Method for preparing high flame-retardant insulation board by mixing and foaming phenolic resin and polystyrene

A technology of phenolic resin and polystyrene, which is used in the field of mixing and foaming phenolic resin and expandable polystyrene to prepare high flame-retardant thermal insulation boards, can solve the problems of low production efficiency, uneven upper and lower structures, inaccurate control of process conditions, etc. problem, to achieve the effect of high production efficiency, uniform thickness and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

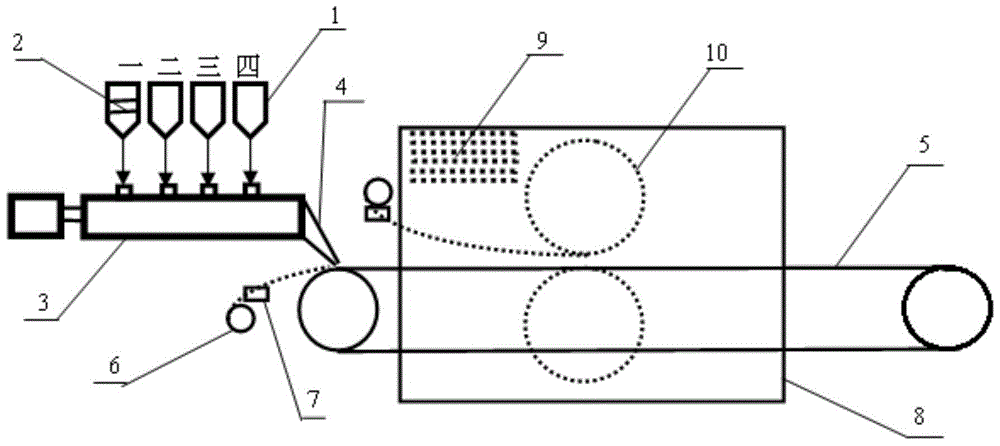

Method used

Image

Examples

specific Embodiment

[0041] Table 1, the proportioning of each component in parts by weight in three kinds of embodiments

[0042]

[0043] catalyst

[0044] Component one of Example 1 in above-mentioned table 1 is phenolic resin; Component two is furfural phenolic resin; Component three is expandable polystyrene; Curing agent is sulfuric acid; Catalyst is sodium carbonate; Magnesium; auxiliary agent is fatty alcohol polyoxyethylene ether.

Embodiment 2

[0045] Component one of embodiment 2 is phenolic resin; Component two is furfural urea-formaldehyde resin; Component three is expandable polystyrene; Curing agent is sulfuric acid; Catalyst is ammonia water; Flame retardant is aluminum hydroxide; Fatty alcohol polyoxyethylene ether.

Embodiment 3

[0046] In Example 3, component one is phenolic resin; component two is furfural urea-formaldehyde resin; component three is expandable polystyrene; curing agent is phosphoric acid; catalyst is hydrogen peroxide; flame retardant is ammonium dihydrogen phosphate.

[0047] Following Table 2, Table 3, and Table 4 are the processing conditions of Embodiment 1, Embodiment 2, and Embodiment 3 respectively.

[0048] Table 2, the process condition of embodiment 1

[0049] Weight loss scale - preheating temperature (°C)

40

Loss in weight scale-feeding speed (kg / min)

1.5

Mixer liquid residence time (s)

40

Conveyor belt transmission speed (m / min)

1

Outlet temperature (°C)

75

Surface temperature of the conveyor belt in the oven (°C)

60

Pressure roller foaming temperature

100~120

[0050] Table 3, the process condition of embodiment 2

[0051] Weight loss scale - preheating temperature (°C)

40

L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com