A kind of preparation method of metal/nonmetal composite film with superhydrophobic property

A composite thin film, non-metallic technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of expensive graphene, cumbersome and complicated steps, and unfavorable widespread promotion, and achieve material safety and non-toxicity , friendly process and environment, and convenient equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the metal / nonmetal composite film with superhydrophobic properties of the present invention comprises the following steps:

[0030] 1) Perform ultrasonic cleaning and drying on the substrate made of single crystal silicon, quartz, silicon oxide, stainless steel or sapphire, then clamp it on the sample tray and send it into the sputtering chamber.

[0031] 2) Copper, silver, gold, aluminum or titanium metal target and aluminum oxide, zinc oxide, silicon oxide, zirconium oxide, hafnium oxide, or aluminum nitride, titanium nitride, silicon nitride, zirconium nitride, or carbonized Non-metallic targets such as silicon, titanium carbide or tungsten carbide are installed on a target position with an unbalanced magnetic field, and the sputtering chamber is pumped to a predetermined background vacuum.

[0032] 3) Using high-purity argon as the working gas, the working pressure is 0.1-0.3Pa, and the bias voltage is -80--100V; at a predetermined temperat...

Embodiment 1

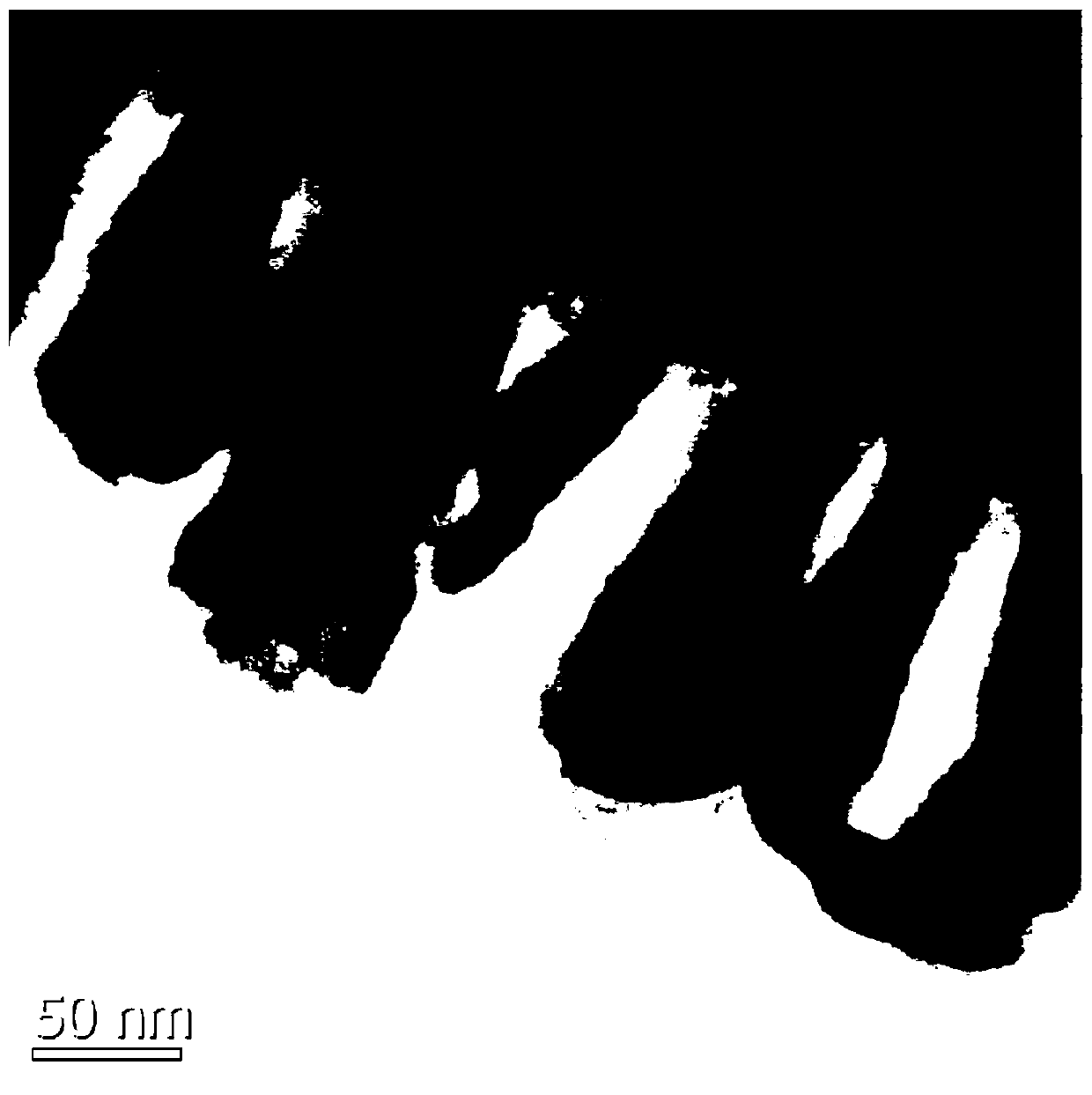

[0038] al 2 o 3 Preparation of / Cu superhydrophobic composite film: use single crystal silicon as the substrate, after ultrasonic cleaning and drying, the substrate is clamped on the sample tray and sent into the sputtering chamber. Install the copper target and the alumina target on the unbalanced magnetron target respectively, and pump the background vacuum of the sputtering chamber to 2×10 -4Pa, the substrate temperature rises to 450°C, and the power ratio between the non-metallic target and the metal target is controlled to be 3:1, and then the coating operation starts. Turn on the rotation switch of the sample disc to make it rotate at a speed of 10 degrees per second, pass in Ar gas and keep the working pressure at 0.1Pa, and use radio frequency power to co-sputter the copper target and the alumina target, the copper target and the oxide The powers of the aluminum targets were 40W and 120W respectively, and a negative bias of -80V was applied during the sputtering proc...

