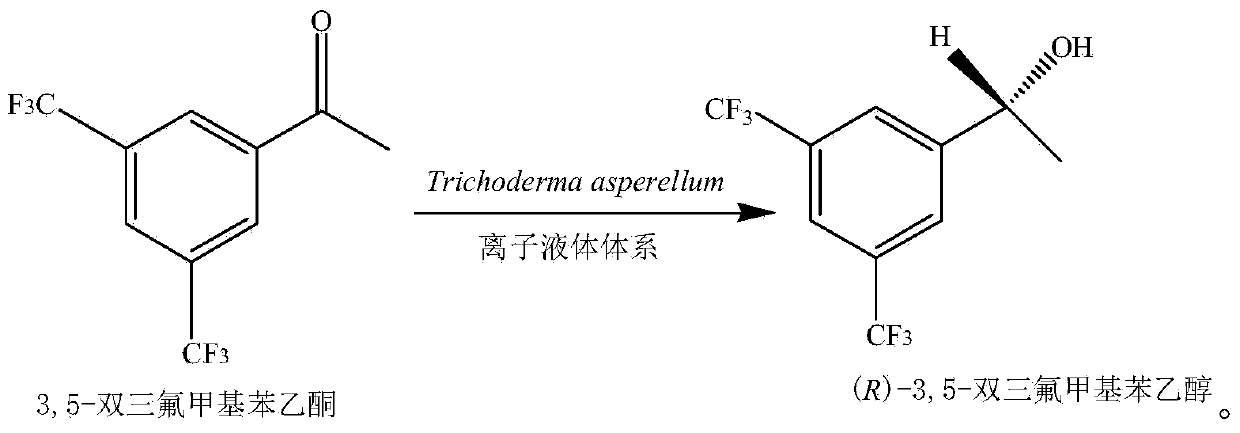

Method for preparing chiral alcohol by using reaction system containing ionic liquid

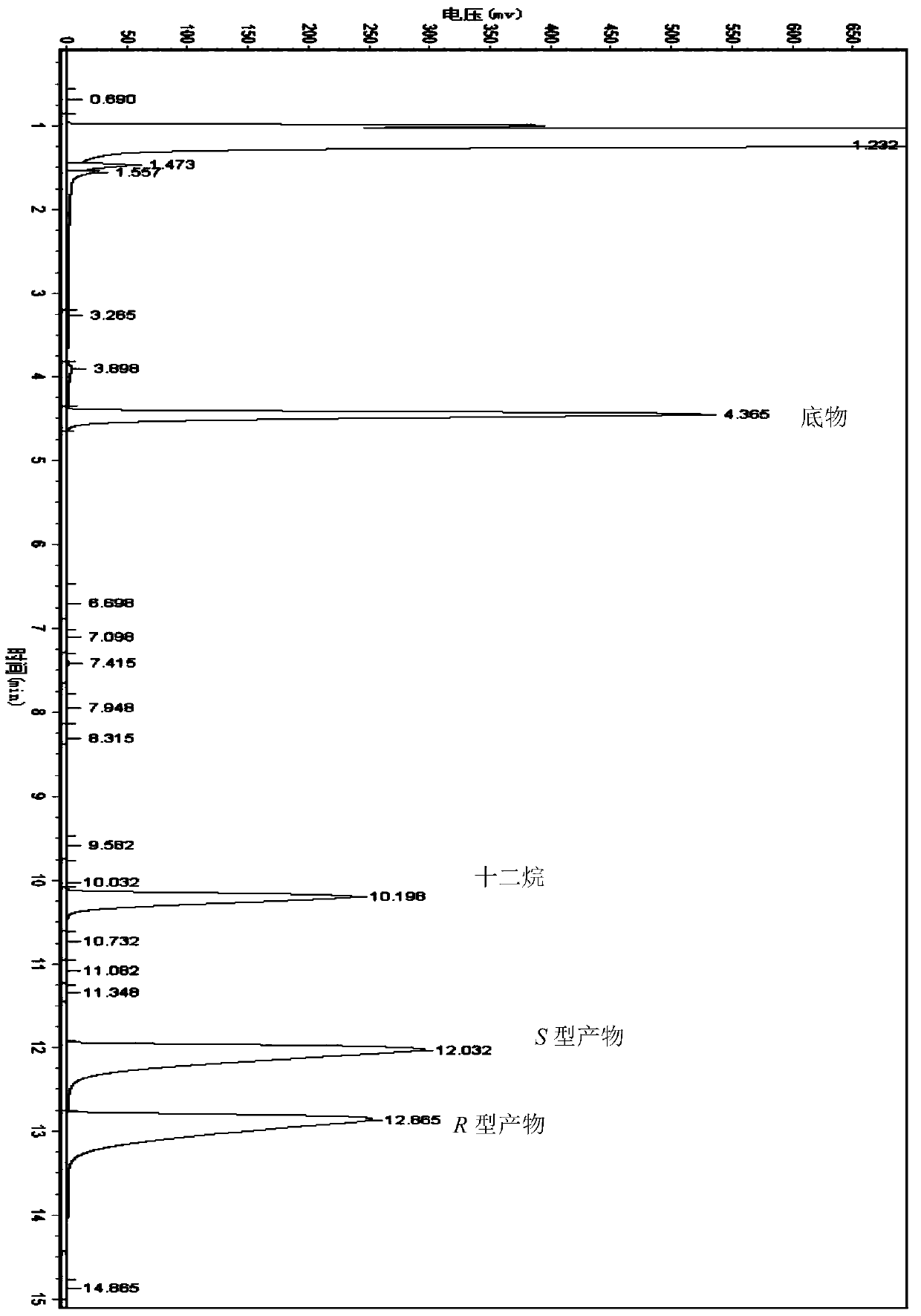

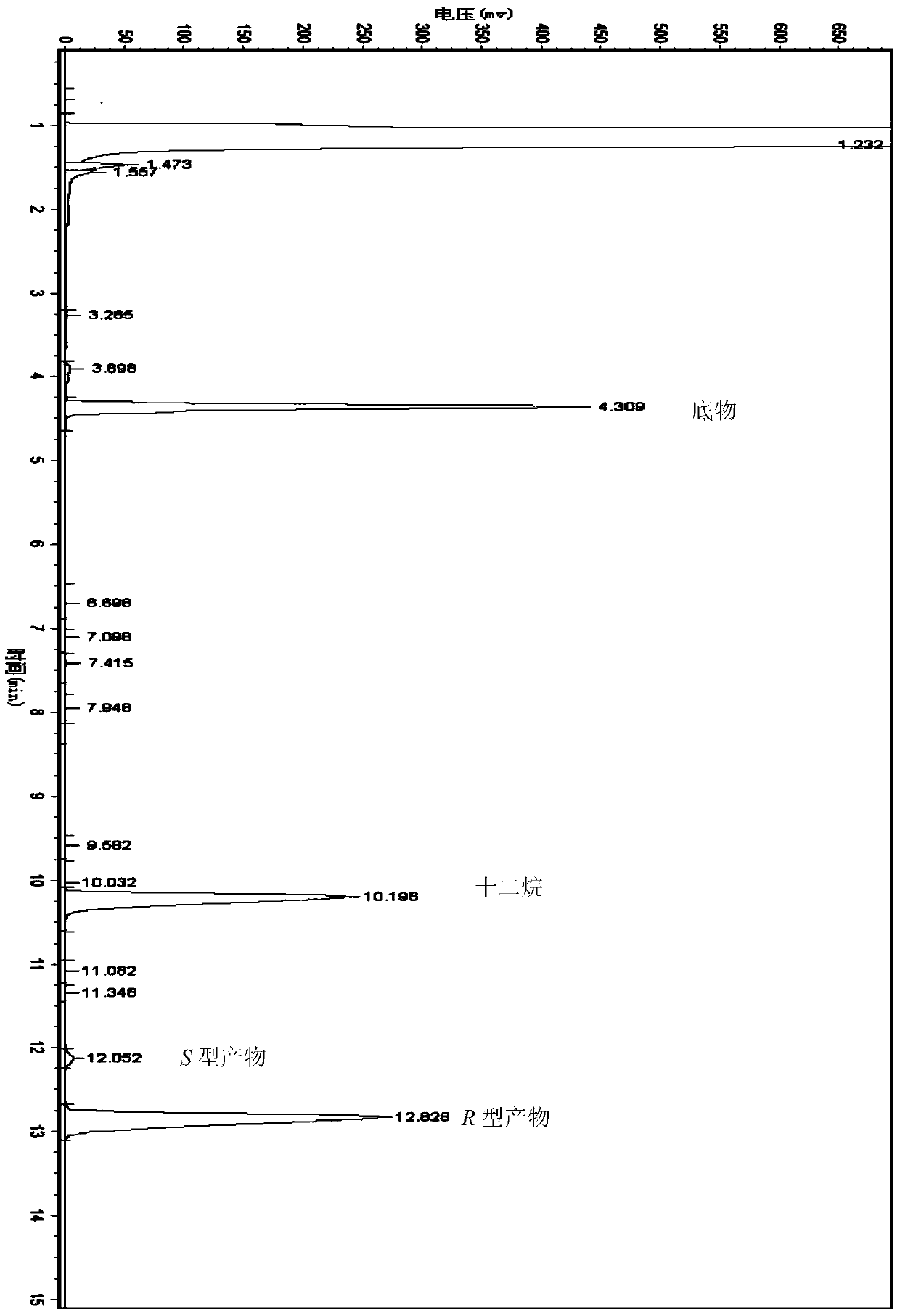

ActiveCN103695480ALow toxicityPromote regenerationMicroorganism based processesFermentationAlcoholTrichoderma asperellum

The invention discloses a method for preparing (R)-[3,5-bi(trifluoromethyl) phenyl]ethanol in a reaction system containing ionic liquid. The method comprises the following steps: with wet mycelium obtained by cultivation of trichoderma asperellum ZJPH0810 as a catalyst and 3,5-bi(trifluoromethyl) hypnone as a substrate, reacting for 6-50 hours under the conditions of 25-45 DEG C and 100-300r / min inside the reaction system composed of amino acid ionic liquid shown in a formula (I) and a phosphate buffer of which the pH value is 5.5-8.0; and separating and purifying the reaction liquid to obtain the product (R)-[3,5-bi(trifluoromethyl) phenyl]ethanol. The amino acid ionic liquid disclosed by the invention has the function of facilitating coenzyme regeneration, and is low in toxicity, green and environment-friendly, renewable and biodegradable; the reaction system containing the ionic liquid is applied to biological catalytic reaction, so that the method is friendly to the environment, and accords with the green development strategy, and the defects that the traditional ionic liquid is poor in biodegradability, nonrenewable and the like can be overcome.

Owner:扬州市冠科科技有限公司

Preparation method of rough-rice-fermented active lactobacillus beverage

ActiveCN104342340AImprove gelatinizationReduce lossesAlcoholic beverage preparationAdditive ingredientFood flavor

The invention discloses a preparation method of a rough-rice-fermented active lactobacillus beverage. The method comprises the following steps: dividing the rough rice raw material into two parts, and carrying out humidity regulation, surface airing and high-temperature fluidization treatment on one part of the rough rice raw material; crushing and wetting the rough rice subjected to high-temperature fluidization, mixing with Chinese yeast, fermenting, and separating after the fermentation finishes, thereby obtaining a clear solution A; immersing the other part of rough rice, pulping, gelatinizing and saccharifying to obtain a saccharification solution B; and mixing the clear solution A and saccharification solution, adding additives, inoculating lactobacillus, and fermenting to obtain the rough-rice-fermented active lactobacillus beverage. By using the rough rice or mashed rough rice as the raw material and adopting the high-temperature fluidization technique, the method has the advantages of high treatment and utilization ratio, thick flavor of beverage, low loss of natural nutritional ingredients of rough rice, and short fermentation time; and the raw material gelatinization degree is high, and therefore, the product does not generate the phenomena of starch retrogradation, precipitation and the like in the storage process, thereby implementing high-value utilization of mashed rice resources. The method does not generate wastewater, and is environment-friendly in technique.

Owner:ZHEJIANG UNIV OF TECH

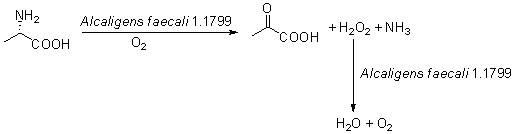

Biocatalysis method for preparing pyruvic acid from L-alanine

ActiveCN102586343ASimple separation processHigh chemical purityMicroorganism based processesFermentationL-amino-acid oxidaseAmmonia

The invention provides a biocatalysis method for preparing pyruvic acid from L-alanine. The method comprises the steps of: carrying out permeability treatment on Alcaligens faecalisl.1799 cells; catalyzing oxidative deamination of L-alanine by utilizing L-amino acid oxidase in the cells in the presence of air to form pyruvic acid, ammonia and hydrogen peroxide; catalyzing the hydrogen peroxide formed in the reaction by utilizing catalase in the cells to realize pyruvic acid accumulation without producing by-products. The method provided by the invention has the advantages of low cost, high product yield and purity and environment friendliness, and is suitable for industrial production of pyruvic acid.

