Preparation method for high-purity methylphenyl-dimethoxysilane

A technology of methylphenyldimethoxysilane and methylphenyldichlorosilane, which is applied in the field of synthetic monomers of organic silicon packaging materials, can solve problems such as lower yield, pollute the environment, and defects in rectification technology, and achieve Reduce the production of hydrogen chloride, prevent the production of high boiling substances, and increase the effect of nucleophilic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

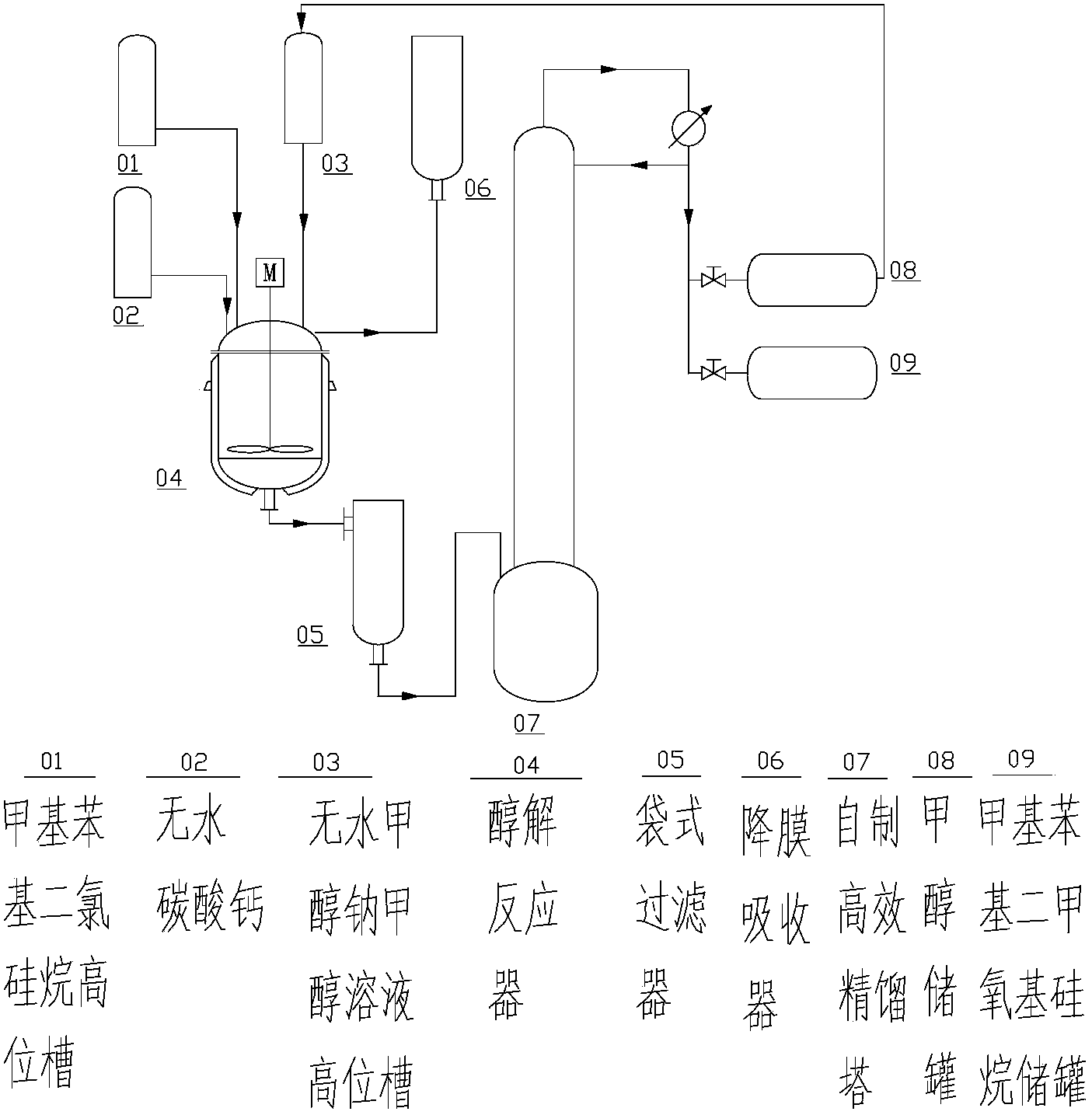

Image

Examples

example 1

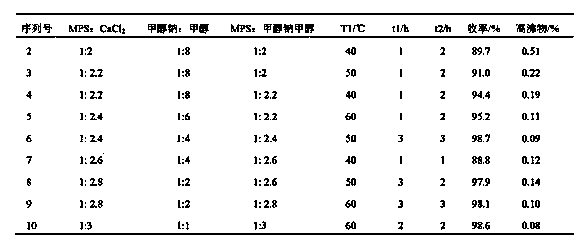

[0021] (1) Add methylphenyldichlorosilane and hydrogen chloride absorbent anhydrous calcium carbonate in a molar ratio of 1:2 to the alcohol decryption closed stirring reactor, and then add the catalyst sodium methoxide into anhydrous methanol to dissolve to obtain anhydrous methanol Sodium methanol solution, control the molar ratio of catalyst sodium methoxide and anhydrous methanol to 1:10, then pump air, nitrogen replacement, and then slowly add anhydrous sodium methoxide methanol solution to the reactor at constant pressure to control methylphenyl The molar ratio of dichlorosilane to anhydrous sodium methoxide methanol solution is 1:2, the time for dropping is 1h, and the reaction temperature is 40°C. Crude phenyldimethoxysilane;

[0022] (2) Add the crude product of methylphenyldimethoxysilane to the self-made gradient high-efficiency distillation column, control the rectification temperature at 64~65°C to recover methanol, and then adjust the reflux ratio to control the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com