White glaze for glass surface and preparation process for glass mosaic

A glass mosaic and glass surface technology, applied in coating and other directions, can solve the problems of restricting the production and application of matte glass mosaic, affecting the physical and mental health of employees, unstable surface color, etc., to achieve color stability and bright surface color. Even, smooth-feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

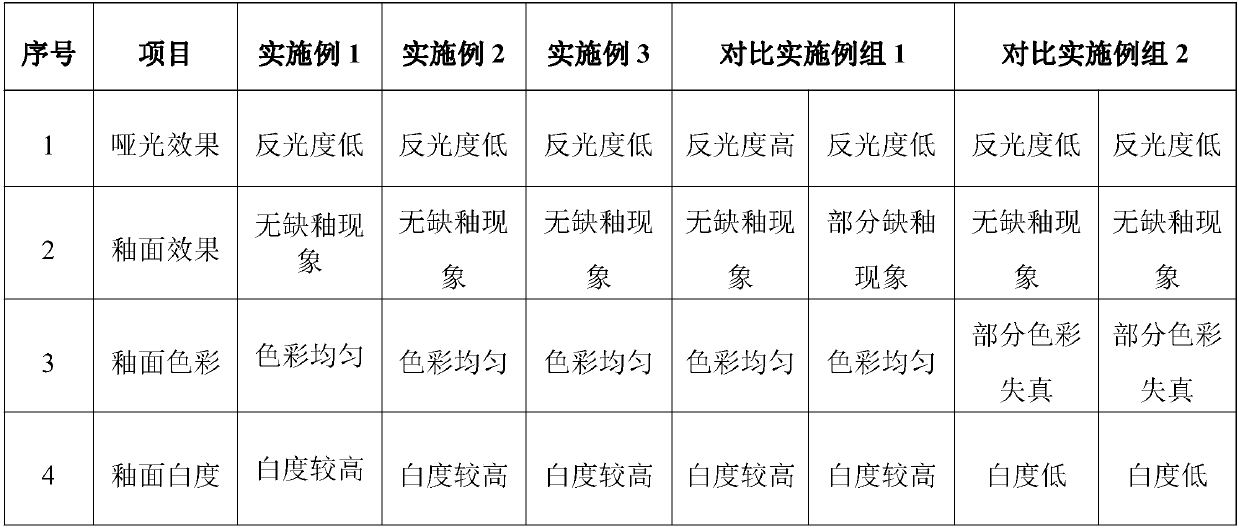

Examples

Embodiment 1

[0028] Embodiment 1-a kind of preparation technology of glass mosaic, comprises the steps:

[0029] 1. Preparation of white glaze:

[0030] (1) Weigh respectively 82% raw glass powder, 10% waste glass powder, 4% titanium dioxide and 0.5% auxiliary materials according to the proportioning ratio, and add 3.5% water to carry out mixed ball milling, the ball milling time is 10min, and the obtained whiteness powder with a fineness of 250 mesh glaze slurry;

[0031] The melting temperature of the raw glass powder is 600-700°C, and the melting temperature of the waste glass powder is >1000°C.

[0032] 2. Preparation steps:

[0033] (1) prepare mosaic glass body according to known mosaic body raw material;

[0034] (2) distributing white glaze slurry on the surface of the mosaic glass body to form a glaze layer, wherein the thickness of the glaze layer is 0.05mm;

[0035] (3) Carry out inkjet printing on the mosaic glass body with the glaze layer, and after firing, the firing temp...

Embodiment 2

[0036] Embodiment 2-a kind of preparation technology of glass mosaic, comprises the steps:

[0037] 1. Preparation of white glaze:

[0038] (1) Weigh 74% raw glass powder, 12% waste glass powder, 6% titanium dioxide, 0.2% auxiliary material and 5% color material respectively according to the proportioning ratio, and add 2.8% water to carry out mixed ball milling, and the ball milling time is 20min to obtain fine powder 300 mesh white glaze slurry;

[0039] The melting temperature of the raw glass powder is 600-700°C, and the melting temperature of the waste glass powder is >1000°C.

[0040] 2. Preparation steps:

[0041] (1) prepare mosaic glass body according to known mosaic body raw material;

[0042] (2) The surface of the mosaic glass body is sprayed with white glaze slurry under constant pressure conditions, and the pressure is 0.3Mpa to form a glaze layer, wherein the thickness of the glaze layer is 0.15mm;

[0043](3) Ink-jet printing is performed on the mosaic glas...

Embodiment 3

[0044] Embodiment 3-a kind of preparation technology of glass mosaic, comprises the steps:

[0045] 1. Preparation of white glaze:

[0046] (1) Weigh 72% raw glass powder, 20% waste glass powder, 5% titanium dioxide, 0.1% auxiliary material and 0.1% color material respectively according to the proportion, and add 2.8% water to carry out mixed ball milling. The ball milling time is 15min to obtain fine powder 280 mesh white glaze slurry;

[0047] The melting temperature of the raw glass powder is 600-700°C, and the melting temperature of the waste glass powder is >1000°C.

[0048] 2. Preparation steps:

[0049] (1) prepare mosaic glass body according to known mosaic body raw material;

[0050] (2) The surface of the mosaic glass body is sprayed with white glaze slurry under constant pressure conditions, and the pressure is 2.5Mpa to form a glaze layer, wherein the thickness of the glaze layer is 0.1mm;

[0051] (3) Carry out inkjet printing on the mosaic glass body with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com