Method for extracting and recovering precious metal and rare metal from wastes

A rare metal and recycling method technology, applied in the direction of improving process efficiency, can solve the problems of pollution, low utilization rate, singleness, etc., and achieve the effects of less pollution, environmental friendliness, and high resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

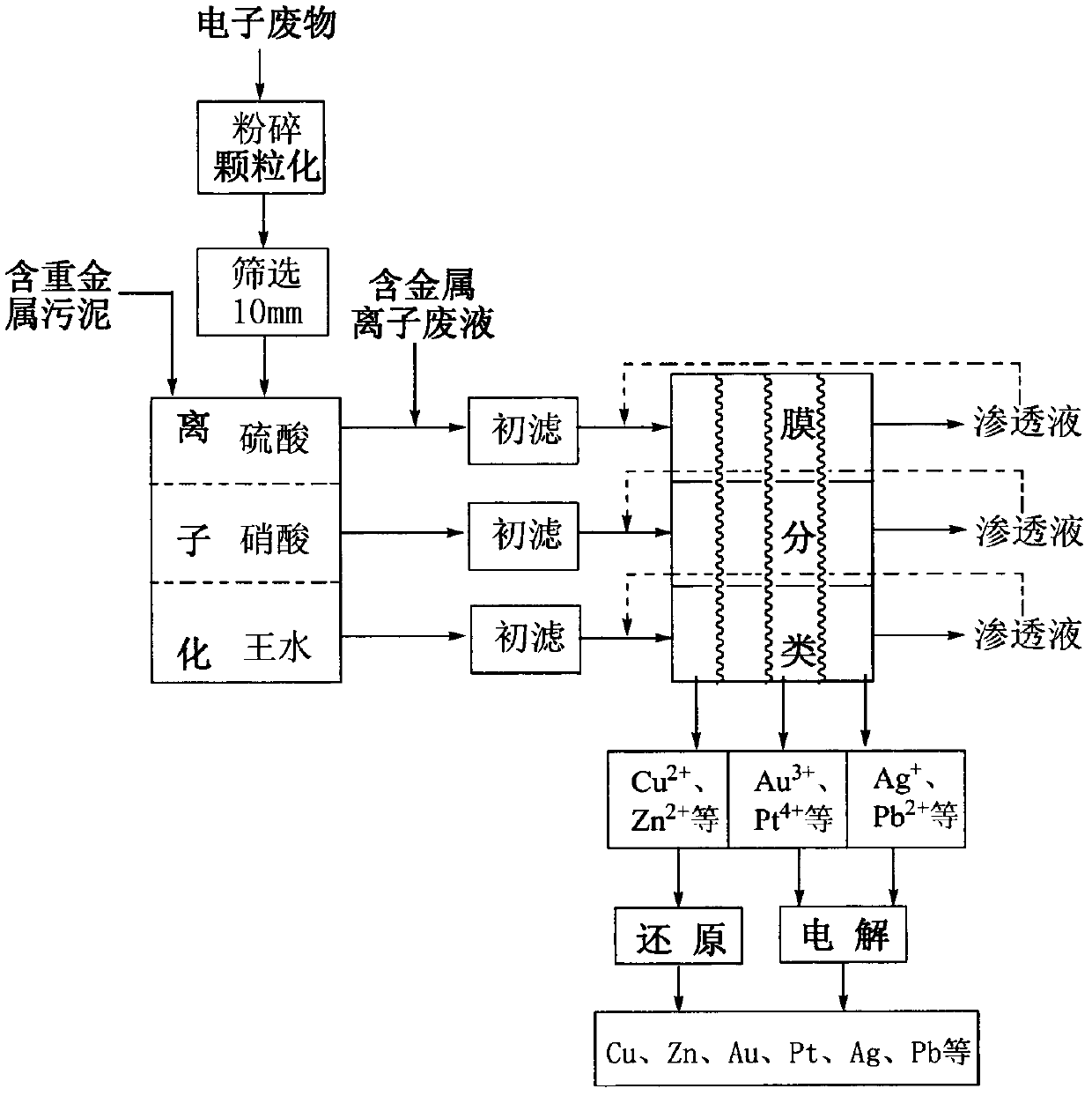

Method used

Image

Examples

Embodiment Construction

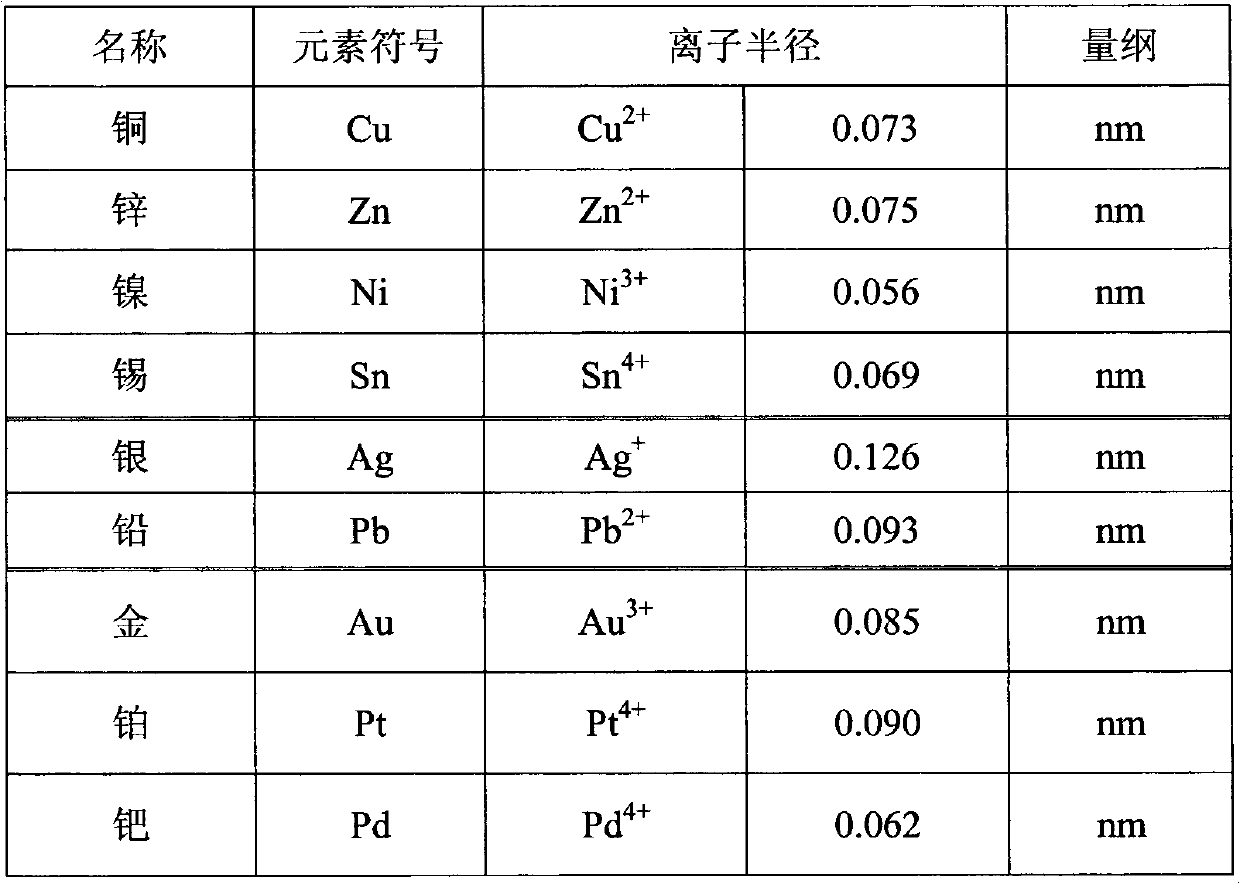

[0049] (1) After the waste or sludge containing precious metals is dissolved and ionized with sulfuric acid (solid-to-liquid mass ratio 1:10), the solution is initially filtered through ordinary acid-resistant filter cloth to remove impurities, and the filtrate is then permeated through a 0.08nm nanofiltration membrane. Set, while intercepting and removing large particle ions larger than 0.08nm. The above containing Cu 2+ , Zn 2+ , Sn 2+ 、Ni 2+ The enrichment solution of four ions is reduced by oxalic acid to obtain a mixture of four metal particles, and then various metal crude products are obtained by regional melting.

[0050] Table 4 Statistical Table of Recovery Rates of Four Kinds of Metals

[0051] metal name Melting range ℃ Crude product content% Metal Recovery %

[0052] tin 231.5~232.2 98.03 82.6 zinc 419.4~420.6 95.38 92.1 copper 1083.6~1084.4 98.60 89.7 nickel 1452.6~1452.8 92.68 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com