Owner:CHONGQING UNIV OF POSTS & TELECOMM +1

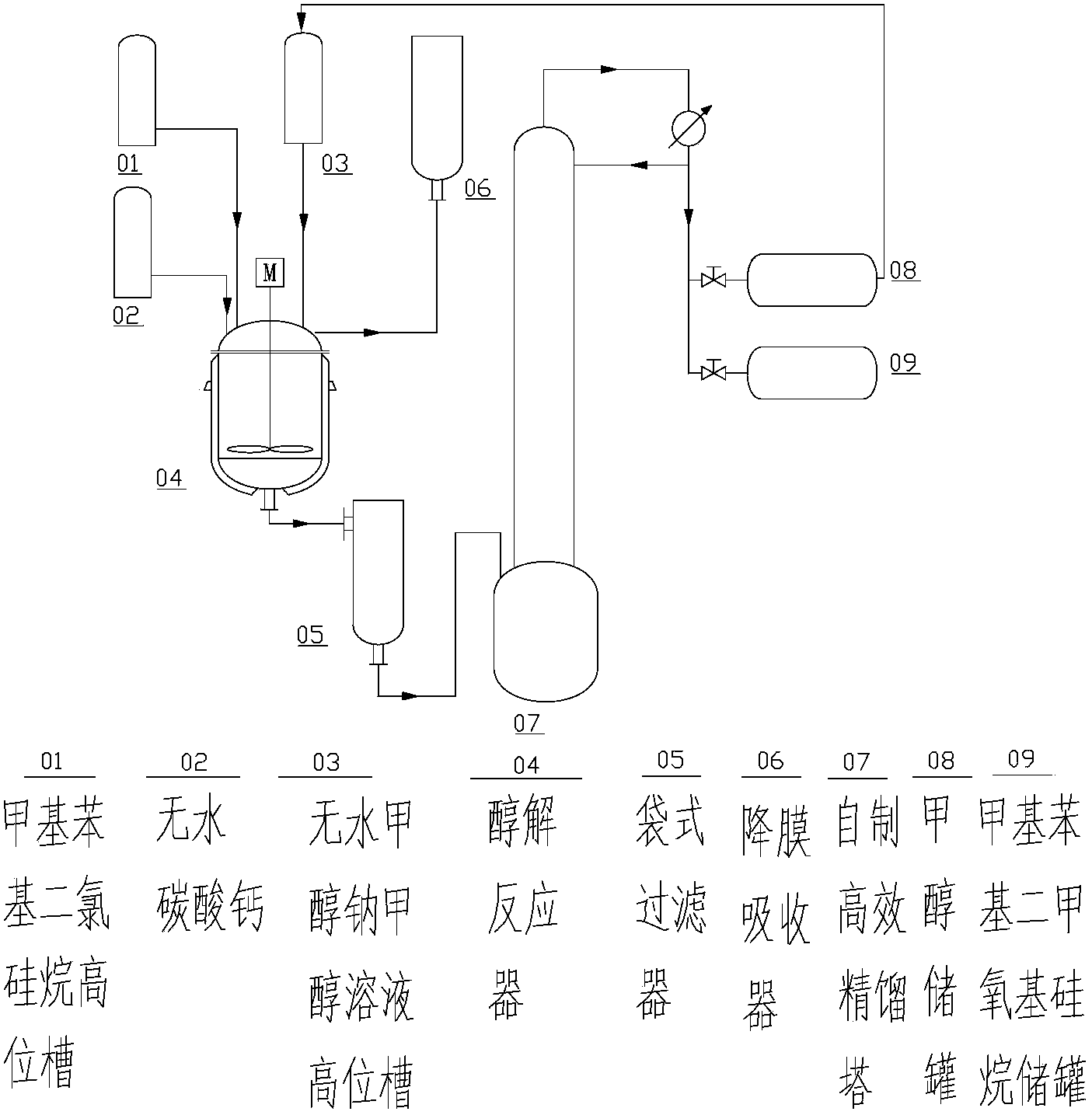

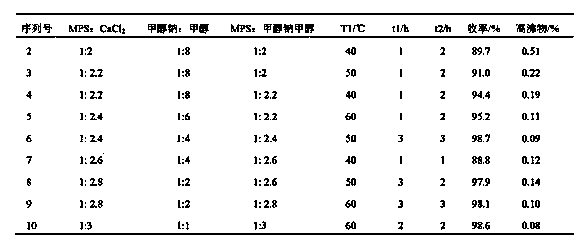

Preparation method for high-purity methylphenyl-dimethoxysilane

InactiveCN103896978AAvoid it happening againReduce generationChlorine/hydrogen-chlorideGroup 4/14 element organic compoundsAlcoholReaction temperature

The invention relates to a preparation method for high-purity methylphenyl-dimethoxysilane. The preparation method is characterized in that high-purity methylphenyl-dimethoxysilane is prepared through four-step deacidification. The method comprises the following steps: 1) adding dichloromethyl phenylsilane and a hydrogen chloride absorbent into an alcoholysis enclosed agitation reactor, then slowly adding a mixed liquor of absolute methanol and a catalyst drop by drop, controlling a certain reaction temperature, carrying out reflux deacidification at a certain temperature after completion of dropwise addition, carrying out filtering after complete reaction so as to obtain a crude methylphenyl-dimethoxysilane product and recovering the tail gas--hydrogen chloride gas by using a falling film absorption system for preparation of hydrochloric acid; and 2) adding the crude methylphenyl-dimethoxysilane product into a self-made gradient high-efficiency rectifying tower bottom, controlling rectification temperature for fractionation and recovery of methanol and adjusting a reflux ratio to rectify high-quality methylphenyl-dimethoxysilane with quality reaching an international advanced level. The preparation method for methylphenyl-dimethoxysilane has the advantages of environment friendliness, cyclic utilization of resources, stable process, simple operation and product purity of more than 99.5%.

