Patents

Literature

38results about How to "Has a matte finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Matt release film

ActiveCN105348946ASolve technical problems caused by residuesHigh residual adhesionCoatingsPolymer scienceAcrylic resin

The invention relates to a matt release film. The matt release film comprises a base film and a matt release coating layer arranged at one side of the base film; and the matt release coating layer is formed by coating a fluorine-containing thermosetting coating, and the coating comprises fluorine series resin, acrylic resin, aldehyde ketone resin, a curing agent system, an assistant, a delustering agent and a mixed solvent. The matt release film has the advantages of low surface tension, good adhesiveness and overcoatability, excellent heat and solvent resistance, and high residual adhesion rate and excellent matt effect after peeling when the matt release film is used in the field of electron manufacturing.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

Skin care products for neck and preparation technique thereof

InactiveCN101259095AIncrease firmnessIncrease elasticityCosmetic preparationsToilet preparationsElastomerWrinkle skin

The invention relates to a neck skin care product and a preparation technique thereof. The proportioning for the components of neck skin care product is scientific and reasonable; the neck skin care product comprises active ingredients of Limnanthes Alba seed oil (meadowfoam seed oil), palmitoyl pentapeptide, soliquoid of organosilicone elastomers, etc., and the preparation of the neck skin care product aims at caring the neck skin of pregnant women and lying-in women that is characterized by hydropenia and easy aging caused by escalatory secretion of thyrotropin and corticotrophin; the neck skin care product has prominent anti-oxidation and free radical capturing properties, and is not greasy with strong permeability, obviously reinforcing the synthesis of elastin and collagen protein of the skin, smoothening the wrinkles and promoting skin elasticity; meanwhile, the neck skin care product ensures the skin moist and silken texture and covers the fine wrinkles of the neck; through the synergistic effect on the skin from endothecium to surface, the neck skin care product is capable of promoting the elasticity of the skin, preventing the loss of moisture, supplying moisture and nutrition inside the skin simultaneously, and ensuring the skin of the neck to be healthier and more lustrous.

Owner:天津盛世永业科技发展有限公司

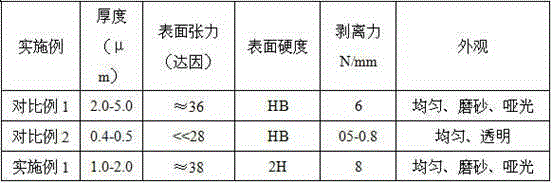

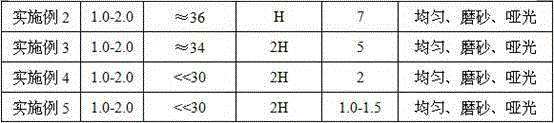

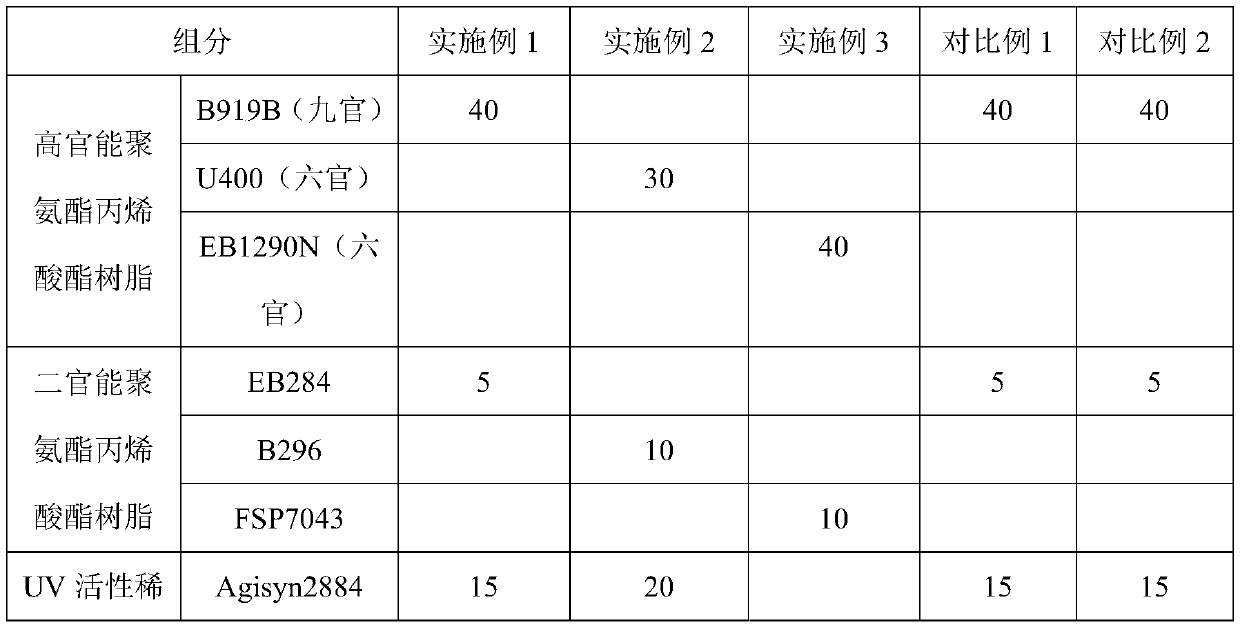

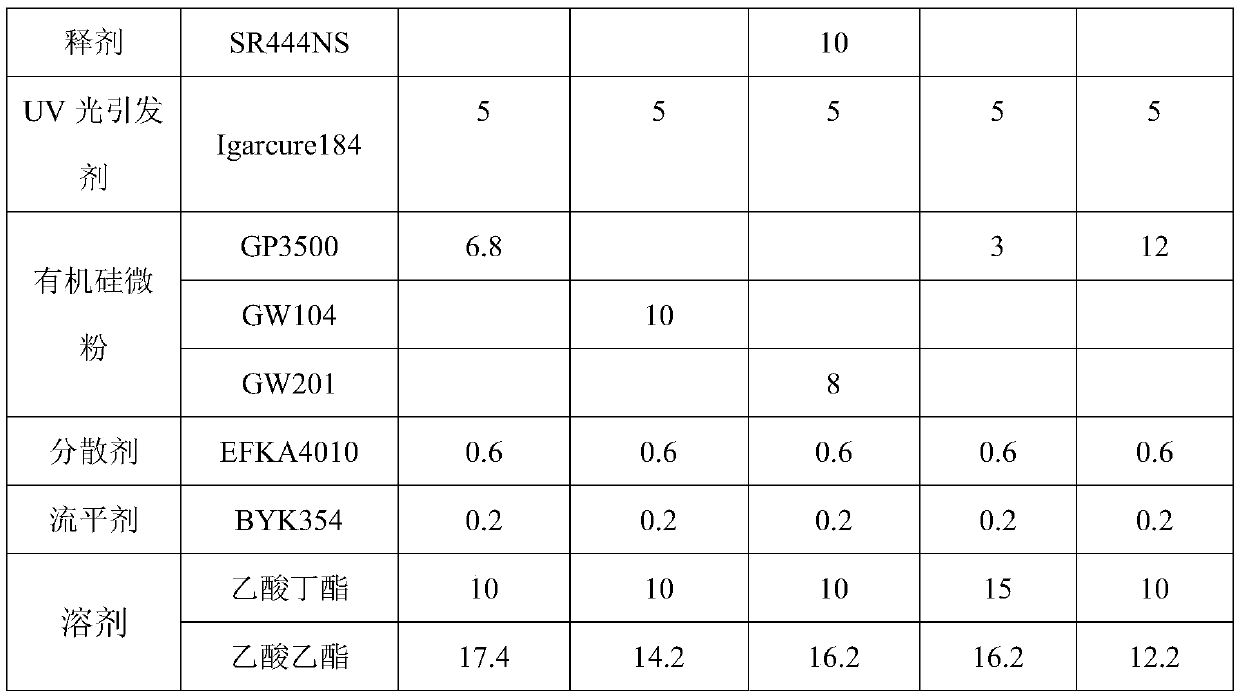

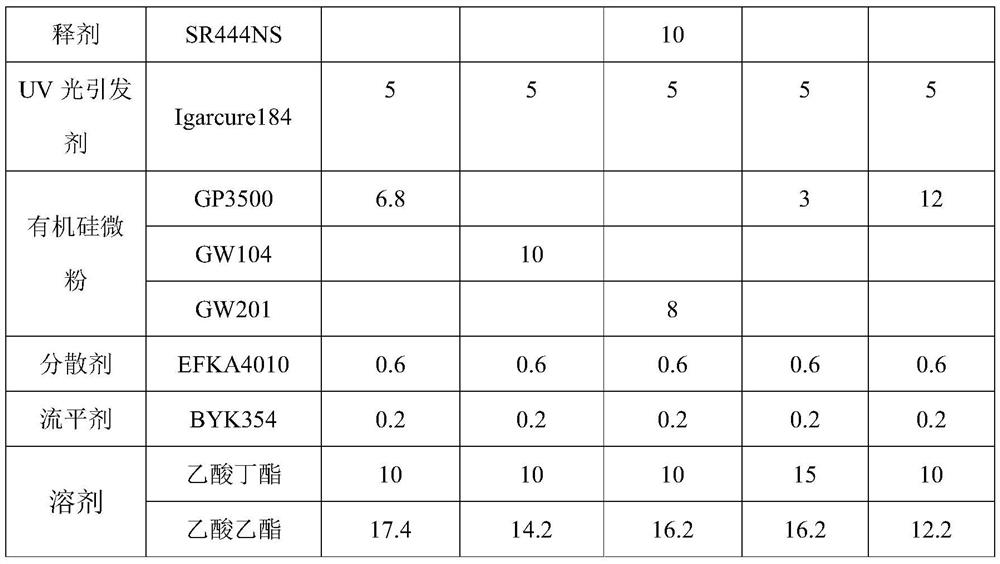

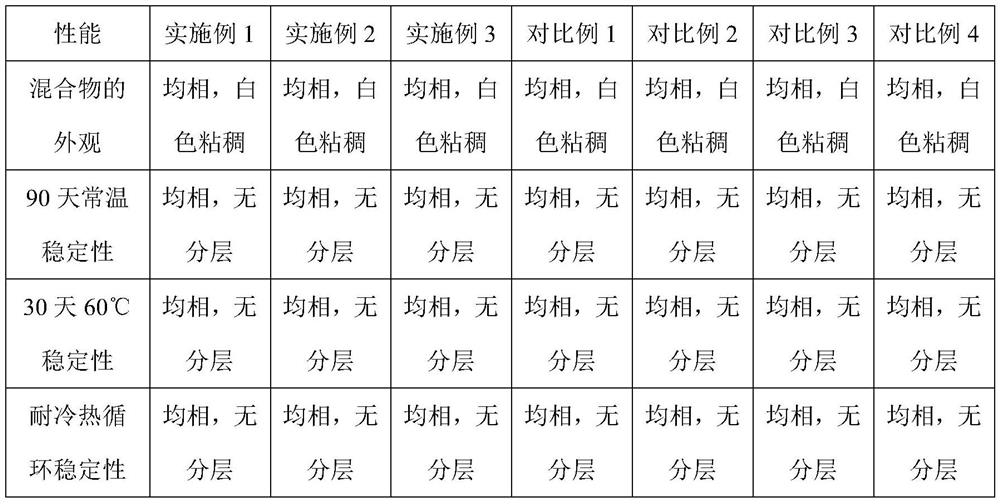

White board film matte UV coating and preparation method thereof

ActiveCN111484798AImprove wear resistance and chemical resistanceGood adhesion and chemical resistancePolyurea/polyurethane coatingsPhotoinitiatorOrganosilicon

