A kind of optical grade pmma continuous bulk polymerization method and production system thereof

A bulk polymerization, optical-grade technology, which is applied in the field of optical-grade PMMA continuous bulk polymerization method and its production system, can solve the problems of easy production of a large amount of solvent and water, complex synthesis method, and need for recycling, so as to shorten the residence time and replace Product flexibility, polymer purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

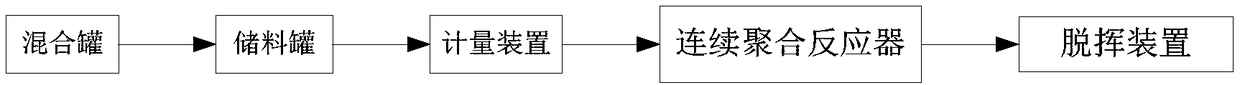

[0038] A kind of production optical grade PMMA continuous mass polymerization method, comprises the steps: reaction component methyl methacrylate (being MMA), initiator, auxiliary agent are mixed into mixed solution by proportioning, the raw material of mixed solution comprises (by weight ): 100 parts of methyl methacrylate, 1 part of di-tert-butyl peroxide, and 1 part of dodecanethiol. When mixing, control the temperature below 87°C, put each raw material into a spray mixing tank and mix thoroughly, the mixed solution is introduced from the mixing tank into the storage tank for storage, and then through the metering device, the mixed solution is injected into the qualified product that has passed nitrogen replacement. Carry out polymerization reaction and extrude continuously in the uniaxial continuous polymerization reactor system, in the reaction process, the screw speed of uniaxial continuous polymerization reactor is 60rpm, and the pressure in the reaction chamber of uniax...

Embodiment 2

[0040]A kind of production optical grade PMMA continuous mass polymerization method, comprises the steps: reaction component methyl methacrylate (being MMA), initiator, auxiliary agent are mixed into mixed solution by proportioning, the raw material of mixed solution comprises (by weight ): 100 parts of methyl methacrylate, 1 / 2 part of di-tert-butyl peroxide, and 1 / 2 part of dodecanethiol. When mixing, control the temperature below 80°C, put each raw material into a spray mixing tank and mix thoroughly, the mixed solution is introduced from the mixing tank to the storage tank for storage, and then through the metering device, inject the mixed solution into the qualified product that has passed nitrogen replacement. Carry out polymerization reaction and extrude continuously in the uniaxial continuous polymerization reactor system, in the reaction process, the screw speed of uniaxial continuous polymerization reactor is 45rpm, and the pressure in the reaction chamber of uniaxial ...

Embodiment 3

[0042] A kind of production optical grade PMMA continuous mass polymerization method, comprises the steps: reaction component methyl methacrylate (being MMA), initiator, auxiliary agent are mixed into mixed solution by proportioning, the raw material of mixed solution comprises (by weight ): 100 parts of methyl methacrylate, 1 / 2 part of di-tert-butyl peroxide. When mixing, control the temperature below 85°C, put each raw material into a spray mixing tank and mix thoroughly, the mixed solution is introduced from the mixing tank to the storage tank for storage, and then through the metering device, inject the mixed solution into the qualified product that has passed nitrogen replacement. Carry out polymerization reaction and extrude continuously in the uniaxial continuous polymerization reactor system, in the reaction process, the screw speed of uniaxial continuous polymerization reactor is 50rpm, and the pressure in the reaction chamber of uniaxial continuous polymerization reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com