Owner:安徽祥源科技股份有限公司

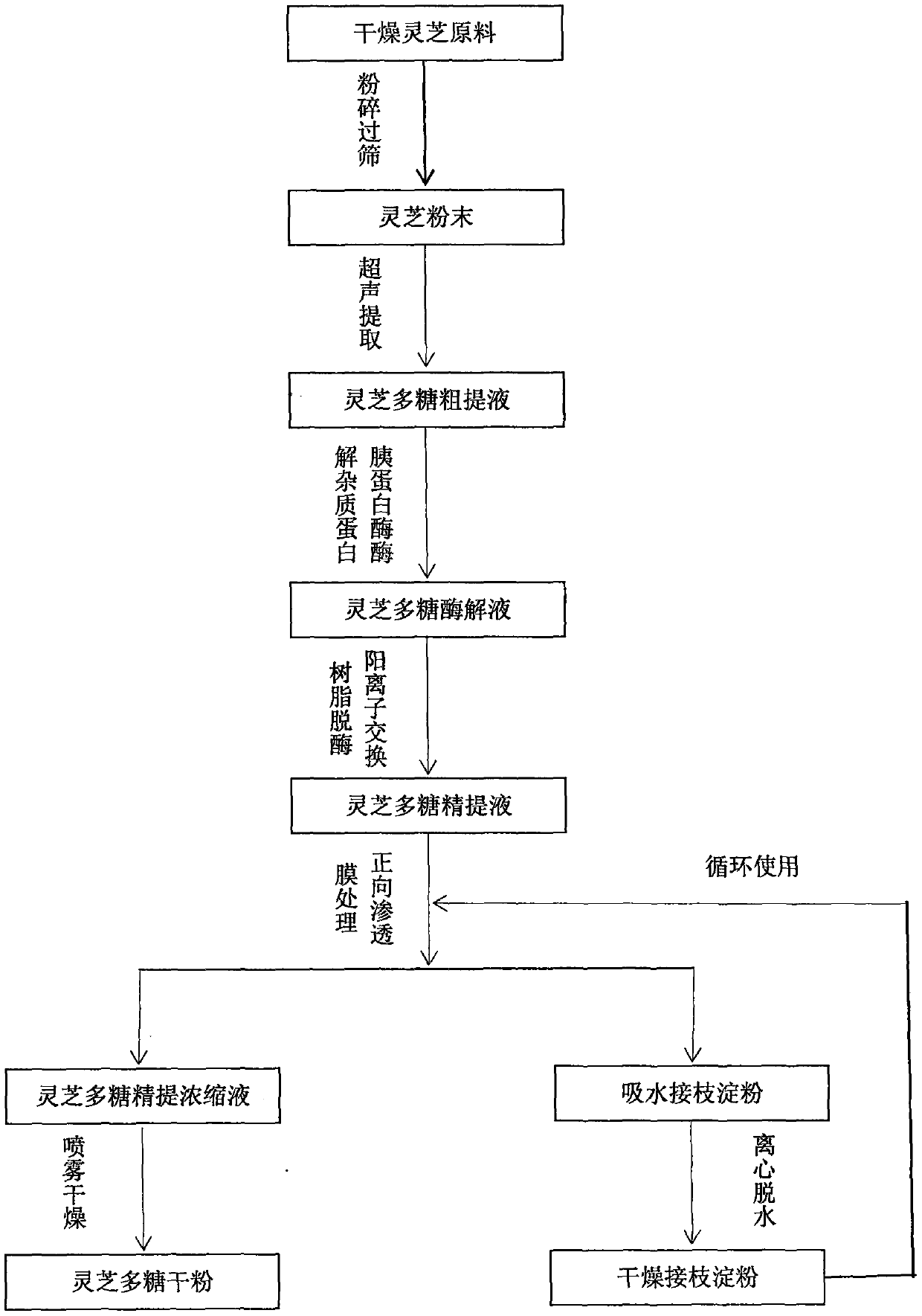

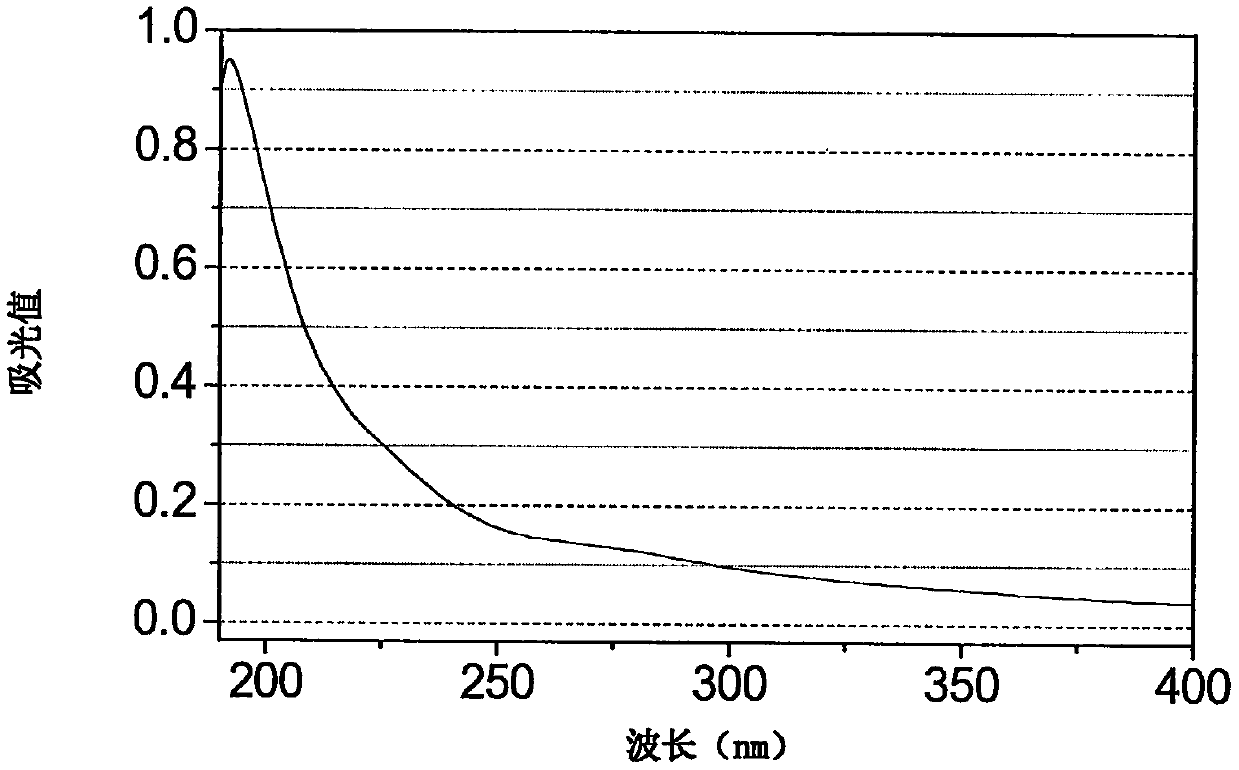

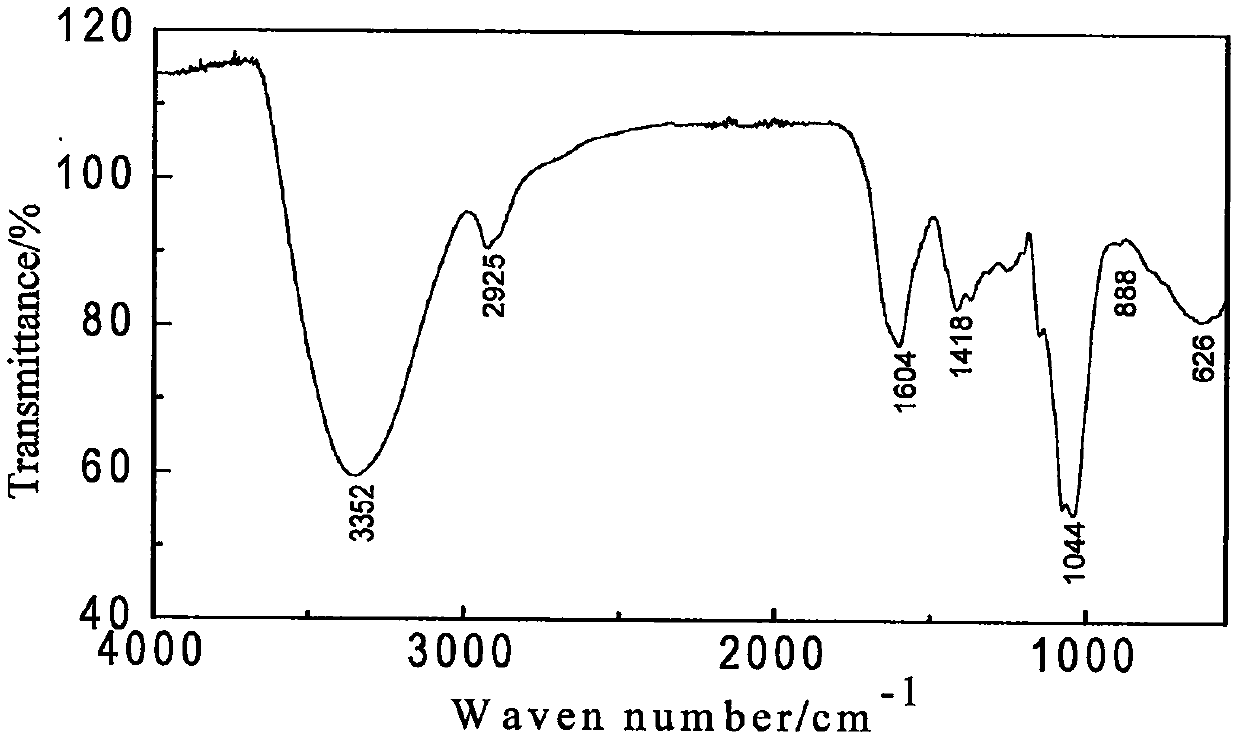

Refining process of Ganoderma lucidum polysaccharide

The present invention relates to a refining process of Ganoderma lucidum polysaccharide, which is prepared from dried Ganoderma lucidum by pulverizing and sieving, ultrasonic extracting polysaccharide, trypsin hydrolyzing protein impurities, cation exchange resin deenzyme, forward osmotic membrane treatment, spray drying and other technological steps, so as to obtain refined Ganoderma lucidum polysaccharide. Protein impurities in Ganoderma polysaccharide extract are hydrolyzed with single trypsin, the isoelectric point of trypsin is high than that optimum reaction pH, and after enzymatic hydrolysis, a cation exchange resin is directly used to deenzyme, thus eliminating the need to adjust pH value again, and the process is simple. The deenzymatic polysaccharide extract is filled with 100-fold water-absorbent grafted starch and treated with forward osmotic membrane with molecular weight cut-off of 5000Da. The proteolytic peptides are removed at the same time of concentration. The separation efficiency is high and the energy consumption is low. The trypsin enzymatic hydrolysis, cation exchange resin deenzyme and forward osmosis membrane treatment are carried out in series, which can not only completely remove protein impurities and achieve high purity of polysaccharide, but also mild deproteinization conditions and stable structure of polysaccharide can be achieved.

Owner:HEFEI UNIV OF TECH +1

Method for preparing metallic cladding expansion graphite

ActiveCN102631922ANot easy to bring outDecomposition reaction is mildCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsGraphiteOrganic matter

The invention provides a method for preparing metallic cladding expansion graphite by means of liquid phase technology. The method includes the steps: synthesizing raw graphite into expansion graphite; uniformly mixing anhydrous metal salt with liquid aprotic organic matters at the temperature of 20-100 DEG C to obtain anhydrous metal salt organic suspending liquid; uniformly stirring the expansion graphite with the anhydrous metal salt organic suspending liquid prior to standing for 0-4h; preserving heat for 12-48h at the temperature of 400-700 DEG C in an air isolating manner; and cooling the expansion graphite to obtain the metallic cladding expansion graphite. By the aid of the method, high embedding quantity of metallic elements can be ensured, so that the relative content of metallics in the metallic cladding expansion graphite can be precisely controlled. Compared with a traditional method for preparing metallic cladding expansion graphite by means of solid phase technology, the method is higher in operability, environment-friendly and low in energy consumption.

Owner:HUNAN SHINZOOM TECH

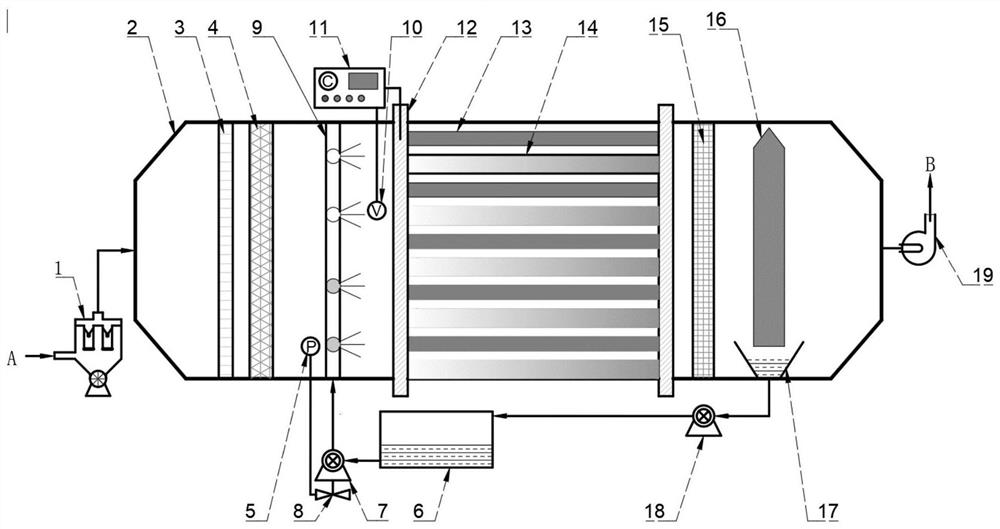

System and method for treating VOCs (Volatile Organic Chemicals) by excimer optical coupling catalysis means

ActiveCN111603929AImprove purification efficiencyIncrease profitGas treatmentDispersed particle filtrationHEPAPtru catalyst

The invention discloses a system and a method for treating VOCs (Volatile Organic Chemicals) by an excimer optical coupling catalysis means. Removing particles in the industrial waste gas through a dust remover and a Hepa filter screen; after being fully mixed with water vapor and passing through a catalyst layer, O2 and H2O generate active substances such as O3 and. OH free radicals under the synergistic effect of excimer light and a catalyst, then VOCs are thoroughly converted into CO2 and H2O, and finally harmless treatment of industrial waste gas is achieved; a substrate of the catalyst isTiO2 existing in an anatase form, and a cocatalyst is one or a compound of ZnO, SnO2, ZrO2, g-C3N4 and g-C3N4; the utilization rate of energy is effectively improved, the complexity of the system isreduced, and the operation and maintenance costs of the VOCs recovery system are reduced. The method has the characteristics of high treatment capacity, high purification rate and the like, auxiliaryheating equipment is not needed in the operation process, the energy consumption loss of the system can be reduced, the operation cost is reduced, and secondary pollution is avoided.

Owner:XI AN JIAOTONG UNIV

Method for removing gas-liquid inclusion in quartz sand by using microwave bursting method

The invention discloses a method for removing gas-liquid inclusion in quartz sand by using a microwave bursting method. Microwave power is the most significant factor which can affect the removal effect of the gas-liquid inclusion in quartz sand, and the scientific and precise method comprises the following steps: putting primarily purified quartz sand in microwave radiation of which the microwave power is 2100-2700w, and treating for 1-3 hours when the temperature of microwave treatment is kept being 700-900 DEGC. A great number of tests show that the gas-liquid inclusion removal effect of a quartz sand material treated by using the method disclosed by the invention is good, gas-liquid inclusion can be even completely removed, and the high-purity quartz sand can meet the requirement of being a crystal substitute product. The method is good in environmental friendliness, simple to operate, stable and reliable in process and applicable to industrial large-scale production.

