Method for removing gas-liquid inclusion in quartz sand by using microwave bursting method

A process method, the technology of quartz sand, which is applied in the field of quartz sand purification, can solve the problems of poor effect and destruction of gas-liquid inclusions, etc., and achieve the effect of stable and optimal removal effect, friendly process environment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

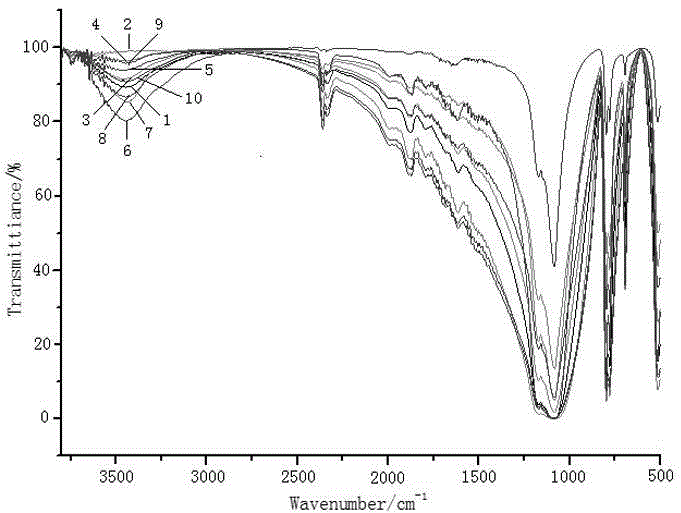

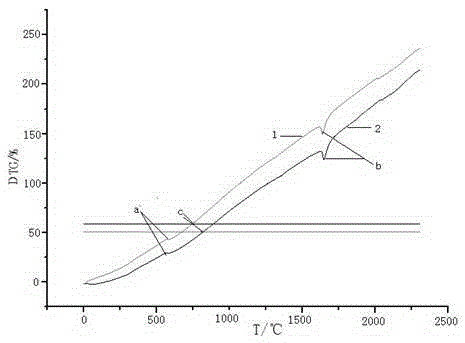

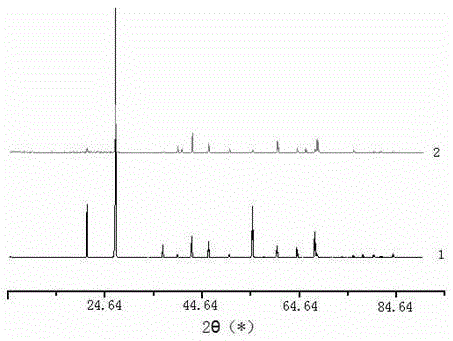

[0044] Put the quartz sand powder under the conditions of microwave radiation with a microwave power of 2400w, while maintaining a microwave treatment temperature of 800°C and a time of 1h.

Embodiment 2

[0046] Put the quartz sand powder under the condition that the microwave power is 2400w microwave radiation, while keeping the microwave treatment temperature at 700°C for 2h.

Embodiment 3

[0048] Put the quartz sand powder under the condition that the microwave power is 2100w, and the temperature is 800°C, and the time is 3h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com