Uniform-hole amine resin and preparation and application method thereof

An amine-based resin and application method technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of difficulty in resin regeneration, difficult elution of pigments, and reduced recovery rate, etc. To achieve the effect of being suitable for large-scale industrial application, friendly process environment, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

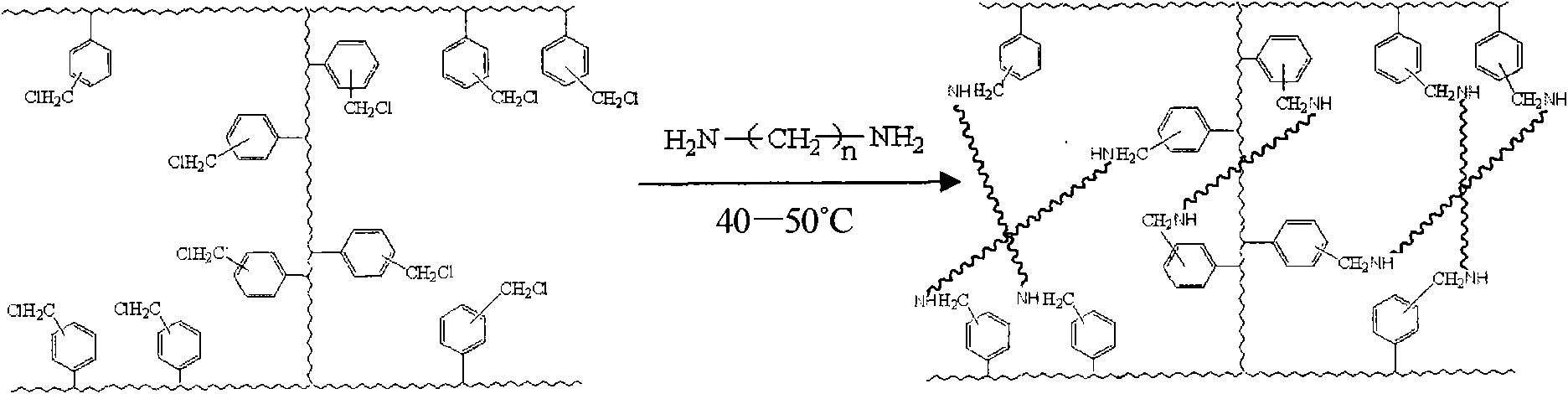

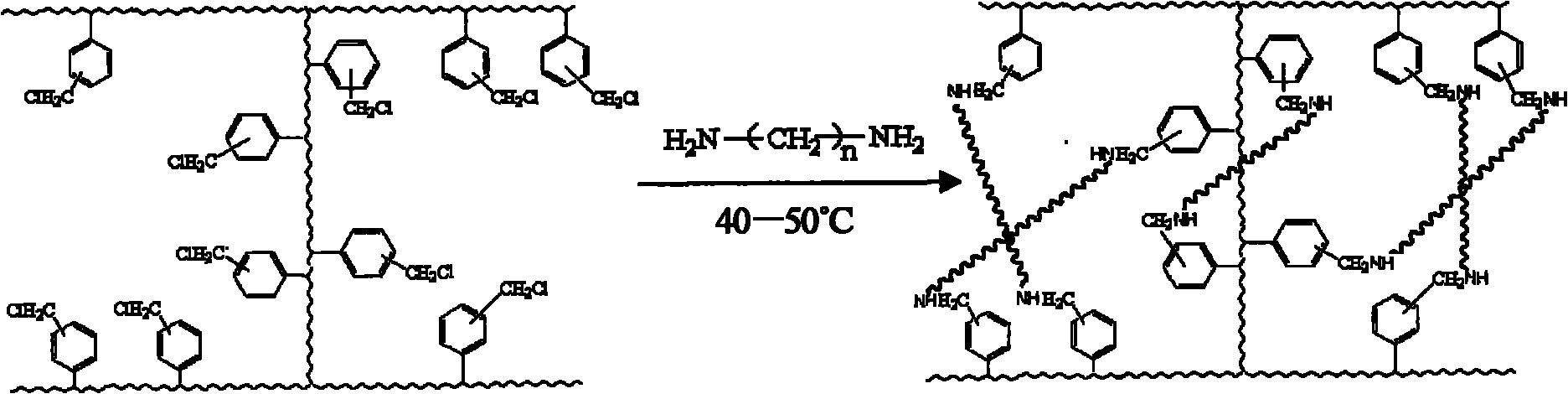

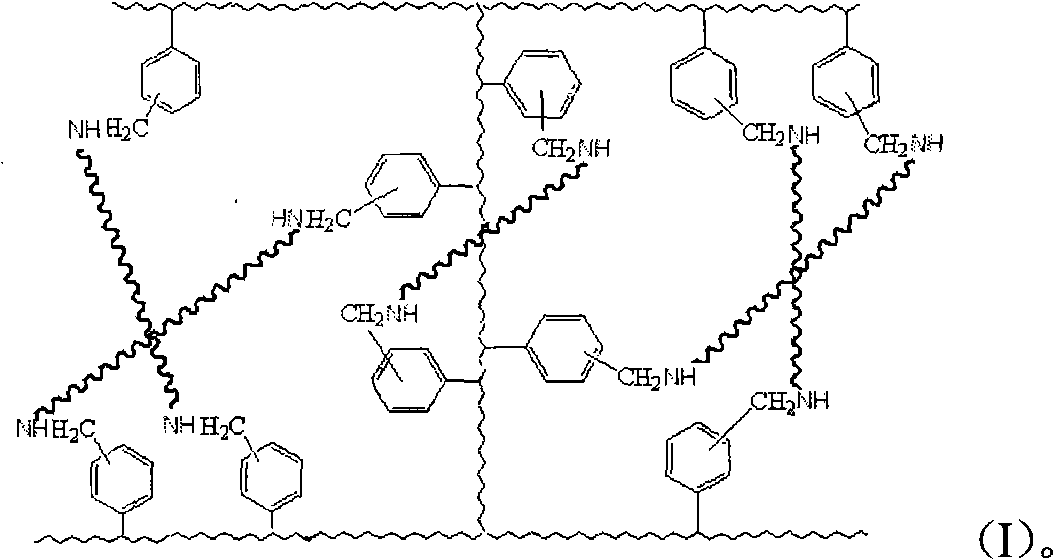

[0028] The synthetic method of novel homoporous amine-based resin:

[0029]At room temperature, dissolve 5.0 g of polyvinyl alcohol (PVA) in 500 g of water in a 1000 ml three-necked bottle, and heat to 40°C. Mix 50g of divinylbenzene, 25g of chloromethylated styrene, 75g of toluene, and 0.75g of BPO to form an oil phase. Add the oil phase to the water phase, start stirring and raise the temperature to 76°C at a rate of 0.5°C / min, keep it warm for 3 hours, then continue to heat up to 85°C for 10 hours, stop the reaction, filter to obtain transparent spherical solid particles, and It is washed with a large amount of deionized water and dried in vacuum to obtain chloromethylated polystyrene resin.

[0030] In a 1000ml three-necked bottle, fully swell 71.4g of dry chloromethylated polystyrene resin with 500g of dichloroethane, add 30g of 1,2-ethylenediamine, start stirring, after mixing evenly, heat up to 45°C and keep warm Stop the reaction after 6 hours, filter out the resin, ...

Embodiment 2

[0032] The synthetic method of novel homoporous amine-based resin:

[0033] At room temperature, dissolve 3.0 g of polyvinyl alcohol (PVA) in 450 g of water in a 1000 ml three-necked bottle, and heat to 42°C. Mix 40g of divinylbenzene, 35g of chloromethylated styrene, 100g of toluene, and 1.0g of BPO to form an oil phase. Add the oil phase to the water phase, start stirring and raise the temperature to 75°C at a rate of 0.5°C / min, keep it warm for 2 hours, then continue to heat up to 87°C and react for 8 hours, stop the reaction, filter, and obtain transparent spherical solid particles. It is washed with a large amount of deionized water and dried in vacuum to obtain chloromethylated polystyrene resin.

[0034] In a 1000ml three-necked bottle, fully swell 72.8g of dry chloromethylated polystyrene resin with 400g of dichloroethane, add 40g of 1,3-propylenediamine, start stirring, after mixing evenly, heat up to 48°C and keep warm Stop the reaction after 8 hours, filter out th...

Embodiment 3

[0036] The synthetic method of novel homoporous amine-based resin:

[0037] At normal temperature, dissolve 15g of polyvinyl alcohol (PVA) in 1000g of water in a 2000ml three-necked bottle, and heat to 45°C. Mix 100g of divinylbenzene, 50g of chloromethylated styrene, 100g of toluene, and 2.0g of BPO to form an oil phase. Add the oil phase to the water phase, start stirring and raise the temperature to 78°C at a rate of 0.5°C / min, keep it warm for 2 hours, then continue to heat up to 89°C for 6 hours, stop the reaction, filter to obtain transparent spherical solid particles, and It is washed with a large amount of deionized water and dried in vacuum to obtain chloromethylated polystyrene resin.

[0038] In a 2000ml three-necked bottle, fully swell 142.7g of dry chloromethylated polystyrene resin with 800g of dichloroethane, add 100g of 1,4-butanediamine, start stirring, after mixing evenly, heat up to 48°C and keep warm Stop the reaction after 10 hours, filter out the resin,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com