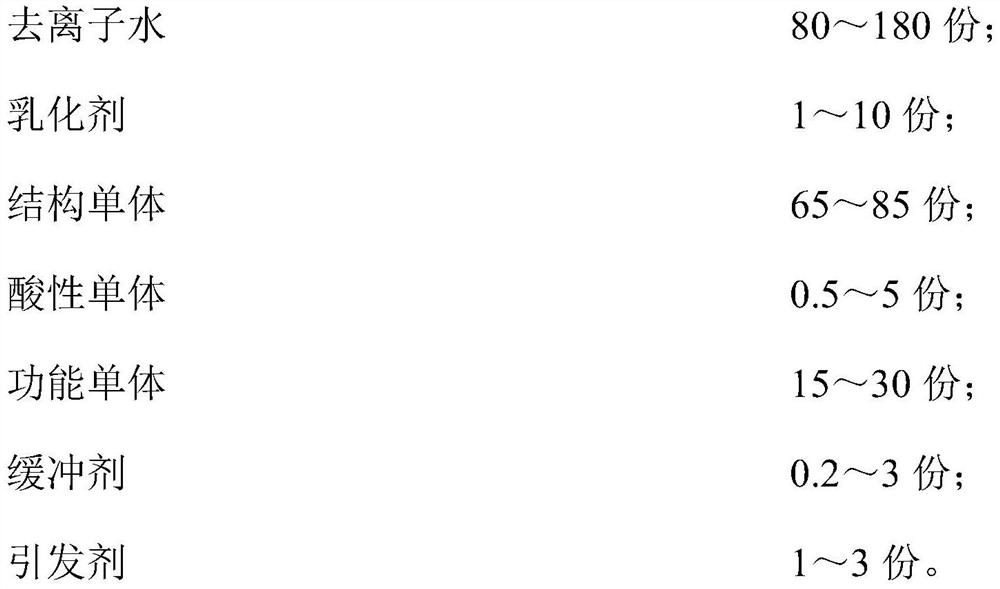

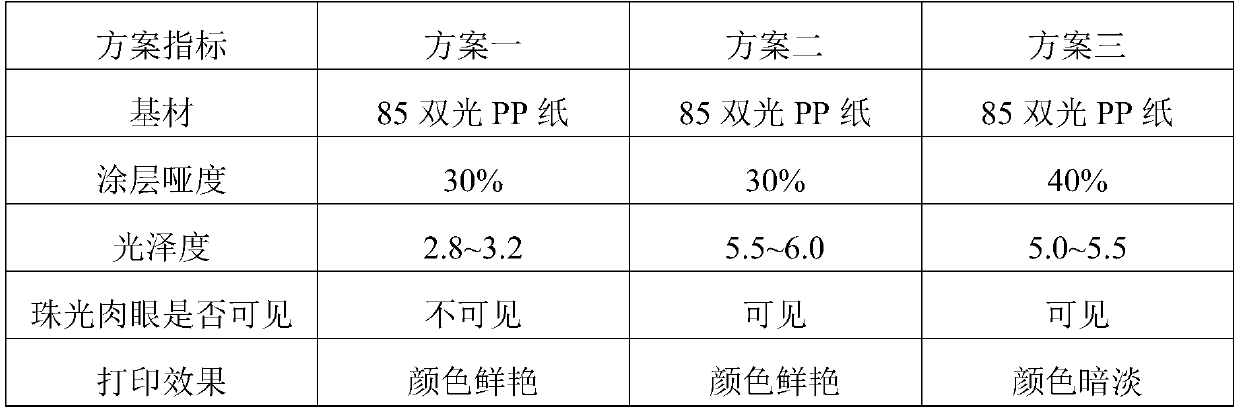

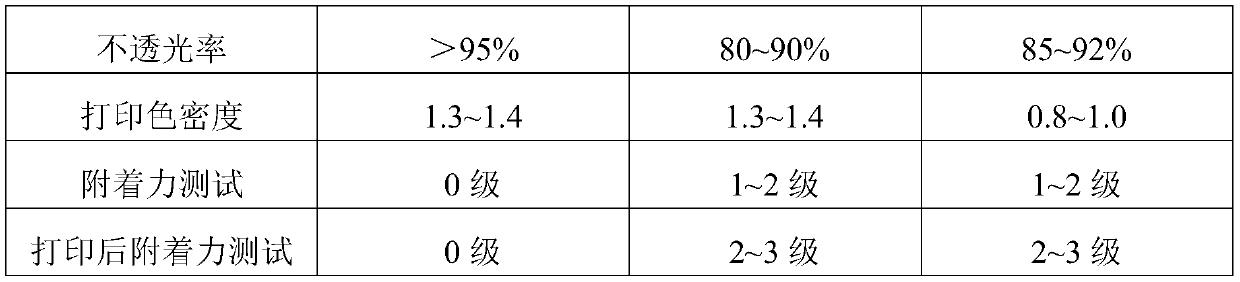

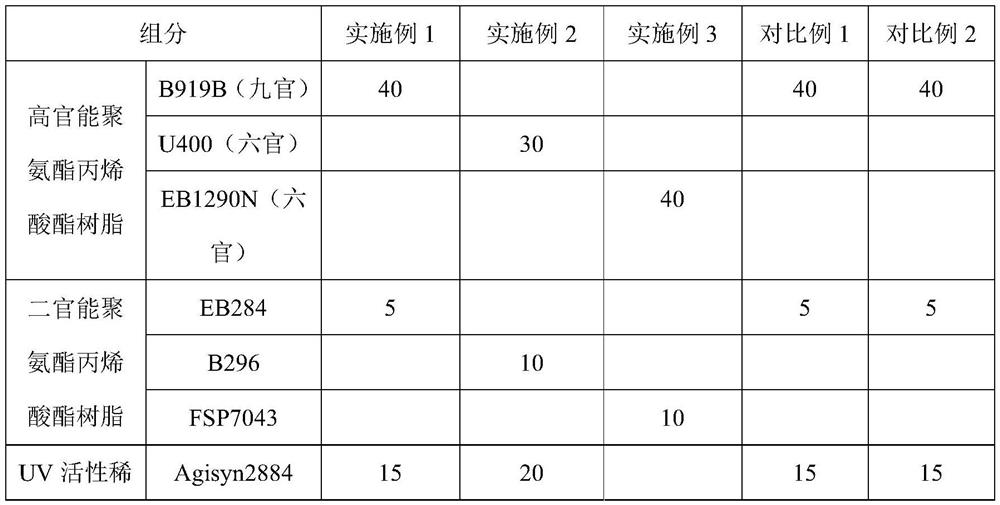

The invention discloses a white board film matte UV coating and a preparation method thereof. The white board film matte UV coating comprises the following components in parts by weight: 30 to 40 parts of high-functionality urethane acrylate resin, 5 to 10 parts of difunctionality urethane acrylate resin, 10 to 20 parts of a UV reactive diluent, 3 to 5 parts of a UV photoinitiator, 5 to 10 parts of organic silicon micro powder, 0.5 to 1 part of a dispersing agent, 0.1 to 0.5 part of a leveling agent and 20 to 30 parts of a solvent. According to the invention, the high-functionality urethane acrylate resin and the difunctional urethane acrylate resin are used as main materials, the organic silicon micropowder is added, and other components are matched to obtain the white board film matte UVcoating. The white board film matte UV coating has a matte effect, is anti-glare, has the characteristics of being easy to write and erase, is easy to wet when a white board pen writes, does not generate an ink shrinkage phenomenon, has clear characters, is easy to erase, has high hardness, high scratch resistance and good durability, and is very suitable for matte treatment and hardening treatment of the surface of a white board film.

Owner:GUANGZHOU SHENWEI NEW MATERIAL TECH

Method for producing thermoprinted matt stay wire

InactiveCN108501413AWith anti-counterfeiting protectionEffective occlusionFlat articlesEngineeringPlastic film

The invention relates to a method for producing a thermoprinted matt stay wire. The method comprises the following steps: 1, performing double-sided corona processing on a BOPP or PET plastic film used as a substrate to form a corona layer; 2, arranging a medium layer on the corona layer and making a plate: coating the printing side of the film substrate with a prepared transparent ink in a full side printing manner to form the medium layer, and engraving a printing plate according to picture and text requirements; 3, performing vacuum aluminizing on the upper surface of the film substrate toform a vacuum aluminizing layer on the film; and 4, performing full side coating on the film substrate by using matting powder mixed aqueous ink to perform matting treatment in order to make the plastic film have a matte effect, and performing printing, coating, chopping and packaging. The stay wire produced in the invention has the same color with a paper bag outer packing box, the color of the stay wire is not different from the color of the paper bag outer packing box, the stay wire has a matte effect, can be fused with the paper bag outer packing box in color, has optical opacity, and caneffectively shield two-dimensional codes on an outer packing brand to prevent illegal code scanning and protect the falsification resistance of the brand to a certain degree.

Owner:广州咏顺包装材料有限公司

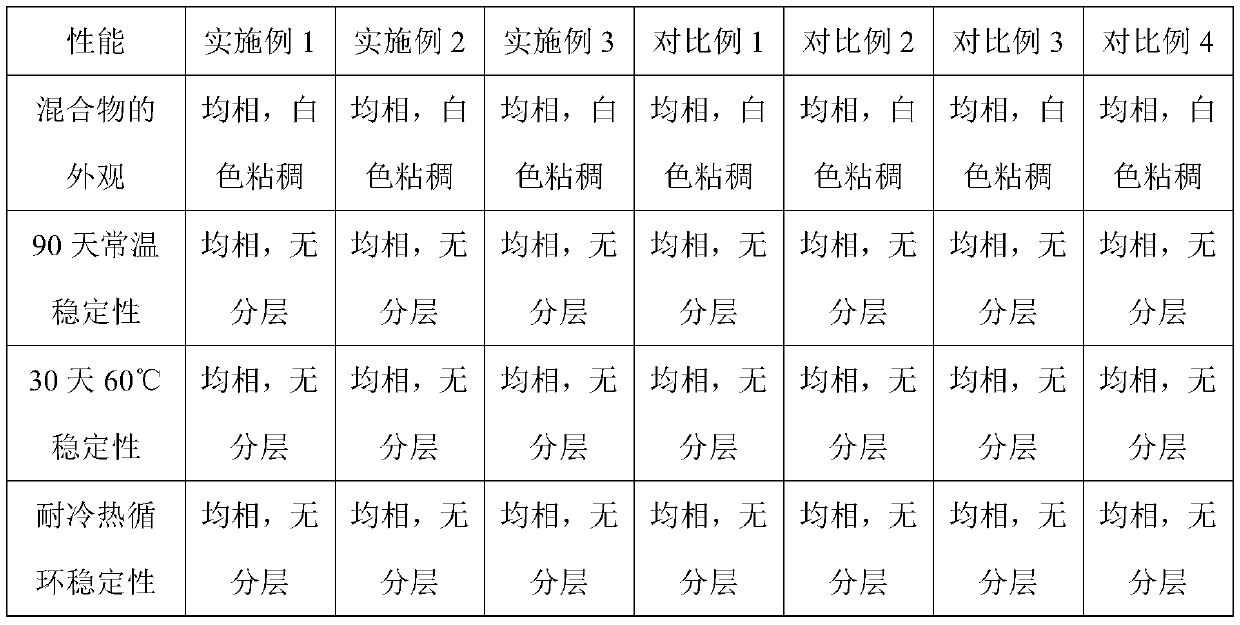

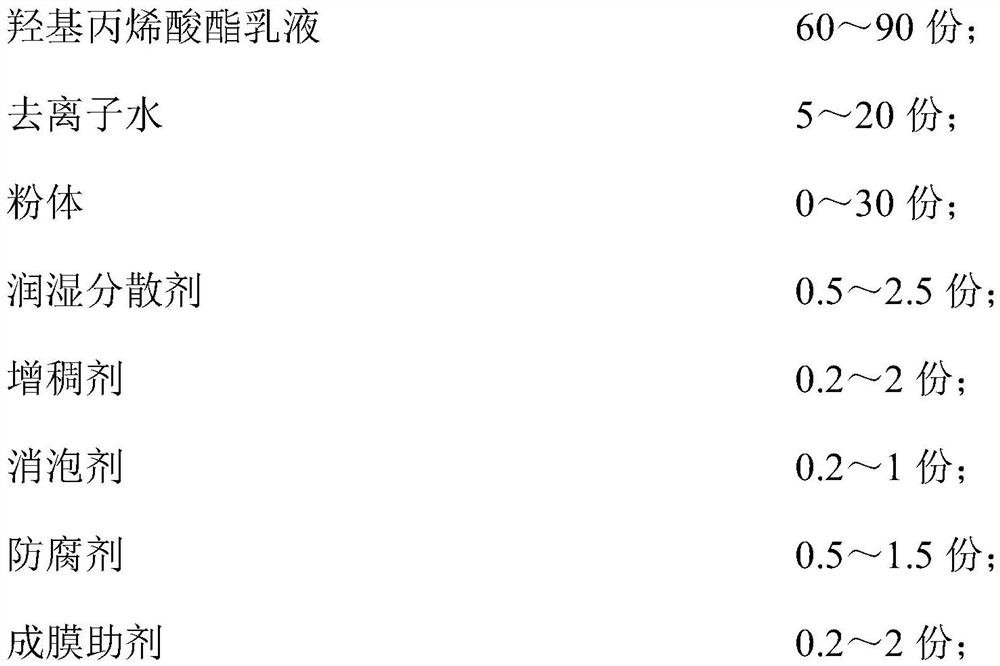

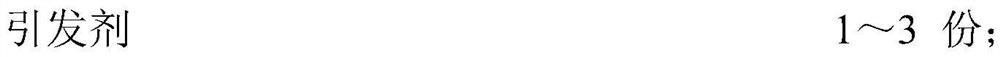

Water-based two-component polyurethane matte coating as well as preparation method and application thereof

ActiveCN113088174AAvoid powder settlingLow costPolyurea/polyurethane coatingsDefoaming AgentsEmulsion

The invention provides a water-based two-component polyurethane matte coating as well as a preparation method and application thereof. The water-based two-component polyurethane matte coating comprises a component A and a component B. The component A is prepared from the following raw materials in parts by weight: 60-90 parts of hydroxyl acrylate emulsion, 5-20 parts of deionized water, 0-30 parts of powder, 0.5-2.5 parts of a wetting dispersant, 0.2-2 parts of a thickening agent, 0.2-1 part of a defoaming agent, 0.5-1.5 parts of a preservative, and 0.2-2 parts of a coalescing agent; the component B is prepared from the following raw material in parts by weight: 0.1 to 5 parts of Covestro 307 water-based curing agent. The polyurethane matt coating disclosed by the invention can have a matt effect without additionally adding matting powder, the water resistance, permeability and stability of the coating can be greatly improved, and the polyurethane matt coating is suitable for the field of coatings.