Embodiment 2

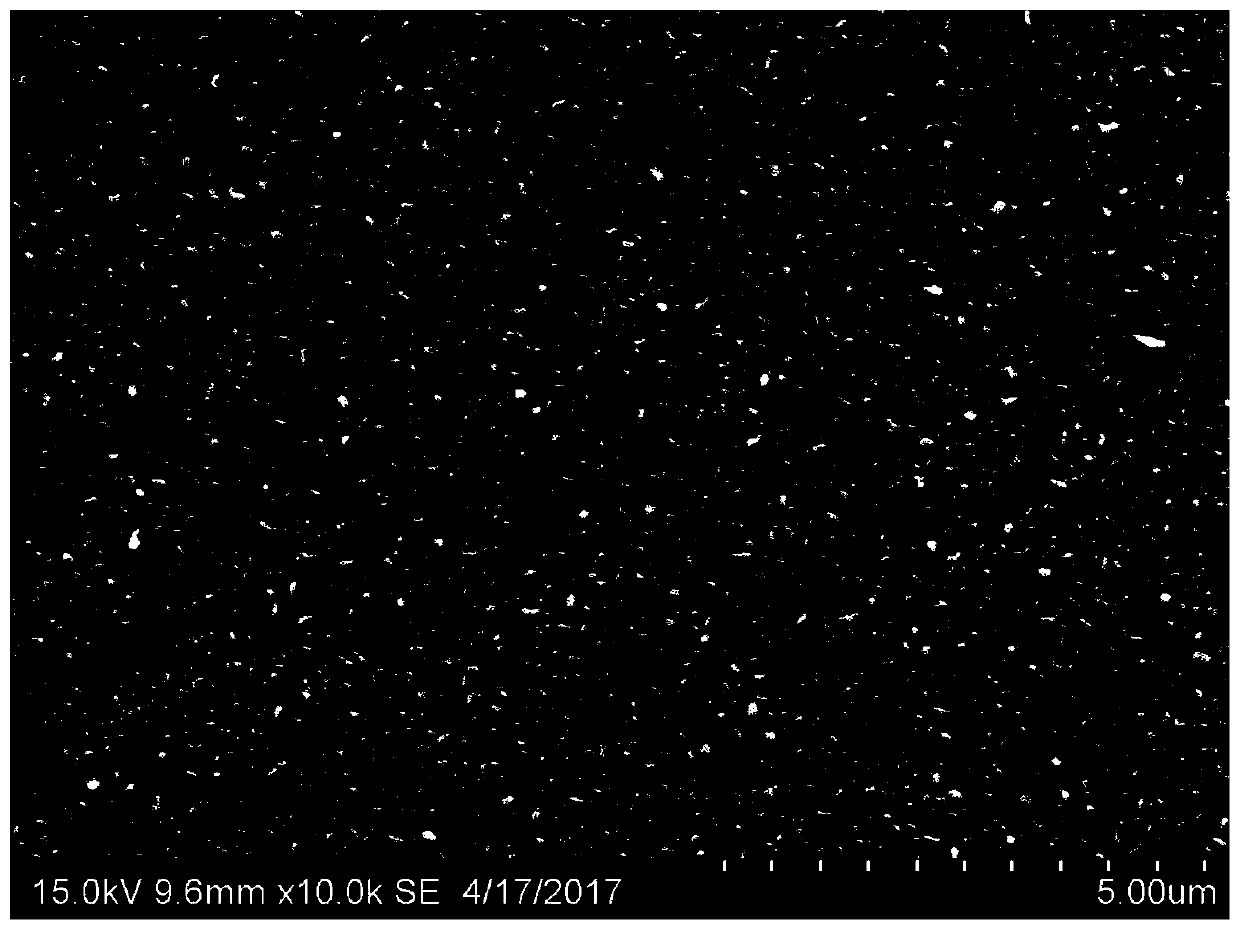

[0041] Preparation of ZnO / Ag super-hydrophobic composite film: use quartz as the substrate, after ultrasonic cleaning and drying, clamp the substrate on the sample tray and send it into the sputtering chamber. Install the silver target and the zinc oxide target on the unbalanced magnetron target respectively, and pump the background vacuum of the sputtering chamber to 2×10 -4 Pa, the substrate temperature rises to 150°C, and the power ratio between the non-metallic target and the metal target is controlled to be 1.25:1, and then the coating operation starts. Turn on the autorotation switch of the sample plate to make it rotate at a speed of 10 degrees per second, pass in Ar gas and keep the working pressure at 0.3Pa, use radio frequency power to co-sputter the silver target and zinc oxide target, the silver target and the oxide The power of the zinc target was 36W and 45W respectively, and a negative bias of -100V was applied during the sputtering process, and the sputtering w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com