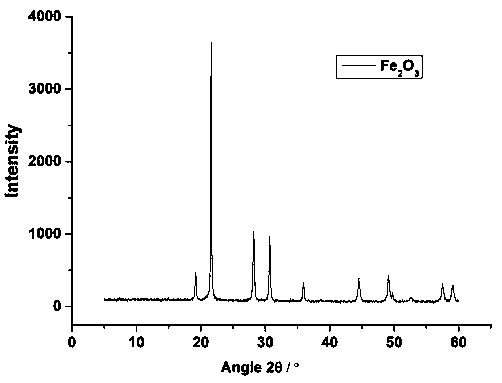

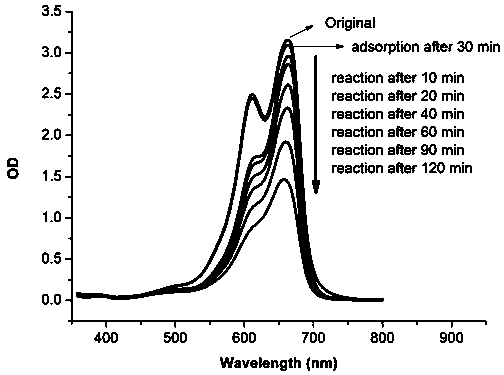

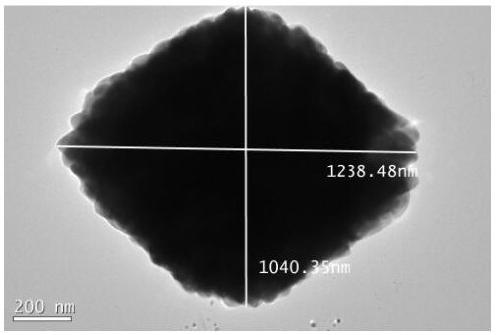

A kind of rice-shaped micron-scale iron oxide heterogeneous photo-Fenton catalyst and its preparation method

A micron-scale, iron oxide technology, applied in iron oxide/iron hydroxide, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of large dosage of iron ion catalyst and application Limitation of scope and inability to recycle, etc., to achieve the effect of high photocatalytic Fenton catalytic performance, single morphology, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First prepare 250 mL of FeCl with a concentration of 10 g / L 2 solution, and added 4 mL of dilute hydrochloric acid with a concentration of 0.03% to prevent its hydrolysis and precipitation; then, under the irradiation of a 300 W xenon lamp, slowly put 10 mL of 25% H 2 o 2 solution; then add the same amount of FeCl every 30 min for 5 consecutive times 2 (2.5g) and a concentration of 25% H 2 o 2 solution (10 mL); ultrasonic temperature was 65 ℃, power 99% under the conditions of continuous ultrasonication for 5 h; after standing for 3 days, the solution without precipitation was collected as the preparation of rice-shaped micron-sized iron oxide heterogeneous photo-Fenton Catalyst mother liquor: take 40mL of mother liquor and pour it into a 50mL hydrothermal reaction kettle, put the hydrothermal reaction kettle into a constant temperature drying oven, set the temperature at 170°C, take it out after 25 hours of reaction, cool, and suction filter to obtain a solid at 105...

Embodiment 2

[0030] First prepare 250 mL of FeCl with a concentration of 12 g / L 2 solution, and added 5 mL of dilute hydrochloric acid with a concentration of 0.03 % to prevent its hydrolysis and precipitation; then, under the irradiation of a 300 W xenon lamp, slowly add 10.2 mL of 30 % H 2 o 2 solution; then add the same amount of FeCl every 30 min for 5 consecutive times 2 (3 g) and a concentration of 30 % H 2 o 2 Solution (10.2 mL); ultrasonic temperature was 69 ℃, power 99% under the conditions of continuous ultrasonication for 6 h; after standing for 3 days, the solution without precipitation was collected as the preparation of rice-shaped micron-sized iron oxide heterogeneous photo-Fenton Catalyst mother liquor: take 40mL of mother liquor and pour it into a 50mL hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a constant temperature drying oven, set the temperature at 180°C, take it out after 28 hours of reaction, cool, and suction filter to obtain a s...

Embodiment 3

[0032] First prepare 250 mL of FeCl with a concentration of 15 g / L 2 solution, and added 6 mL of dilute hydrochloric acid with a concentration of 0.03% to prevent its hydrolysis and precipitation; then, under the irradiation of a 300 W xenon lamp, slowly inject 11 mL of 35% H 2 o 2 solution; then add the same amount of FeCl every 30 min for 5 consecutive times 2 (3.75g) and a concentration of 35% H 2 o 2 solution (11 mL); ultrasonic temperature was 75 °C, power 99% under the conditions of continuous ultrasonication for 7 h; after standing for 3 days, the solution without precipitation was collected as the preparation of rice-shaped micron-sized iron oxide heterogeneous photo-Fenton Catalyst mother liquor: take 40mL of mother liquor and pour it into a 50mL hydrothermal reaction kettle, put the hydrothermal reaction kettle into a constant temperature drying oven, set the temperature at 190°C, take it out after 30 hours of reaction, cool, and suction filter to obtain a solid a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com