A method for manufacturing high-performance bleached impregnated flame-retardant insulating paper

A manufacturing method and technology of insulating paper, applied in paper, papermaking, paper coating and other directions, can solve the problem of low flame retardant loading efficiency, export manufacturing obstacles, and hinder the healthy development of bleaching impregnated insulating paper and environmentally friendly paper-based copper clad laminate industries and other problems, to achieve the effect of excellent breakdown voltage and simplified processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

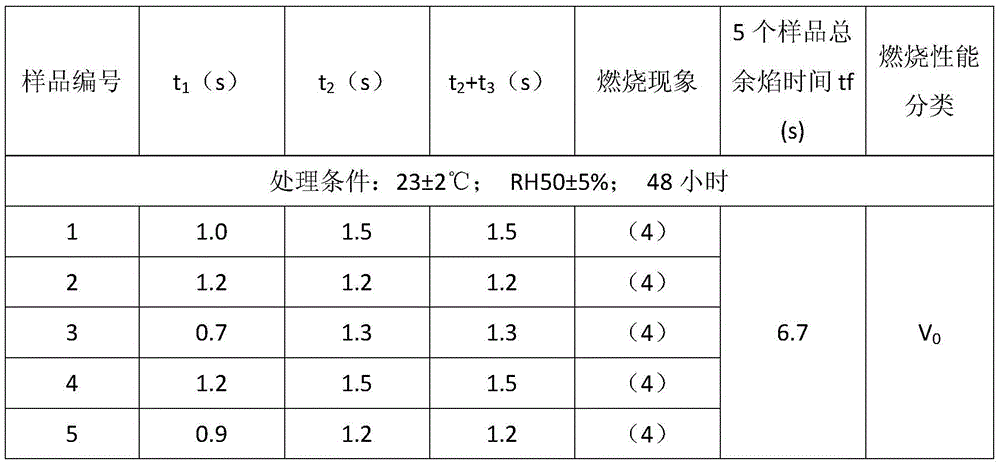

Examples

Embodiment 1

[0030] A manufacturing method of high-performance impregnated bleached flame-retardant insulating paper includes the following steps and process conditions:

[0031] (1) Pulp fiber selection and slurry preparation: Wash the bleached sulphate eucalyptus pulp with water, and disperse it with a decomposer, adjust its beating degree to 20°SR through a free-form beating process, and dilute it to a mass concentration of 0.1 % Pulp suspension.

[0032] (2) Preparation of treatment liquid added in the pulp: The cationic modified starch adhesive (model YZ-121, produced by Hangzhou Zhiyou Technology Co., Ltd.) was gelatinized in an aqueous solution at 90°C for 2 hours, and the prepared starch mass concentration was 5% starch solution for use; dilute and mix polyamide polyepichlorohydrin resin (PPE type, produced by Foshan Nanhai Junneng Paper Material Factory) in an aqueous solution to prepare a PPE solution with a mass concentration of 2%. Use; Sodium carboxymethyl cellulose (CMC) as a wet...

Embodiment 2

[0042] A method for manufacturing high-performance bleach-impregnated flame-retardant insulating paper includes the following steps and process conditions:

[0043] (1) Selection of pulp fiber and preparation of pulp: Wash the bleached sulphate eucalyptus pulp with water, and disperse and disperse it with a decomposer, adjust its beating degree to 22°SR through the free-form beating process, and dilute it to a mass concentration It is a 0.1% pulp suspension.

[0044] (2) Preparation of treatment solution added in the pulp: an appropriate amount of modified cationic starch (YZ-121, produced by Hangzhou Zhiyou Technology Co., Ltd.) was gelatinized in an aqueous solution at 90°C for 2 hours, and the prepared starch mass concentration was 5% The cationic modified starch adhesive solution is ready for use; the modified urea-formaldehyde resin wet strength agent (YM02, produced by Jiangmen Xinhui Dongrun Paint Co., Ltd.) is diluted and mixed in an aqueous solution to prepare a PPE with a...

Embodiment 3

[0050] A manufacturing method of high-performance impregnated bleached flame-retardant insulating paper includes the following steps and process conditions:

[0051] (1) Pulp fiber selection and slurry preparation: Wash the bleached kraft pine wood pulp with water, and use a decomposing machine to decompose and disperse, adjust its beating degree to 25°SR through the free beating process, and dilute it to a mass concentration of 0.1% pulp suspension.

[0052] (2) Preparation of treatment liquid added to the pulp: an appropriate amount of modified anionic starch (model YZ-171, produced by Hangzhou Zhiyou Technology Co., Ltd.) was gelatinized in an aqueous solution at 90°C for 2 hours to prepare anionic modified starch glue The anionic modified starch adhesive solution with the adhesive concentration of 5% is ready for use; the polyamide polyepichlorohydrin resin (PPE type, produced by Foshan Nanhai Junneng Paper Material Factory) is diluted and mixed in the aqueous solution to prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com