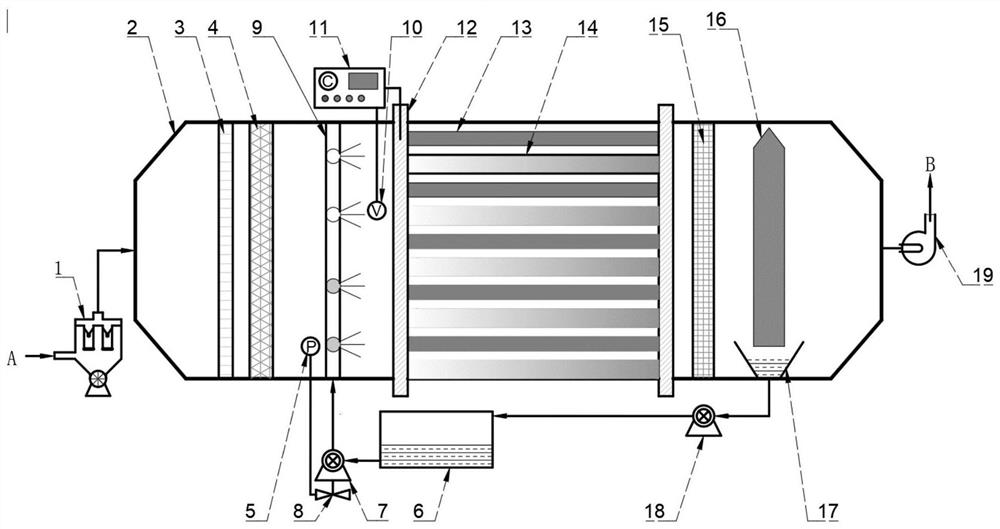

System and method for treating VOCs (Volatile Organic Chemicals) by excimer optical coupling catalysis means

An excimer and optical coupling technology, applied in the field of VOCs processing system based on excimer optical coupling catalytic means, can solve the problems of high cost, secondary pollution, etc., reduce energy loss, reduce operating energy consumption, and have a reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

