Modified polystyrene board, and preparation method and application thereof

A polystyrene board and modification technology, which is applied in the field of preparation and modification of polystyrene board, can solve the problems of potential safety hazards, the inability to recycle waste materials, and the inability to re-foam, etc., to achieve high strength and thermal insulation performance, reduce cost, to achieve the effect of environmental friendliness of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

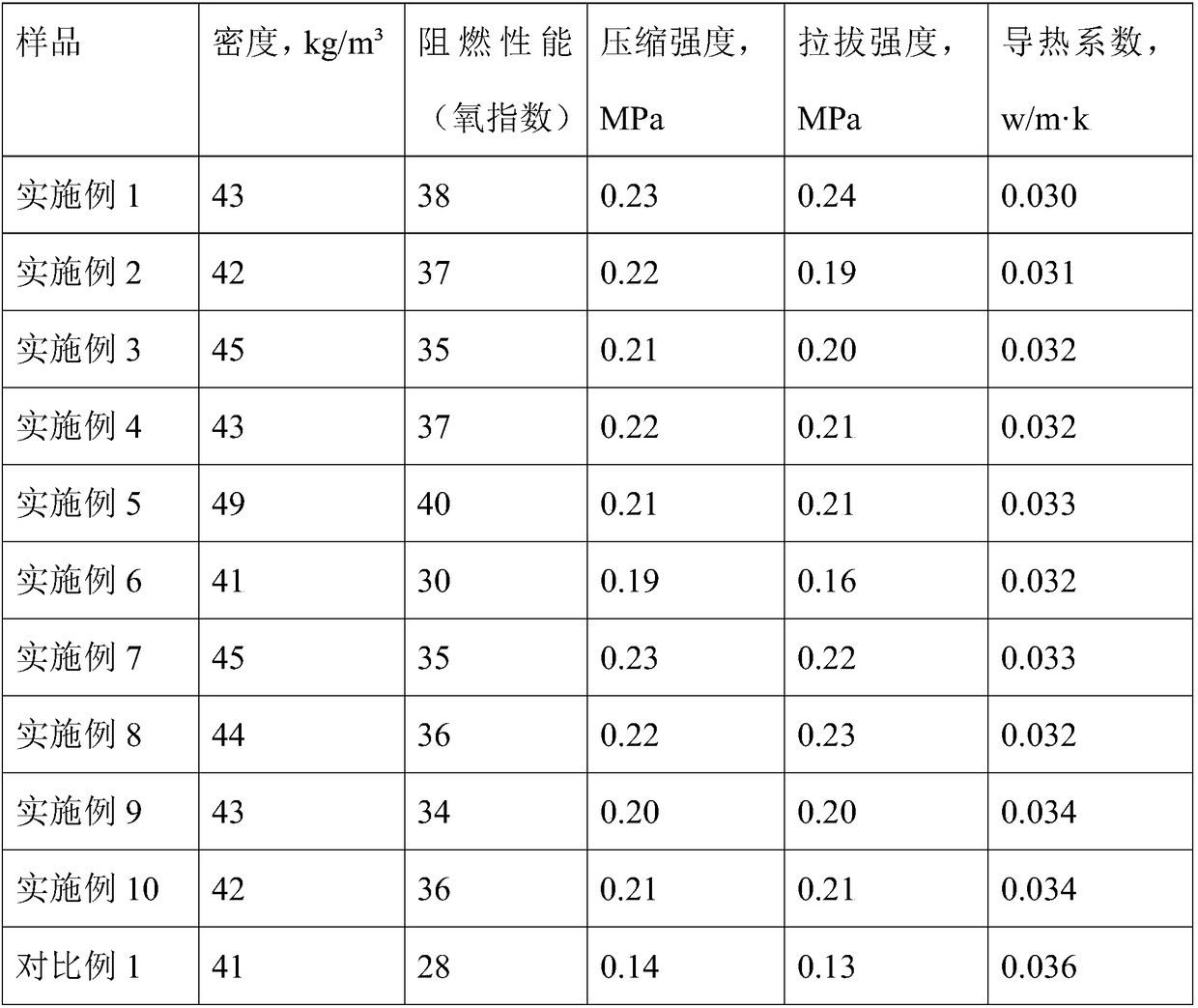

Examples

Embodiment 1

[0052] A modified polystyrene board is prepared by the following method:

[0053] (1) Below 30°C, mix 100 parts by weight of thermosetting phenolic resin, 10 parts by weight of flame retardant decabromodiphenyl ether, foaming agent methylene chloride accounting for 8 wt% of thermosetting resin, and surfactant accounting for 2 wt% of thermosetting resin Polyoxyethylene sorbitan monooleate, dispersant glyceryl tristearate accounting for 2wt% of polystyrene foamed particles to obtain binder;

[0054] (2) 100 parts by weight of pulverized particles of polystyrene plate waste in the range of 2 to 15 mm in particle size and binder are mixed uniformly to obtain molding material;

[0055] (3) Add 11wt% curing agent of thermosetting resin to the molding material and mix, then pressurize and mold for 15 minutes under the conditions of pressure 0.8-1.2MPa and temperature 100°C to 15% of the original bulk volume, and the improved durable polystyrene board.

Embodiment 2

[0057] A modified polystyrene board is prepared by the following method:

[0058] (1) Below 30°C, mix 40 parts by weight of thermosetting phenolic resin, 1 part by weight of flame retardant decabromodiphenyl ether, foaming agent dichloromethane accounting for 6 wt% of thermosetting resin, and surfactant accounting for 5 wt% of thermosetting resin Polyoxyethylene sorbitan monooleate, glyceryl tristearate accounting for 5wt% of polystyrene foamed particles to obtain a binder;

[0059] (2) 100 parts by weight of pulverized particles of polystyrene plate waste in the range of 2 to 15 mm in particle size and binder are mixed uniformly to obtain molding material;

[0060] (3) Add 8wt% curing agent of thermosetting resin to the molding material and mix it, and then perform mechanical press molding for 5 minutes at a pressure of 0.2-0.5MPa and a temperature of 60-100°C to 20% of the original bulk volume, A modified polystyrene board was obtained.

Embodiment 3

[0062] A modified polystyrene board is prepared by the following method:

[0063] (1) Below 30°C, mix 160 parts by weight of thermosetting phenolic resin, 20 parts by weight of flame retardant decabromodiphenyl ether, foaming agent dichloromethane accounting for 12 wt% of thermosetting resin, and surfactant accounting for 1 wt% of thermosetting resin Polyoxyethylene sorbitan monooleate, glyceryl tristearate accounting for 1 wt% of polystyrene foamed particles to obtain a binding material;

[0064] (2) 100 parts by weight of pulverized particles of polystyrene plate waste in the range of 2 to 15 mm in particle size and binder are mixed uniformly to obtain molding material;

[0065] (3) Add 15wt% curing agent of thermosetting resin to the molding material and mix it, then press and mold it mechanically for 20 minutes at a pressure of 1.2-1.5MPa and a temperature of 110-120°C until it reaches 2% of the original bulk volume, A modified polystyrene board was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com