Owner:HUNAN UNIV OF TECH

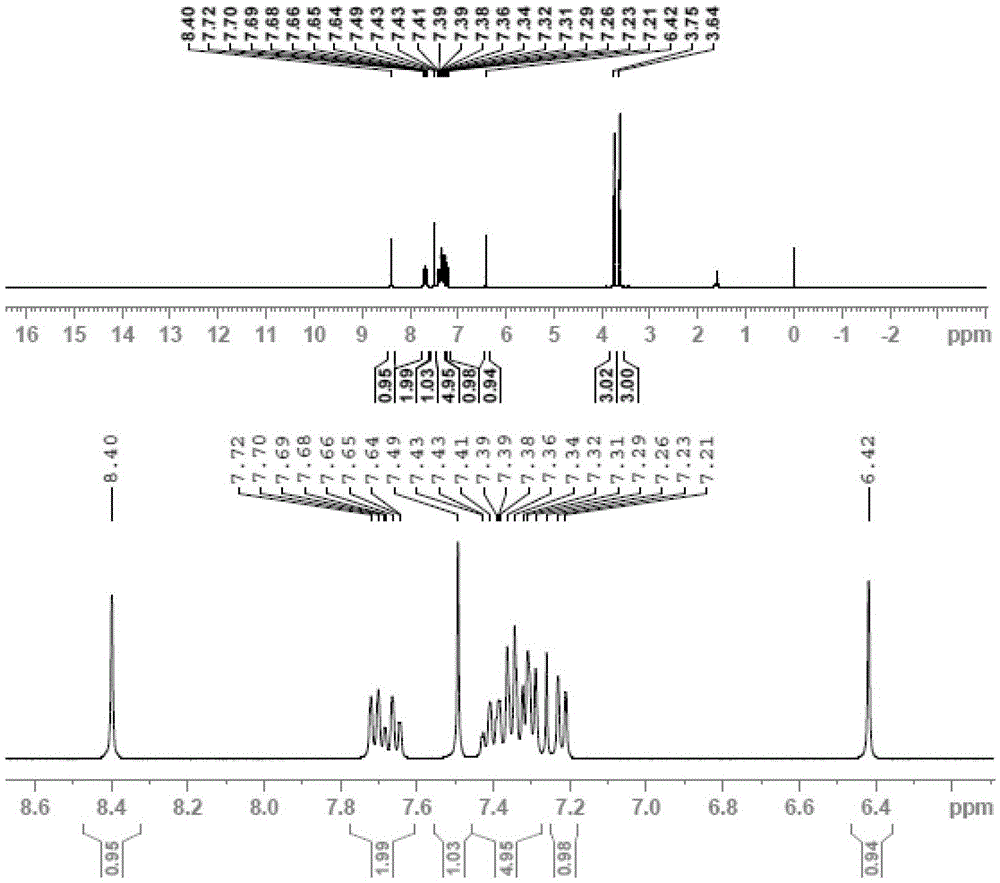

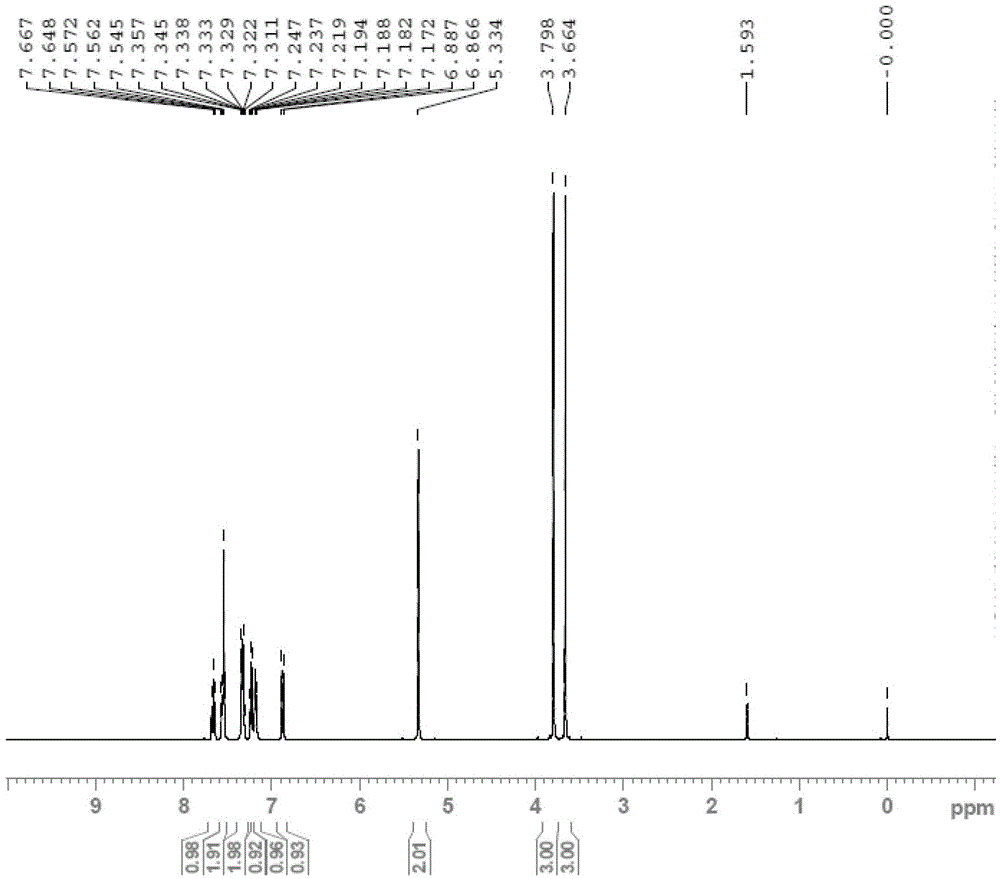

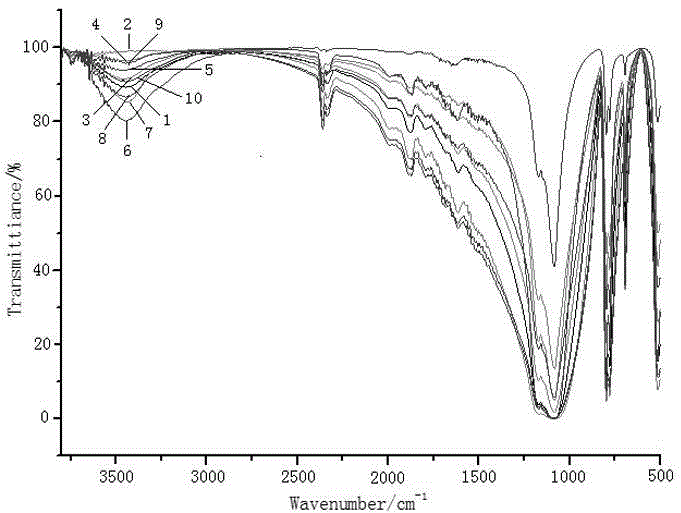

(-)-[gamma]-lactamase, gene, mutant, vector as well as preparation method and application of (-)-[gamma]-lactamase

ActiveCN105950595AHigh optical activityMild reaction conditionsHydrolasesFermentationMutantSubstrate concentration

The invention relates to (-)-[gamma]-lactamase, a gene and a mutant of the (-)-[gamma]-lactamase, a recombinant expression plasmid and a recombinant expression transformant containing the gene and the mutant, a preparation method of the (-)-[gamma]-lactamase and an application of the (-)-[gamma]-lactamase in preparing (+)-[gamma]-lactam. Compared with the prior art, the (-)-[gamma]-lactamase disclosed by the invention has the characteristics of being high in enzymatic activity and good in substrate concentration tolerance; the (+)-[gamma]-lactam, which is prepared through enzymatic catalysis, has the advantages of being mild in reaction condition, high in substrate concentration, low in catalyst dosage and the like; therefore, the (-)-[gamma]-lactamase has a good application prospect in industrial production of the (-)-[gamma]-lactamase which is an intermediate product of carbocyclic nucleoside drugs.

Owner:EAST CHINA UNIV OF SCI & TECH

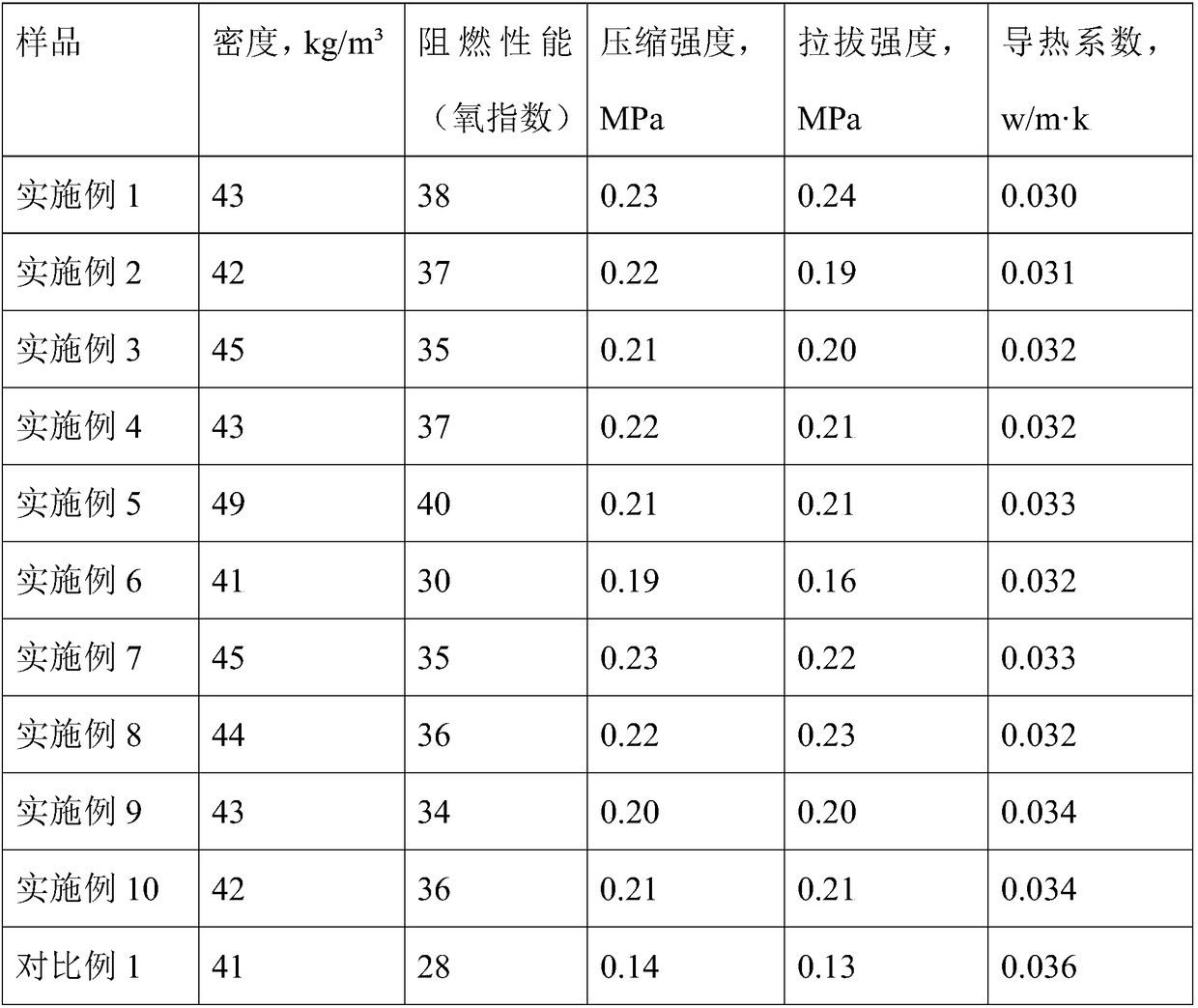

Modified polystyrene board, and preparation method and application thereof

The invention relates to a preparation method of a modified polystyrene board. The preparation method comprises the following steps: (1) mixing thermosetting resin with a flame retardant to obtain a binding material; (2) uniformly mixing polystyrene foaming particles with the binding material to obtain a formed material; and (3) adding a curing agent into the formed material, carrying out mixing,and then carrying out mechanical pressurizing forming to obtain the modified polystyrene board. According to the invention, a conventional method of modified polystyrene board secondary foaming and water vapor forming is replaced by the method combining phenolic resin foaming binding with mechanical pressurization, so that the process is simple, polystyrene board wastes can be effectively utilized, zero pollutant emission can be realized, waste polystyrene beads which are difficult to treat are consumed, the cost is reduced, and the environment-friendly process is realized. In a preferable technical scheme, a foaming agent is added into the binding material, so that phenolic resin can be foamed, and the polystyrene board becomes more compact with the matching of mechanical pressure, so that the board has higher strength and heat-preservation performance.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

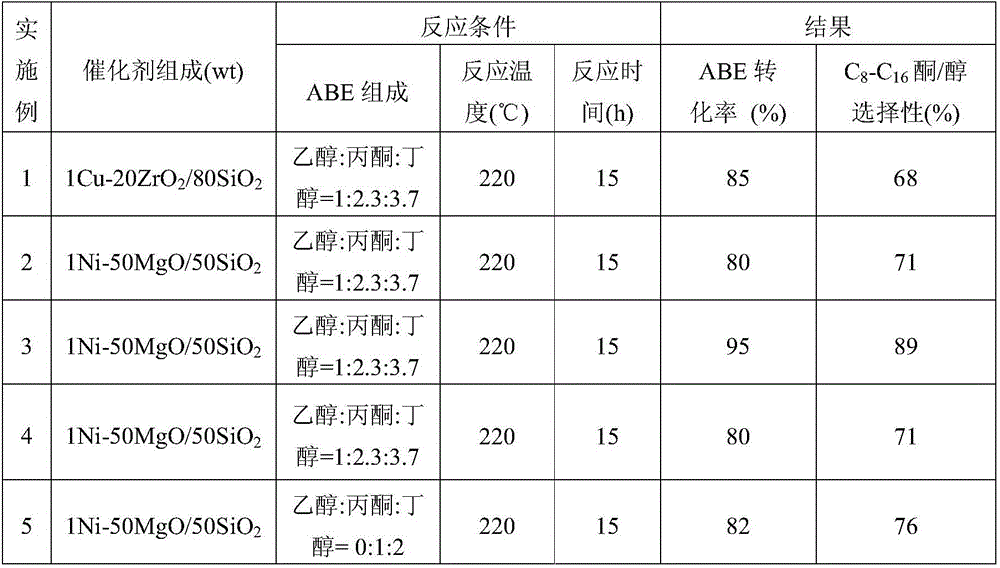

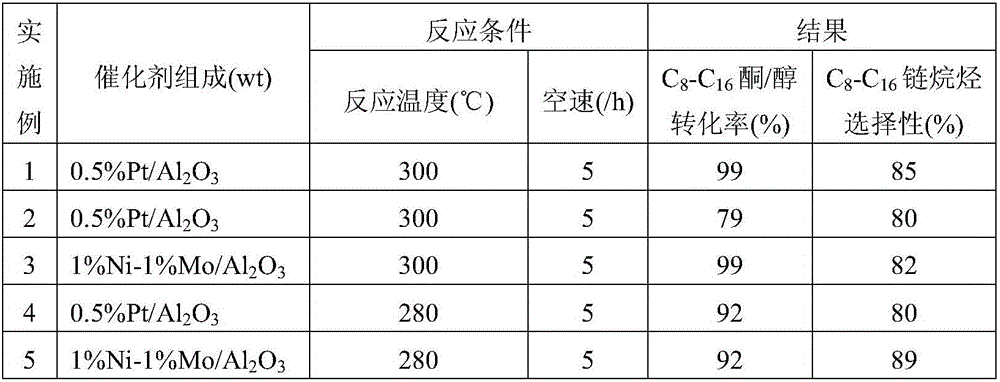

Aviation fuel additive and preparation method and application thereof

The invention relates to an aviation fuel additive and a preparation method and application thereof. The method comprises the step that the aviation fuel additive is prepared by taking material liquid or fermentation liquid which is obtained by means of fermentation of non-grain biomass and contains acetone, butanol and optional ethanol through a condensation reaction and hydrodeoxygenation treatment. The aviation fuel additive is C8-C16 alkane and does not contain arene, and the mass content of carbon and hydrogen is larger than 98 wt%; the aviation fuel additive can be compounded with aviation fuel to be prepared into aviation alternative fuel, the aviation fuel standard is met, and meanwhile consumption of petroleum-based aviation fuel can be greatly reduced. According to the preparation method of the aviation fuel additive, the production technology is simple, the product quality is good, the yield is high, the raw materials are wide in source, the production cost is low, and large-scale production can be achieved.