Owner:DONGGUAN CTL NEW MATERIAL TECH

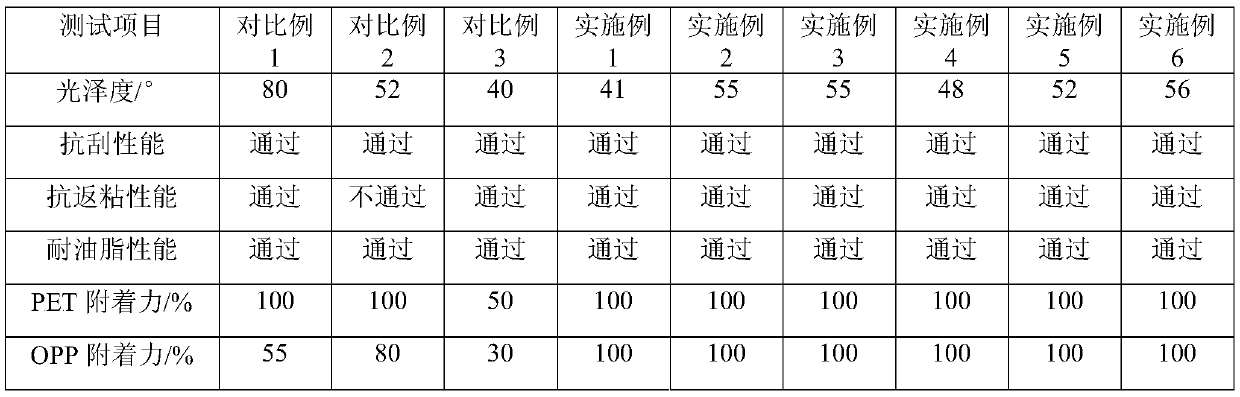

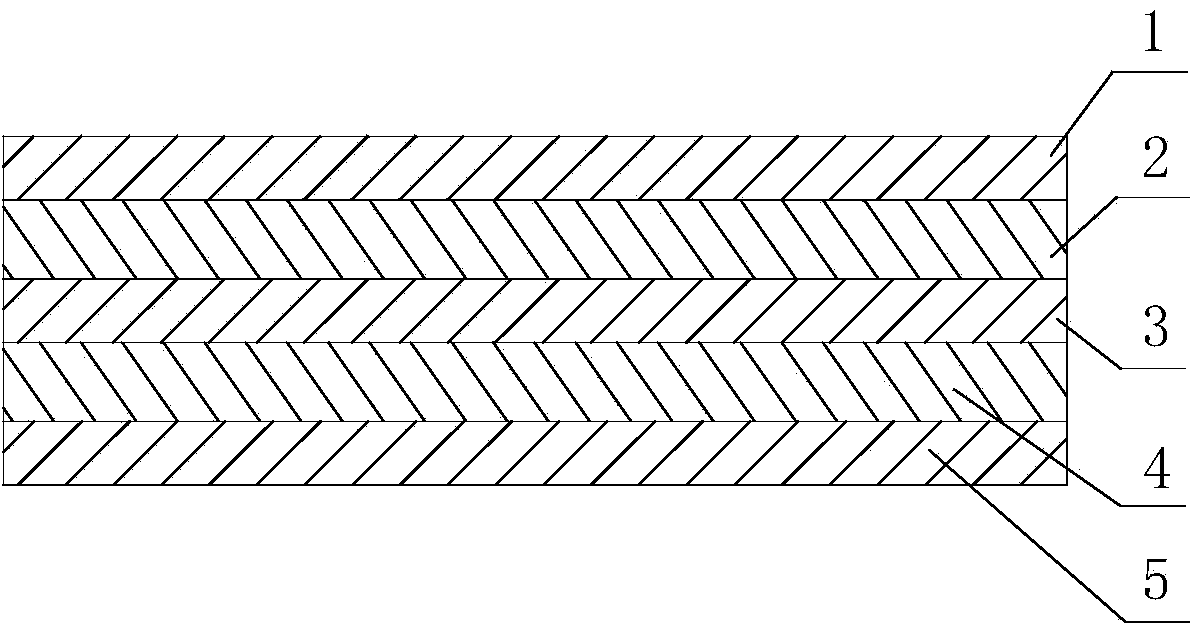

Plastic surface antibacterial grease-resistant coating and preparation method thereof

InactiveCN111471390AAdaptableHigh hardnessAntifouling/underwater paintsPaints with biocidesBenzeneFirming agent

The invention discloses a plastic surface antibacterial grease-resistant coating which is prepared from a matrix resin, an auxiliary resin, an adhesion promoting resin, a scratch-resistant additive, amatte powder, a wear-resistant powder, a filler, a dispersing agent, a solvent and an antibacterial agent. In addition to strong sterilization and bacteriostasis effects, the coating also has the advantages that no benzene, ketone or other toxic solvents are contained, no curing agent is needed, single-component packaging is realized, convenient construction can be realized by spraying, roller coating (plastic sheet) or gravure printing (plastic film) and other modes; drying is quick; the cost is low; a prepared coating layer is high in hardness; the coating is high in adaptability, suitablefor polar base materials such as PET and non-polar base materials such as OPP, excellent in adhesive force, high in scratch resistance, good in matte effect and high in decorativeness. The invention also provides a preparation method of the plastic surface antibacterial grease-resistant coating.

Owner:东莞市凯成环保科技有限公司

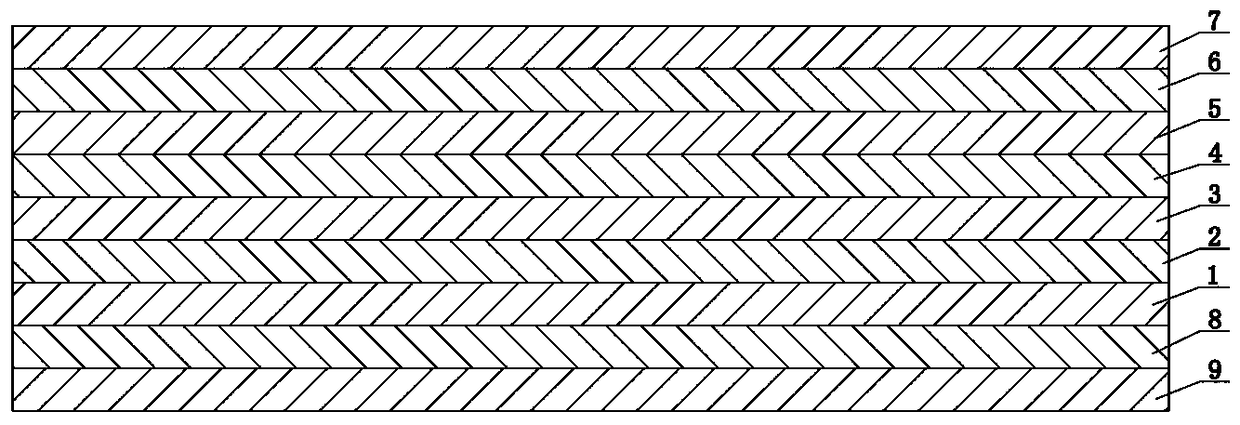

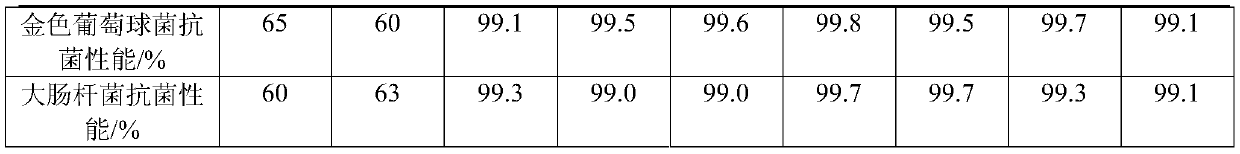

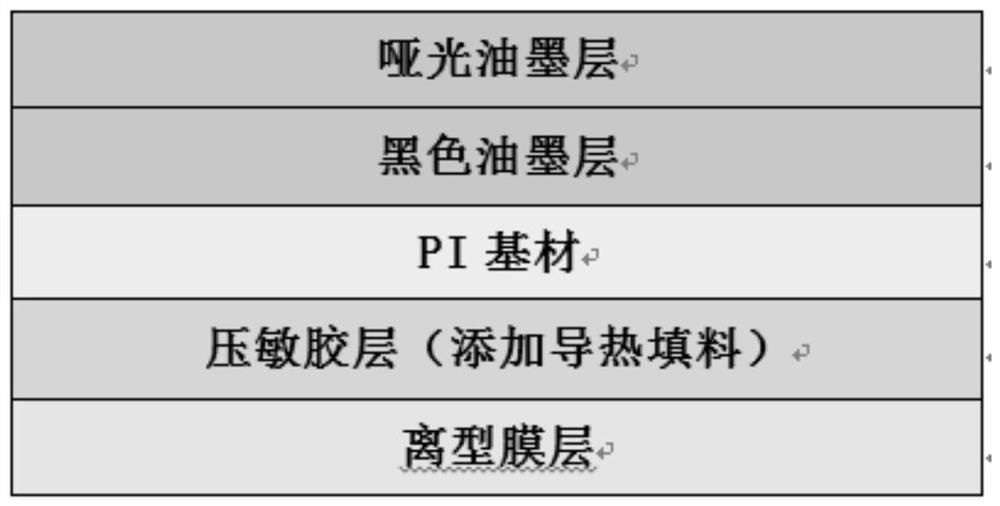

Heat-conducting matt black adhesive tape and preparation method thereof

PendingCN112898910AImprove thermal conductivityGood heat dissipationNon-macromolecular adhesive additivesInksSilicone tapePolymer chemistry

The invention provides a heat-conducting matt black adhesive tape and a preparation method thereof. The heat-conducting matt black adhesive tape sequentially comprises a matt ink layer, a black ink layer, a PI base material layer, a pressure-sensitive adhesive layer added with heat-conducting filler and a release film layer from outside to inside, wherein the thicknesses of the matte ink layer, the black ink layer, the PI substrate layer, the pressure-sensitive adhesive layer added with the heat-conducting filler and the release film layer are 1-10 microns, 1-10 microns, 4.5-100 microns, 1-50 microns and 25-100 microns respectively. The heat-conducting matt black adhesive tape can be rapidly prepared, has the effects of shading, fingerprint prevention, scratch prevention and the like, can increase the heat-conducting property while having viscosity, improves the heat conduction effect of the adhesive tape, and effectively solves the problems that in the prior art, the adhesive tape does not have a heat dissipation effect, components are easy to damage, the service life is short and the like.

Owner:四川羽玺新材料股份有限公司

PET matte aluminium laminated film

The invention belongs to the technical field of packaging materials and in particular relates to a PET aluminium laminated film. The PET matte aluminium laminated film is characterized by comprising a UV printable coating, a PET matte film, an aluminium layer, a network adhesive layer and body paper, wherein the aluminium layer is plated (vacuum plating) to the lower surface of the PET matte film; the thickness of the aluminium layer is 300-400 angstroms; the bottom of the aluminium layer is glued with the body paper via the network adhesive layer; the UV printable coating is coated on the PET matte film. The film is printable and has the matte effect.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

Preparation method of paper pulp with walnut shell as raw material

ActiveCN106012630AImprove antioxidant capacityGood antibacterial effectDefoamers additionNatural cellulose pulp/paperOysterLimonene

The invention discloses a preparation method of paper pulp with walnut shell as a raw material. The raw materials of the paper pulp comprise the following components, in parts by weight: 400-450 parts of walnut shell, 1-4 parts of a heat initiator, 1-4 parts of a defoaming agent, 2-8 parts of an oxidant, 10-20 parts of bentonite, 10-30 parts of oyster shell powder, 2-8 parts of medical stone powder, 2-8 parts of limonene, 2-8 parts of distillers' grain residue, 4-20 parts of toosedarin-containing plant insecticide, and 0.2-0.4 part of an auxiliary agent. According to the invention, waste is utilized, and the paper pulp is energy-saving and environmentally friendly. The paper pulp has special insect-resistant and antibacterial functions, and has long service life and high cleanness. With the paper pulp, worm damage and bacterium growth can be effectively prevented, such that collection and preservation are facilitated. The paper pulp has high safety, and the method has an important significance. The method can be widely popularized for application.