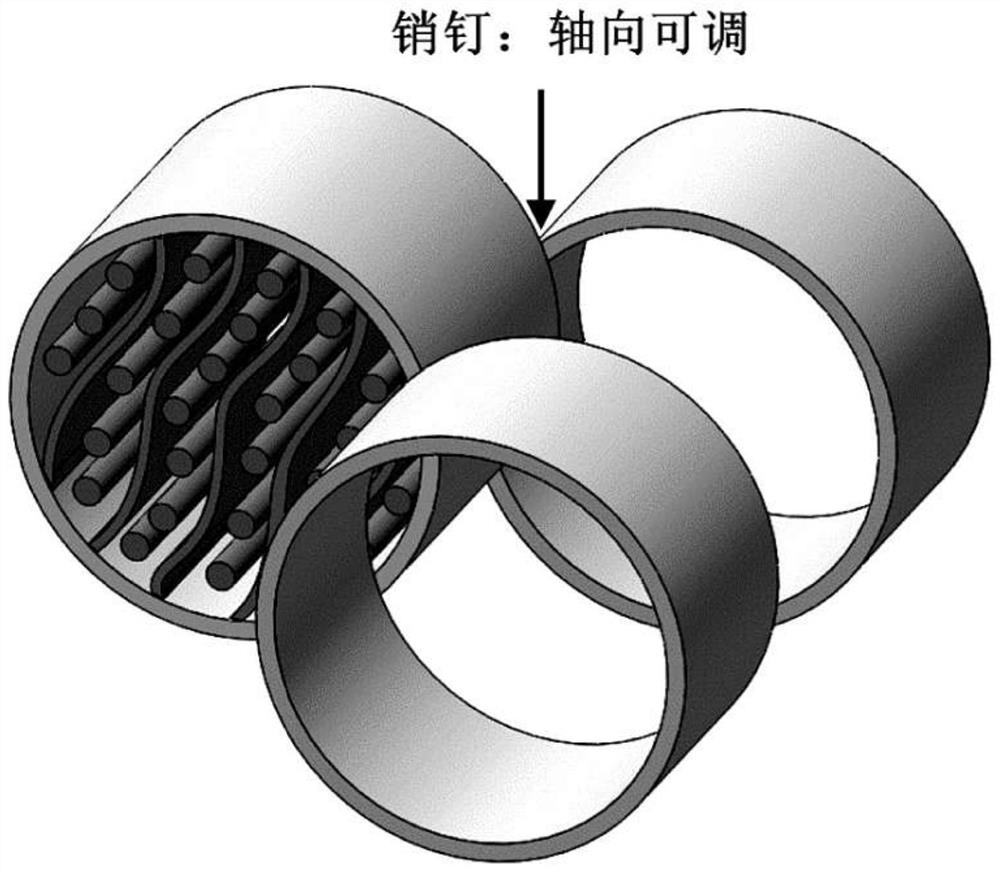

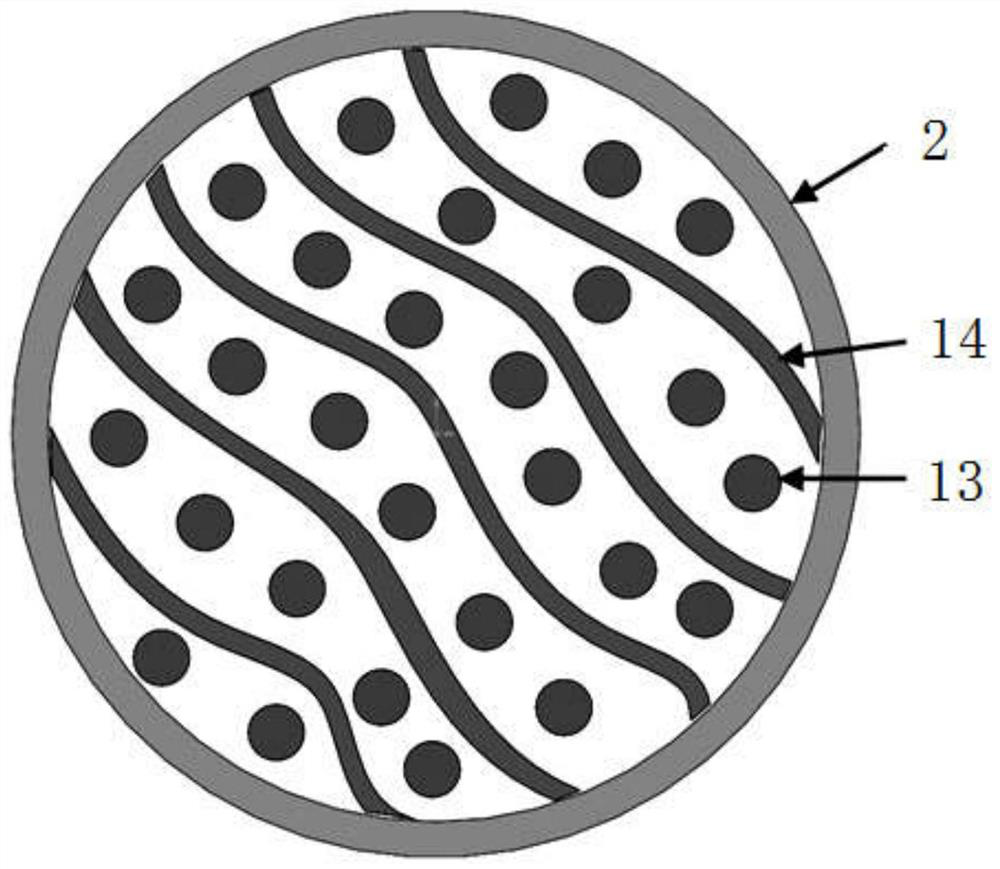

Method used

Image

Examples

Embodiment 2

[0036] When using the method of Example 1 to treat VOCs, the VOCs components mainly include: toluene: 600mg / m 3 , Ethyl acetate: 1300mg / m 3 , Formaldehyde 800mg / m 3 ; The catalyst is 15% ZrO 2 -TiO 2 , The wavelength of excimer light is 245nm, the flue gas humidity is controlled at 12%, the high-voltage power supply is adjusted to 15KV, and the purification efficiency of VOCs is as high as 99.1%.

Embodiment 3

[0038] When using the method of Example 1 to treat VOCs, the VOCs components mainly include: toluene: 950mg / m 3 , Ethyl acetate: 600mg / m 3 , Formaldehyde 1200mg / m 3 ; The catalyst is 10% SnO 2 -TiO 2 , The wavelength of excimer light is 222nm, the flue gas humidity is controlled at 12%, the high-voltage power supply is adjusted to 11KV, and the VOCs purification efficiency is as high as 98.5% after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com