Owner:BEIJING UNIV OF CHEM TECH

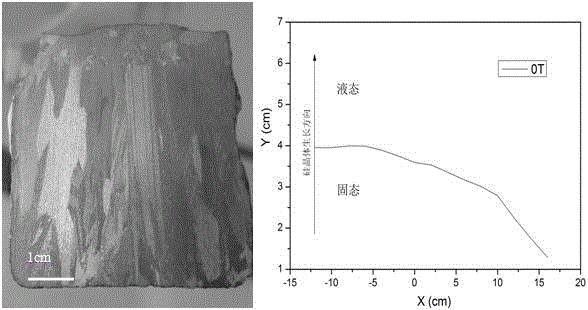

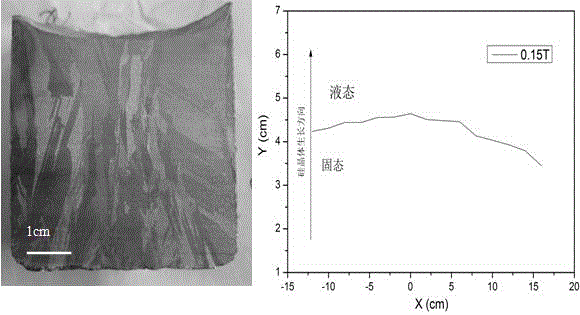

Method for improving metallurgical-method polycrystalline silicon growth interface

InactiveCN106567125AImprove ingot qualityProcess environment friendlyPolycrystalline material growthAfter-treatment detailsCrystalliteDirectional solidification

The invention relates to a method for improving a metallurgical-method polycrystalline silicon growth interface. The method comprises the steps: (1) loading polycrystalline-silicon silicon materials to a high-purity quartz crucible, placing the high-purity quartz crucible into a directional solidification furnace, and carrying out vacuumizing until the internal degree of vacuum of the furnace is lower than 10Pa; (2) heating the temperature of the furnace to 1,450 DEG C to 1,550 DEG C so as to melt the silicon materials; (3) carrying out external-field treatment on the silicon materials for 10 to 30 minutes at the magnetic intensity of 0.15T to 0.5T, then, cooling the furnace body at the rate of 5 DEG C / min to 10 DEG C / min, downwards shifting a moving part of the furnace body at the rate of 5mm / h to 10mm / h, enabling silicon melt to be divorced from a heater and start to grow crystals, and closing a magnetic field when the temperature is 1,100 DEG C to 1,200 DEG C; and (4) after crystal growth, enabling the moving part of the furnace body to rise to an initial position in a furnace chamber at the rate of 2mm / s to 4mm / s, then, heating the temperature to 1,250 DEG C to 1,350 DEG C, carrying out heat preservation for 2 to 5 hours, and then, carrying out cooling at the cooling rate lower than 4 DEG C / min. According to the method, the form of a solid-liquid interface in a silicon material growth process is regulated and controlled by adopting an external static magnetic field, so that a smooth solid-liquid interface is obtained, ideal columnar crystal grain tissue is obtained, and the quality of silicon ingots is improved; and the process is more environmentally friendly, is compatible with the existing technologies of enterprises and is applicable to large-scale production.

Owner:XINYU UNIV

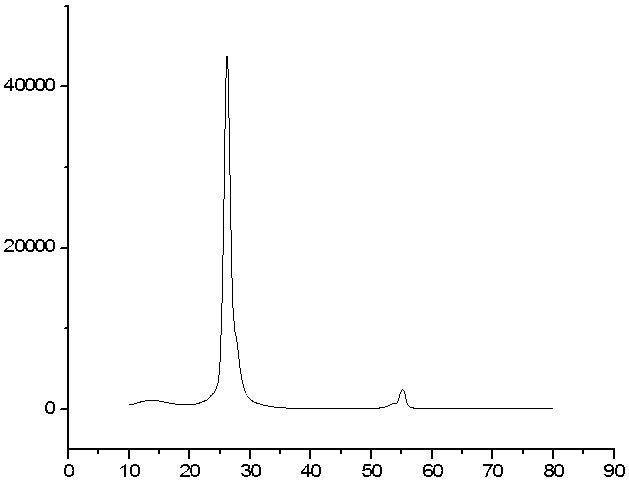

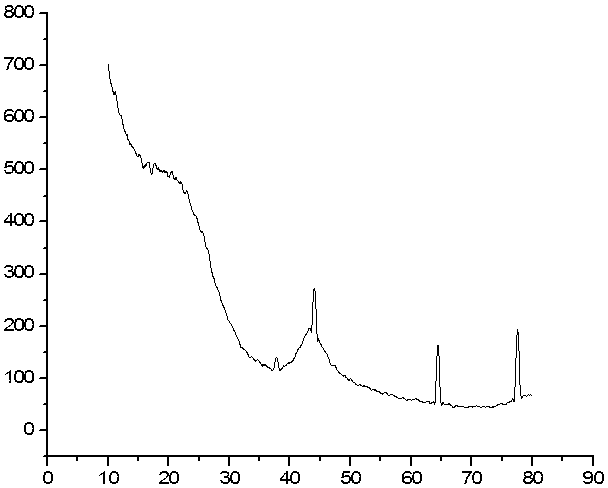

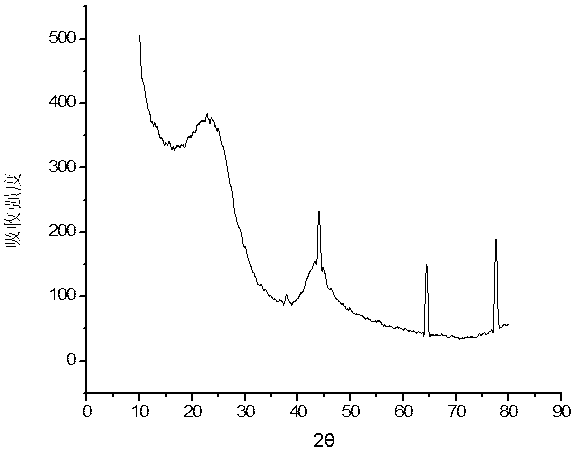

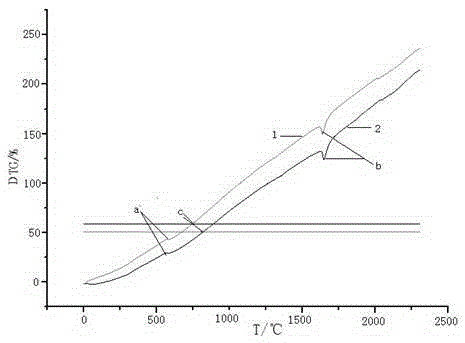

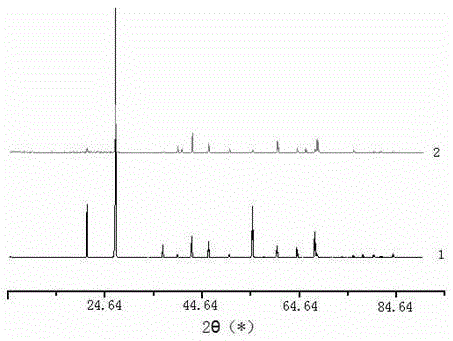

Bio-ene charcoal material and preparation method thereof

The invention relates to a bio-ene charcoal material and a preparation method thereof. According to the invention, a powdery biomass raw material is impregnated with a mixed water solution of phosphoric acid and sulfate; filtering is carried out, and the obtained material is dried by dipping; the material is activated for 60-150min under a temperature of 200-500 DEG C in a protective atmosphere; the activated biomass raw material is heated to a temperature of 1000 DEG C in a protective atmosphere, and the temperature is maintained for 10-40min; the material is heated to a temperature of 1200-1400 DEG C, and the temperature is maintained for 10-30min, such that the biomass raw material is catalytically charred, and an intermediate product is obtained; the obtained intermediate product is cooled, and is washed with ultrapure water; filtering is carried out, and the obtained product is dried; a mixed water solution of hydrochloric acid and / or hydrofluoric acid and ethylenediaminetetraacetic acid is used for dusting and for carrying out an activation treatment for 60-120min; filtering is carried out; and the obtained material is heated and dried, and is crushed, such that the bio-ene charcoal material is obtained. The XRD diagram of the material shows diffraction peak at 26 DEG, such that the material is a charcoal material with a graphitized structure. The material has the characteristics of high specific surface area, developed cavities, good conductivity, high electrochemical activity, and good charge and discharge stability.

Owner:谢镕安

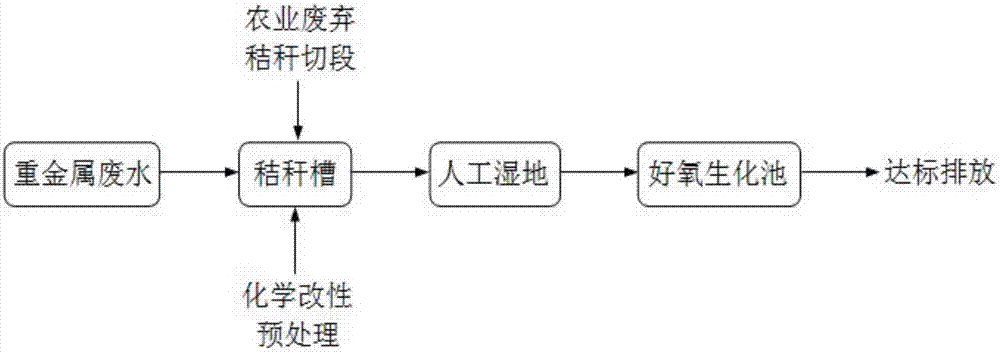

Three-stage biodegradation method for treating heavy metals

InactiveCN107445390ALower levelProcess environment friendlyWater/sewage treatmentMultistage water/sewage treatmentActivated sludgeConstructed wetland

The invention discloses a three-stage biodegradation method for treating heavy metals. The three-stage biodegradation method comprises the following steps: 1) allowing discharged heavy metal wastewater to enter a straw tank from the bottom of the straw tank, and properly controlling the flow rate of inflow water so as to ensure 3-hour effective adsorption time; 2) allowing clear liquid flowing out from the straw tank to enter a constructed wetland system, and reducing heavy metals in the wastewater through the adsorption, precipitation, enrichment and other effects of a unique matrix-plant-microbial ecosystem of the constructed wetland system; and 3 ) allowing the wastewater treated by the constructed wetland system to enter an aerobic pond and further reducing the content of heavy metals in the wastewater through the surface complexation, biological adsorption and flocculation effect of microorganisms in activated sludge in the pond. The method adopts waste straw-aquatic plant-microorganism three-stage biodegradation for treatment of heavy metal wastewater and has the advantages of effective utilization of agricultural waste, low cost, thorough treatment of heavy metals, environment friendliness, no secondary pollution, simple process and convenient operation and management.

Owner:CENT SOUTH UNIV

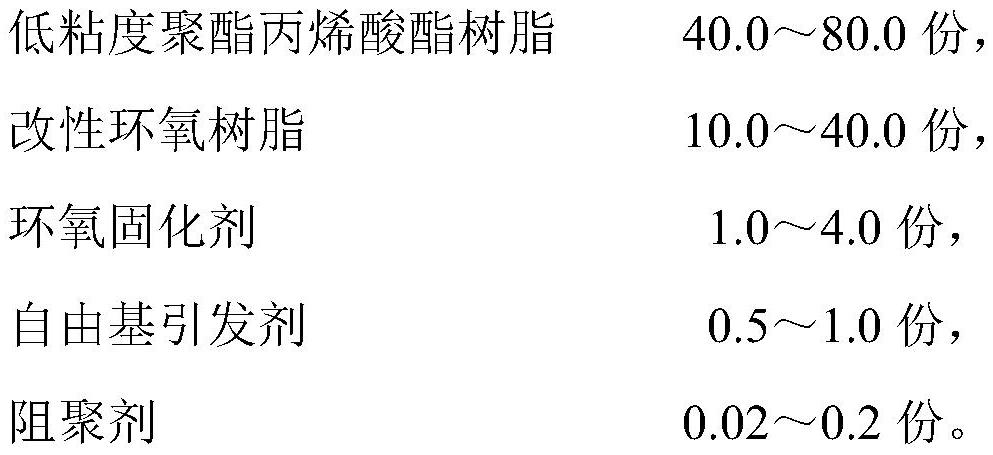

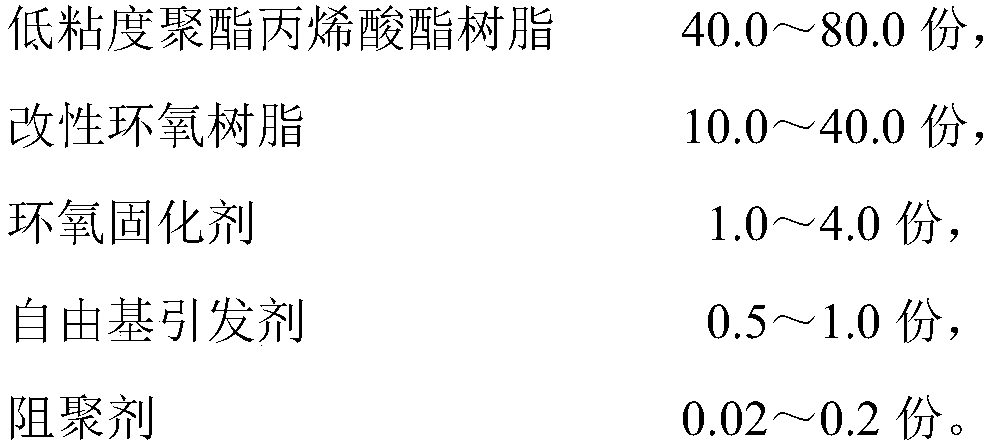

A kind of pure resin type polyester epoxy environment-friendly impregnation resin and preparation method thereof