Owner:深圳市凌晨知识产权运营有限公司

Composition comprising perlite and a polymer bearing a carbosiloxane dendrimer-based unit

InactiveCN103458861AHas a matte finishImproves matte finish retentionCosmetic preparationsMake-upPerlitePolymer

The present invention concerns a composition comprising a physiologically acceptable medium containing perlite and at least one vinyl polymer bearing at least one carbosiloxane dendrimer-based unit.

Owner:LOREAL SA

Insect-resistant paper pulp for preparing corrugated boards and preparation method and application thereof

InactiveCN106012651AImprove antioxidant capacityGood antibacterial effectDefoamers additionReinforcing agents additionOysterPulp and paper industry

The invention discloses an insect-resistant pulp used for preparing corrugated cardboard and its preparation method and application. The raw materials include the following components in parts by weight: 400-450 parts of corn stalks; 30-50 parts of walnut shells; 1-4 parts of initiator; 1-4 parts of defoamer; 2-8 parts of oxidant; 10-20 parts of bentonite; 10-30 parts of oyster shell powder; 2-8 parts of medical stone powder; 2-8 parts of distiller's grains; 4 to 20 parts of phytograms; 0.2 to 0.4 parts of additives. The pulp prepared by the invention is energy-saving and environment-friendly for waste utilization, and has special anti-insect and antibacterial effects, long service life, high cleanliness, can effectively avoid decay and bacterial growth, is conducive to storage and preservation, has high safety, and is of significant significance. Widely promoted and used.

Owner:JIANGSU JINWO MACHINERY

White glaze for glass surface and preparation process for glass mosaic

The invention discloses a white glaze for a glass surface and a preparation process for glass mosaic. The water glaze comprises the following raw materials in percentage by mass: 72-82% of raw glass powder, 10-20% of waste glass powder, 4-6% of titanium dioxide, 0-0.5% of an auxiliary material and the balance of water, and the fineness of the white glaze is in a range of 250-300 meshes. Accordingto the white glaze used for the glass surface provided by the invention, effective recycling of the waste glass powder material is realized, the preparation cost is reduced, a matt glaze effect can beachieved, the whiteness is high, the glaze is uniform, the color development is more stable and brighter, the glaze is more smooth, the process is simpler and more energy-saving and environmentally friendly, and the production cost is low.

Owner:佛山市唯格建材有限公司 +1

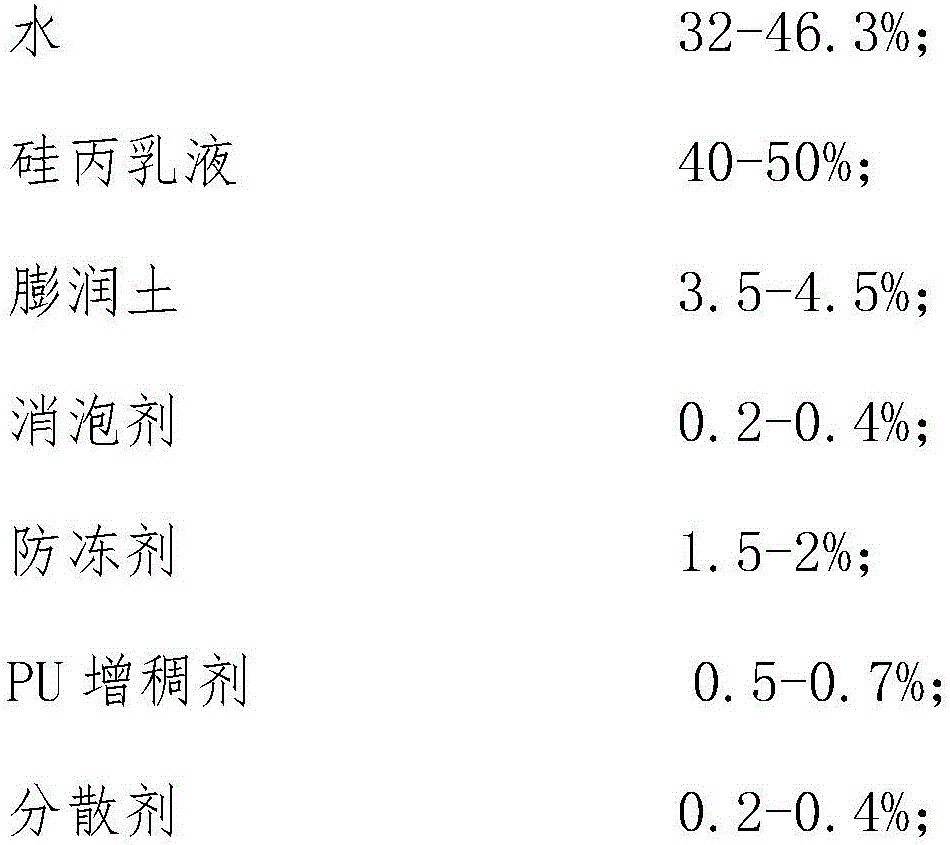

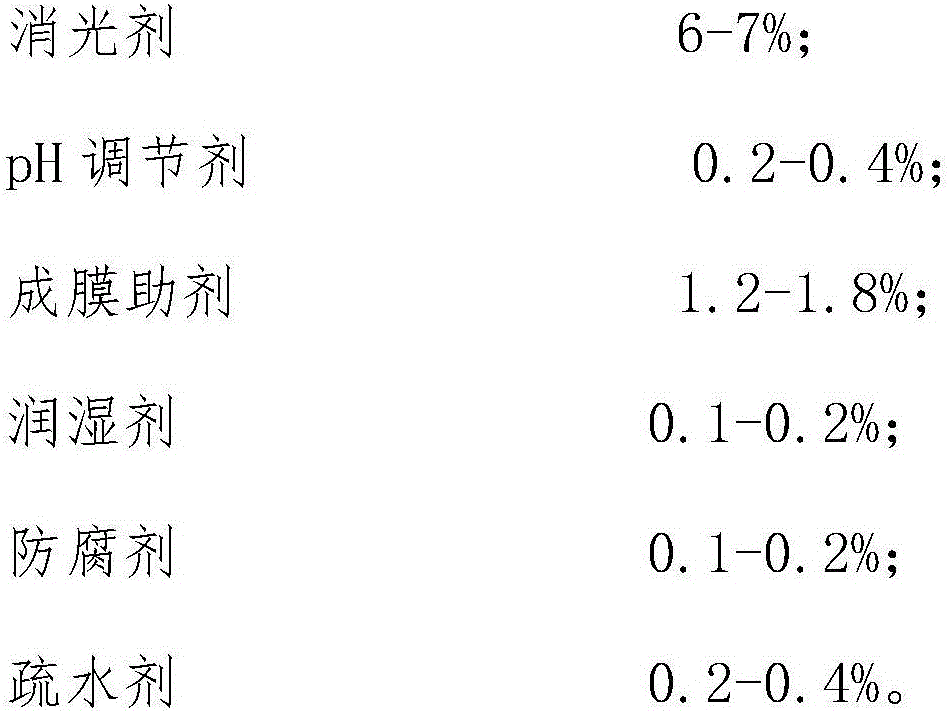

Matte transparent finishing coat and preparation method thereof

The invention relates to the technical field of coating preparation, and in particular, relates to a matte transparent finishing coat and a preparation method thereof, wherein the method comprises the following steps: firstly, evenly stirring a silicon-acrylate emulsion, a part of water, a defoaming agent, bentonite, a thickening agent, a dispersing agent and an antifreeze agent; then adding an extinction powder, and dispersing at high speed to ensure that the extinction powder is dispersed evenly; and finally adding a film-forming auxiliary agent, a preservative, a wetting agent, a hydrophobic agent and the remaining part of water, and stirring evenly, wherein a pH regulator is added at any time during adding, and the pH value is maintained at 7.0-8.0. The matte transparent finishing coat has the advantages that a coating layer treated by the matte transparent finishing coat has a matte effect, the degree of simulation is improved, water resistance, stain resistance, yellowing resistance and other properties of the coating layer can be enhanced, and a good protection role is played to the coating layer.

