Preparation method of ultra-fine and ultra-long Au nanowire

A nanowire and ultra-long technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that it is difficult to obtain one-dimensional nanowires, and achieve simple and easy process and high purity , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

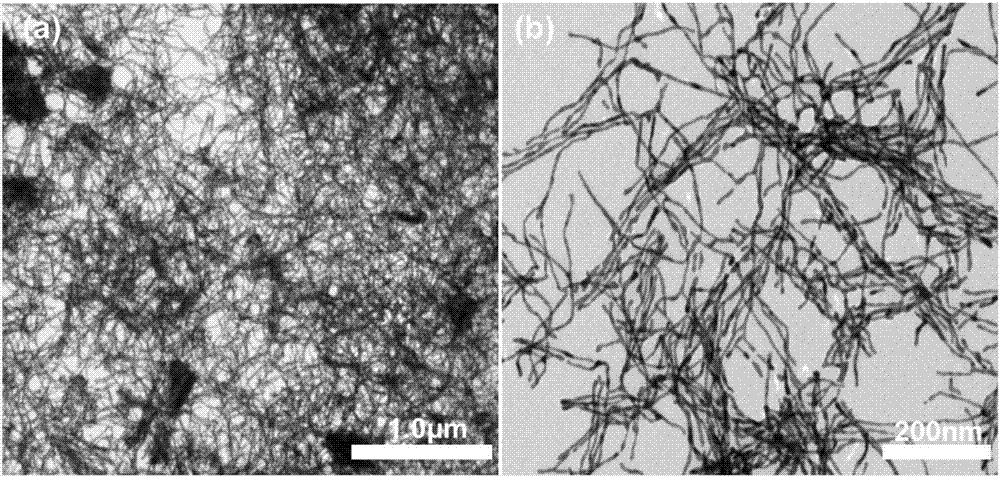

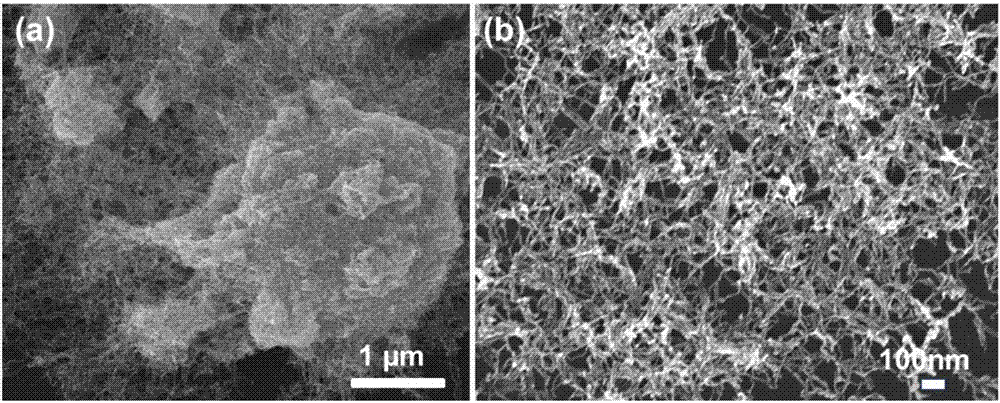

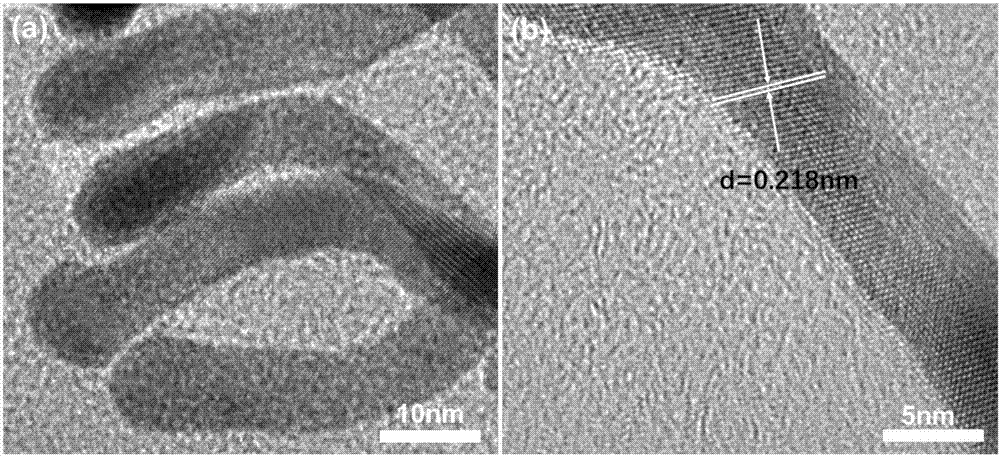

[0022] An ultra-fast and macro-preparation method for ultra-fine and ultra-long Au nanowires, comprising the following steps: s

[0023] 1) Preparation of reaction solution: Measure 22mL of a mixed solution of water and ethanol with a volume ratio of 1:1 as a dispersant, add 4mL of 0.5mol L -1 The ethanol solution of 1-naphthol was used as surfactant, reducing agent and shape-directing agent and 4mL 0.05mol L -1 HAuCl 4 As a precursor, shake and mix evenly;

[0024] 2) Preparation of Au nanowires: put the prepared reaction solution in a water bath at 60°C and let it stand for 2 hours. After the reaction, the black product was ultrasonically washed three times with ethanol, and dried in vacuum at room temperature for 6 hours to obtain ultrafine and ultralong nanowires. Au nanowires.

Embodiment 2

[0026] An ultra-fast and macro-preparation method for ultra-fine and ultra-long Au nanowires, comprising the following steps:

[0027] 1) Preparation of reaction solution: Measure 22mL of a mixed solution of water and ethanol with a volume ratio of 1:1 as a dispersant, add 4mL of 0.5mol L -1 The ethanol solution of 1-naphthol was used as surfactant, reducing agent and shape-directing agent and 4mL 0.05mol L -1 AuAc 3 As a precursor, shake and mix evenly;

[0028] 2) Preparation of Au nanowires: put the prepared reaction solution in a water bath at 60°C and let it stand for 2 hours. After the reaction, the black product was ultrasonically washed three times with ethanol, and dried in vacuum at room temperature for 6 hours to obtain ultrafine and ultralong nanowires. Au nanowires.

Embodiment 3

[0030] An ultra-fast and macro-preparation method for ultra-fine and ultra-long Au nanowires, comprising the following steps:

[0031] 1) Preparation of reaction solution: Measure 22mL of a mixed solution of water and ethanol with a volume ratio of 1:1 as a dispersant, add 4mL of 0.5mol L -1 The ethanol solution of 1-naphthol was used as surfactant, reducing agent and shape-directing agent and 4mL 0.05mol L -1 of, KAuBr 4 As a precursor, shake and mix evenly;

[0032] 2) Preparation of Au nanowires: put the prepared reaction solution in a water bath at 60°C and let it stand for 2 hours. After the reaction, the black product was ultrasonically washed three times with ethanol, and dried in vacuum at room temperature for 6 hours to obtain ultrafine and ultralong nanowires. Au nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com