ActiveCN109627726BMeet the requirements of environmentally friendly impregnating resinsImprove completenessPolyesterPolymer science

A pure resin type polyester epoxy environment-friendly impregnating resin, mainly prepared from the following raw materials in parts by mass: 40.0-80.0 parts of low-viscosity polyester acrylate resin, 10.0-40.0 parts of modified epoxy resin, epoxy cured 1.0-4.0 parts of agent, 0.5-1.0 parts of free radical initiator, and 0.02-0.2 parts of polymerization inhibitor. The preparation method of the present invention: mix the low-viscosity polyester acrylate resin, modified epoxy resin, epoxy curing agent, polymerization inhibitor, and free radical initiator according to the proportion, and then the online speed is 10m / s~15m / s Disperse evenly under the action of high shear and filter to obtain the pure resin type polyester epoxy environment-friendly impregnating resin. The impregnating resin of the present invention does not contain diluent, directly adopts low-viscosity polyester acrylate resin to control the overall resin viscosity, so that the cured volatile matter of the obtained impregnating resin is close to zero, and meets the requirements of the truly environment-friendly impregnating resin.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Ion exchange resin purification method of alkaloid

InactiveCN107715926ASimple purification processIncrease productivityIon-exchange column/bed processesIon-exchanger regenerationMedicinal herbsPurification methods

The invention relates to an ion exchange resin purification method for alkaloids, belonging to the technical field of ion exchange resins. The present invention adopts macroporous cation exchange resin resin method to separate and purify the alkaloid effective components in Chinese herbal medicine, so that the alkaloid can be purified. Compared with the traditional process, the purification process is simple and feasible, the production efficiency is high, the product yield is high, and the process environment is friendly. , low production cost and other advantages.

Owner:王鹏

A kind of preparation method of brown rice fermented active lactic acid bacteria drink

ActiveCN104342340BImprove gelatinizationReduce lossesAlcoholic beverage preparationAdditive ingredientFood flavor

The invention discloses a preparation method of a rough-rice-fermented active lactobacillus beverage. The method comprises the following steps: dividing the rough rice raw material into two parts, and carrying out humidity regulation, surface airing and high-temperature fluidization treatment on one part of the rough rice raw material; crushing and wetting the rough rice subjected to high-temperature fluidization, mixing with Chinese yeast, fermenting, and separating after the fermentation finishes, thereby obtaining a clear solution A; immersing the other part of rough rice, pulping, gelatinizing and saccharifying to obtain a saccharification solution B; and mixing the clear solution A and saccharification solution, adding additives, inoculating lactobacillus, and fermenting to obtain the rough-rice-fermented active lactobacillus beverage. By using the rough rice or mashed rough rice as the raw material and adopting the high-temperature fluidization technique, the method has the advantages of high treatment and utilization ratio, thick flavor of beverage, low loss of natural nutritional ingredients of rough rice, and short fermentation time; and the raw material gelatinization degree is high, and therefore, the product does not generate the phenomena of starch retrogradation, precipitation and the like in the storage process, thereby implementing high-value utilization of mashed rice resources. The method does not generate wastewater, and is environment-friendly in technique.

Owner:ZHEJIANG UNIV OF TECH

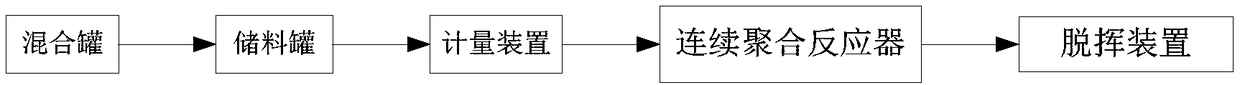

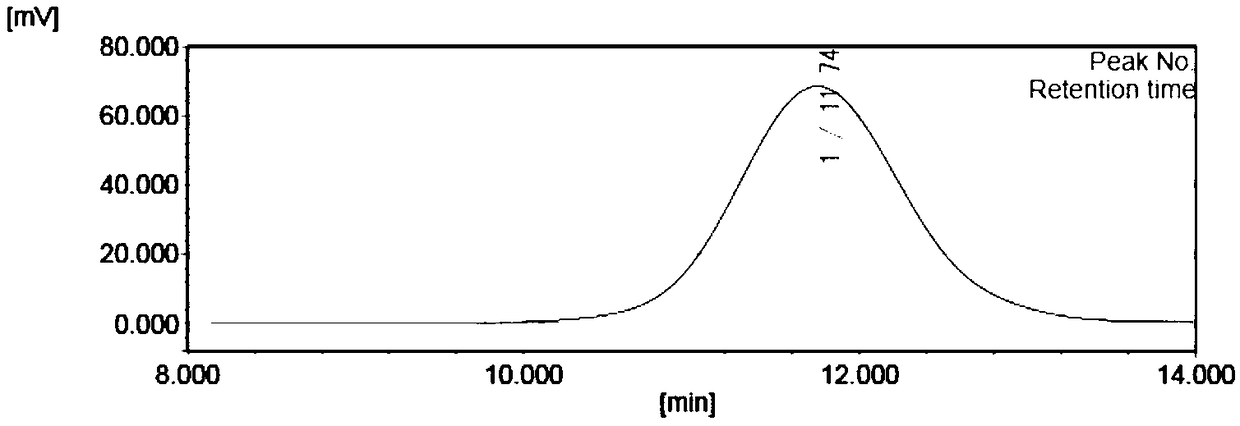

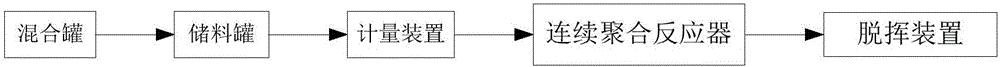

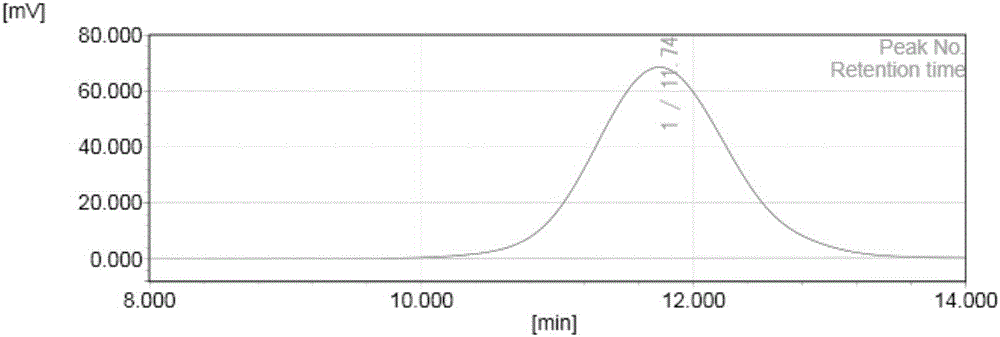

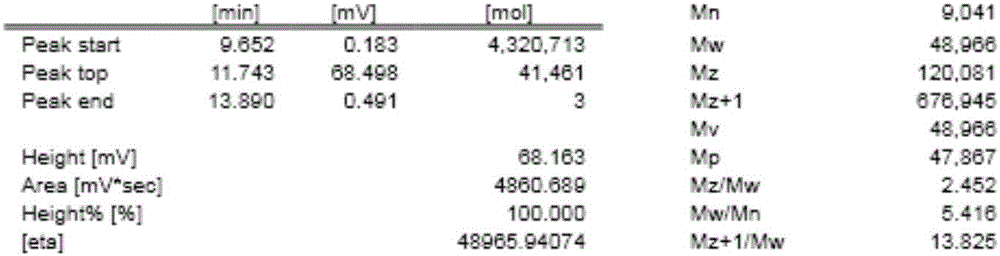

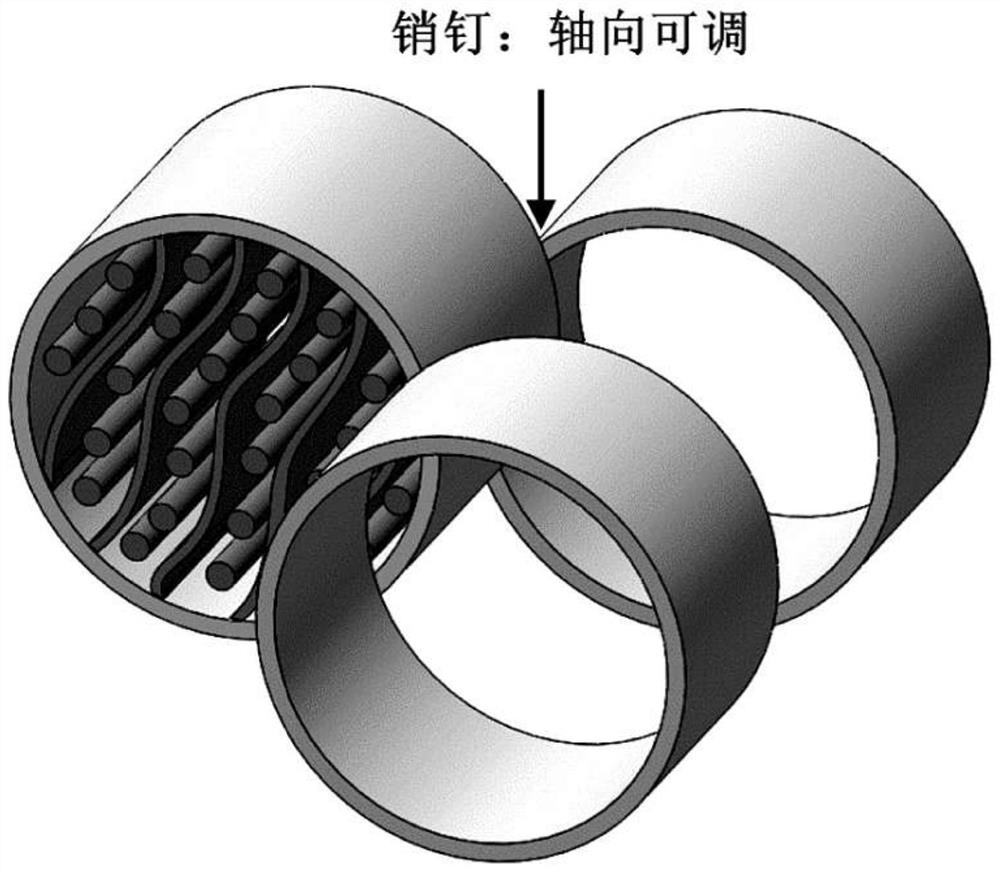

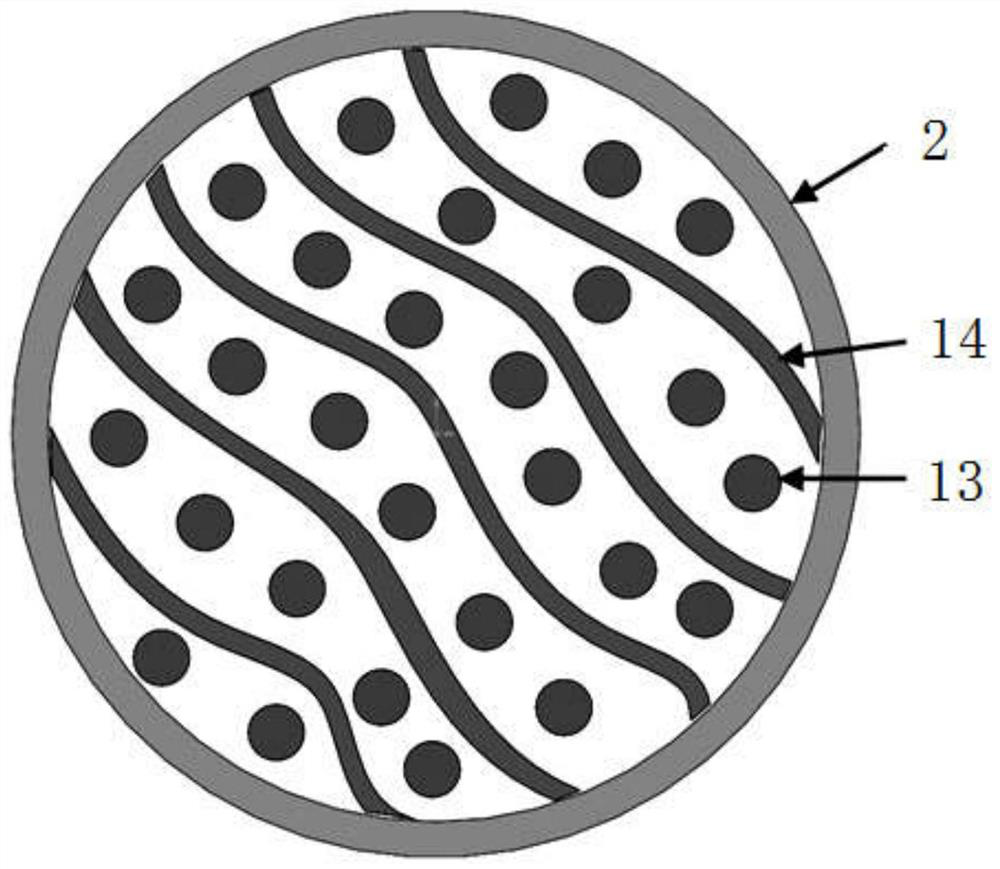

A kind of optical grade pmma continuous bulk polymerization method and production system thereof

The invention provides an optical-grade PMMA (polymethyl methacrylate) continuous bulk polymerization method and production system. The method comprises the following steps: mixing reaction raw materials methyl methacrylate, initiator and assistant according to proportions to obtain mixed solution, performing metering, then injecting the mixed solution into a continuous polymerization reactor to perform polymerization reaction and continuous extrusion, and performing devolatilization treatment after extrusion to obtain a PMMA solid material. By dispersing and thinning the materials through screw-type shaft body rotation and shearing, the molecular weight of the materials is enabled to be reasonably distributed, the mixing uniformity of reaction components is improved, the reaction components are enabled to exchange heat with a machine barrel wall and a shaft outer wall in time, the entire process is continuous, the material retention time is reduced, the probability of heat accumulation is reduced, the temperature gradient between the materials is reduced, the problem of reaction heat control of bulk polymerization is solved and finally the continuous extrusion of the product in the reaction process is realized.