Owner:SUZUKA INTERNATIONAL (SHANGHAI) CO LTD

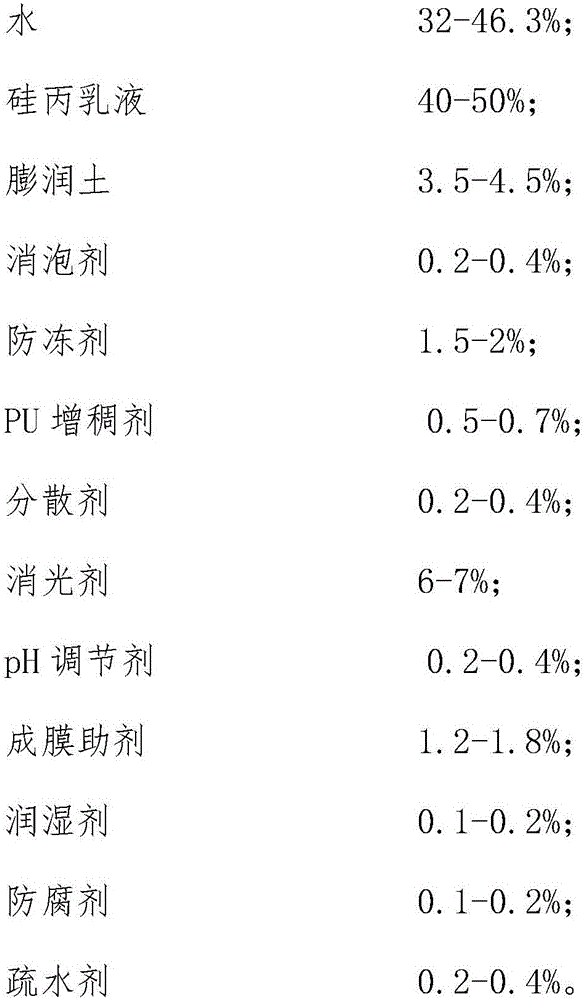

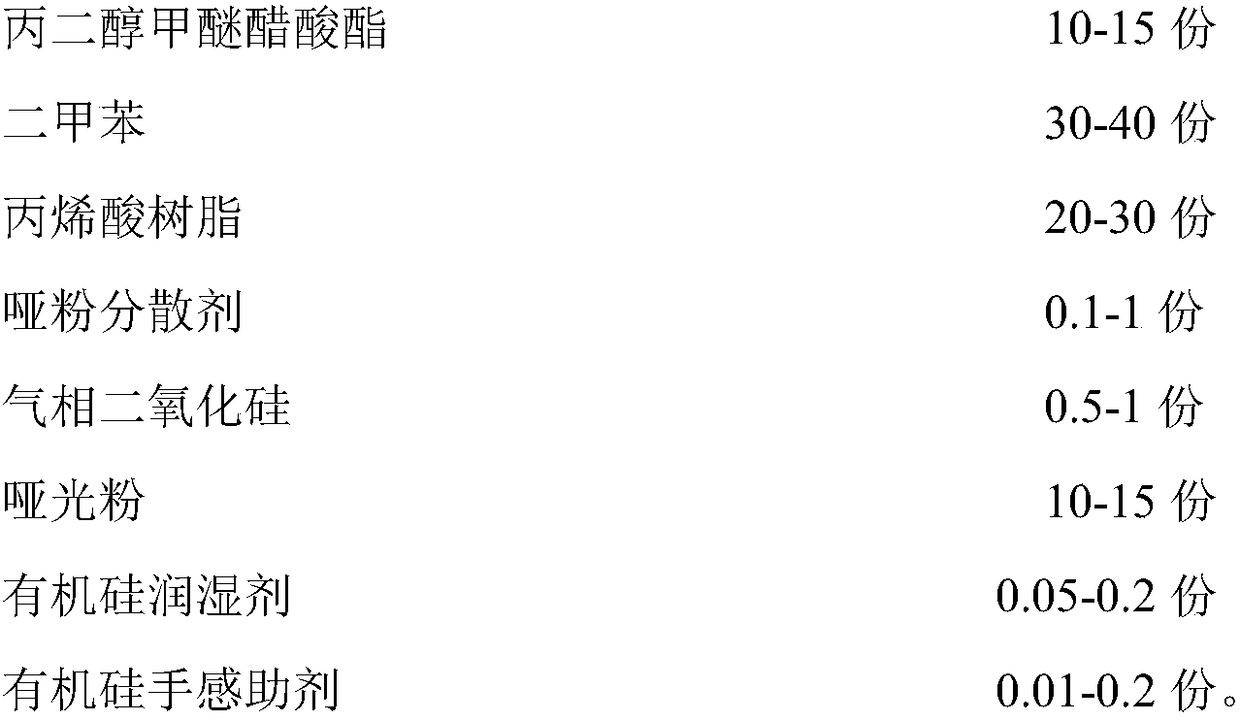

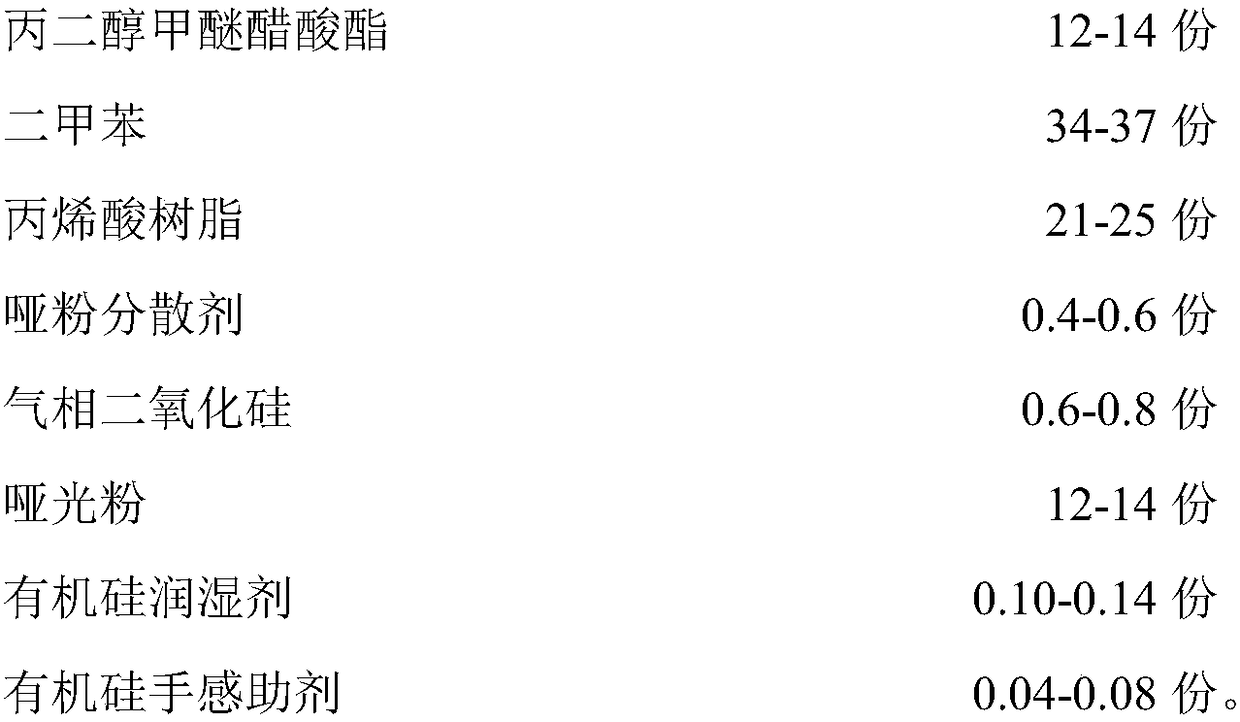

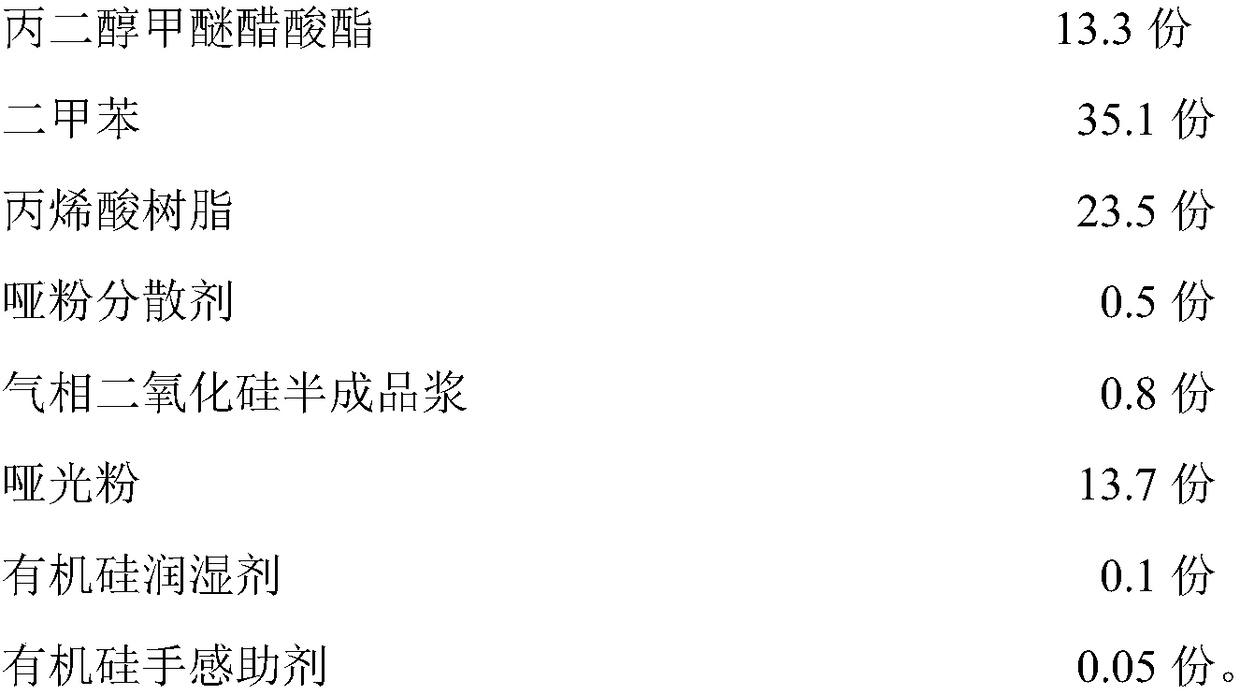

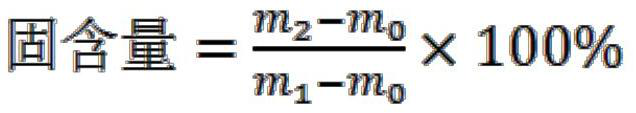

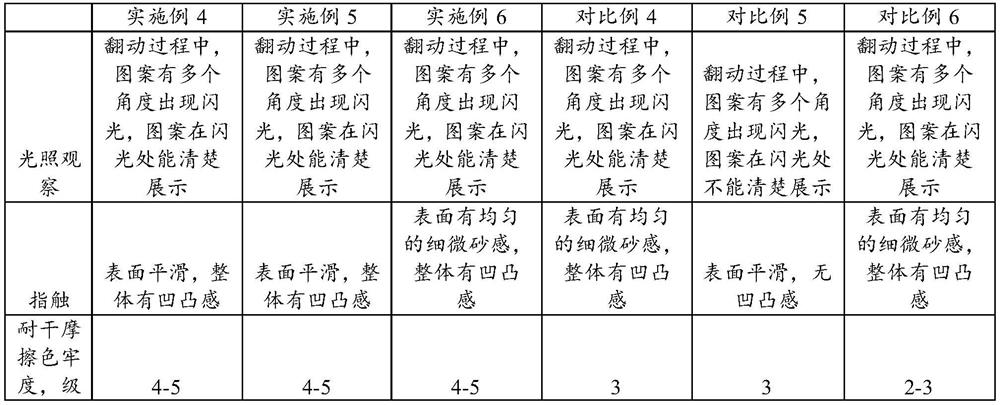

Additive capable of regulating coating gloss and preparation method thereof

The invention discloses an additive capable of regulating coating gloss and a preparation method thereof. The additive is composed of, by weight, 10-15 parts of propylene glycol ether solvent, 30-40 parts of diluent, 20-30 parts of resin carrier, 0.1-1 part of matte powder dispersant, 0.5-1 part of fumed silica, 10-15 parts of matte powder, 0.05-0.2 part of wetting agent and 0.01-0.2 part of mattehand feeling auxiliaries. The additive not only has a paint film with matte effects, but also can adjust different gloss levels by changing the content of additive formula; liquid coating added withthe additive has a transparency which is 20% higher than transparency of existing liquid coating; the case of misty surface dyeing is greatly reduced, the surface of the obtained paint film is smooth,and the hand feels fine and smooth.

Owner:GUANGDONG YATU CHEM

Matt ink for wall cloth, wall cloth and preparation method of wall cloth

InactiveCN112694782AHas a matte finishHigh solid contentInksOther printing apparatusPolymer scienceAcrylic resin

The invention provides matte ink for wall cloth, which comprises the following components in parts by weight: 40-90 parts of water-based acrylic resin, 50-90 parts of solvent, 10-20 parts of color paste, 7-10 parts of surfactant, 60-85 parts of filler, 0.5-2 parts of dispersing agent and 1-2 parts of stabilizer. The surfactant is one or more of fatty alcohol-polyoxyethylene ether, polyoxyethylene alkyl amide, alkylphenol polyoxyethylene ether and polyoxyethylene sorbitan monolaurate. By using the high-content filler, the solid content of the ink is increased, so that a three-dimensional effect and a matte effect are achieved after printing. When the ink is used for wall cloth production, even if the wall cloth is exposed to light, the patterns of the wall cloth can still be seen clearly, the patterns are concave-convex, the layering sense is rich, and the ornamental value and the decorative effect of the wall cloth are effectively enhanced. The invention further provides the wall cloth and a preparation method of the wall cloth.

Owner:GUANGDONG YULAN GRP

Cloth-grain-imitated PVC mat and preparation method thereof

InactiveCN112318982ARaise the gradeDense surfaceSynthetic resin layered productsFlat articlesComposite materialCeramic materials

The invention discloses a cloth-grain-imitated PVC mat and a preparation method thereof. The cloth-grain-imitated PVC mat comprises a base layer and a printed surface layer, wherein the base layer comprises a PVC foamed layer and base cloth embedded in the PVC foamed layer, wherein the printed surface layer is attached to the PVC foamed layer, the printed surface layer comprises a PVC surface layer body and a printed layer body, the PVC surface layer body is prepared through calendaring molding, and the printed layer is a cloth-grain-imitated printed layer. The preparation method comprises thesteps of preparation of the printed surface layer, preparation of the base layer and composite foaming. According to the cloth-grain-imitated PVC mat and the preparation method thereof, the purpose of printing special grains and patterns on the PVC mat is achieved by arranging the printed surface layer and the base layer which are made of PVC materials; the PVC surface layer is prepared through acalendering forming process, so curling and pattern printing are facilitated; a calendered PVC film is good in binding force with the base layer and ink and does not fall off; and the printed surfacelayer obtained after printing not only has excellent wear resistance and scratch resistance, but also has an ornamental effect, so the grade of the PVC mat is greatly improved.

