A kind of pure resin type polyester epoxy environment-friendly impregnation resin and preparation method thereof

A technology of impregnating resin and resin type, which is applied in the field of pure resin type polyester epoxy environmental protection impregnating resin, which can solve the problems such as difficulty in meeting the requirements of green environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

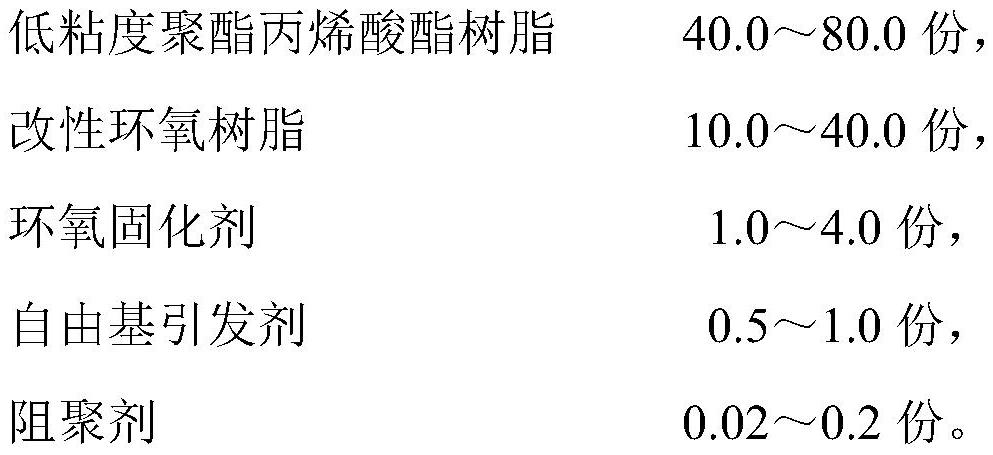

[0030] A pure resin type polyester epoxy environment-friendly impregnating resin of the present invention is mainly prepared from the raw materials of the following mass fractions:

[0031] 75.0g low-viscosity polyester acrylate (comprising 40.0gM6100 and 35.0gM8530, Toagosei Co., Ltd., viscosity is 600mPa.s),

[0032] 20.0g modified epoxy resin MEP-1,

[0033] 2.0g epoxy curing agent zinc naphthenate,

[0034] 0.8gDCP,

[0035] 0.2g polymerization inhibitor (including 0.1g 2,6-di-tert-butyl-p-cresol and 0.1g p-tert-butylcatechol).

[0036] The preparation method of the pure resin type polyester epoxy environment-friendly impregnating resin of the present embodiment may further comprise the steps:

[0037] (1) Preparation of modified epoxy resin MEP-1: In a 1000mL four-necked round-bottomed flask with mechanical stirring, reflux condenser and air duct, add 800.0g of E51 epoxy resin, 98.0g of methacrylic acid and polymerization inhibitor Add 0.2 g of hydroquinone, react at ...

Embodiment 2

[0041] A pure resin type polyester epoxy environment-friendly impregnating resin of the present invention is mainly prepared from the following raw materials in parts by mass:

[0042] 75.0g low-viscosity polyester acrylate (comprising 45.0gM6500 and 30gM8030, Toagosei Co., Ltd., viscosity is 680mPa.s),

[0043] 18.0g parts of modified epoxy resin MEP-2,

[0044] 2.0g epoxy curing agent zinc naphthenate,

[0045] 0.8gDCP,

[0046] 0.2g polymerization inhibitor (including 0.1g 2,6-di-tert-butyl-p-cresol and 0.1g p-tert-butylcatechol).

[0047] The preparation method of the pure resin type polyester epoxy environment-friendly impregnating resin of the present embodiment comprises the following steps:

[0048](1) Preparation of modified epoxy resin MEP-2: In a 1000mL dry four-necked round-bottomed flask with mechanical stirring, reflux condenser and air guide tube, add 800.0g of E51 epoxy resin, 92.0g of acrylic acid and polymerization inhibitor Hydroquinone 0.2g, reacted at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com