a led filament

A technology of LED filament and LED chip, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of poor filament protection, poor heat dissipation performance, and poor uniformity, so as to improve photoelectric performance, service life, and good light uniformity And the effect of improving stability and vulcanization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

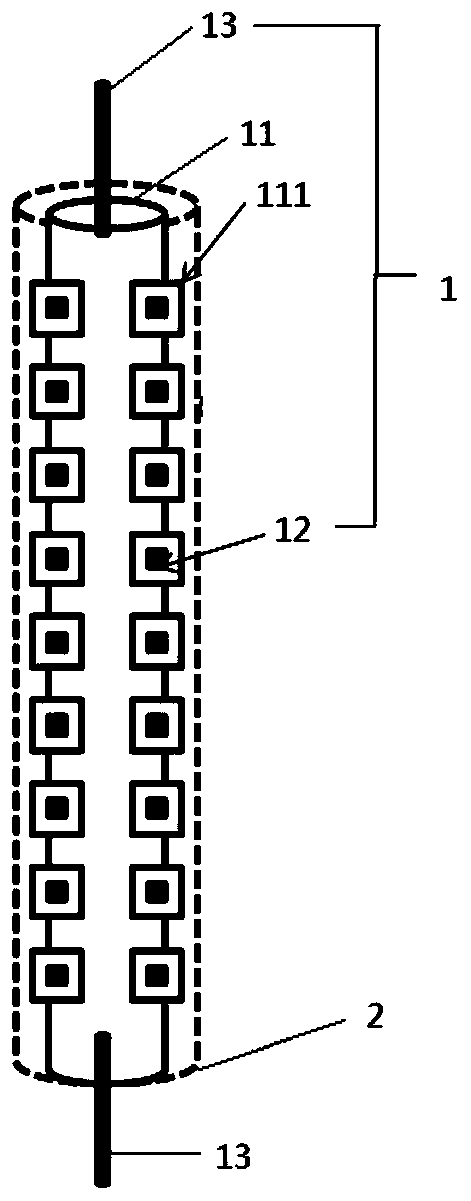

[0042] A kind of LED filament, comprising:

[0043] LED filament base, the LED filament base includes a filament base and several LED chips arranged on the filament base, wherein the filament base includes a cylindrical base, and the outer surface of the filament base is provided with several grooves; LED The chip is arranged in the groove of the filament base, and the LED chips radially distributed on the outer wall of the filament base are electrically connected;

[0044] A flexible glass film, the flexible glass film is seamlessly coated on the surface of the groove, wherein the flexible glass film is a flexible fluorescent glass film, the flexible fluorescent glass film contains glass powder, fluorescent powder and graphene, and the In the flexible fluorescent glass film, the weight ratio of the glass powder, fluorescent powder and graphene is 5:1:0.3.

[0045] Wherein, the filament substrate is a copper / graphene composite substrate, wherein graphene accounts for about 10...

Embodiment 2

[0047] The difference from Example 1 is that the filament substrate is a SiC / graphene composite substrate, wherein graphene accounts for about 10%.

Embodiment 3

[0049] The difference from Example 1 is that the filament substrate is an AlN / graphene composite substrate, wherein graphene accounts for about 10%; in the flexible fluorescent glass film, the weight ratio of the glass powder, phosphor powder and graphene is 4:1:0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com