Owner:广东远华新材料股份有限公司

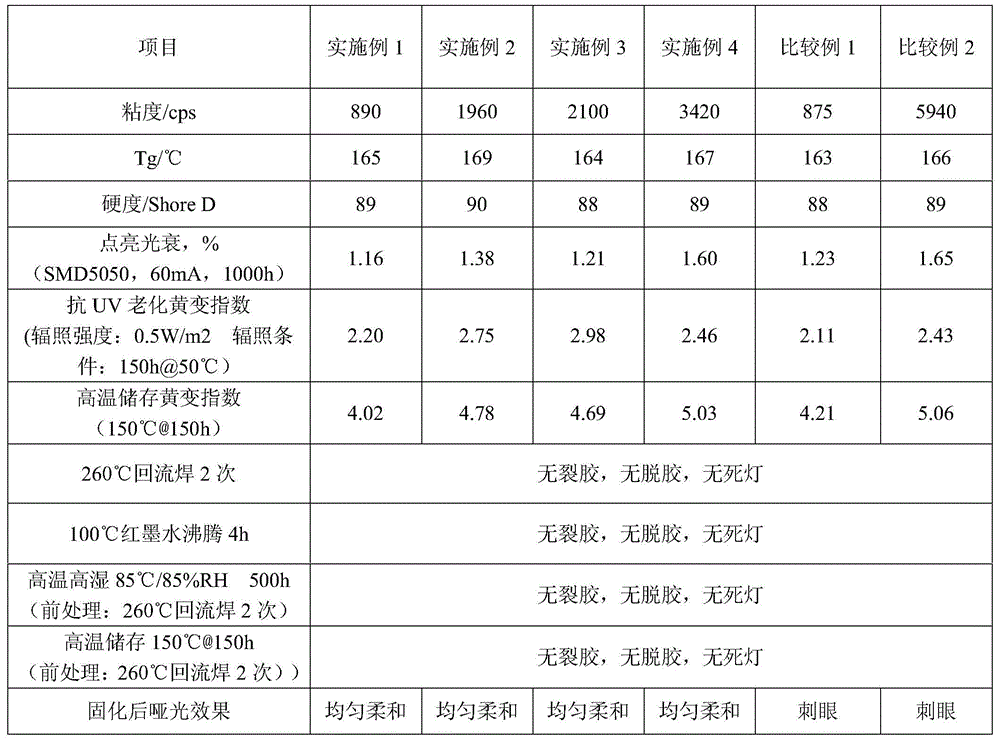

A kind of matte type epoxy resin encapsulation adhesive for outdoor LED encapsulation and preparation method thereof

ActiveCN104804688BLow viscosityEasy to operateNon-macromolecular adhesive additivesMacromolecular adhesive additivesHigh humidityAntioxidant

An outdoor LED packing matt epoxy resin package adhesive comprises a component A and a component B; the component A comprises the following ingredients in parts by weight: 100 parts of cycloaliphatic epoxy resin, 0.05-2 parts of an antioxidant, 0.1-5 parts of an accelerant A, 5-25 parts of matt powder, and 0.1-1 part of a defoamer; the component B comprises the following ingredients in parts by weight: 60-150 parts of acid anhydride, 0.05-2 parts of an antioxidant, 0.1-5 parts of an accelerant B and 0.1-1 part of a defoamer; the mole ratio of an epoxy group in the component A to acid anhydride in the component B is 1:1; the acceleration effects of the accelerant A and the accelerant B are different. The invention also provides a preparation method of the epoxy resin package adhesive. The epoxy resin package adhesive has the advantages of being low in viscosity, strong in operability, and high in reliability, and resisting high temperature and high humidity; the surface of a cured material has a matt effect; the packed LED brightness is high and soft, and the heat yellowness resistance and the UV yellowness resistance are superior.

Owner:NICHE TECH KAISER SHANTOU

Preparation method of ceramic tile with geometric textures and ceramic tile

The invention discloses a preparation method of a ceramic tile with geometrical textures and the ceramic tile, and the preparation method comprises the following steps: A, mixing a ceramic backing material raw material and a black pigment to prepare a black backing material with the water content of 13-15%, and carrying out pressure granulation on the ceramic backing material raw material and a white pigment to prepare a white granular material, adding a part of the black backing material into the white granules, and uniformly mixing to obtain a mixture; b, distributing the remaining black backing material to obtain a backing material layer, distributing the mixture on the surface of the backing material layer to obtain a surface material layer, and pressing and drying to obtain a spot green body; and C, printing concave-convex geometric texture patterns on the whole surface of the spot green body through roller printing. According to the preparation method of the ceramic tile with thegeometric textures, the texture of the green body can be presented while the bright effect and the matte effect are combined and presented on the tile surface, and the ceramic tile prepared through the preparation method of the ceramic tile with the geometric textures is good in overall texture, high in stereoscopic impression and rich in layering sense.

Owner:FOSHAN PINWEIXIAN CERAMICS CO LTD

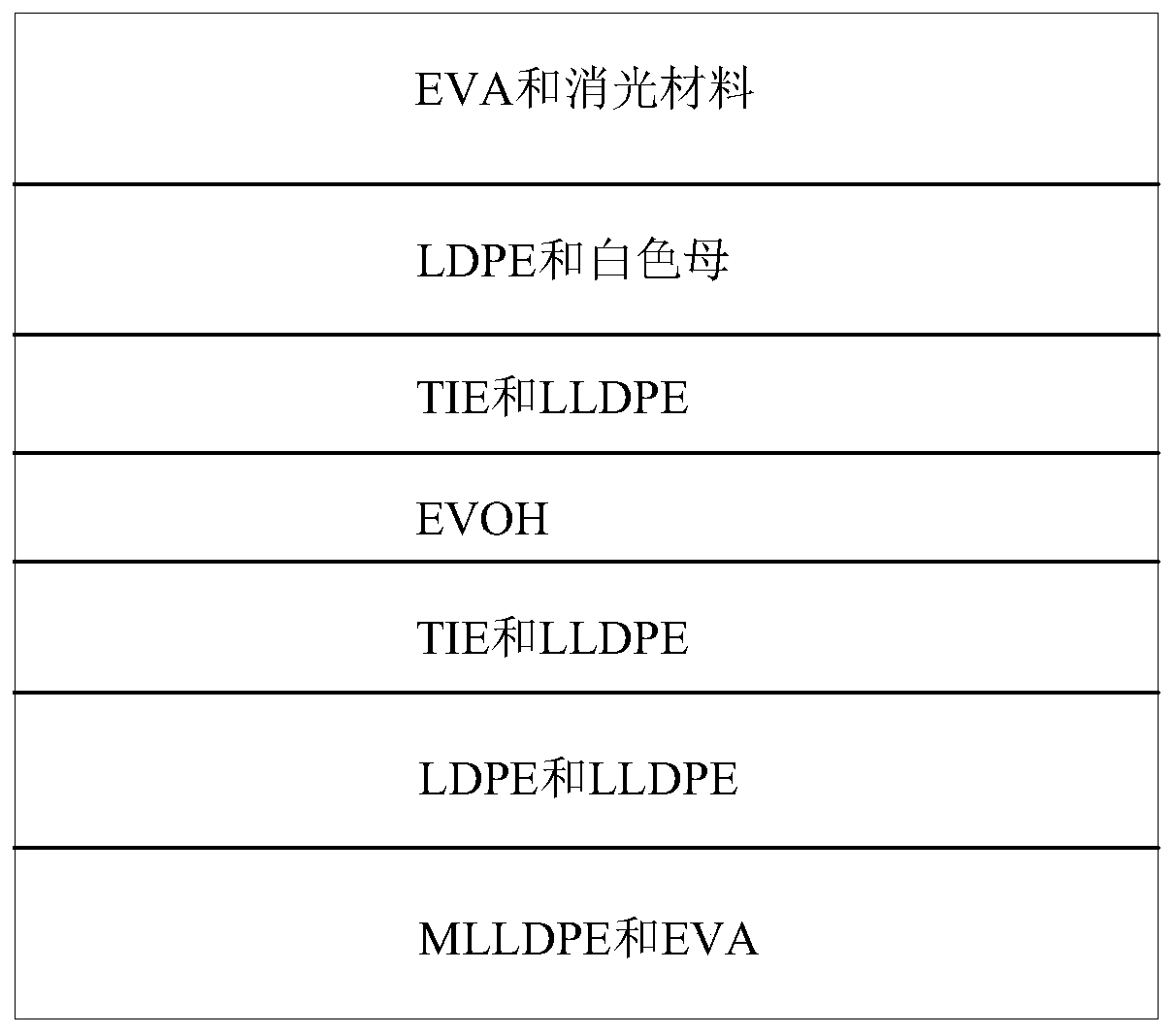

Outer bag film used for personal-care supplies and packaging bag using outer bag film

PendingCN110803388AMarketableImprove adhesionSynthetic resin layered productsBagsPolymer scienceTotal thickness

The invention relates to an outer bag film used for personal-care supplies. The outer bag film has a total thickness of 25-40 [mu]m and sequentially comprises a delustered layer, a covering layer, anupper bonding layer, a high barrier layer, a lower bonding layer, a waterproof layer and a heat-sealing layer, wherein the delustered layer is made of a mixture of 90 wt% of EVA and 10 wt% of delusteirng materials, the covering layer is made of a mixture of 80 wt% of LDPE and 20 wt% of white master batch, the upper bonding layer and the lower bonding layer are made of a mixture of 30 wt% of TIE and 70 wt% of LLDPE, the high barrier layer is made of EVOH, the waterproof layer is made of a mixture of 50 wt% of LDPE and 50 wt% of LLDPE, and the heat-sealing layer is made of a mixture of 70 wt% ofMLLDPE and 30 wt% of EVA. The invention further provides a preparation method of the outer bag film and a packaging bag made of the outer bag film.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

Paper pulp taking walnut shells as raw materials

InactiveCN106012664AImprove antioxidant capacityGood antibacterial effectWaste product additionNon-macromolecular organic additionSodium BentoniteOyster

The invention discloses a paper pulp using walnut shell as raw material and a preparation method thereof. The raw material comprises the following components in parts by weight: 400-450 parts of walnut shell; 1-4 parts of thermal initiator; 1 part of defoaming agent ~4 parts; 2~8 parts of oxidizing agent; 10~20 parts of bentonite; 10~30 parts of oyster shell powder; 2~8 parts of medical stone powder; 2~8 parts of limonene; ~20 parts; 0.2~0.4 parts of additives. The pulp prepared by the invention is energy-saving and environment-friendly for waste utilization, and has special anti-insect and antibacterial effects, long service life, high cleanliness, can effectively avoid decay and bacterial growth, is conducive to storage and preservation, has high safety, and is of significant significance. Widely promoted and used.

Owner:JIANGSU JINWO MACHINERY

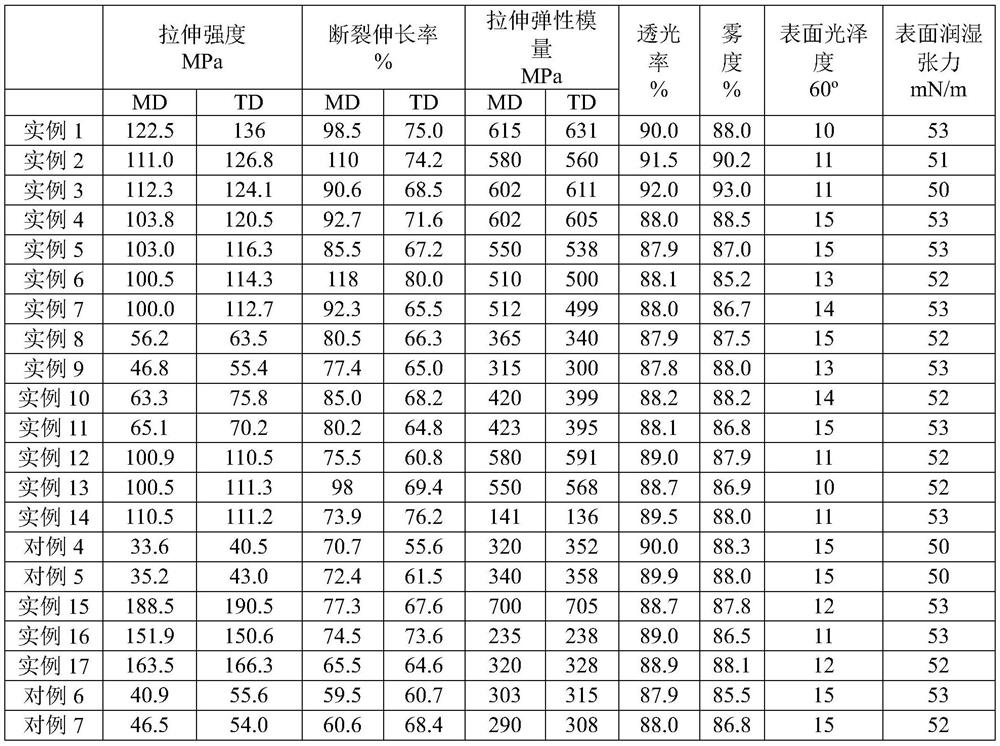

A kind of matte molding film and its preparation method and matte packaging material

ActiveCN111923537BHigh tensile strengthGood light transmissionFlexible coversWrappersAdhesive gluePrinting ink

The invention discloses a matte forming film, a preparation method thereof and a matte packaging material. The matte forming film comprises a matte layer, a core layer and a corona layer which are sequentially arranged, the weight ratio of the matte layer to the core layer to the corona layer is (0.8-1.2): (6-8): (1.5-2.2), and the matte layer, the core layer and the corona layer are prepared through a co-extrusion process. The matte packaging material comprises a plastic base material layer, a gloss oil layer and a matte forming film. According to the matte forming film, the preparation method of the matte forming film and the matte packaging material, the matte forming film can enable the packaging material to present a high-grade matte effect, cracking or appearance change does not occur during secondary forming, and the matte forming film is good in tensile strength, good in light transmission, long in corona retention time and capable of being well adhered to printing ink and glue. The matte forming film can replace matte ink to cover the surface of a pattern, can be used as a wear-resistant protective layer while providing a three-dimensional and matte high-grade effect, andprovides protection for a gloss oil pattern and a plastic base material layer.