Owner:CENTURY OPTICOMM CO LTD

Optical-grade PMMA (polymethyl methacrylate) continuous bulk polymerization method and production system

The invention provides an optical-grade PMMA (polymethyl methacrylate) continuous bulk polymerization method and production system. The method comprises the following steps: mixing reaction raw materials methyl methacrylate, initiator and assistant according to proportions to obtain mixed solution, performing metering, then injecting the mixed solution into a continuous polymerization reactor to perform polymerization reaction and continuous extrusion, and performing devolatilization treatment after extrusion to obtain a PMMA solid material. By dispersing and thinning the materials through screw-type shaft body rotation and shearing, the molecular weight of the materials is enabled to be reasonably distributed, the mixing uniformity of reaction components is improved, the reaction components are enabled to exchange heat with a machine barrel wall and a shaft outer wall in time, the entire process is continuous, the material retention time is reduced, the probability of heat accumulation is reduced, the temperature gradient between the materials is reduced, the problem of reaction heat control of bulk polymerization is solved and finally the continuous extrusion of the product in the reaction process is realized.

Owner:CENTURY OPTICOMM CO LTD

A two-step method for the recovery of copper and gold from waste electronic materials

ActiveCN104073639BImprove the efficiency of leaching goldGuaranteed leaching rateProcess efficiency improvementChemical industryElectrolysis

The invention belongs to the fields of chemical industry and hydrometallurgy and in particular relates to a method for recycling copper and gold from a waste electronic material through a two-step method. The method comprises the following steps: firstly leaching ordinary metals out of the material in the presence of acidophilic microorganisms, recycling the copper from an acidophilic microorganism leaching solution by using an extraction electrolysis process; and subsequently leaching zero-valence gold out of residue in an acidic thiourea system and recycling thiourea gold by using active carbon or ion exchange resin method. The method has the advantages that the environment of the process for leaching copper out of the microorganisms is environment-friendly, pollution-free and low in cost; the materials can be recycled in a closed cycle mode; by virtue of the pretreatment materials of the microorganisms, higher gold-leaching efficiency of the acidic thiourea is achieved, a faster speed is achieved; reagents used in the gold-leaching system are non-toxic; and moreover, the copper-leaching efficiency can reach over 95% and the gold-leaching efficiency can reach over 90%.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Pure resin type polyester epoxy environment-friendly impregnating resin and preparation method thereof

ActiveCN109627726AMeet the requirements of environmentally friendly impregnating resinsImprove completenessPolyesterEpoxy

The invention relates to a pure resin type polyester epoxy environment-friendly impregnating resin, which is mainly prepared, by mass, from the following raw materials: 40.0-80.0 parts of low-viscosity polyester acrylate resin, 10.0-40.0 parts of modified epoxy resin, 1.0-4.0 parts of an epoxy curing agent, 0.5-1.0 part of a free radical initiator and 0.02-0.2 part of a polymerization inhibitor. The preparation method comprises the following steps: uniformly mixing the low-viscosity polyester acrylate resin, the modified epoxy resin, the epoxy curing agent, the polymerization inhibitor and thefree radical initiator according to the proportion, then uniformly dispersing under the action of high shear with a linear speed of 10m / s-15m / s, filtering so as to obtain the pure resin type polyester epoxy environment-friendly impregnating resin. The impregnating resin does not contain a diluent, and the viscosity of the whole resin is directly controlled by adopting the low-viscosity polyesteracrylate resin, so that the obtained impregnating resin is cured, the volatile component is close to zero, and the requirement of environment-friendly impregnating resin in a real sense is met.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

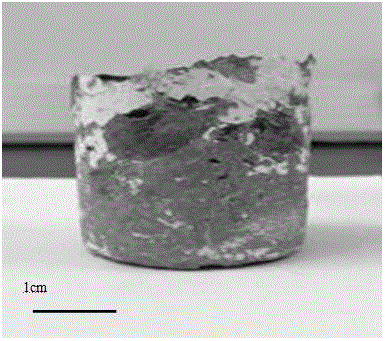

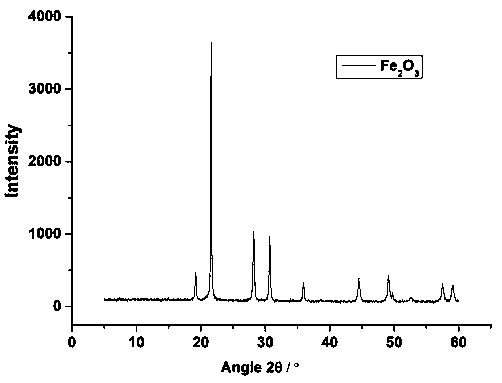

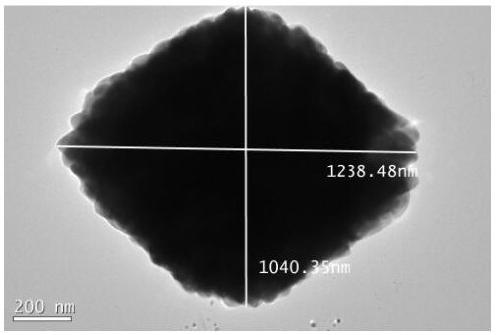

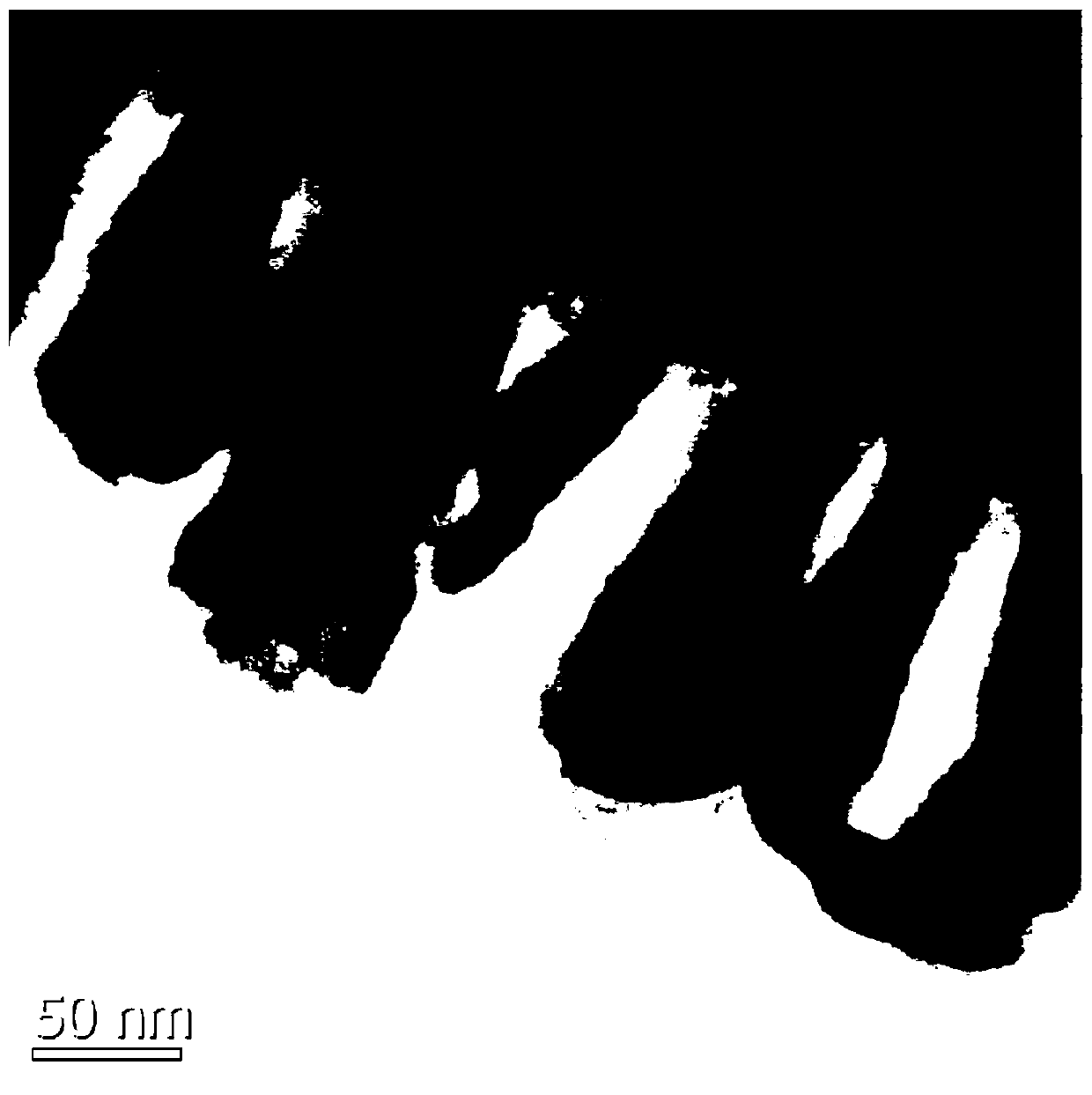

A kind of rice-shaped micron-scale iron oxide heterogeneous photo-Fenton catalyst and its preparation method

ActiveCN107899578BSingle shapeHigh degree of crystallizationWater/sewage treatment by irradiationWater treatment compoundsOptical radiationPtru catalyst

The invention discloses a rice dumpling-shaped micron-sized iron oxide heterogeneous photo-Fenton-like catalyst and a preparation method thereof. The method uses FeCl 2 as raw materials, by adding dilute hydrochloric acid and H under light radiation. 2 O 2 The solution is prepared into a mother liquid for preparing a rice dumpling-shaped micron-sized iron oxide heterogeneous photo-Fenton catalyst, and finally a rice dumpling-shaped micron-sized iron oxide heterogeneous photo-Fenton catalyst is generated under hydrothermal reaction conditions. The rice dumpling-shaped micron-sized iron oxide heterogeneous photo-Fenton-like catalyst prepared by the invention has a single morphology, high degree of crystallization, high purity, good stability, and high photo-promoted Fenton catalytic performance, and can be widely used in In the field of catalytic degradation of pollutants; the preparation method of the present invention uses low-cost raw materials, simple reaction conditions, good product reproducibility, and an environmentally friendly process.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

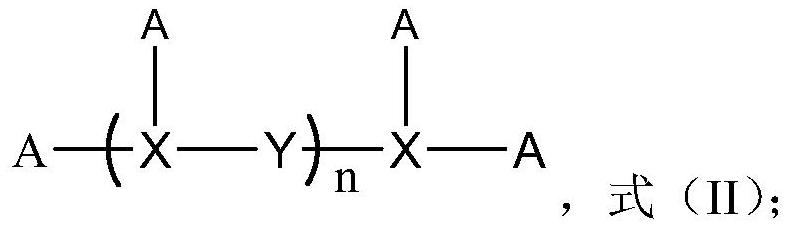

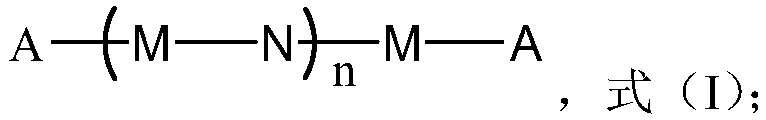

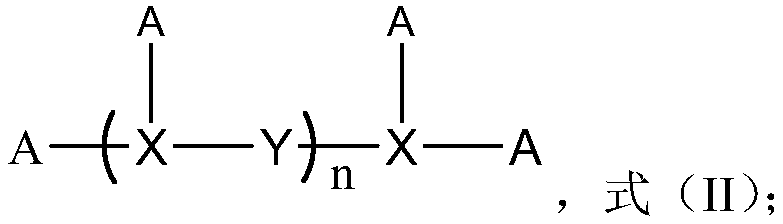

The preparation method of methoxy acrylate fungicide

ActiveCN103030598BRaw materials are cheap and easy to getProcess environment friendlyOximes preparationArylFungicide

The invention relates to a method for preparing strobilurin fungicide. The method comprises the following steps: (1) mixing the compound in formula (II) with the compound in formula (III) for reaction for 5 to 10 h at the temperature of 90 to 120 DEG C to obtain the compound in formula (IV), wherein the compound in formula (III) is acetal of formamides compound, R1, R2 and R3 are substituted alkyl or aryl; and (2) hydrolyzing the compound in formula (IV) under an acidic condition, and then stirring the hydrolyzed product at the room temperature for 2 to 4 h under the condition of alkali, methylating reagent and phase transfer catalyst to obtain the product, wherein X is 6-(2'-cyanophenoxyl) pyrimidine-4-oxy or 6-trifluoromethylpyridine-2-oxymethyl; 6-(2'-cyanophenoxyl) pyrimidine-4-oxy or 6-trifluoromethylpyridine-2-oxymethyl;[2-[[[[4-(4-chlorophenyl)-but-3-en-2-yl]imido]oxy]methyl]phenyl]; and 2-(2-((3-butyl-4-methyl-coumarin-7-yloxy)metyl)phenyl). The total yield of the method reaches above 85%.

