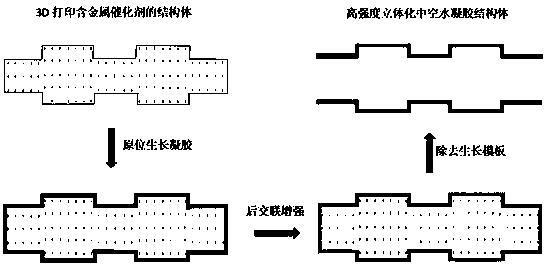

Preparation method for high-strength three-dimensional hollow hydrogel structural body

A structure and hydrogel technology, which is applied in the field of preparation of high-strength three-dimensional hollow hydrogel structures, can solve the problem of inability to prepare three-dimensional structural units of hydrogels, inability to use tissue and organ structure models, water Solve problems such as poor strength of the gel structure, achieve excellent mechanical properties, high strength, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

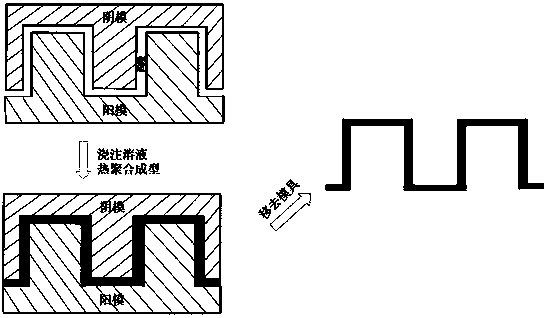

Method used

Image

Examples

Embodiment

[0029] Embodiment: the preparation of a kind of high-strength three-dimensional hydrogel structure comprises the following steps:

[0030] a. Preparation of iron-based polylactic acid (PLA@Fe) film material: Weigh 30 g of polylactic acid particles, add them to 200 mL of chloroform, stir rapidly until the particles are completely dissolved and the solution becomes transparent, then add 6 g of iron powder for After mixing and stirring for 30 min, the mixed solution was poured into a glass mold, and the PLA@Fe composite film material was formed after the solvent evaporated naturally.

[0031] b. Preparation of iron-based polylactic acid (PLA@Fe) wire: crush the PLA@Fe composite film material into granules, add it to the screw extruder, set the extrusion temperature rise program, the screw inlet temperature is 170 ℃, the cavity temperature The temperature was 175 °C, the outlet temperature was 180 °C, and a PLA@Fe wire with a diameter of 1.75 mm was obtained by simultaneous feedin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com