Owner:佛山新长盛塑料薄膜有限公司

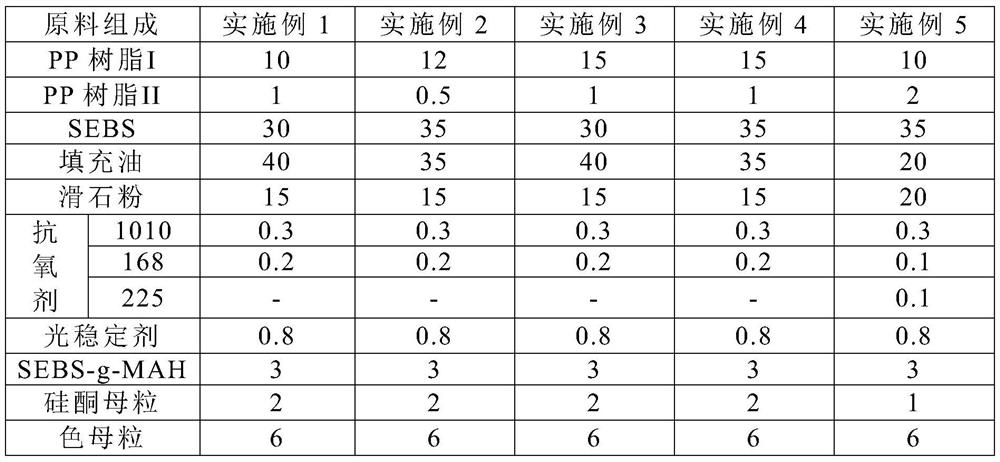

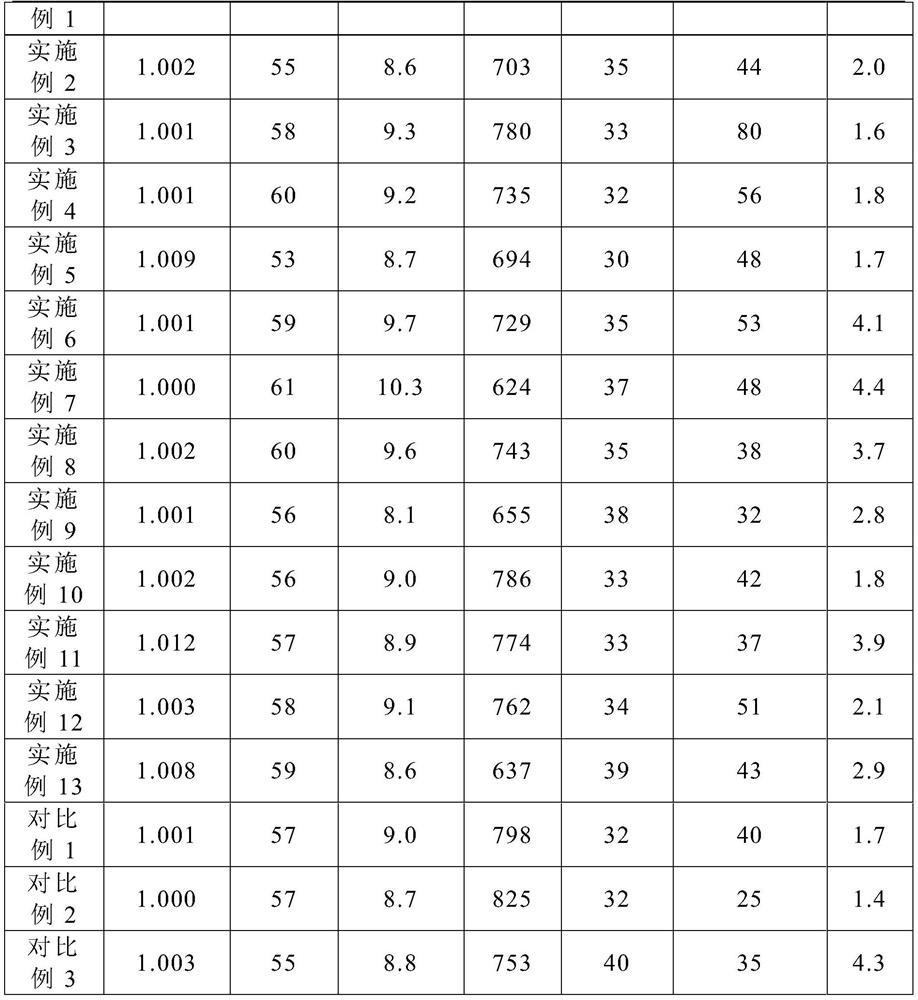

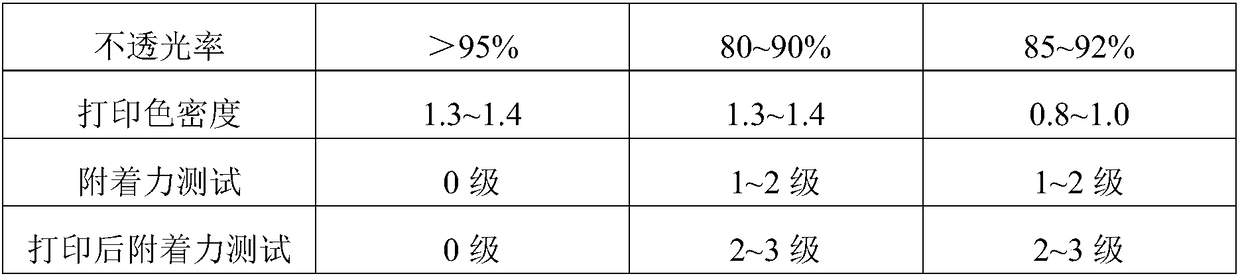

A kind of high fluidity and low luster styrene-based thermoplastic elastomer material and preparation method thereof

The invention belongs to the technical field of polymer material modification and processing, and in particular relates to a high-fluidity low-gloss styrene-based thermoplastic elastomer material and a preparation method thereof. The raw material of the present invention includes the following components in parts by weight: PP resin I: 5-20 parts, PP resin II: 0.5-2 parts, styrene block copolymer: 20-40 parts, extender oil: 20-50 parts , filler: 10-20 parts, antioxidant: 0.3-0.6 parts, light stabilizer: 0.6-1 parts, compatibilizer: 2-5 parts, release agent: 0.5-2 parts, masterbatch: 3- 6 servings. The present invention selects block copolymerized PP resin with high fluidity and low gloss as the main material, cooperates with ultra-high molecular weight linear SEBS, and adds ultra-high fluidity PP resin to improve the fluidity of the material. Firstly, SEBS and paraffin oil are mixed in a certain proportion Pre-filled with oil, then mixed, extruded and granulated, so that the prepared styrene-based thermoplastic elastomer material has the advantages of high fluidity and low gloss, which not only meets the technical requirements of injection molding, but also meets the requirements of interior and exterior parts of automobiles. product appearance requirements.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

Surface treating agent of pearlescent BOPP film and preparation method thereof

ActiveCN108624211AStrong adhesionImprove water resistancePolyurea/polyurethane coatingsAdhesion forceWater based

The invention belongs to the field of surface treating agents, and specifically relates to a surface treating agent of a pearlescent BOPP film. The surface treating agent comprises the following raw materials in parts by weight: 2-4 parts of water-based ylate emulsion, 0.5-1.5 parts of water-based anionic polyurethane dispersion, 1.2-2.5 parts of a curing agent, 0.1-0.3 part of ammonia water, 0.02-0.05 parts of a wetting agent, and 6-10 parts of water. The invention further discloses a preparation method of the surface treating agent. According to the water-based double-component BOPP surfacetreating agent, a film and flexible paint film can be formed after crosslinking and curing of the BOPP film surface, and the paint film is outstanding in adhesion force, water resistance and chemicalsresistance; the pearlescent BOPP film surface can be modified, and the BOPP film pearlescent luster can be shielded, so that the glossiness of the product can be reduced.

Owner:HUIZHOU YIDU IMAGE TECH

A kind of water-based two-component polyurethane matte coating and its preparation method and application

ActiveCN113088174BHas a matte finishGloss ControlPolyurea/polyurethane coatingsPolymer scienceEmulsion

The invention provides a water-based two-component polyurethane matte coating and its preparation method and application. The water-based two-component polyurethane matte coating includes A component and B component, and the preparation raw materials of the A component include the following weight Components in parts: 60-90 parts of hydroxyacrylate emulsion; 5-20 parts of deionized water; 0-30 parts of powder; 0.5-2.5 parts of wetting and dispersing agent; 0.2-2 parts of thickener; defoamer 0.2 to 1 part; 0.5 to 1.5 parts of preservative; 0.2 to 2 parts of film-forming aid; the raw materials of component B include the following components in parts by weight: 0.1 to 5 parts of Covestro 307 water-based curing agent. The polyurethane matte paint of the invention can have a matte effect without adding additional matting powder, can greatly improve the water resistance, permeability and stability of the paint, and is suitable for the field of paint.

Owner:DONGGUAN CTL NEW MATERIAL TECH

A kind of surface treatment agent of pearlescent bopp film and preparation method thereof

ActiveCN108624211BStrong adhesionImprove water resistancePolyurea/polyurethane coatingsAdhesion forcePolyurethane dispersion

Disclosed are a surface treating agent for a pearlylustre BOPP film and a preparation method therefor. The surface treating agent is prepared from the following raw materials in parts by weight: 2~4 parts of waterborne polyacrylate emulsion, 0.5~1.5 parts of waterborne anionic polyurethane dispersion, 1.2~2.5 parts of curing agent, 0.1~0.3 parts of ammonia water, 0.02~0.05 parts of wetting agent, and 6~10 parts of water. The surface treating agent forms a hard but flexible coat after cross-linking and curing on the surface of the BOPP film, and has outstanding adhesion force, water resistance and chemical resistance. By using the surface treating agent to modify the surface of the pearlylustre BOPP film, the pearlylustre of the BOPP film can be shielded, and the glossiness of the product can be reduced.

Owner:HUIZHOU YIDU IMAGE TECH

A kind of paper pulp preparation method using walnut shell as raw material

ActiveCN106012630BImprove antioxidant capacityGood antibacterial effectNatural cellulose pulp/paperDefoamers additionSodium BentoniteOyster

The invention discloses a preparation method of paper pulp with walnut shell as a raw material. The raw materials of the paper pulp comprise the following components, in parts by weight: 400-450 parts of walnut shell, 1-4 parts of a heat initiator, 1-4 parts of a defoaming agent, 2-8 parts of an oxidant, 10-20 parts of bentonite, 10-30 parts of oyster shell powder, 2-8 parts of medical stone powder, 2-8 parts of limonene, 2-8 parts of distillers' grain residue, 4-20 parts of toosedarin-containing plant insecticide, and 0.2-0.4 part of an auxiliary agent. According to the invention, waste is utilized, and the paper pulp is energy-saving and environmentally friendly. The paper pulp has special insect-resistant and antibacterial functions, and has long service life and high cleanness. With the paper pulp, worm damage and bacterium growth can be effectively prevented, such that collection and preservation are facilitated. The paper pulp has high safety, and the method has an important significance. The method can be widely popularized for application.