Owner:上海禾本药业股份有限公司

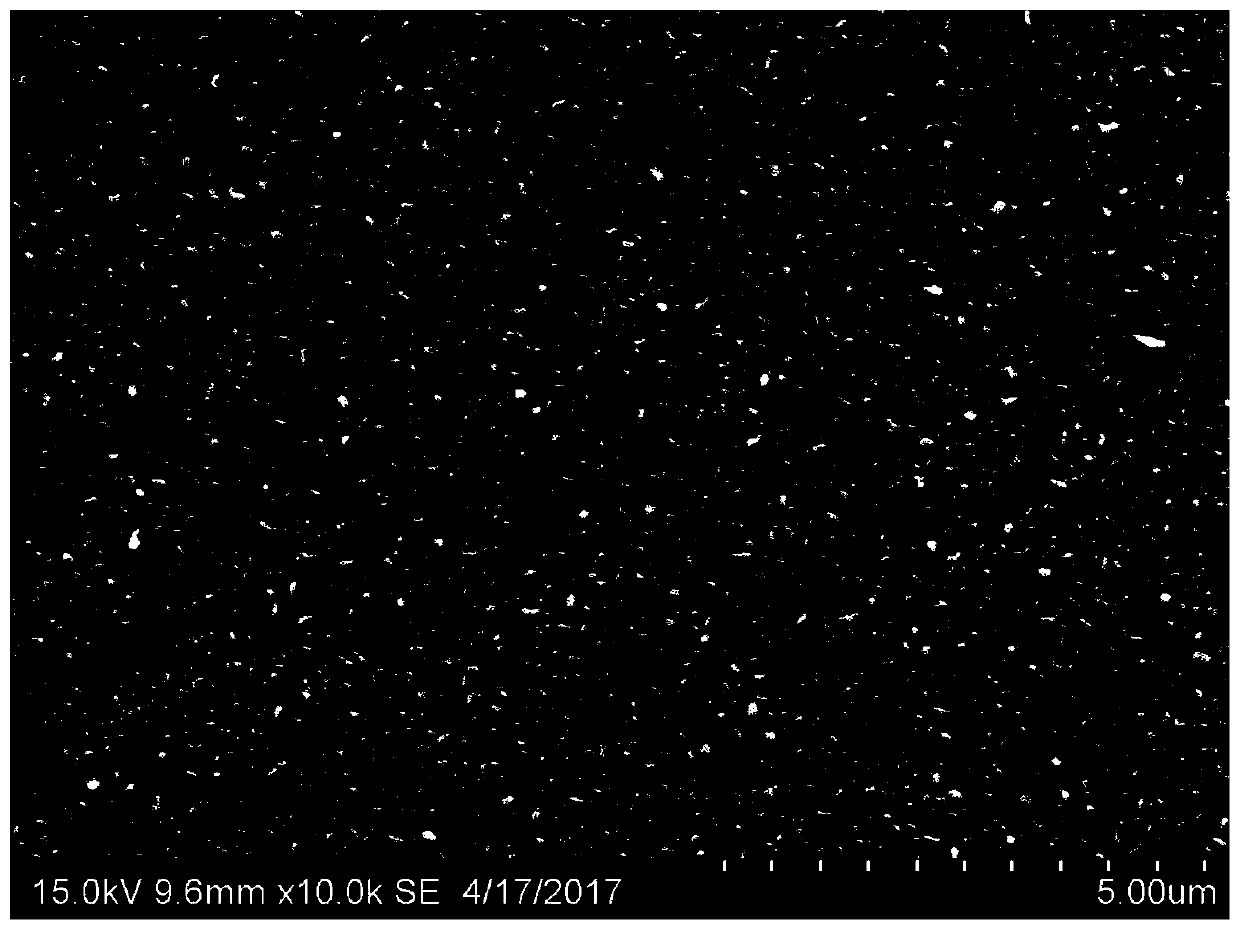

A kind of preparation method of metal/nonmetal composite film with superhydrophobic property

ActiveCN108707871BImprove bindingSimple processVacuum evaporation coatingSputtering coatingDeposition temperatureComposite film

The invention discloses a preparing method for a metal / nonmetal composite film with super-hydrophobicity. According to the method, a substrate is subjected to ultrasonic cleaning and drying treatment,the metal / nonmetal composite structure film is prepared by a magnetic control co-sputtering technology, and a special surface nanostructure is obtained by a certain nonmetal target / metal target powerratio and deposition temperature, so that the super-hydrophobicity is realized. The preparing method for the metal / nonmetal composite film with the super-hydrophobicity is environmentally friendly inprocess, and simple and practicable without the need of a template, and has no special requirements on the substrate, the composite film with the excellent hydrophobicity and strong film-substrate binding force can be obtained by one step, the preparing method has the better application potential and prospect in the fields such as self-cleaning materials, biomaterials, microfluid devices and corrosion resistance, and a new technical thought is provided for the industrial application of the super-hydrophobic films.

Owner:XI AN JIAOTONG UNIV

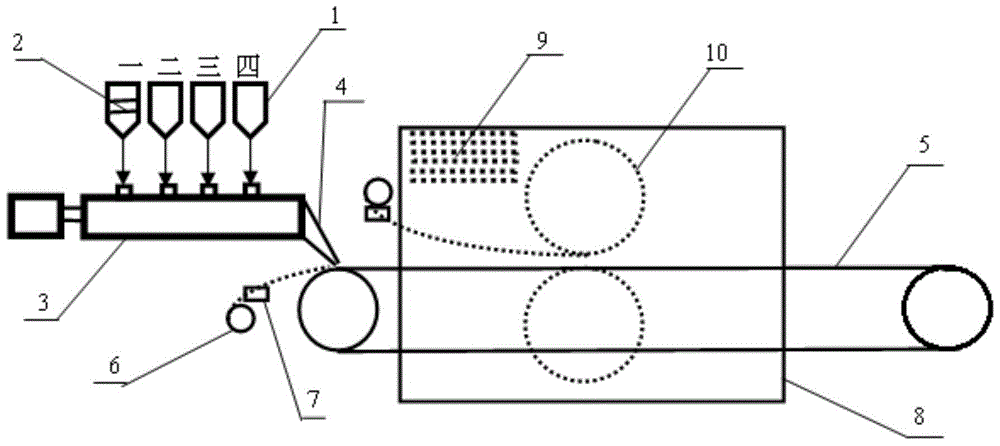

Method for preparing high flame-retardant insulation board by mixing and foaming phenolic resin and polystyrene

The invention discloses a method for preparing a highly flame-retardant thermal insulation board by mixing and foaming phenolic resin and polystyrene. The preparation method comprises the following steps of designing a continuous production line according to characteristics of each component, precisely controlling charging and a temperature by a charging system; sufficiently mixing and dispersing mixed feed liquid by rotating and shearing effect inside mixer equipment; then, feeding the mixed feed liquid into an oven by a conveyor belt, foaming in the oven and laminating by a pressure roller to form a board material and conveying the board material out of the oven; and finally, naturally cooling, curing and forming to obtain the highly flame-retardant thermal insulation board. The method disclosed by the invention has advantages that the method is simple and easy to operate and high in production efficiency, satisfies the trend and requirements of less material waste and environment-friendly process; technical problems that upper and lower structures are not uniform and process condition control is not precise when a material mixture of phenolic resin and an expandable polystyrene is stewed in the process method in the prior art are solved.

Owner:上海高分子功能材料研究所

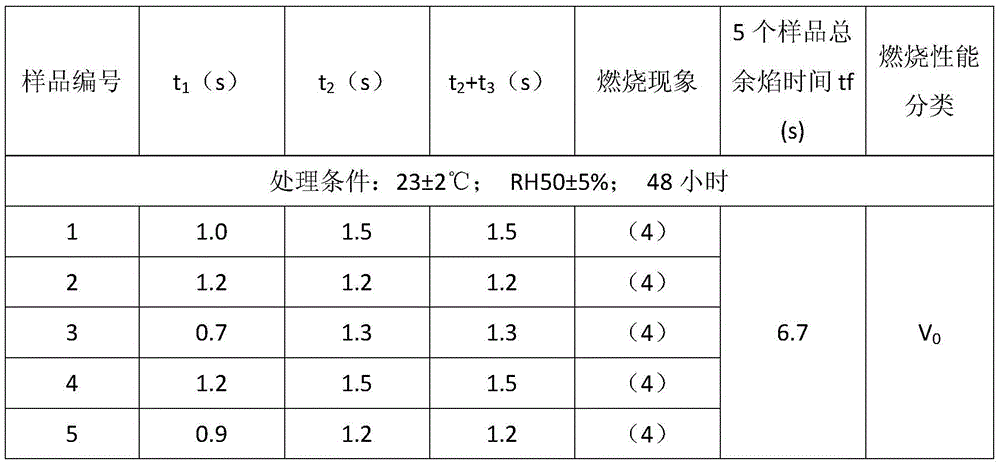

A method for manufacturing high-performance bleached impregnated flame-retardant insulating paper

InactiveCN104452435BImprove breakdown voltageExcellent dry tensile strengthPaper coatingReinforcing agents additionFire retardantDielectric strength

The invention discloses a method for making high-performance bleached impregnated flame-retardant insulating paper. The method is used for making the bleached insulating paper through paper making technology with bleached paper pulp as the base material, and comprises the following steps: adding starch, a wet strength agent and sodium carboxymethyl cellulose in the pulp; performing sizing, squeezing and drying in insulating paper pulp; impregnating the insulating paper in a mixture impregnation liquid for 10-120 seconds, extruding, squeezing and drying, wherein the mixture impregnation liquid is prepared by mixing a flame retardant solution, a modified starch solution and a sodium carboxymethyl cellulose to the homogeneous state under the condition of room temperature. The bleached impregnated flame-retardant insulating obtained according to the method contains no halogen elements, is low-carbon and environmentally friendly, and has excellent breakdown voltage and dielectric strength; and the flame retardant level of the insulating paper is V0, the paper white degree is not less than 80 percent, the dry tensile strength is 3.0-4.2 KN / m, the wet tensile strength is 0.30-0.65 KN / m, and the volume resistivity is (0.8-1.2)*10<6>.

Owner:SOUTH CHINA UNIV OF TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![(-)-[gamma]-lactamase, gene, mutant, vector as well as preparation method and application of (-)-[gamma]-lactamase (-)-[gamma]-lactamase, gene, mutant, vector as well as preparation method and application of (-)-[gamma]-lactamase](https://images-eureka.patsnap.com/patent_img/dcdbcdad-834c-4ae5-82a7-74e96b4933f0/BDA0000993124060000061.PNG)

![(-)-[gamma]-lactamase, gene, mutant, vector as well as preparation method and application of (-)-[gamma]-lactamase (-)-[gamma]-lactamase, gene, mutant, vector as well as preparation method and application of (-)-[gamma]-lactamase](https://images-eureka.patsnap.com/patent_img/dcdbcdad-834c-4ae5-82a7-74e96b4933f0/BDA0000993124060000071.PNG)

![(-)-[gamma]-lactamase, gene, mutant, vector as well as preparation method and application of (-)-[gamma]-lactamase (-)-[gamma]-lactamase, gene, mutant, vector as well as preparation method and application of (-)-[gamma]-lactamase](https://images-eureka.patsnap.com/patent_img/dcdbcdad-834c-4ae5-82a7-74e96b4933f0/BDA0000993124060000072.PNG)