Owner:深圳市凌晨知识产权运营有限公司

A kind of white board film matte UV coating and preparation method thereof

ActiveCN111484798BHas a matte finishWith anti-glarePolyurea/polyurethane coatingsWhiteboardPolymer science

Owner:GUANGZHOU SHENWEI NEW MATERIAL TECH

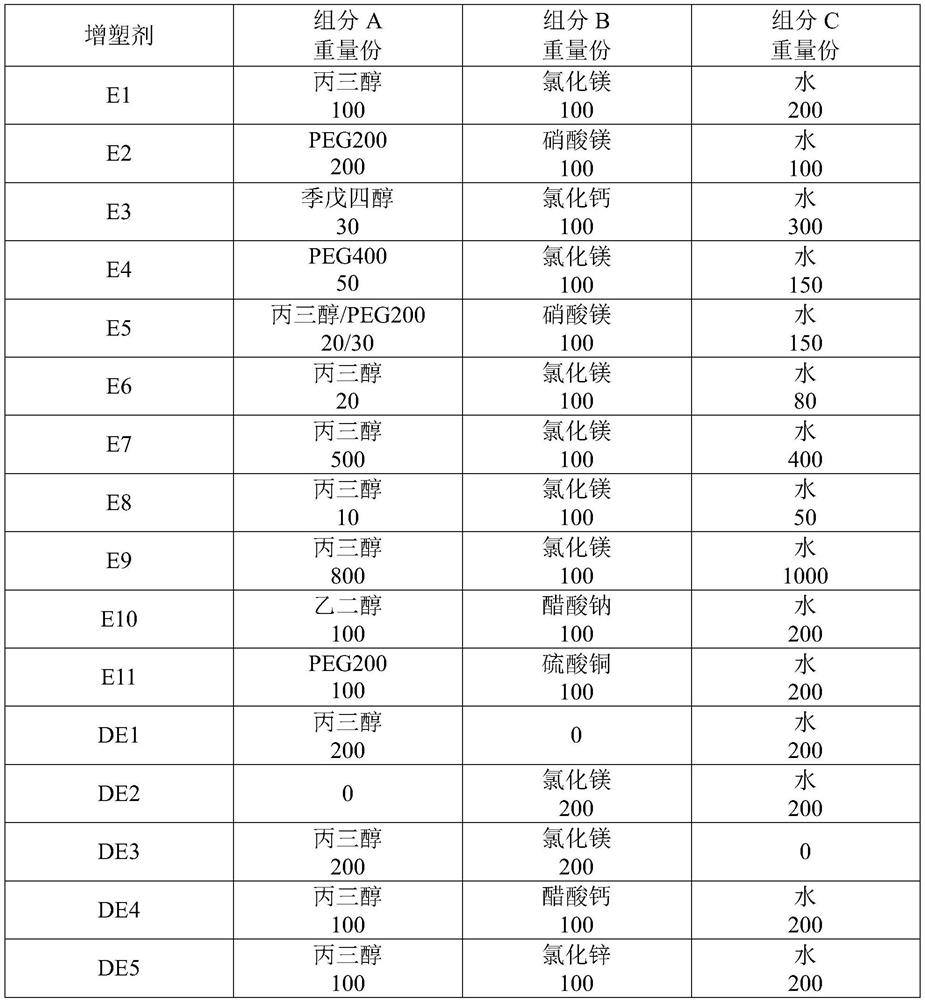

Polyvinyl alcohol matte film, its composition and preparation method

ActiveCN109721908BHas a matte finishAppropriate mechanical strengthFlat articlesSodium acetatePolymer science

The invention relates to the field of polyvinyl alcohol films, in particular to polyvinyl alcohol matte films, compositions and preparation methods thereof. The polyvinyl alcohol composition contains polyvinyl alcohol, a plasticizer, olefin-maleic anhydride copolymer microspheres, a lubricant and optional auxiliary agents; the plasticizer contains component A, component B and component C; the component A is one or more of glycerol, ethylene glycol, polyethylene glycol and pentaerythritol; the component B is magnesium chloride, magnesium nitrate, calcium chloride, copper sulfate and sodium acetate One or more; the component C is water. The present invention can make polyvinyl alcohol with a wide range of alcoholysis degree to be biaxially stretched into a film, and the obtained polyvinyl alcohol matte film has a matte effect, and also has suitable mechanical strength, surface wetting tension and Translucency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of matte decorative board

InactiveCN110813678AHas a matte finishStrong stain resistanceFlat articlesCoatingsUV curingPolishing

The invention relates to a preparation method of a matte decorative board. The preparation method is characterized by comprising the following steps of 1, preparing a base material, and conducting polishing and dedusting on the base material; 2, roll-coating the surface of the base material and the ground with a first layer of UV photocuring priming paint, and conducting UV curing; 3, roll-coatingthe UV photocuring priming paint with colored paint, and conducting UV curing; 4, roll-coating the colored paint with a second layer of UV photocuring priming paint, and then conducting UV curing; 5,roll-coating the second layer of UV photocuring priming paint with drenching matte finishing paint, and then conducting UV curing; 6, painting coating film on the drenching matte finishing paint. Thepreparation method has strong fingerprint resistance and dirt resistance and brings tender and smooth touch sense.

Owner:JIANGSU JIFU NEW MATERIAL

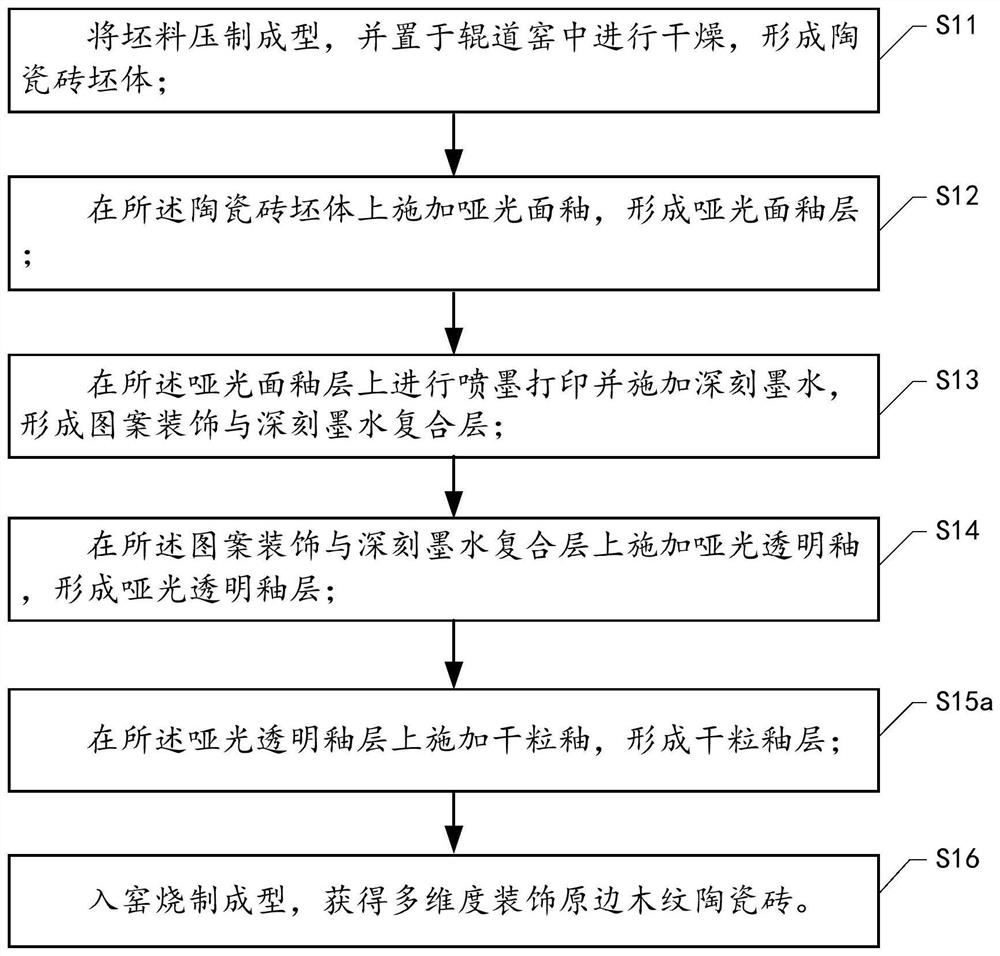

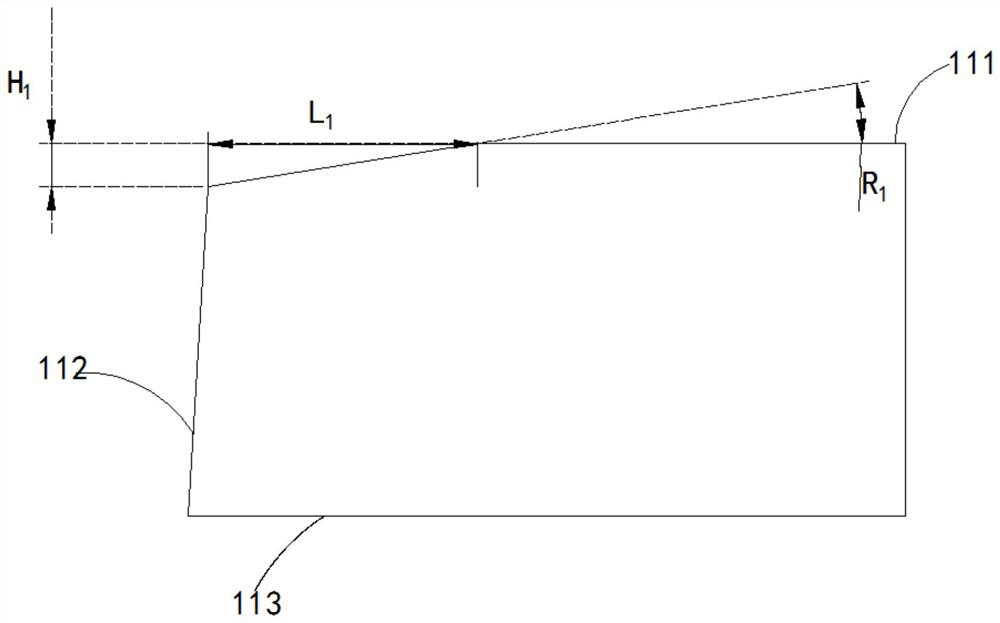

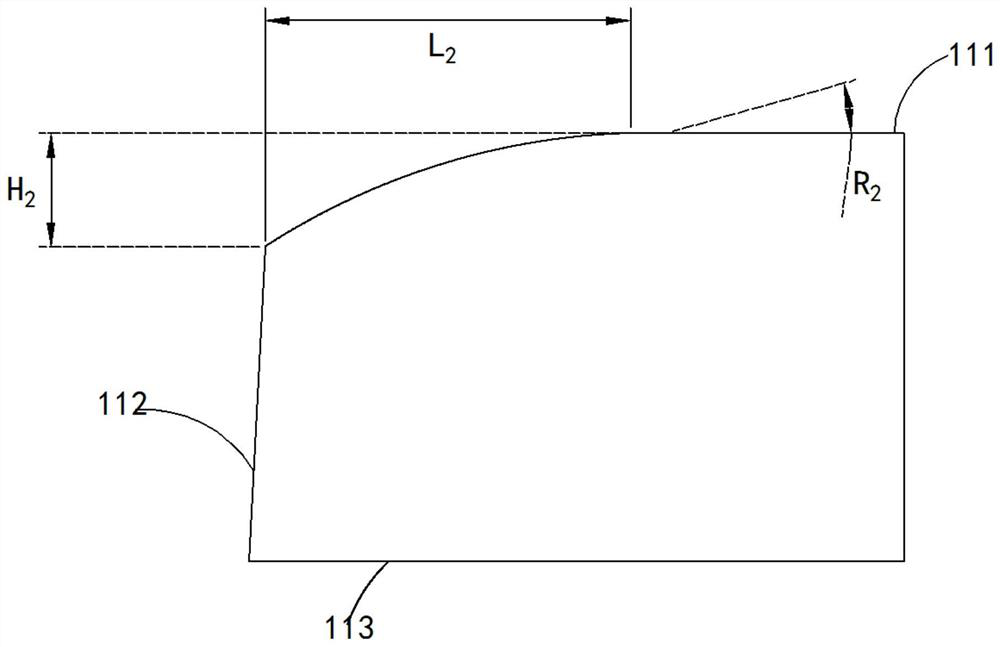

A multi-dimensional decorative original edge wood grain ceramic tile and its preparation method

ActiveCN110372416BReduce glossGuaranteed decorative effectCeramic materials productionClaywaresGlazeKiln

The invention discloses a multi-dimensional decorative original edge wood grain ceramic brick and a preparation method thereof. The method comprises: A. pressing and forming a blank, and placing it in a roller kiln for drying to form a ceramic brick body; B. Matte surface glaze is applied on the brick body to form a matte surface glaze layer; C. Inkjet printing is performed on the matte surface glaze layer and deep ink is applied to form a composite layer of pattern decoration and deep ink; D. After pattern decoration and deep ink A matte transparent glaze is applied on the ink composite layer to form a matte transparent glaze layer; E 1 1. Apply dry glaze on the matte transparent glaze layer to form a dry glaze layer; F. Put it into a kiln for firing and molding to obtain multi-dimensional decorative original edge wood grain ceramic tiles. The flatness of the surface of the ceramic tile body is improved, which ensures the effects of pattern decoration, concave-convex texture, layering, and surface texture. At the same time, the product feels delicate, and has matte, non-slip, wear-resistant and anti-pollution effects.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com